Patents

Literature

66results about How to "To achieve a polished effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polishing disk for polishing crystal glass

InactiveCN102120315AExtended service lifeHydrophilicAbrasion apparatusWater solubleHigh wear resistance

The invention relates to a polishing disk for polishing crystal glass. In the polishing disk for polishing crystal glass, a polishing layer comprises the following components in percentage by mass: 5 to 60 percent of grinding material, 10 to 60 percent of unsaturated resin with water swelling property, 0.5 to 5 percent of curing agent, 0.1 to 30 percent of water soluble additive and 0.05 to 8 percent of functional regulating additive, wherein the total mass percentage of the components is 100 percent. The grinding material may be diamond, carborundum and aluminum oxide. The polishing disk solves the problem that the diamond, carborundum, aluminum oxide and the like, which are harder than workpieces, cannot be used as a grinding material on the polishing disk, and has the advantages of high processing efficiency, high wear resistance and long service life.

Owner:ZHEJIANG PUJIANG MINRUI PRECISION MACHINERY TECH

Chemical polishing method of stainless steel by high-temperature oxidation

InactiveCN103046053AIncrease loading capacityFast and effective mechanical peeling actionCavitationPhosphoric acid

The invention discloses a chemical polishing method of stainless steel by high-temperature oxidation, and belongs to the field of surface treatment of stainless steel parts. The method comprises the following steps: using phosphoric acid, sulfuric acid and nitric acid as main materials; supplementing additives: polyethylene glycol, sulfosalicylic acid and nicotinic acid which are used to prepare a chemical polishing liquor; introducing an ultrasonic cleaning instrument in the chemical polishing process; and polishing the surface of a stainless steel part within a short time by means of cavitation of ultrasonic wave in the polishing liquor. The chemical polishing method provided by the invention is high in polishing efficiency, less in pollution and strong in operability. Polished parts are bright and white in surface, and uniform and meticulous. The method is especially suitable for polishing treatment of stainless steel parts with precision screws, high precision sizes, deep holes, blind holes, superfine holes and complex structures.

Owner:中国兵器工业第二一三研究所

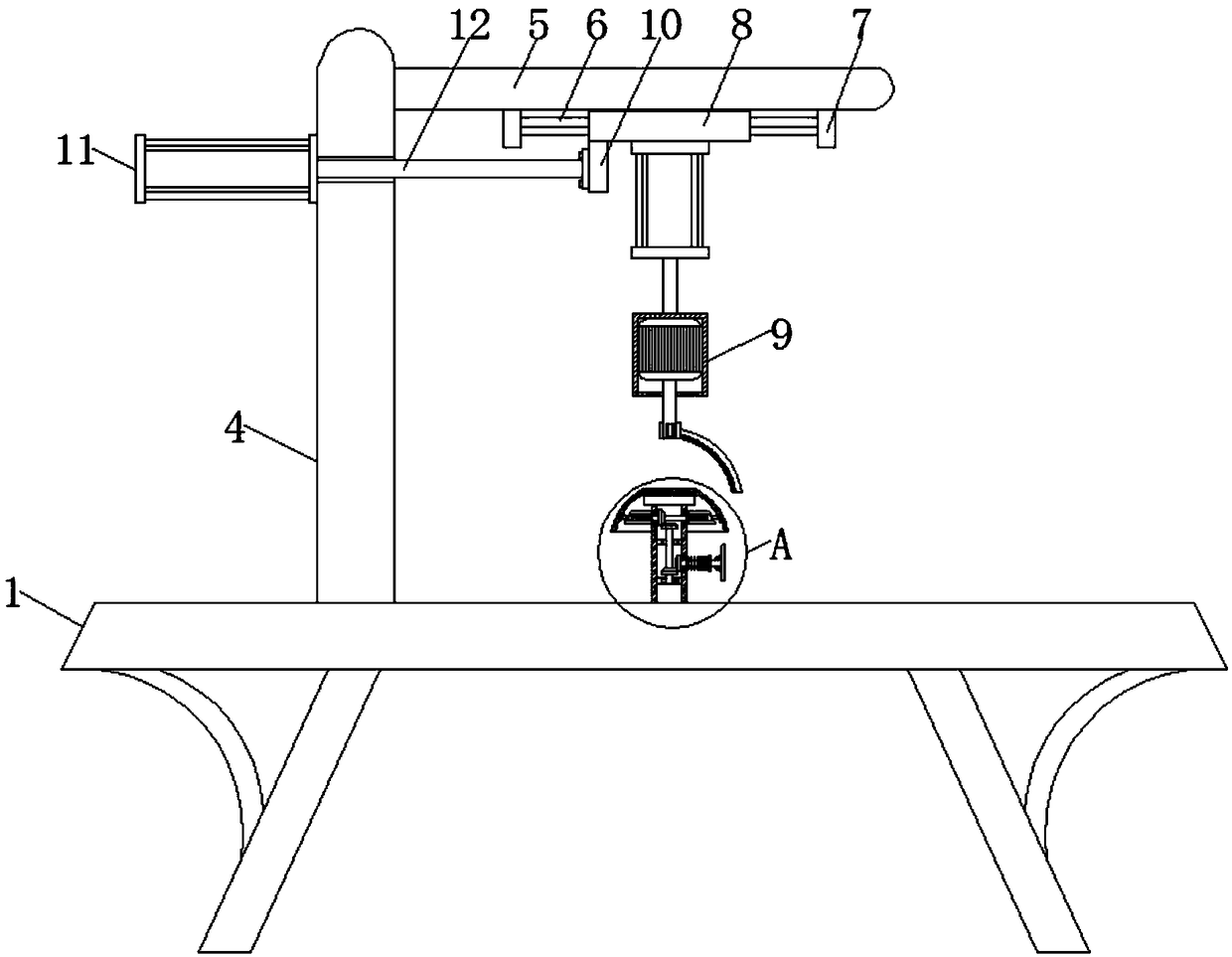

Glaze polishing device for ceramic processing

InactiveCN109079646AEasy to fixEasy to adjust the length of the distancePolishing machinesGrinding drivesMetallurgy

The invention discloses a glaze polishing device for ceramic processing and relates to the technical field of ceramic processing equipment. The glaze polishing device for ceramic processing comprisesa worktable. A positioning device is arranged at the center of the top face of the worktable, and the top of the positioning device is sleeved with a bowl body. The left end of the top face of the worktable is fixedly connected with a stabilizing column, the top of the right side face of the stabilizing column is fixedly connected with a stabilizing plate, a sliding rail is fixedly mounted at theright end of the bottom face of the stabilizing plate, two limiting blocks are fixedly mounted at the two ends of the sliding rail, and a sliding block is connected to the surface of the center of thesliding rail in a clamped mode. According to the glaze polishing device for ceramic processing, by improving a ceramic bowl polishing device, ceramic bowls with various diameters and sizes can be conveniently positioned, the grinding range of the outer surfaces of the ceramic bowls can be further conveniently adjusted through cooperative using of a second air cylinder, the sliding rail and the sliding block, and thus the practicability of the ceramic bowl polishing device is improved to a great extent.

Owner:杨斯晨

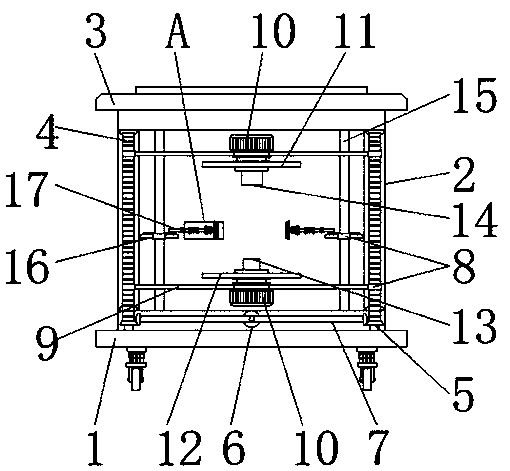

Polishing device for tubular mechanical processing which provides convenience for multi-angle work

ActiveCN109227345AReduce safety incidentsConvenient for fixed workGrinding carriagesPolishing machinesWire rodEngineering

The invention discloses a polishing device for tubular mechanical processing which provides convenience for multi-angle work. The device comprises a base and a lower rising plate, the upper portion ofthe base is connected with a top plate through a support rod, a first wire rod penetrates through the inside of the support rod, the lower bottom of the first wire rod is connected to a first motor through a steering gear set and a conveyor belt, push rods are connected by a compression spring, the top ends of the push rods are provided with third motors, mounting blocks are connected to the topends of the third motors, the mounting blocks and a steel wire brush head are connected by a fixing head, and thread grooves are formed in the upper and lower sides of the steel wire brush head. The polishing device for the tubular mechanical processing which provides convenience for the multi-angle work can perform polishing and grinding work on a large area above tubular parts during single time, and the entire device needs fewer people assist in the work during polishing processing.

Owner:盐城意权汽配制造有限公司

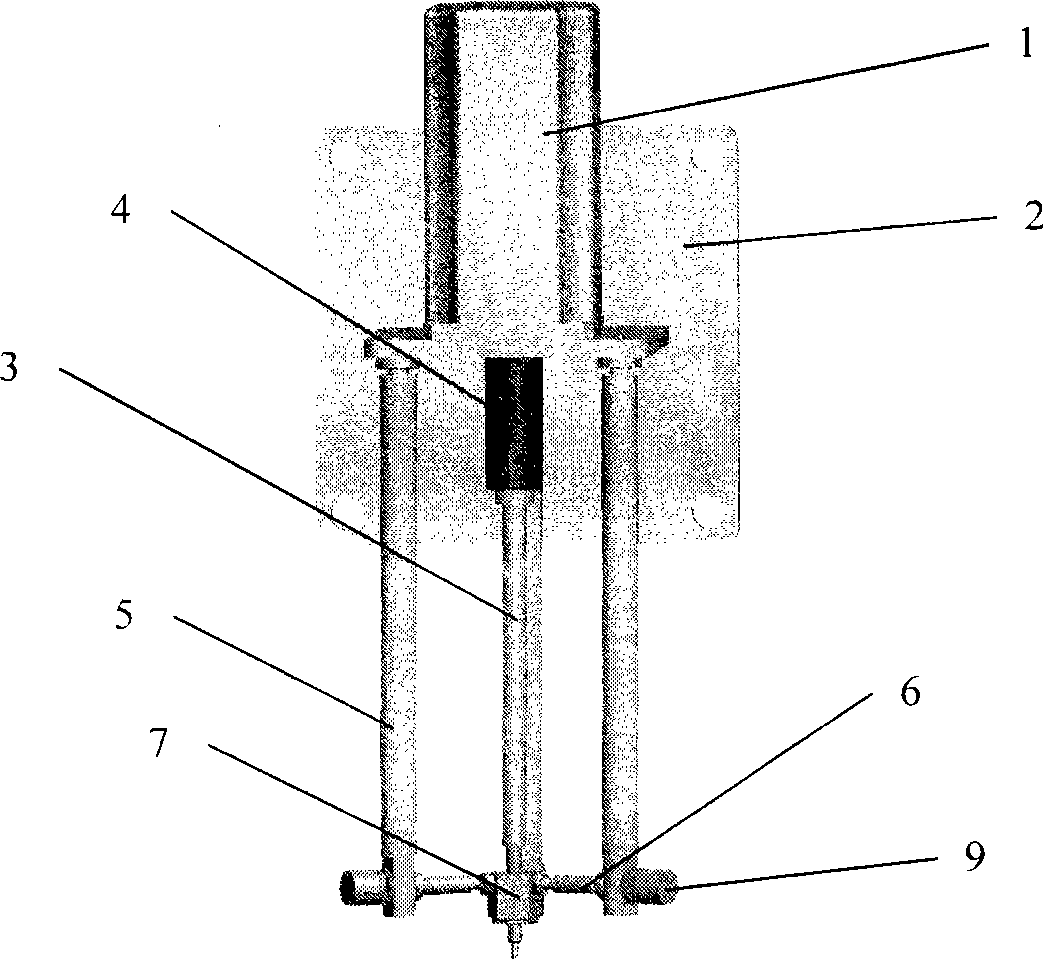

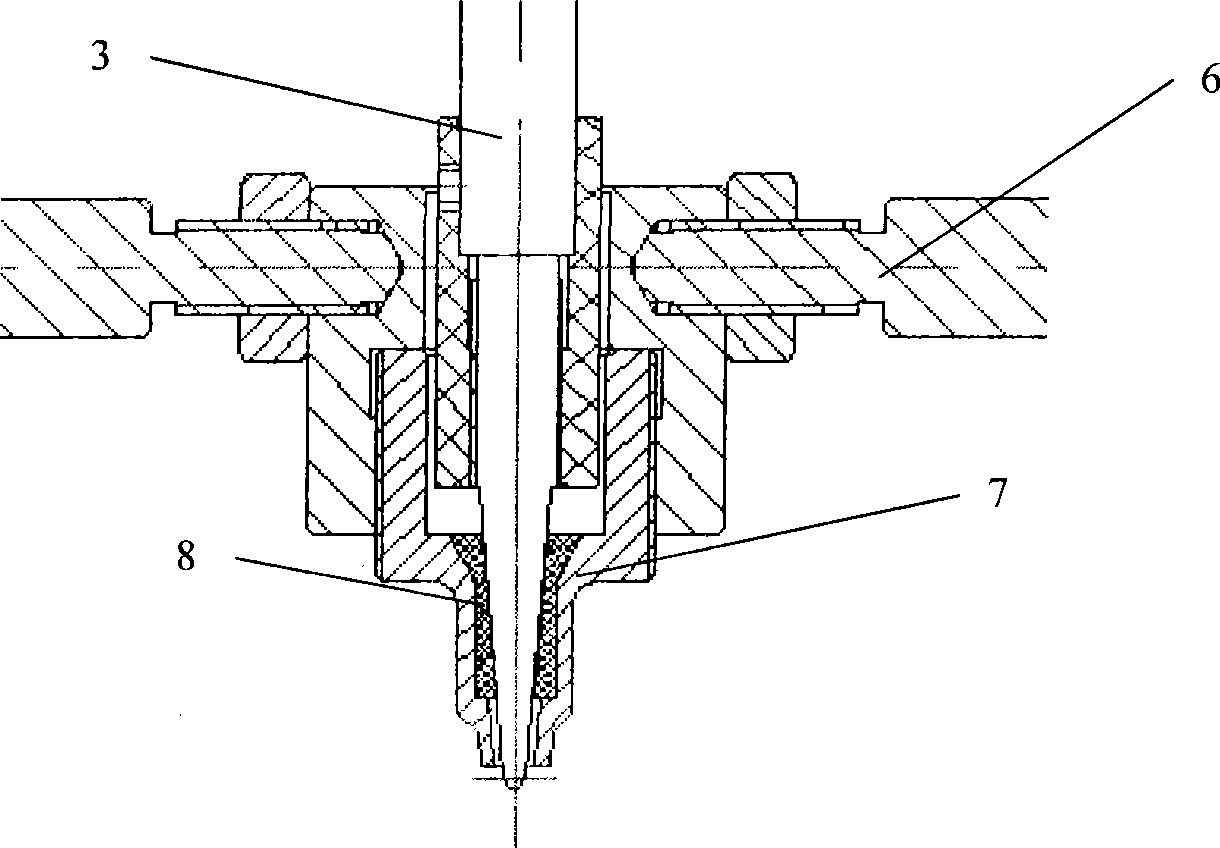

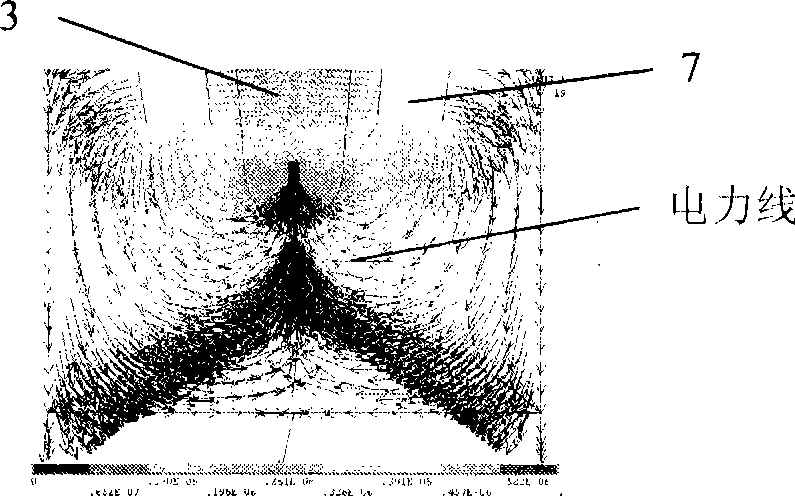

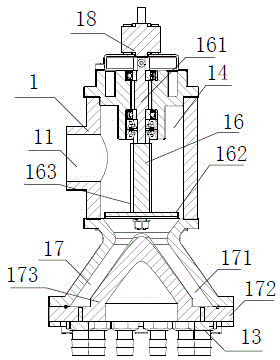

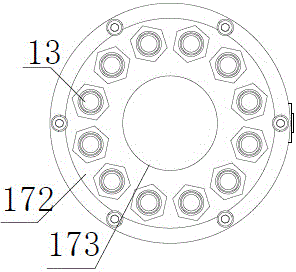

Probe-shaped electrorheological polishing tool

InactiveCN101497177AAchieve deterministic removalRelease fullyEdge grinding machinesPolishing machinesProbe typeRelative motion

The invention relates to an electrorheological effect-based probe-type electrorheological fluid-assisted polishing tool. A motor drives a center shaft to rotate through a coupler; the center shaft passes through a central through of a taper sleeve and vertically forms a probe type convex end downward; and the taper sleeve is positioned by three wiring terminals arranged in a equilateral triangle shape through three supporting rods to ensure the coaxiality with the center shaft. The center shaft is earthed to serve as a cathode, the taper sleeve is connected with a power supply anode through a wiring terminal, the center shaft and the taper sleeve form a ring electrode, the electrode clearance is kept at 0.3 millimeter, and an insulating sleeve is arranged between the electrodes. In the processing process, an electric field of 2,000 to 5,000 V / mm is applied to electrorheological fluid; a loose abrasive material capable of polishing is carried by the electrorheological fluid to gather at the probe type convex end of the center shaft to form a ring chain structure under the special Winslow effect of electrorheological fluid, namely, an effect of obvious viscosity increase under the action of the electric field; and the loose abrasive material removes the surface material of workpieces through the relative motion of the workpieces. The tool is suitable for polishing minor-caliber optical special curved surfaces.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

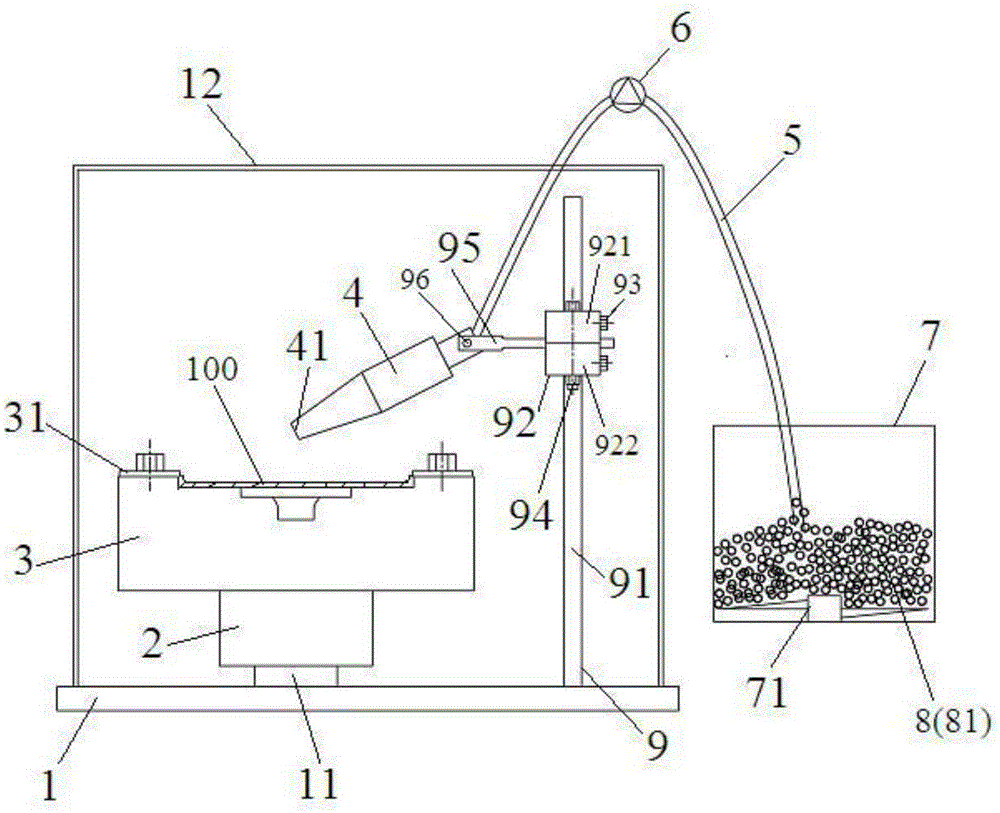

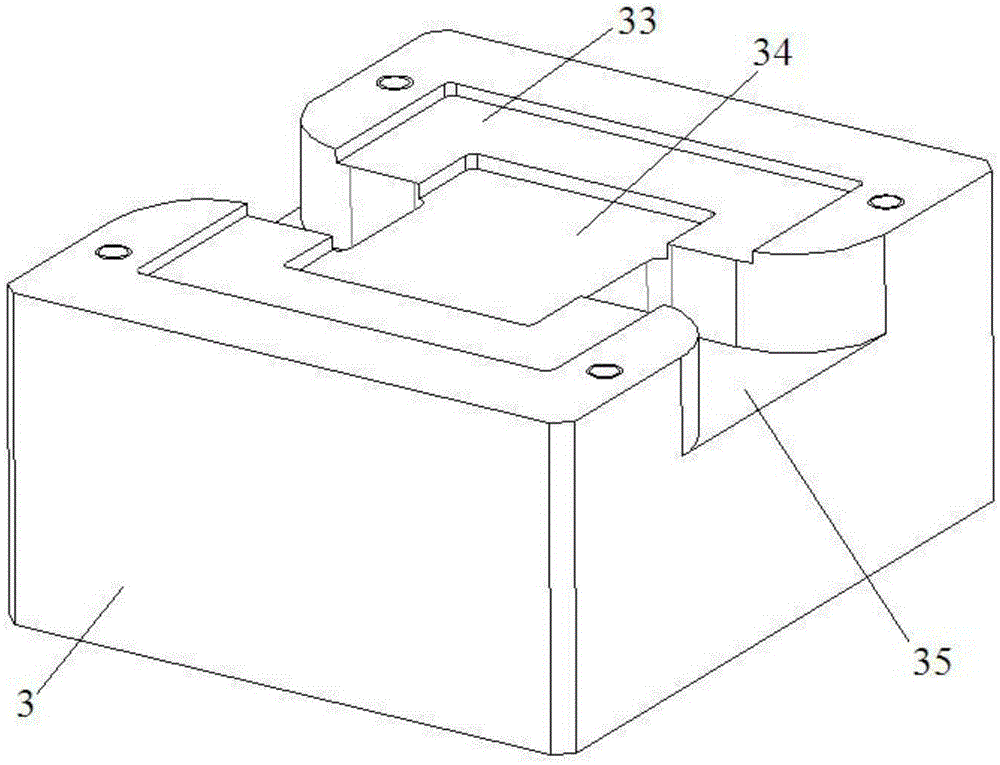

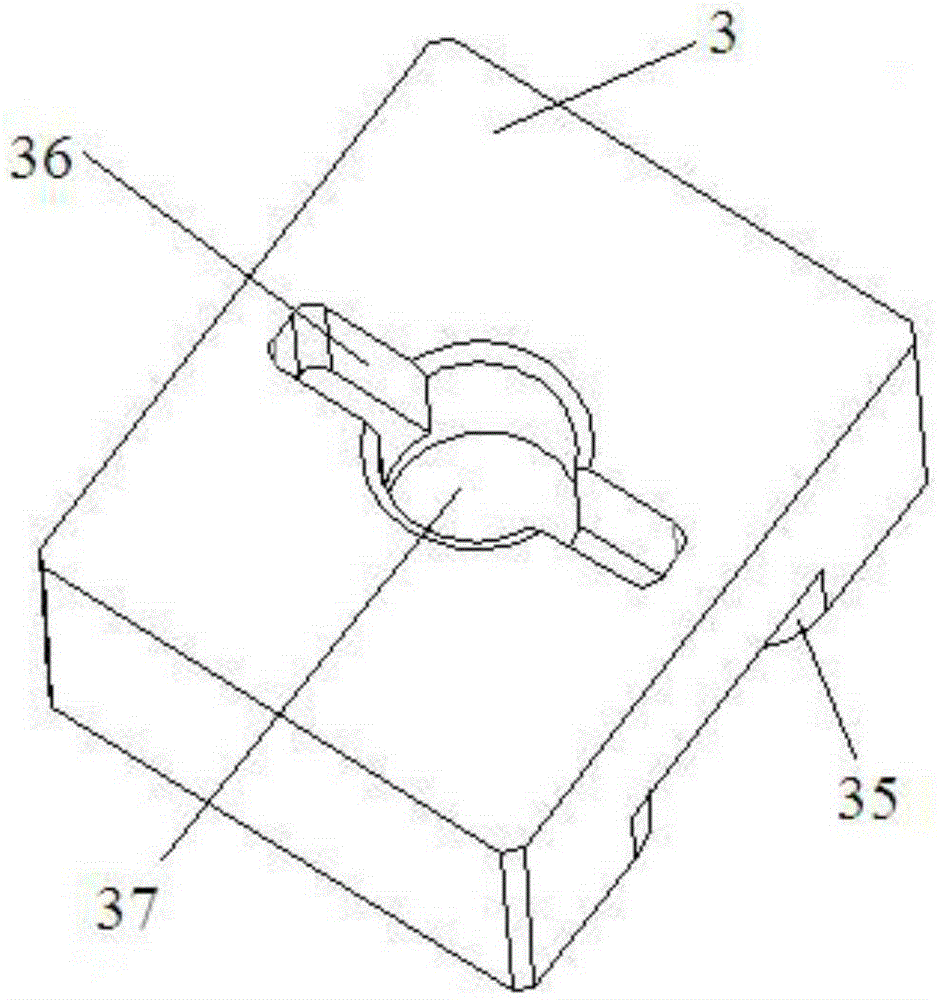

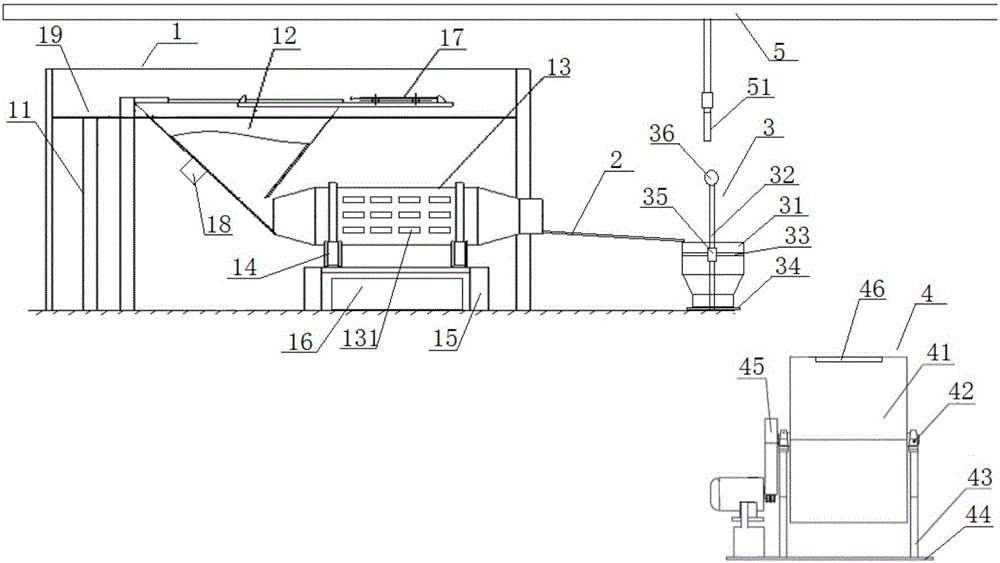

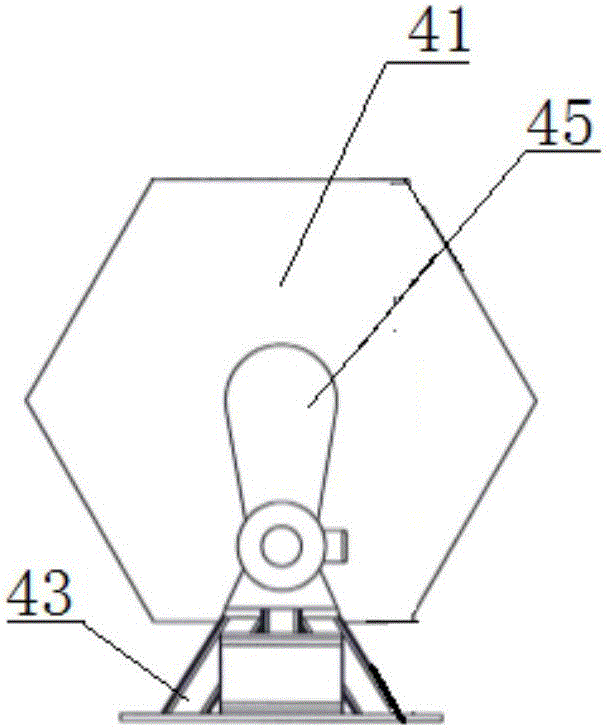

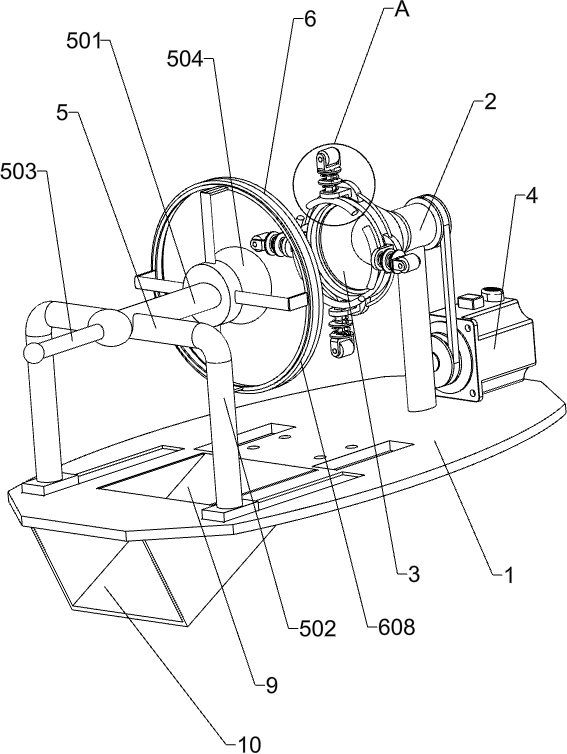

Polishing method and polishing equipment for 3D sapphire

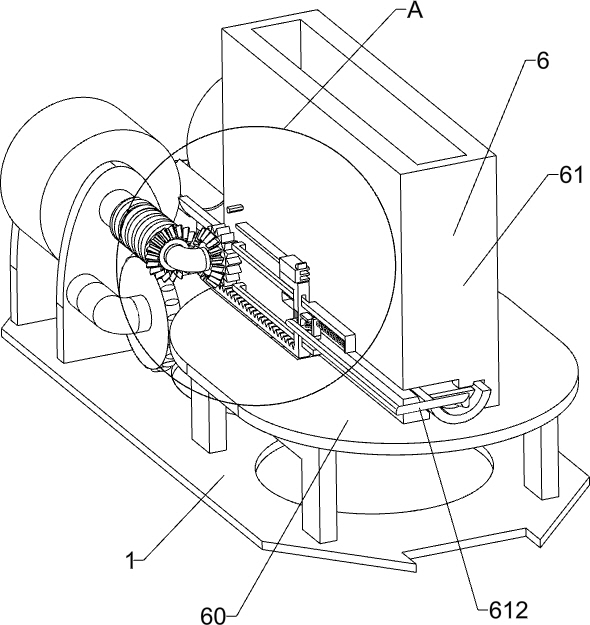

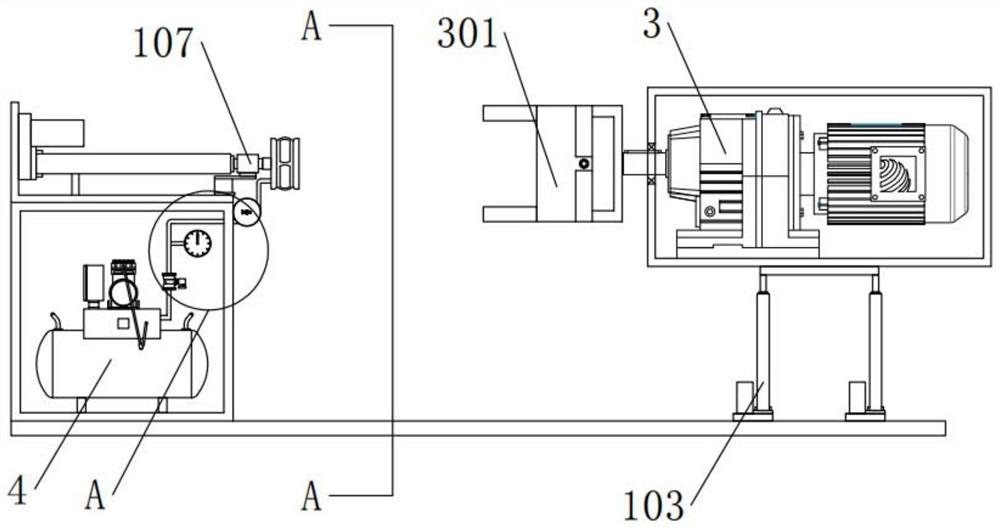

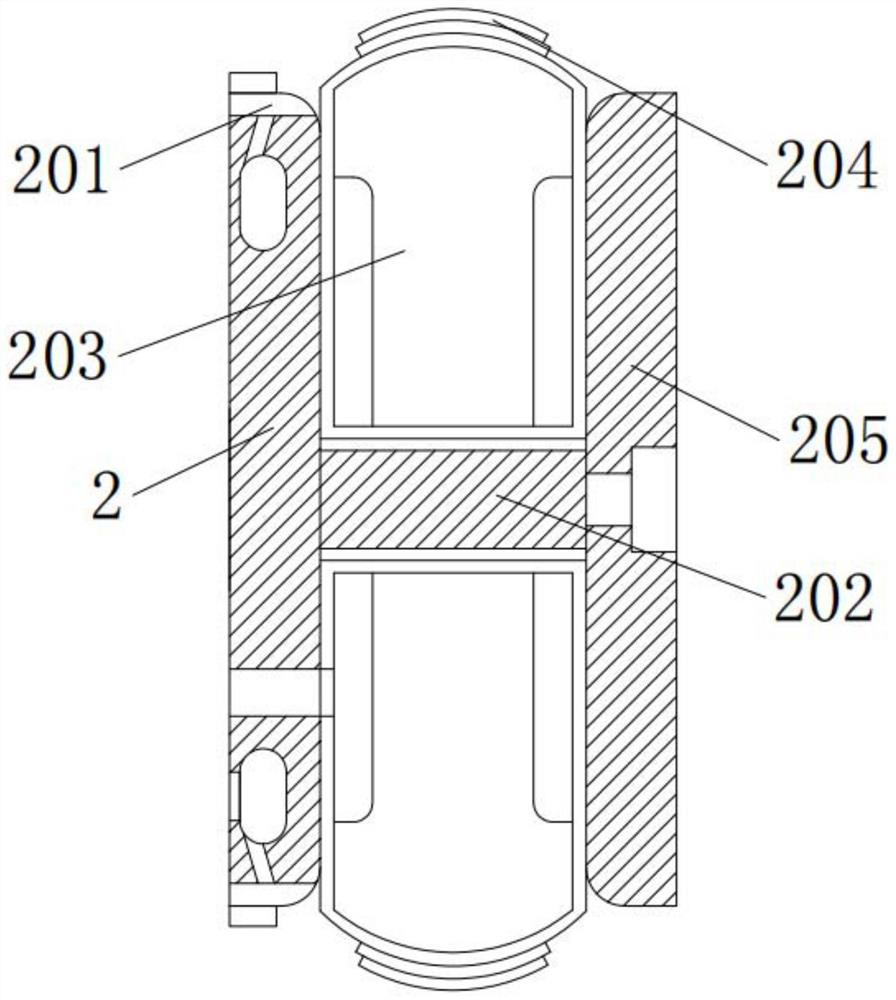

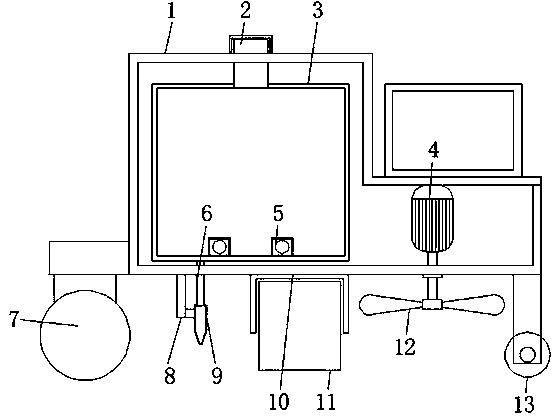

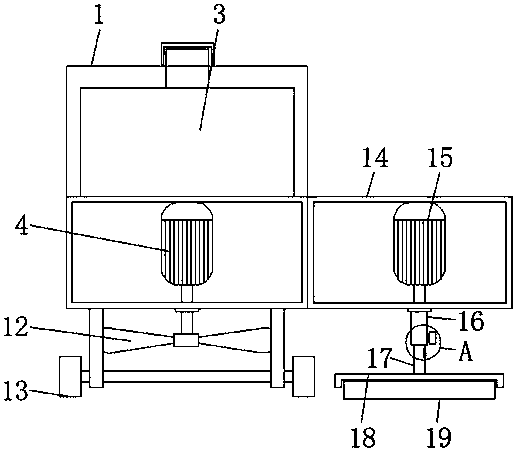

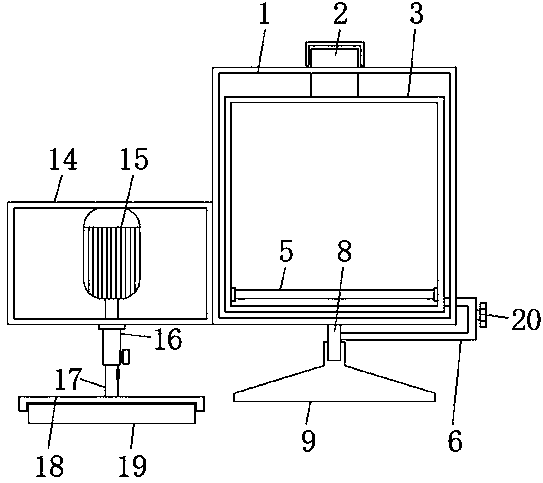

InactiveCN106625275AEasy to hitTo achieve a polished effectBlast gunsAbrasive feedersRough surfaceMaterials preparation

The invention relates to a polishing method set according to polishing equipment, wherein the polishing method comprises abrasive material preparation, clamper installation and starting, spraying nozzle adjustment, abrasive material pre-stirring, air pump starting, abrasive material recovery, and other steps. The present invention further provides polishing equipment for 3D sapphire, wherein the polishing equipment comprises a working table and a rotation base arranged on the working table, the rotation base is provided with a clamper for fixing a 3D sapphire part, a spraying gun fixed on the working table is arranged beside the rotation base, the spraying nozzle of the spraying gun is aligned with the 3D sapphire part on the clamper, the gas inlet of the spraying gun is connected to a gas pump through a gas conveying pipe, the gas inlet of the gas pump is connected to a material bin filled with a abrasive material, and the abrasive material is a rubber ball and / or ceramic ball with diamond micro-powder adhered on the surface. According to the present invention, the rubber ball and / or ceramic ball with diamond micro-powder adhered on the surface is sprayed through the spraying gun and impacts onto the processed surface of the sapphire part, the grinding force is provided for the rough surface of the part by using the impacting force of the diamond micro-powder, the polishing is uniform, and the polishing effect is good.

Owner:LENS TECH CHANGSHA

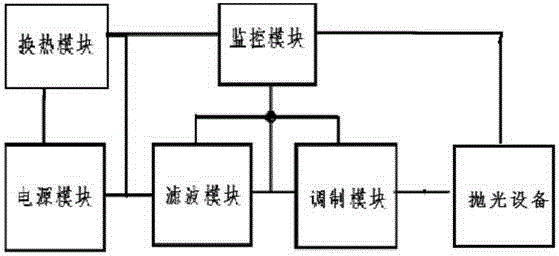

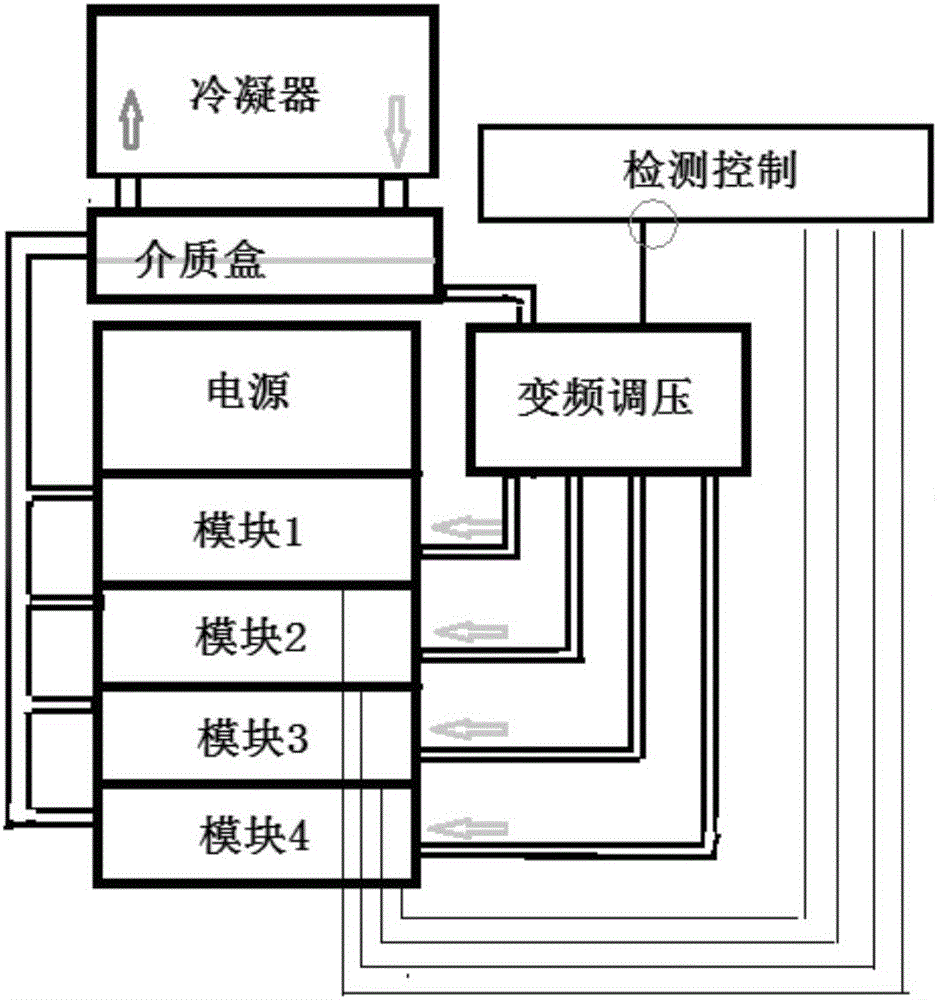

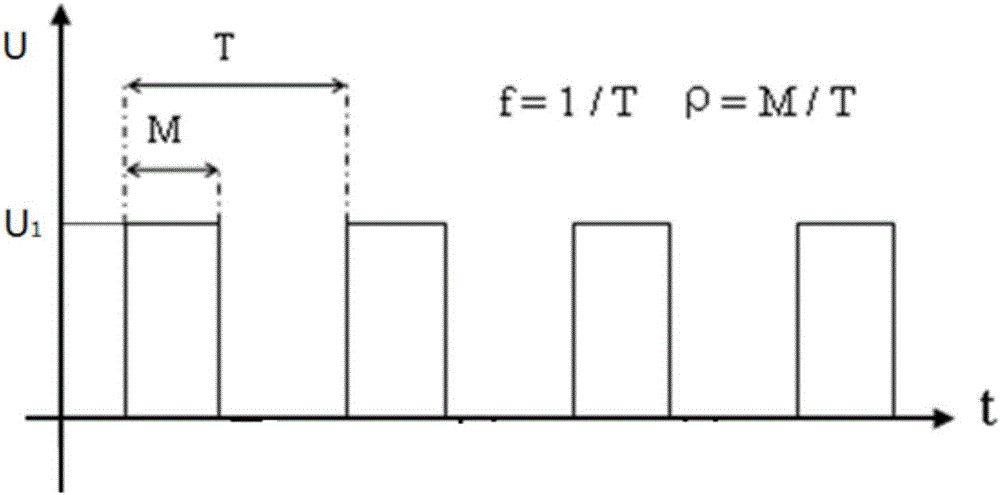

Electrolyte plasma polishing power supply system and control method thereof

InactiveCN105827121AImprove work efficiencyHigh working reliabilityConversion constructional detailsEmergency protective arrangements for limiting excess voltage/currentCapacitanceProcess quality

The invention relates to the technical field of metal material surface treatment, specifically to an electrolyte plasma polishing power supply system and control method thereof, and the system provides pulsation power for metal surface treatment. The power supply system comprises a monitoring module, and a power module, a heat exchange module, a filter module and a modulation module which are connected in sequence, wherein the monitoring module is electrically connected with the rest of modules. The electrolyte plasma polishing power supply system solves the problems existing in the prior art that when a direct current power supply is adopted to supply power, the fault rate is high, the efficiency is low and the process quality is not easy to control. Through adoption of a medium phase-change heat exchange technology, the work efficiency and reliability of the power supply are improved; through setting of appropriate capacitance and inductance parameters, negative influence of surge current on the power supply and a power grid is inhibited, and surge current required by a polishing process is provided at the same time; and through the arrangement of the modulation module between the filter module and polishing equipment, pulsation polishing is realized. The power supply system remarkably improves processing efficiency and process quality, and also saves energy and reduces consumption, thereby generating relatively large economic benefits.

Owner:汪一楠

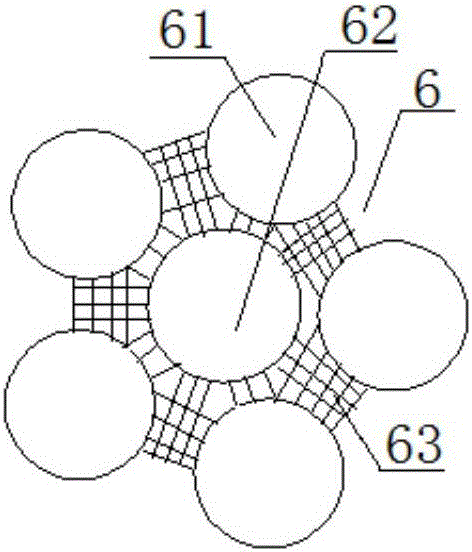

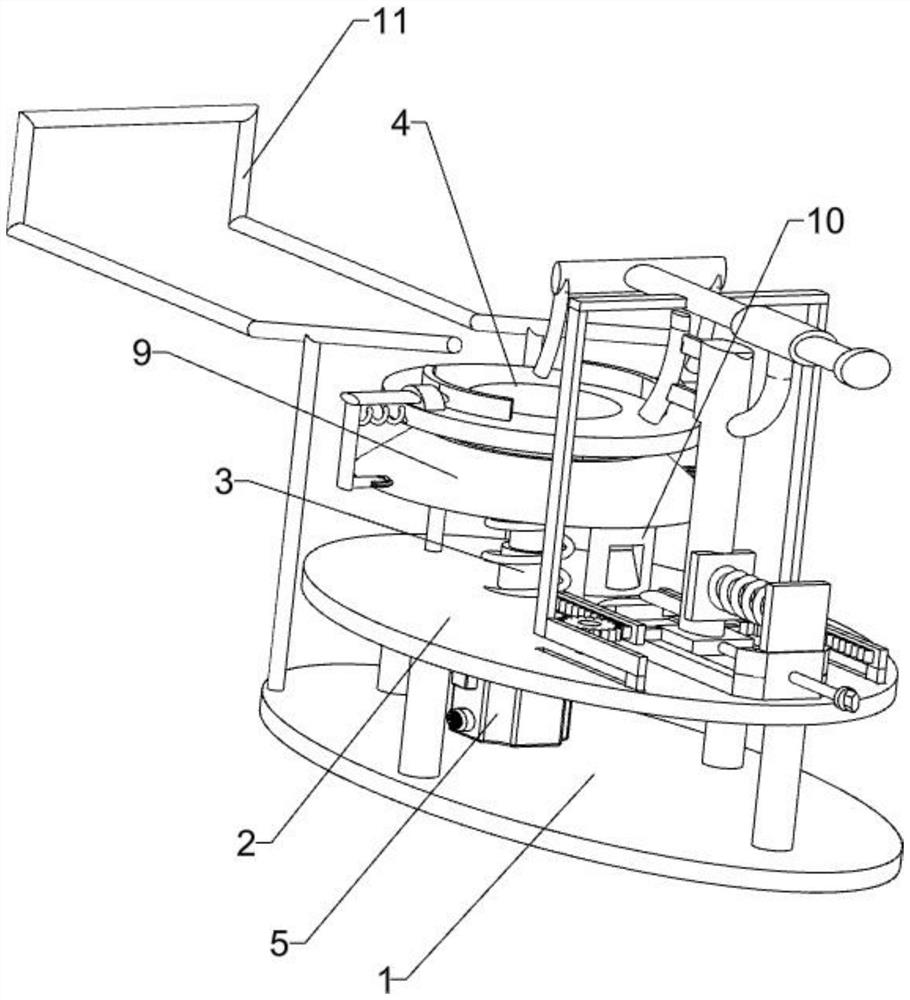

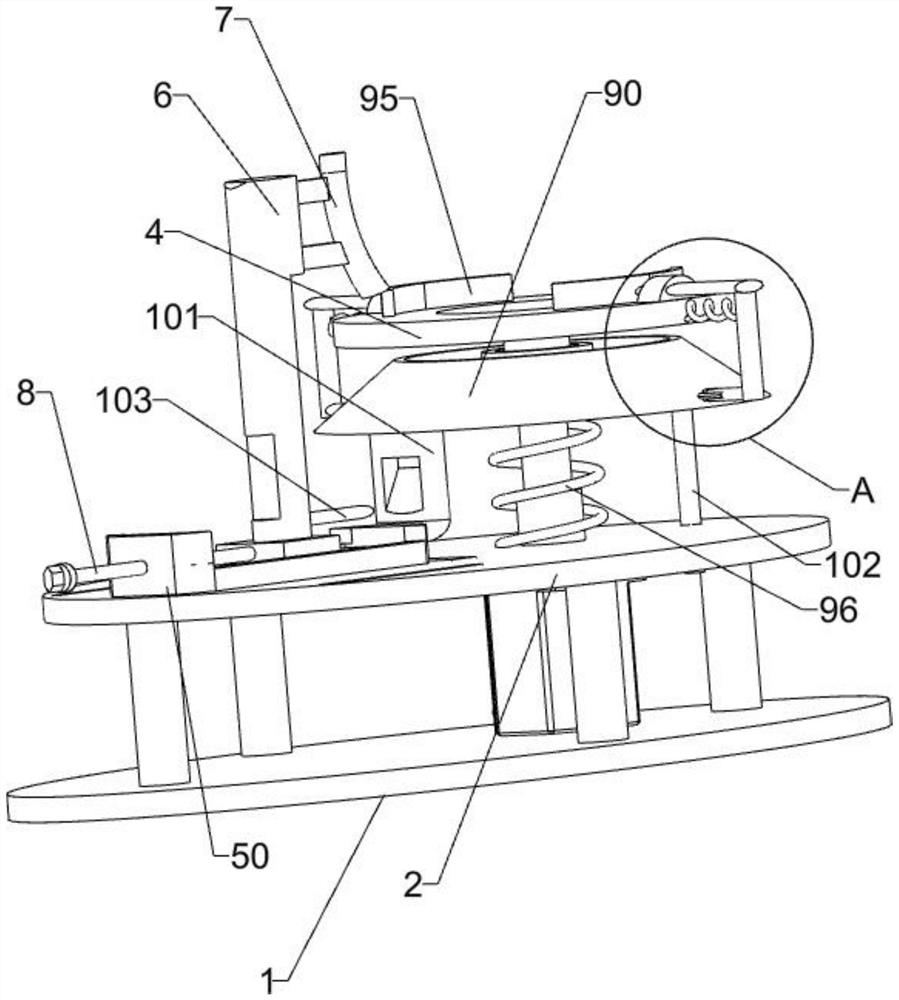

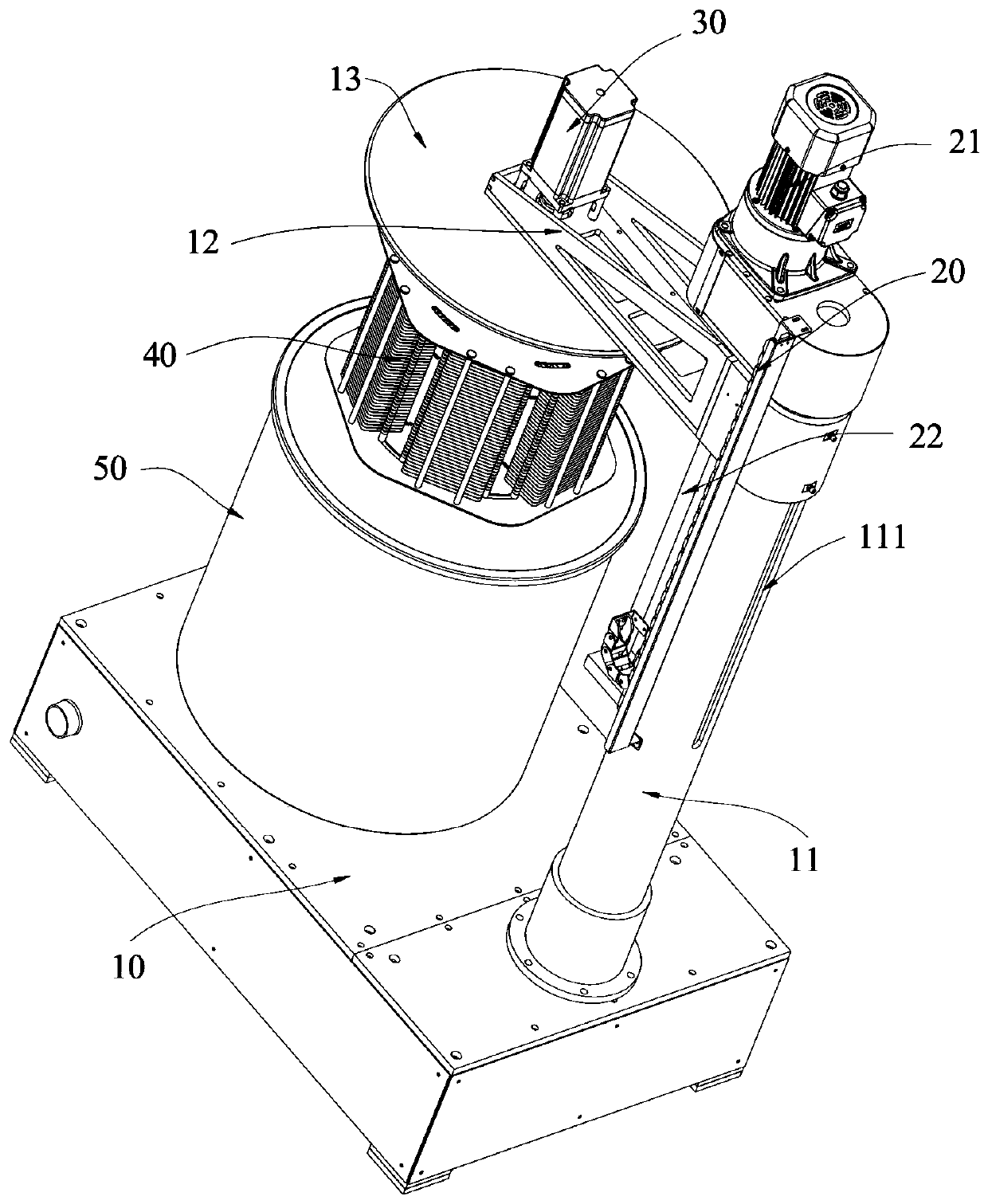

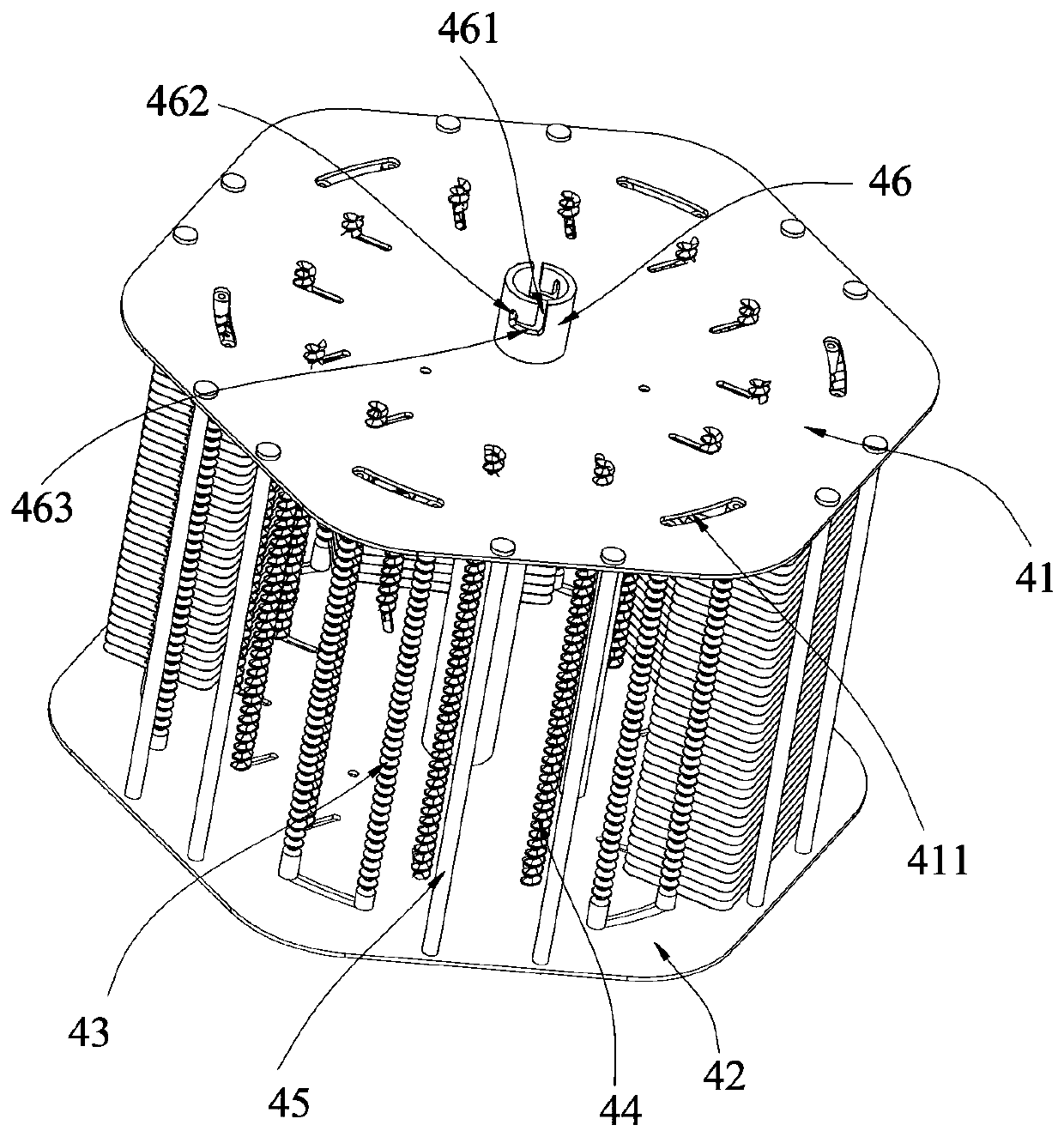

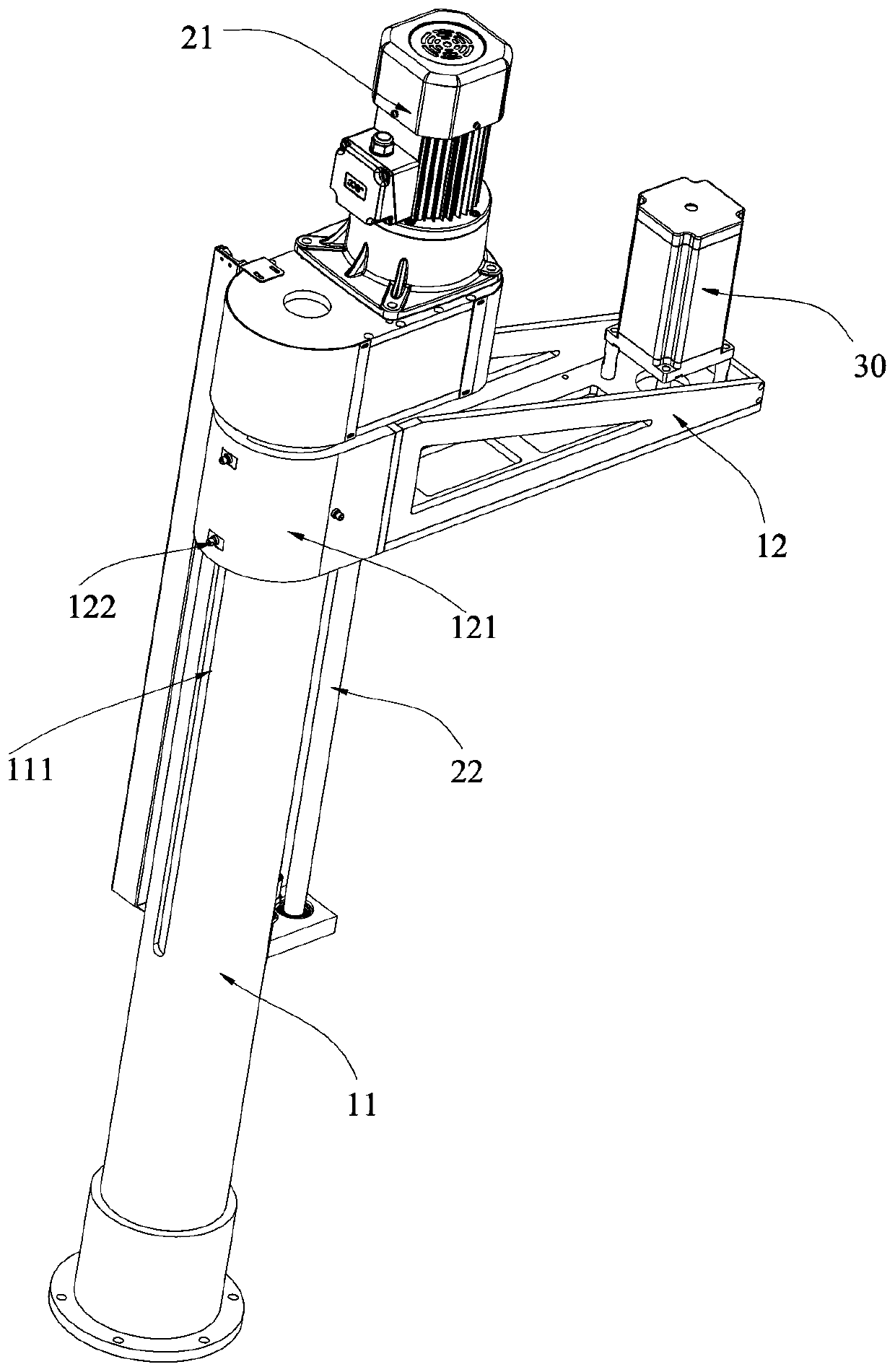

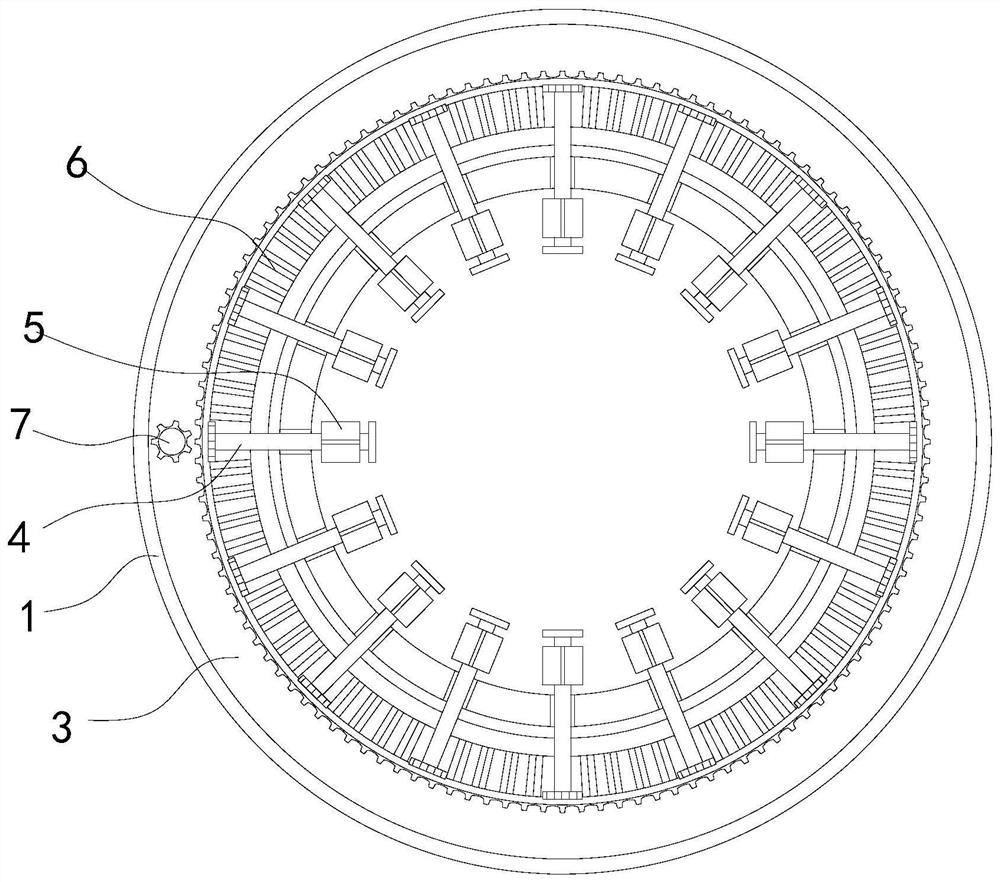

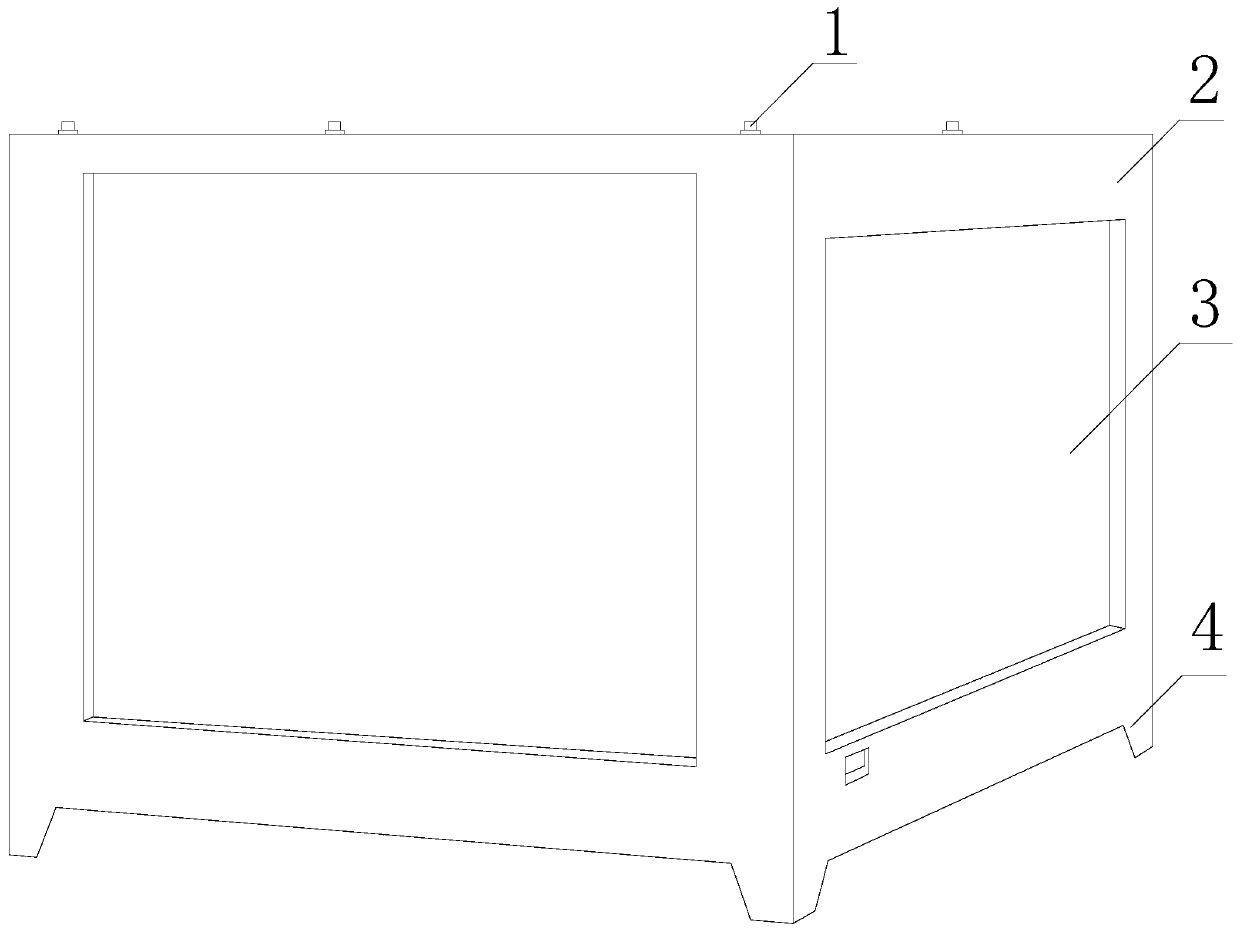

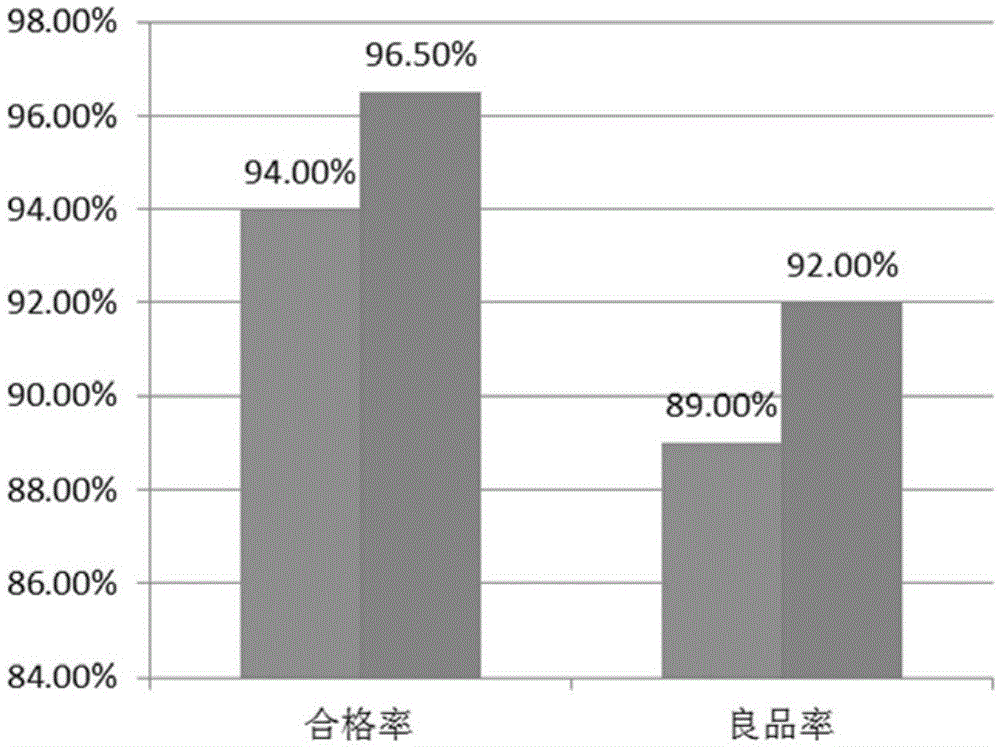

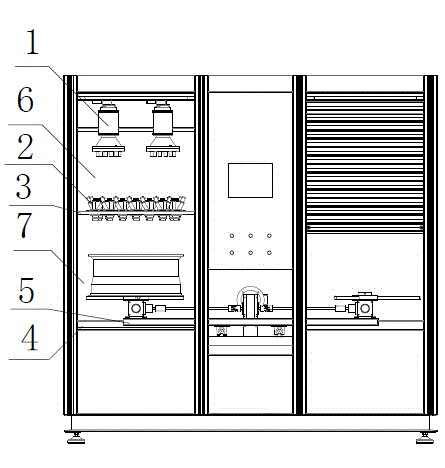

Automatic separating and polishing system and processing technique for steel balls subjected to demolding

ActiveCN106493630AAchieve separabilityReach pickEdge grinding machinesPolishing machinesProduction lineWear resistant

The invention discloses an automatic separating and polishing system and processing technique for steel balls subjected to demolding, and belongs to the technical field of production of wear-resistant steel balls. The automatic separating and polishing system for the steel balls subjected to demolding comprises a hoisting crane, a ball and sand separating device, a sorting table and a polishing device, wherein the ball and sand separating device, the sorting table and the polishing device are distributed in sequence according to a production line, and used for separating, sorting and polishing through the dead load of the steel balls separately. The hoisting crane is hoisted above the production line. As for the ball and sand separating device, the steel balls knock mutually due to weight of the steel balls, so that steel ball modules are separated, the steel balls can roll due to the gravity of the steel balls and the roundness shape, and automatic separation of risers and molding sand is facilitated; and finally, through the gravity of the steel balls and the roundness shape, the steel balls grind and polish one another, the processing efficiency is high, and separation and polishing are thorough.

Owner:安徽卡勒米特鑫力新材料科技有限公司

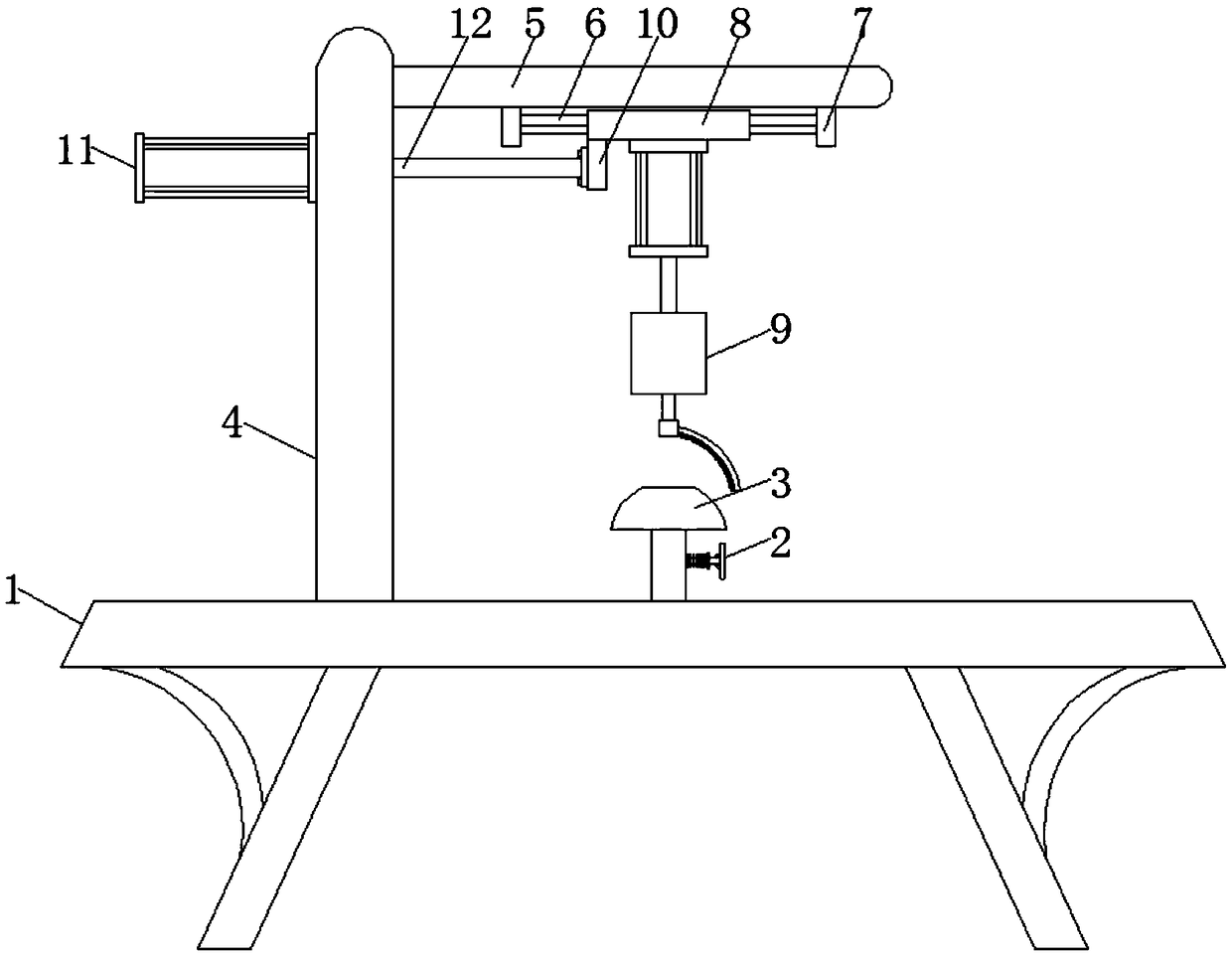

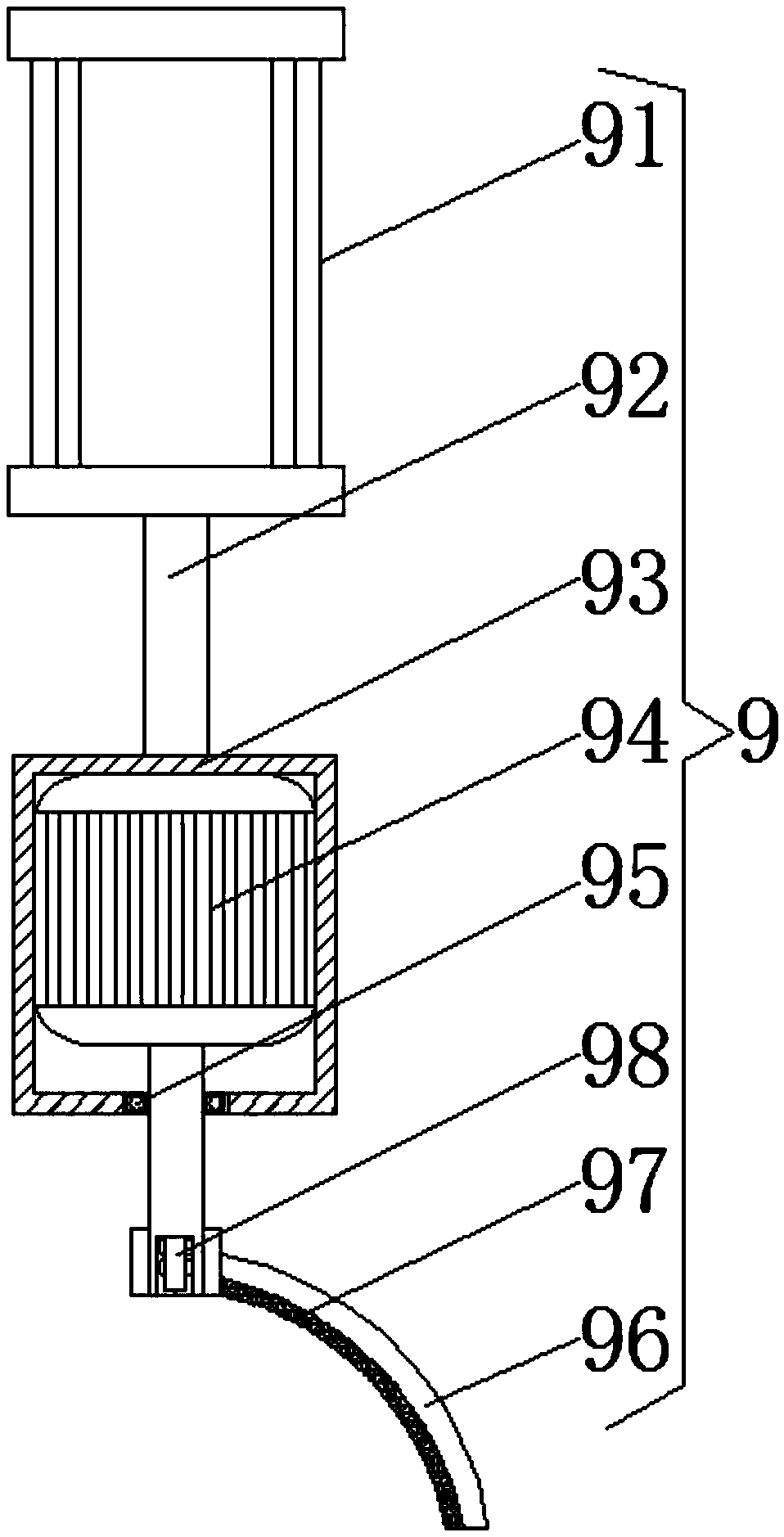

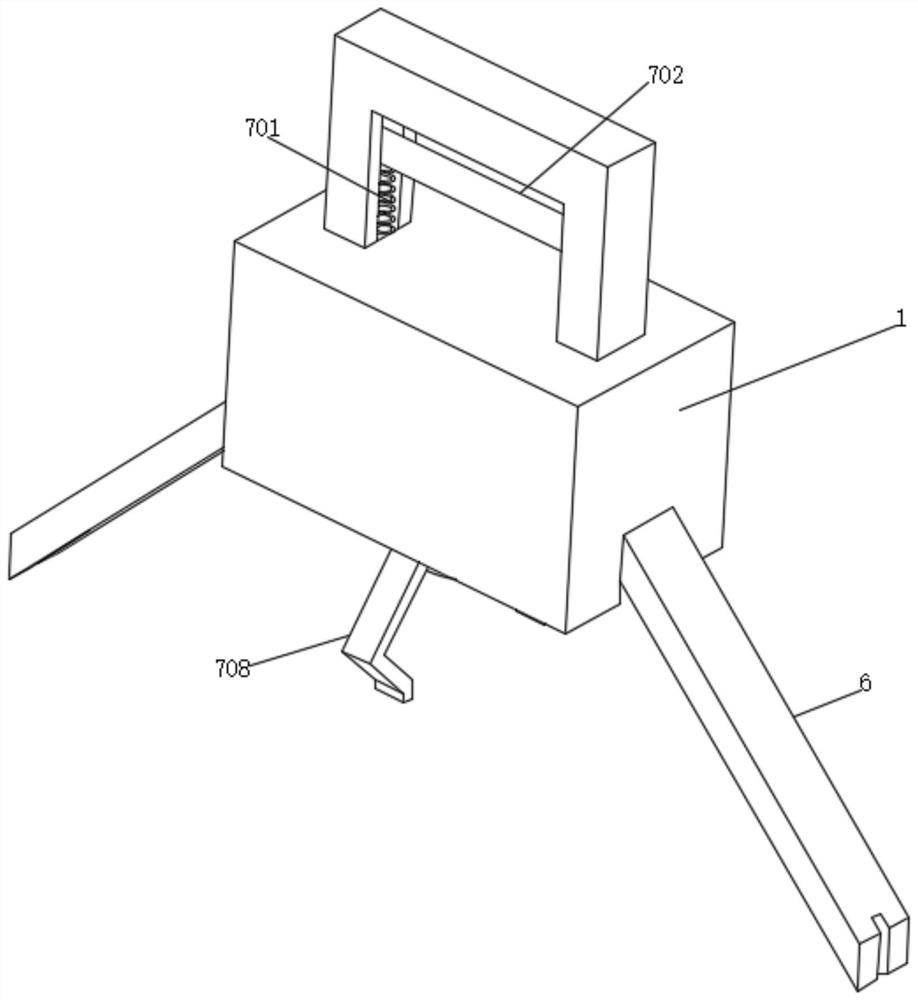

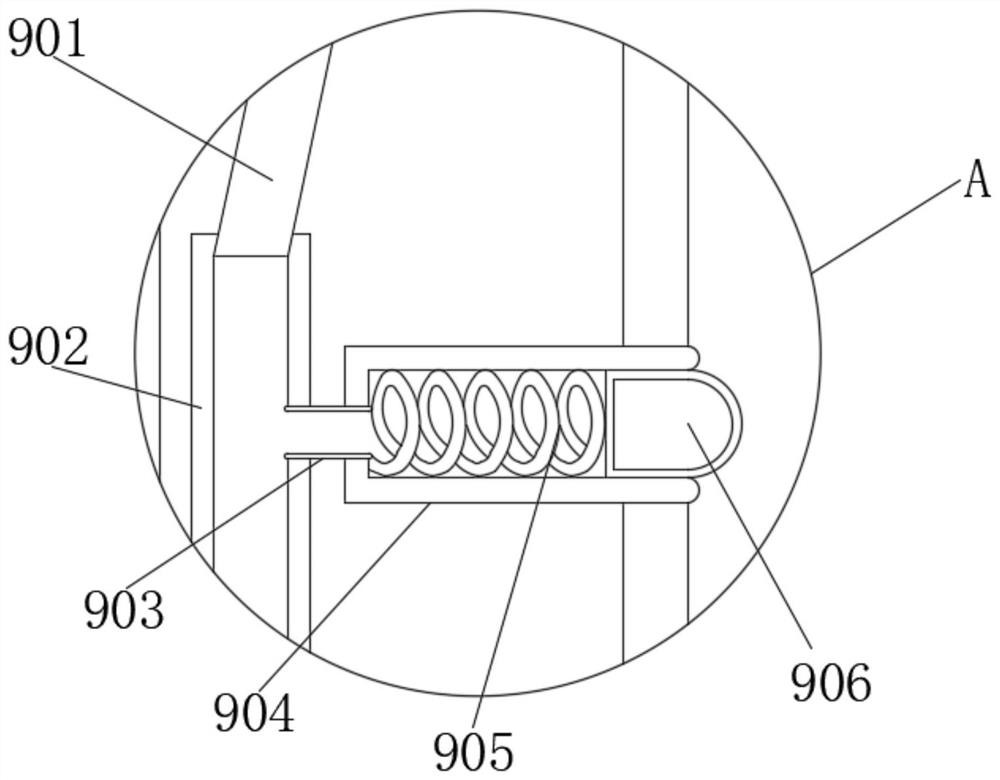

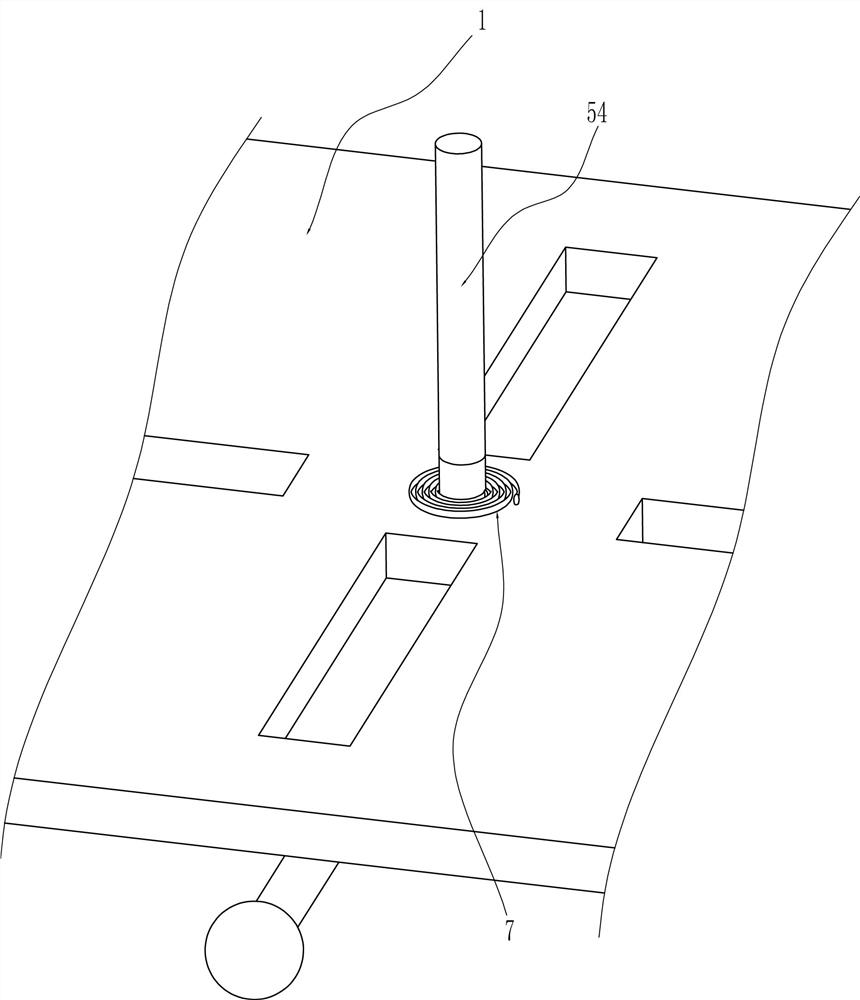

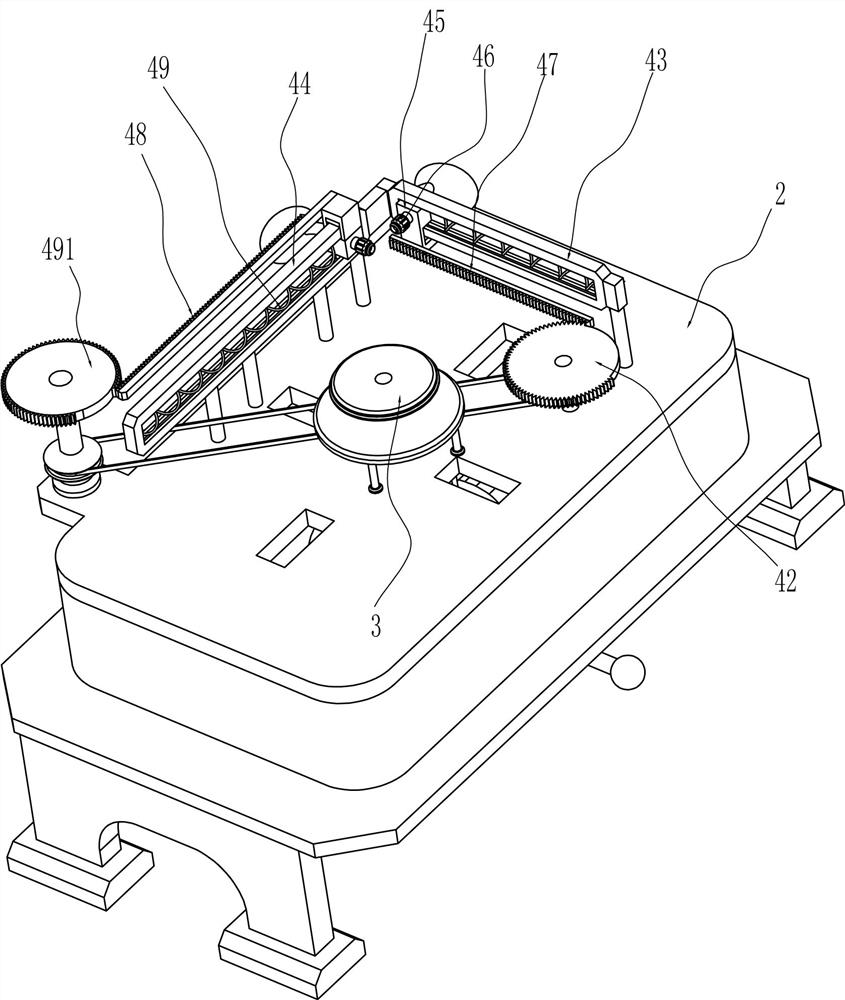

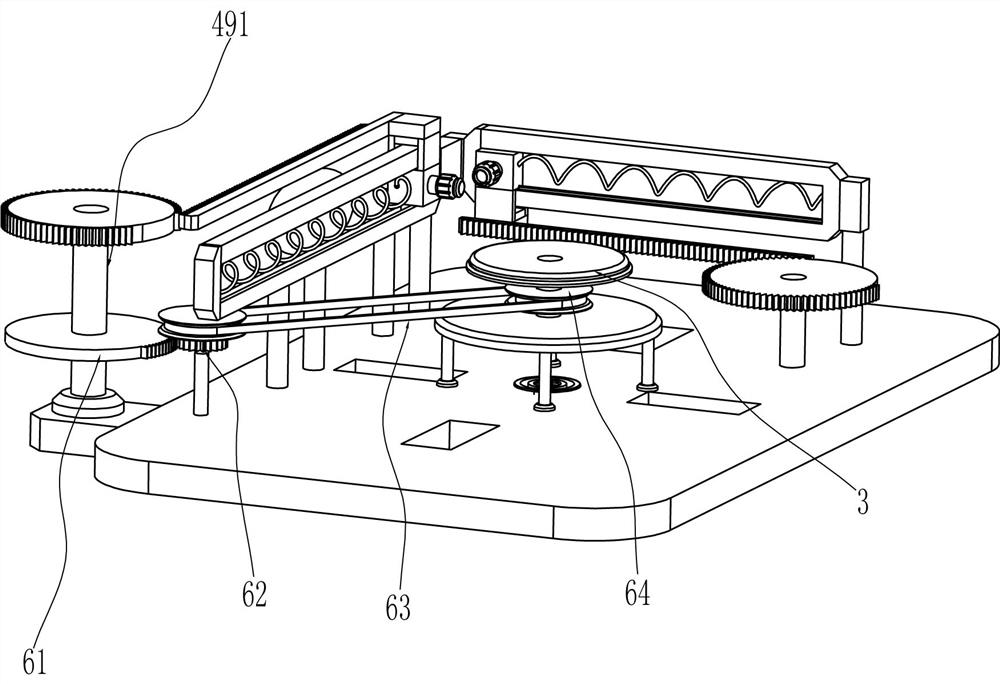

Cambered surface polishing device for ceramic processing

ActiveCN111645199ATo achieve a polished effectSave human effortWorking accessoriesStone-like material working toolsCircular discPolishing

The invention provides a cambered surface polishing device for ceramic processing. The cambered surface polishing device for ceramic processing comprises a base plate, a spindle, a disk, a motor, a sliding seat, a sliding rod, an arc-shaped scraping knife, a pull rod, a clamping mechanism and a transmission mechanism, wherein the top of the base plate is connected with a mounting plate; the spindle is rotatably connected to one side of the mounting plate; the disk is connected to the top of the spindle; the motor is mounted on the top of the base plate; an output shaft of the motor is connected with the spindle; the sliding seat is connected to the other side of the top of the base plate; the sliding rod is slidably connected to the top of the sliding seat; the arc-shaped scraping knife isconnected to the sliding rod; the pull rod is connected to the sliding rod and is in sliding fit with the sliding seat; the clamping mechanism is arranged between the spindle and the disk; and the transmission mechanism is arranged between the clamping mechanism and the sliding rod. The cambered surface polishing device for ceramic processing conducts polishing on ceramic through the clamping mechanism, the transmission mechanism and the arc-shaped scraping knife to achieve the polishing effect on the ceramic, discharges the polished ceramic through a discharge mechanism without frequent manual discharging, and effectively saves manpower. During operation, an operator just needs to place the ceramic and then pull the pull rod. The cambered surface polishing device for ceramic processing is easy to operate and effectively improves the working efficiency.

Owner:佛山市冠神陶瓷机械有限公司

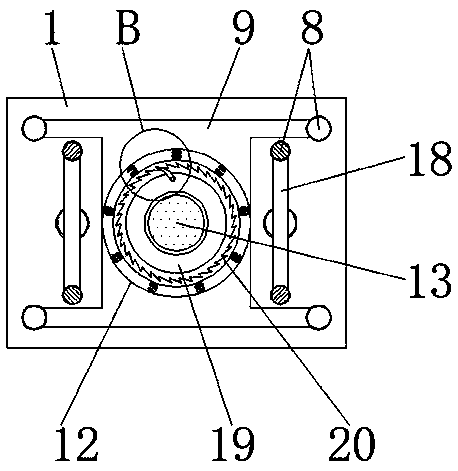

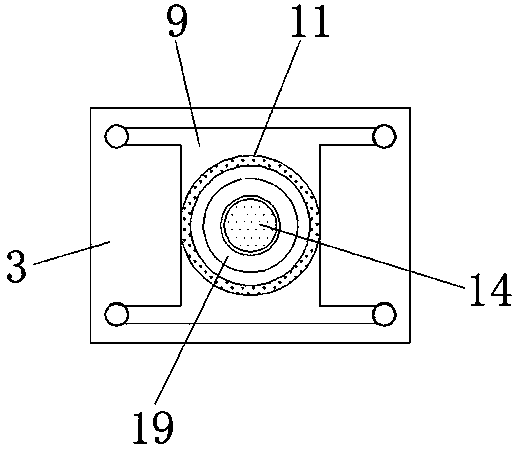

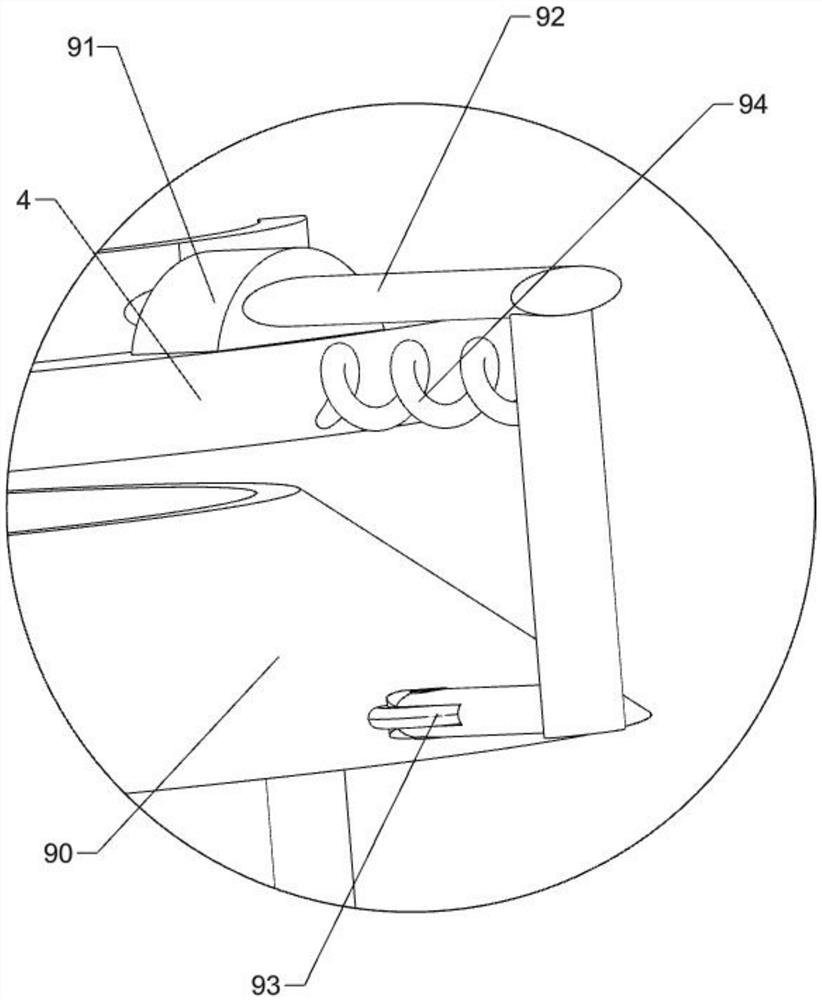

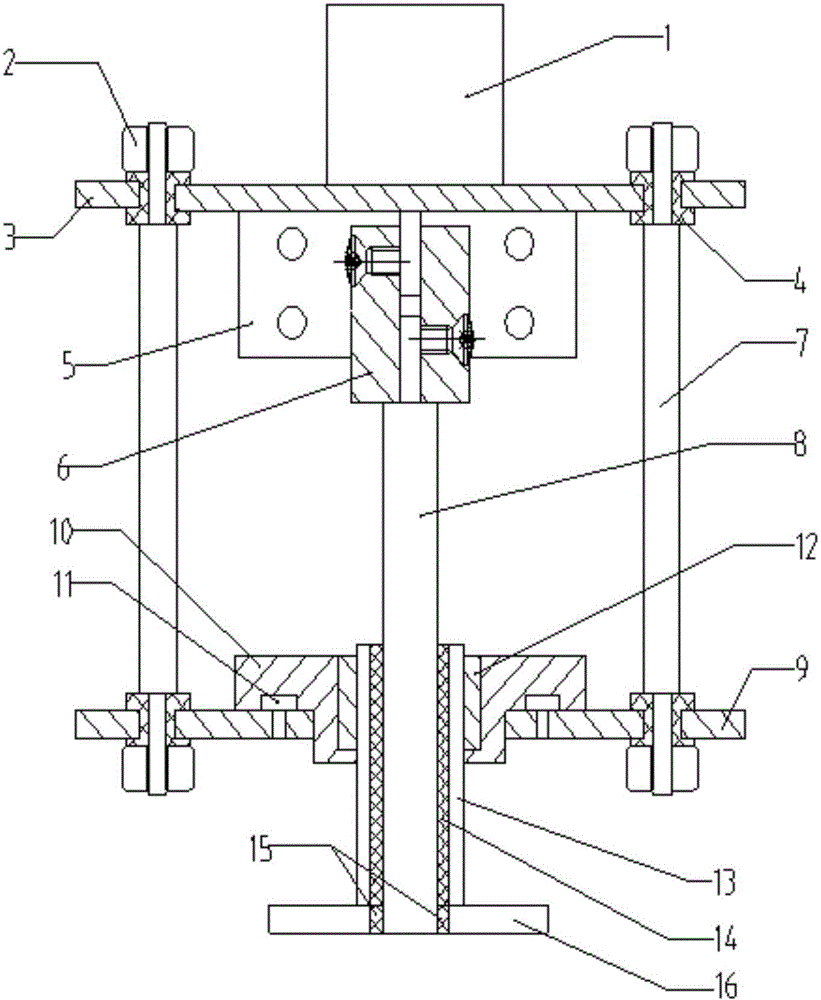

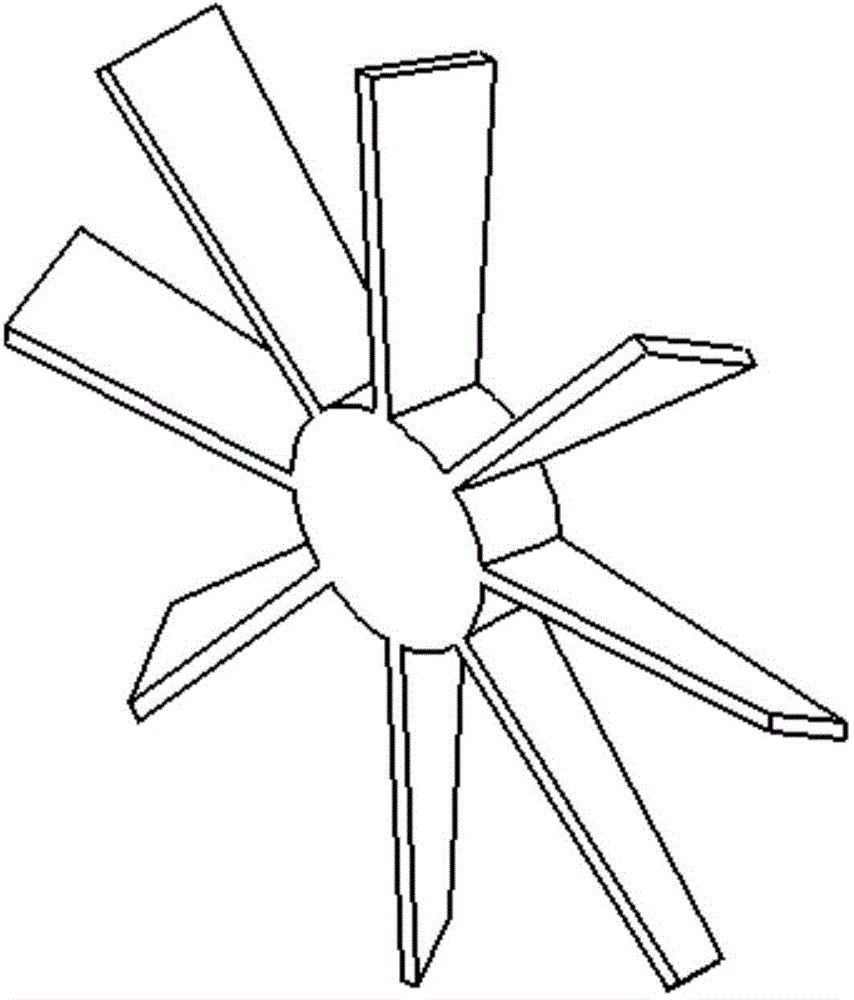

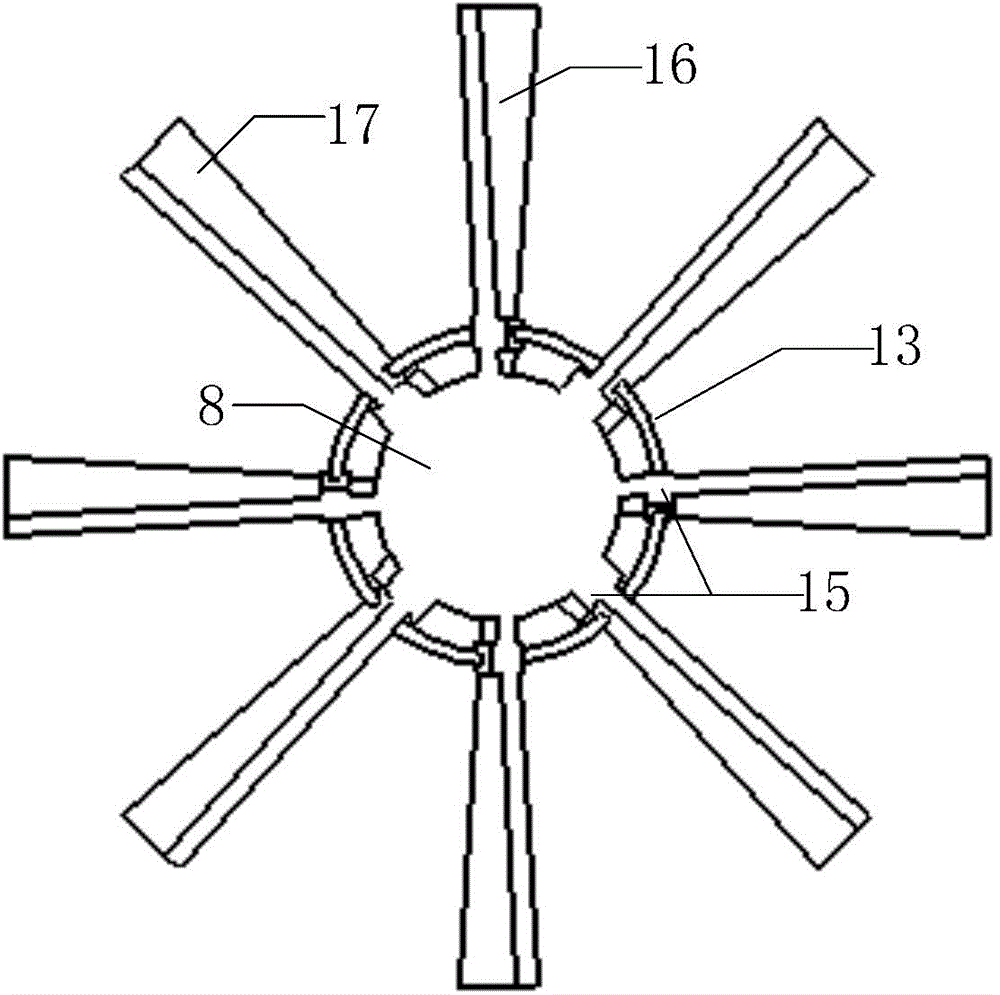

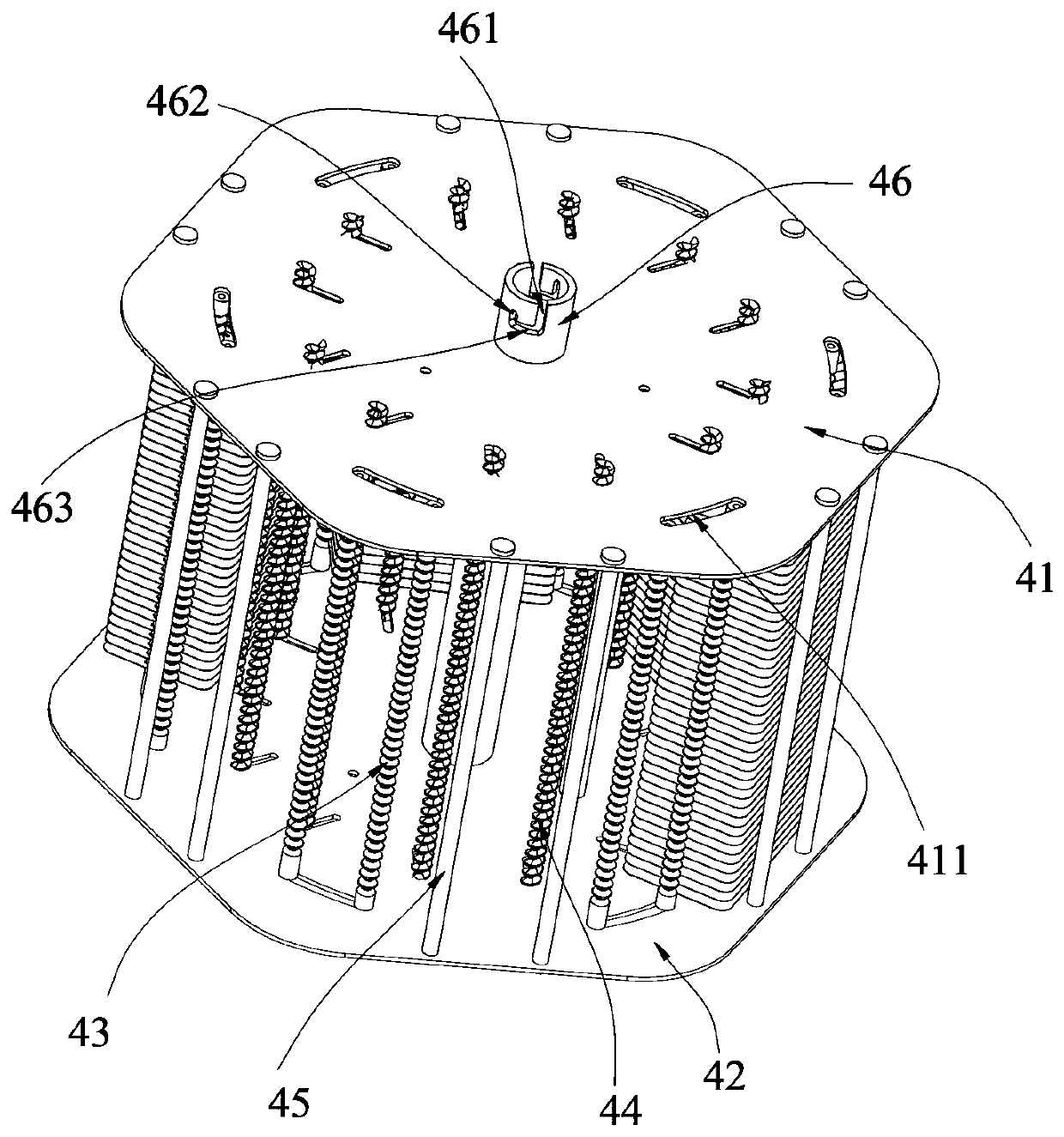

Positive and negative blade electrodes alternated type electrorheological buffing device

The invention relates to a positive and negative blade electrodes alternated type electrorheological buffing device. The device comprises a motor, a coupler, a supporting rod, a rotation shaft, a positive electrode conductive cylinder, an insulation cylinder, a blade insulation sleeve, negative electrode buffing blades, positive electrode buffing blades and the like, wherein the negative electrode buffing blades and the lower end of the rotation shaft are fixed to form a negative electrode, and the contact position between the negative electrode and the positive electrode conductive cylinder is insulated by the blade insulation sleeve; the positive electrode buffing blades and the positive electrode conductive cylinder are fixed to form a positive electrode, the positive electrode and the rotation shaft are fixed through the blade insulation sleeve, and the positive electrode and the negative electrode buffing blades are alternatively distributed; an annulus brush is placed in a brush sleeve groove and closely contacted with the positive electrode conductive cylinder. After energization, electrorheological buffing liquids distributed between the positive electrode buffing blades and the negative electrode buffing blades are subjected to electrorheology effects to form a flexible buffing head, and workpieces are buffed by the flexible buffing head driven by the blades. According to the positive and negative blade electrodes alternated type electrorheological buffing device, by means of the streamline blades and alternatively distributed electric fields, high shearing speeds are achieved, and electrorheological buffing efficiency is effectively improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

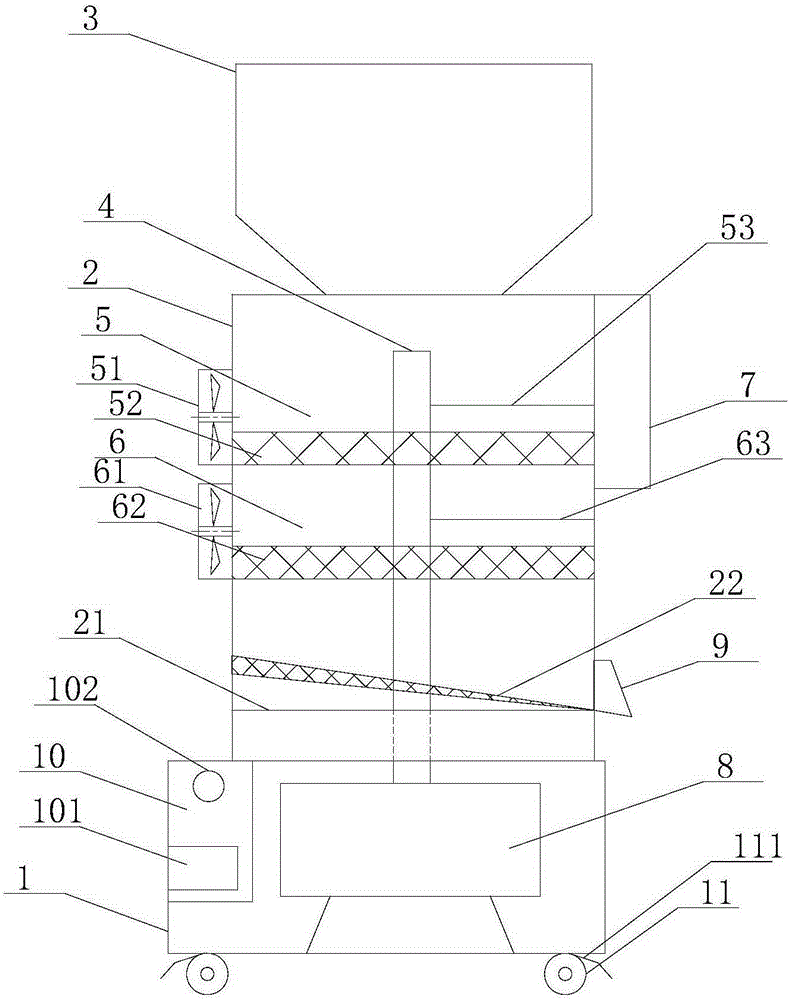

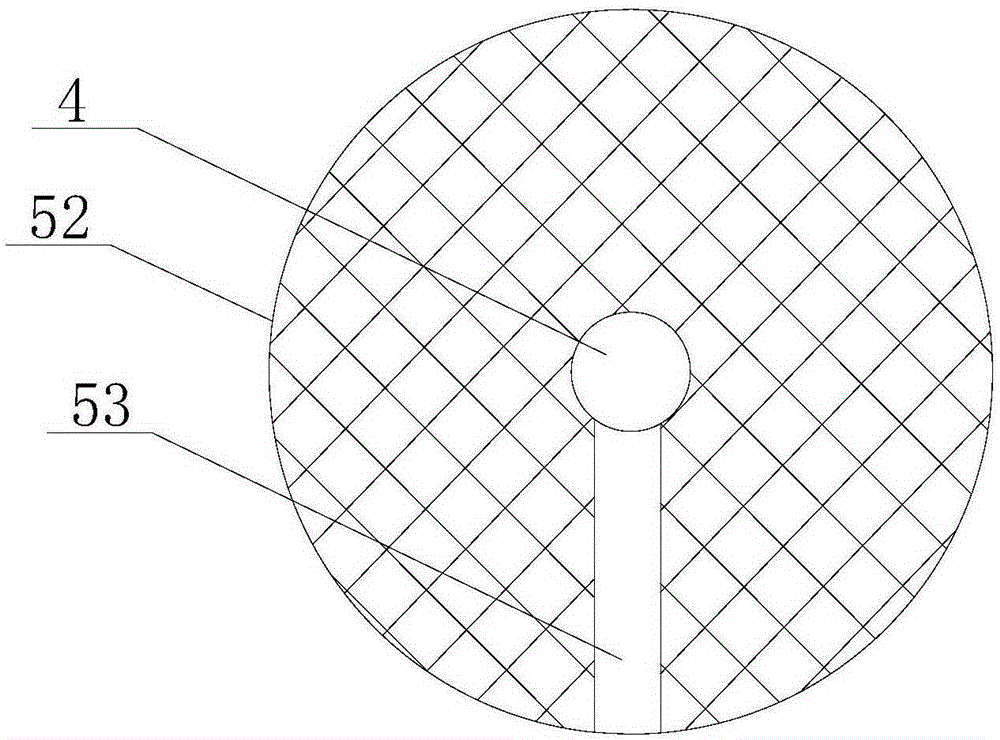

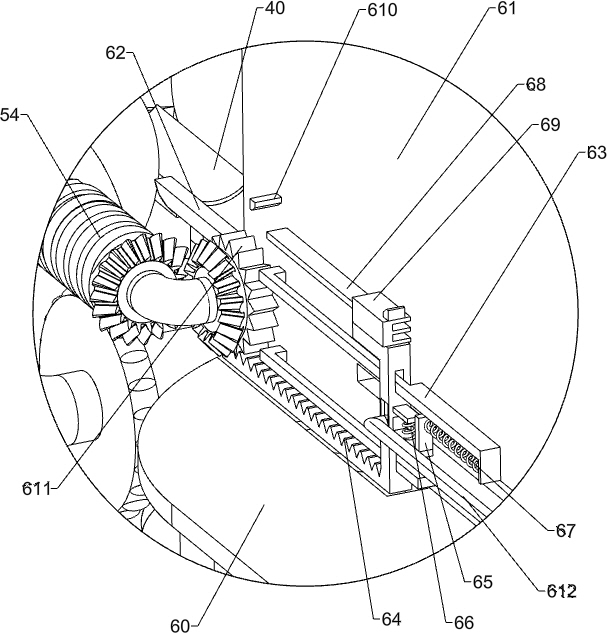

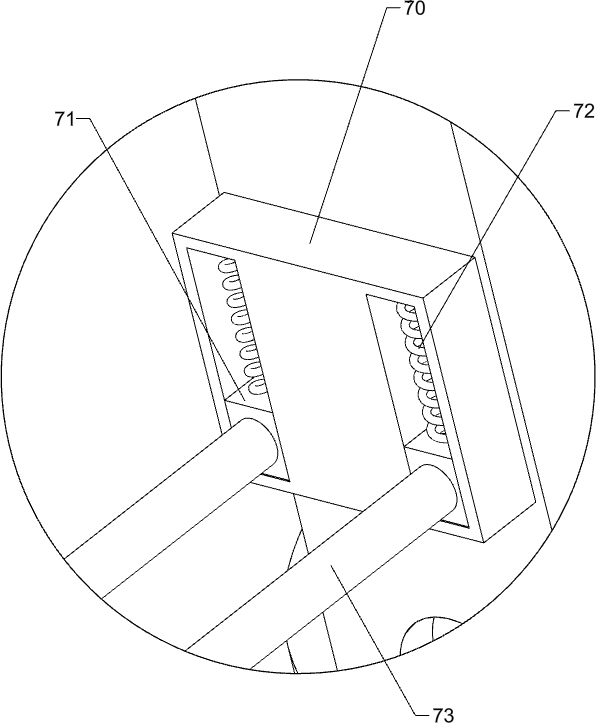

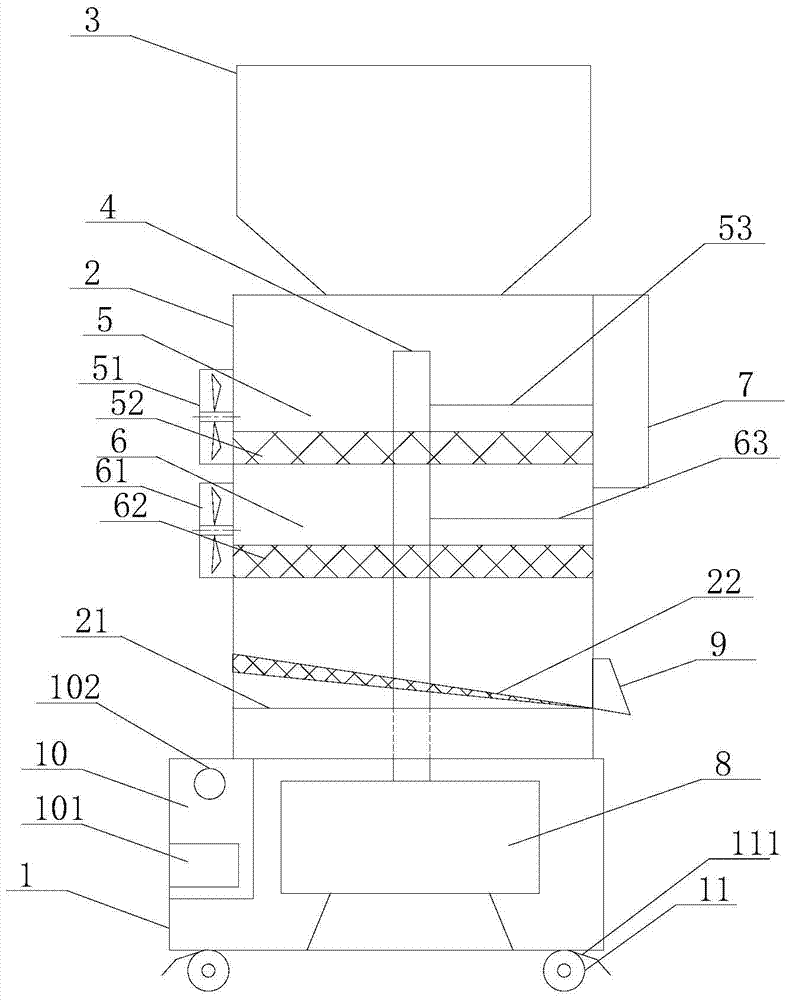

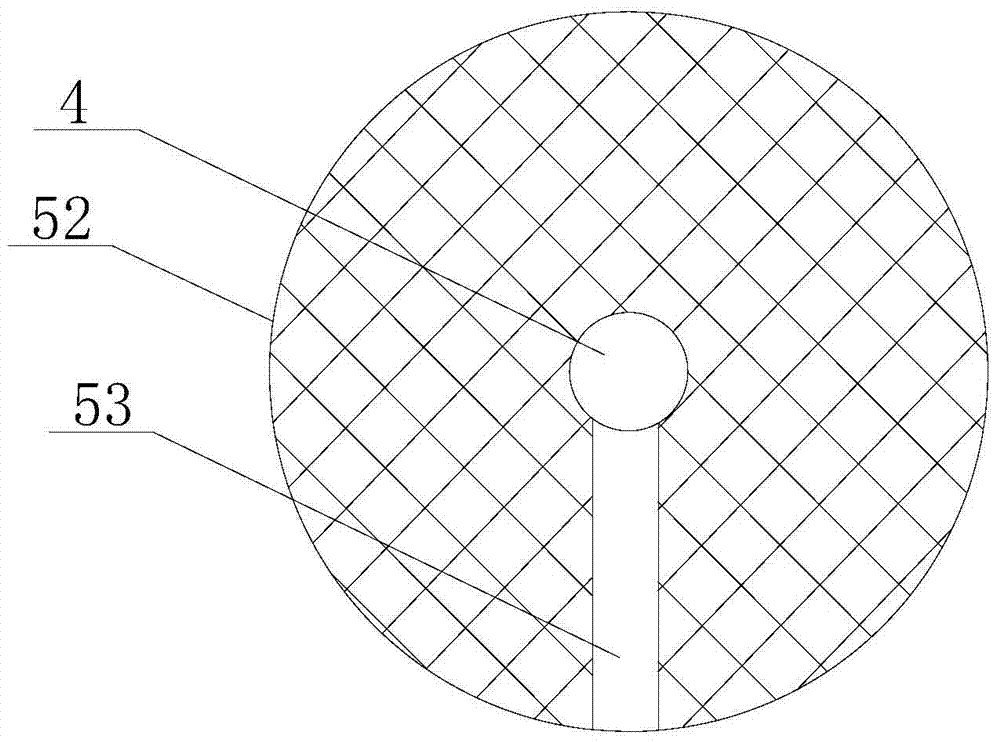

Polishing device for capsules

InactiveCN105170501ATo achieve a polished effectReasonable structureGas current separationCleaning using toolsEngineeringMechanical engineering

The invention discloses a polishing device for capsules. The polishing device comprises a case, a polishing mechanism, a feeding hopper, a rotary shaft, a first dust removal device, a second dust removal device, a control device, a motor, a discharge hopper and a speed measuring device. The control device is electrically connected with the rotary shaft, the motor and the speed measuring device. The speed measuring device comprises a Hall sensor and an alarm. The first dust removal device comprises a first draught fan, a first filter net and a first brush. The second dust removal device comprises a second draught fan, a second filter net and a second brush. The case is provided with a waste storage tank. Compared with the prior art, the polishing device for the capsules is reasonable in structure; the capsules enter the first dust removal device and the second dust removal device under the effects of rotation of the rotary shaft at the 360-degree angle and the brushes, dust can be effectively separated, and the polishing effect on the capsules is achieved; and the polishing device for the capsules is monitored in real time through the speed measuring device, and the alarm starts an alarming system when the speed exceeds the set range.

Owner:SHAOXING ZHONGYA CAPSULE

Device for polishing outer walls of aluminum pipes

ActiveCN111843806ATo achieve a polished effectSave human effortGrinding carriagesPolishing machinesElectric machineDrive shaft

The invention relates to a polishing device, in particular to a device for polishing the outer walls of aluminum pipes. The device for polishing the outer walls of the aluminum pipes aims at achievingthe technical purposes that labor can be saved during operation, and the safety of operators during operation is guaranteed. The device for polishing the outer walls of the aluminum pipes comprises abottom plate, a first roller, a second roller, a motor, a discharge device and a transmission device. One side of the top of the bottom plate is connected with two mounting seats. The first roller isrotationally connected to one mounting seat. The second roller is rotationally connected to the other mounting seat. The motor is mounted on the mounting seat connected with the first roller, and anoutput shaft of the motor is connected with a transmission shaft of the first roller. The discharge device is arranged on the other side of the top of the bottom plate. The transmission device is arranged between the first roller and the second roller. The aluminum pipes are polished through cooperative operation of an arc-shaped grinding plate and the transmission device, and therefore the effectof polishing the aluminum pipes is achieved.

Owner:广东顺德德润隆金属制品有限公司

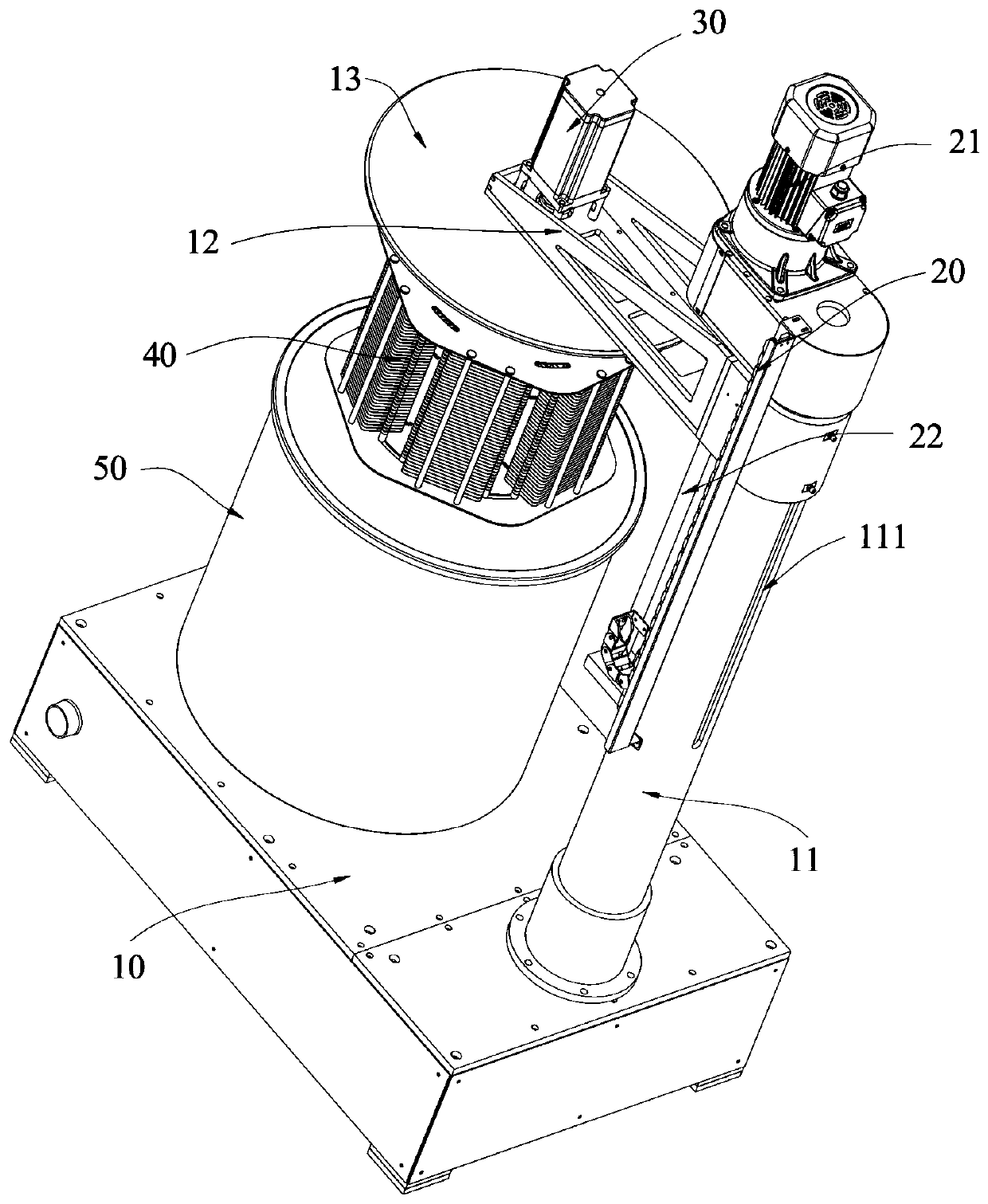

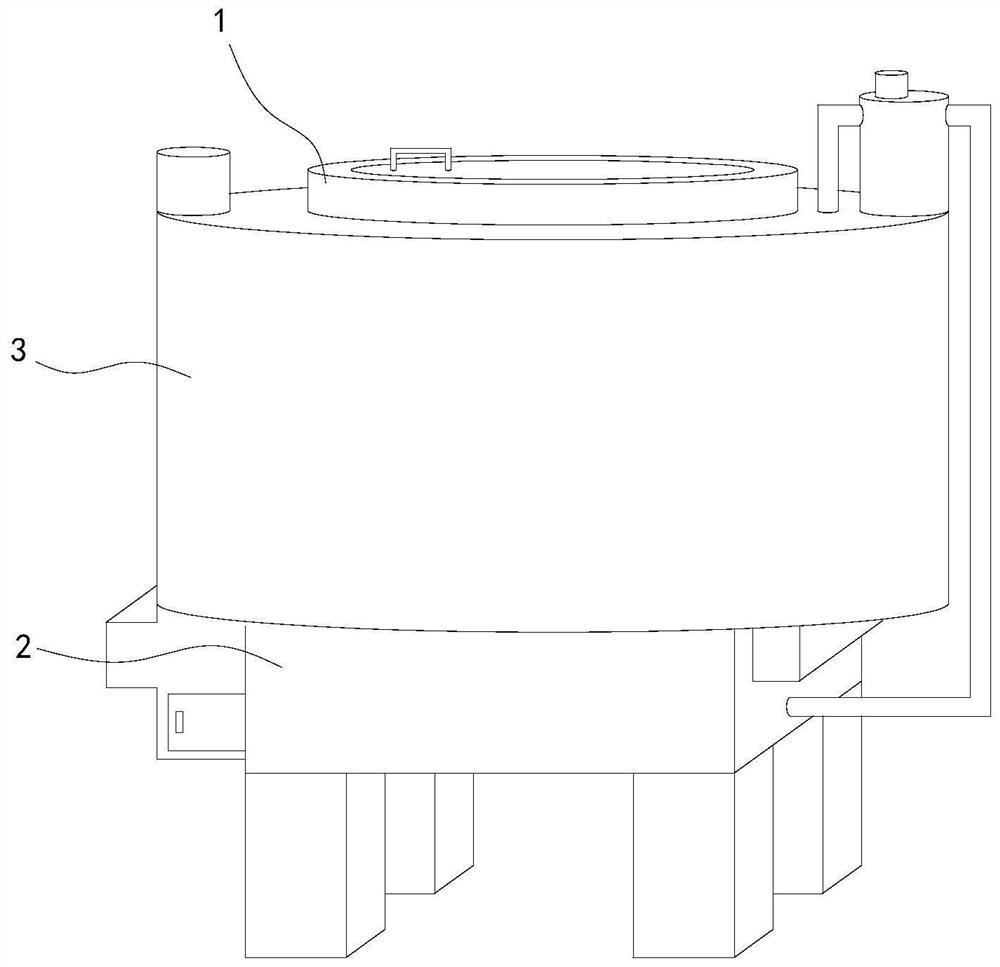

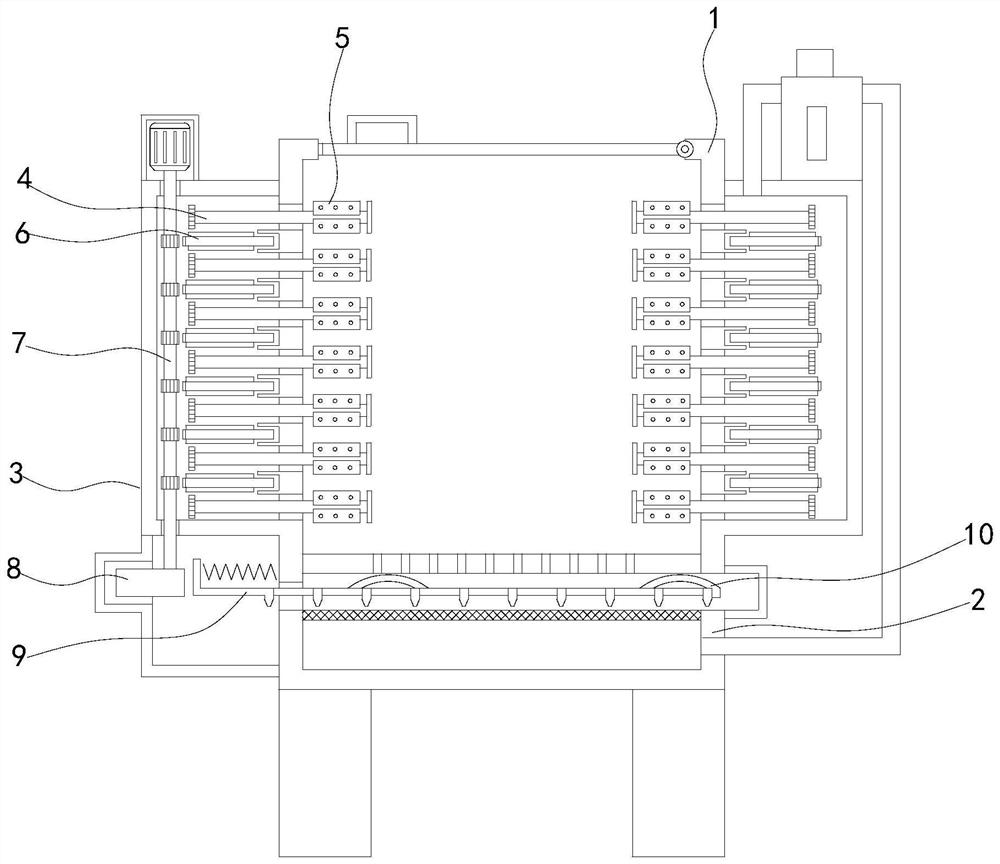

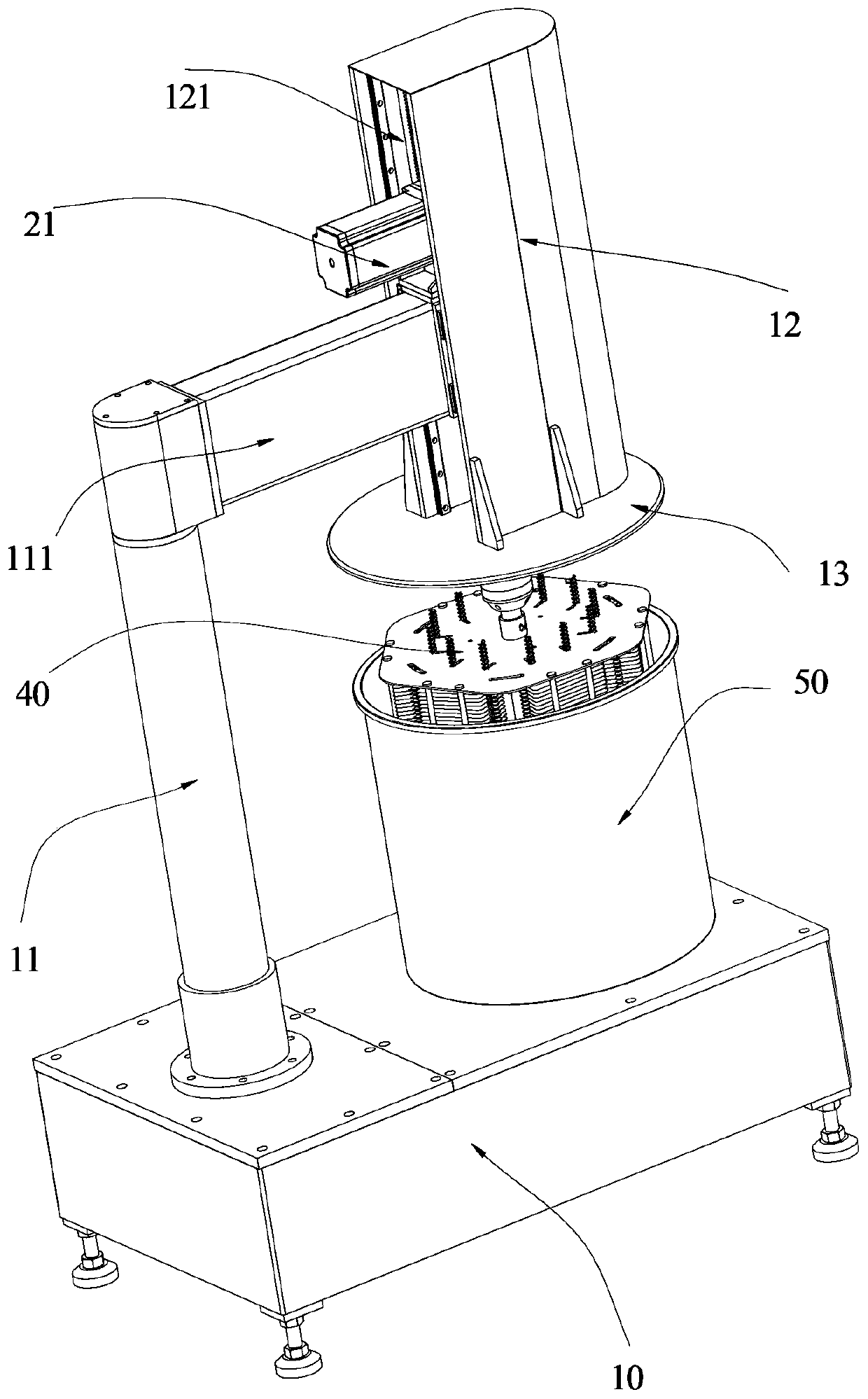

Automatic fluid polishing machine

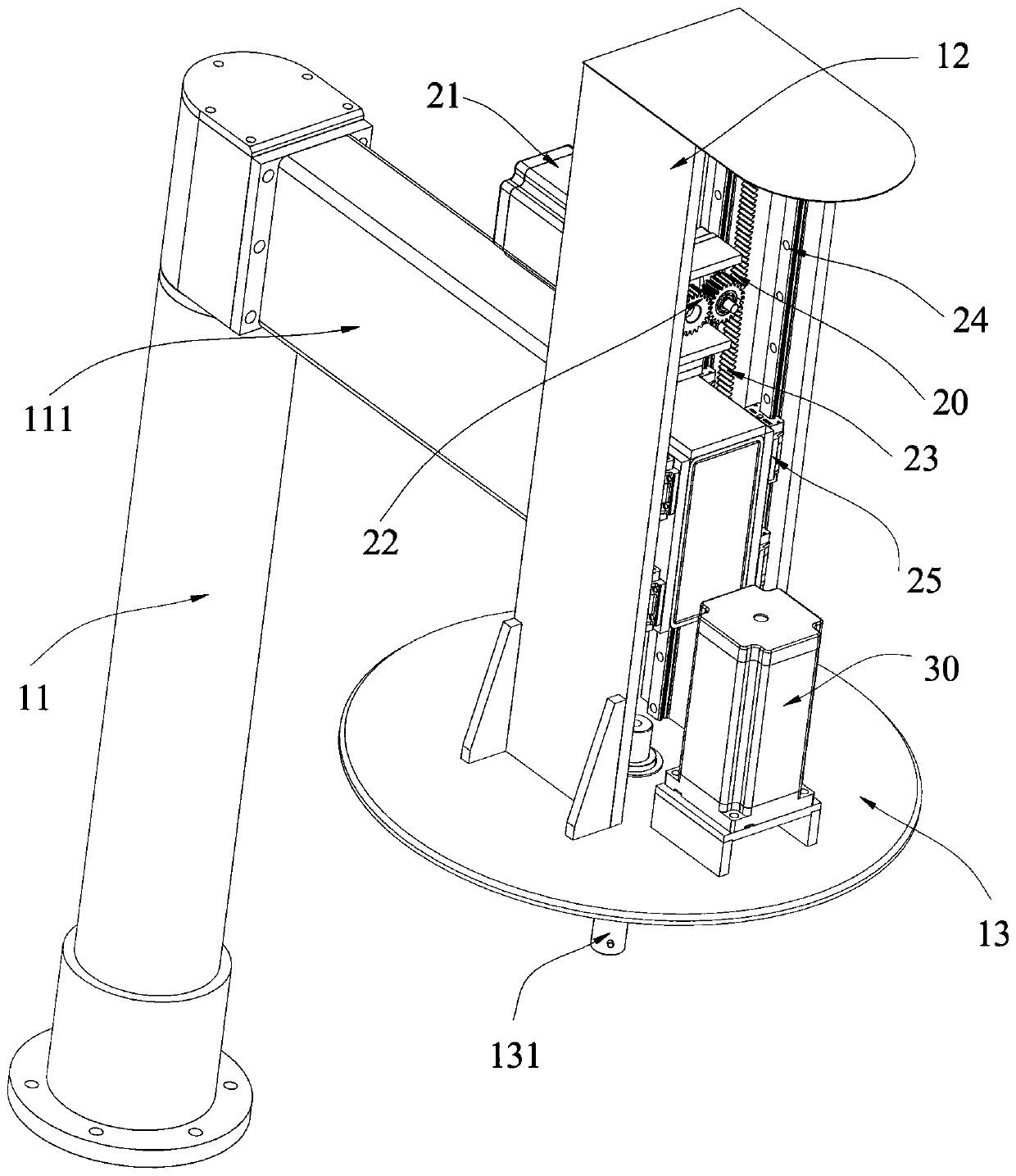

PendingCN110014333ATo achieve a polished effectImprove polishing effectEdge grinding machinesPolishing machinesBody heightEngineering

The invention discloses an automatic fluid polishing machine. The machine comprises a machine body, a workpiece insert frame, a polishing barrel and a third driving mechanism. A mounting column is arranged on the machine body. A mounting support and a first driving mechanism are arranged on the mounting column. The first driving mechanism is used for driving the mounting support to move in the machine body height direction. The mounting support is provided with a second driving mechanism and a connecting shaft. The connecting shaft is in pivot joint with the mounting support and is driven by the second driving mechanism to rotate. The workpiece insert frame is used for allowing a plurality of workpieces to be inserted therein. The workpiece insert frame is fixedly connected with the connecting shaft in a detachable mode. The polishing barrel is used for loading a polishing solution and internally provided with a plurality of ultrasonic generators and a rotating component. The rotatingcomponent is in pivot joint with the bottom end of the polishing barrel through a rotary shaft. The third driving mechanism is mounted on the machine body and used for driving the rotating component to rotate. According to the automatic fluid polishing machine, through cooperation of high-speed rotation of the polishing solution and ultrasonic propagation in the polishing solution, polishing particles in the polishing solution are made to rotate continuously at a high speed and collide with the surface of glass for multiple times in multiple directions, and accordingly, a polishing effect is achieved.

Owner:江西宇瀚智慧装备科技有限公司

Automobile accessory surface strengthening technology

ActiveCN108554755ARestores and improves surface hardnessPrevent oxidationPretreated surfacesSolid state diffusion coatingSurface layerChemical composition

The invention discloses an automobile accessory surface strengthening technology which comprises the following steps: 1) spraying; 2) polishing; 3) gas nitriding; 4) primary coating; 5) spraying glaze; 6) secondary coating. A gas nitriding technology is applied to surface treatment of automobile accessories such as automobile chairs, car bodies and the like which are most made of a material of metal sheets and goes deep into surface layers of the automobile accessories, so that chemical composition and organization of the surface layers are changed, surface hardness of automobile accessories are restored and improved, oxidization and rusting are prevented, the service life is prolonged, a very good application prospect is achieved, and great economical benefits are brought.

Owner:宁波明望汽车饰件有限公司

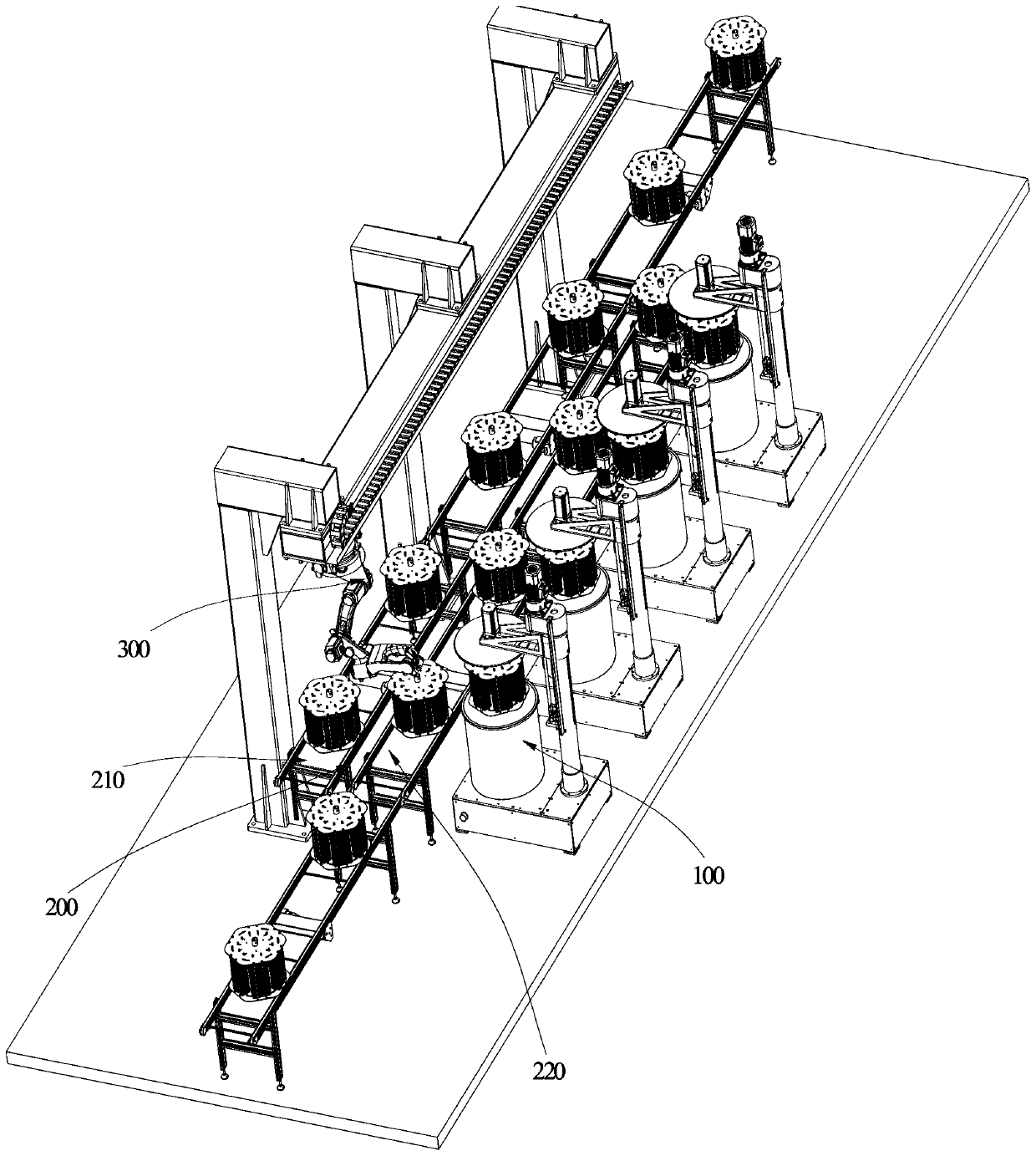

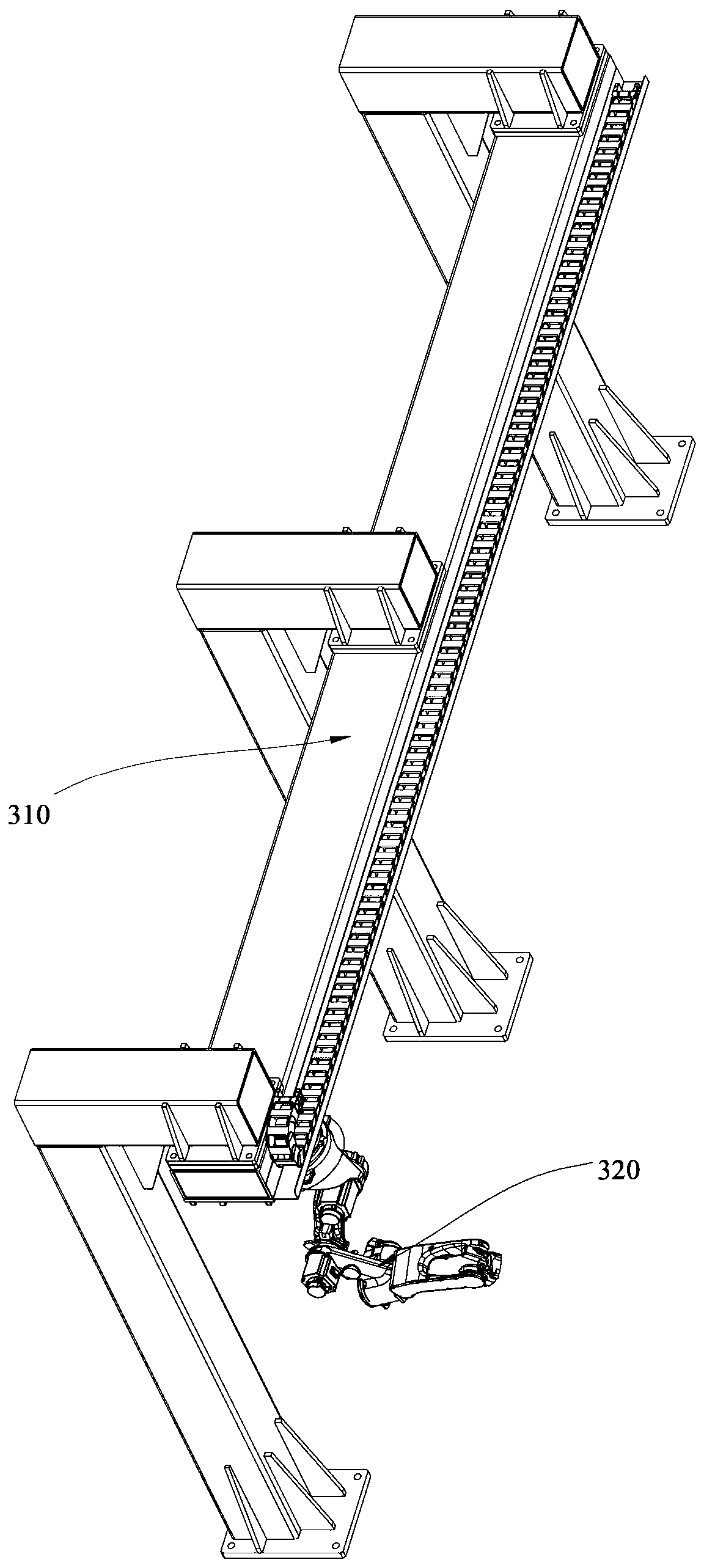

Automatic feeding and discharging fluid polisher automatic line

PendingCN110052901AHigh degree of automationImprove processing efficiencyCharge manipulationGrinding feedersReciprocating motionEngineering

The invention discloses an automatic feeding and discharging fluid polisher automatic line. The automatic feeding and discharging fluid polisher automatic line comprises fluid polishers, a conveying line and a transferring manipulator; each fluid polisher comprises a machine body, a workpiece inserting frame and a polishing barrel, wherein an installation column is disposed on the machine body, aninstallation frame and a first driving mechanism are disposed on the installation column, the first driving mechanism is used for driving the installation frame to move in the height direction of themachine body, a second driving mechanism and a connecting shaft are disposed on the installation frame, the connecting shaft is in pivot joint with the installation frame and is driven by the seconddriving mechanism to rotate, the workpiece inserting frame is used for inserting of a plurality of workpieces, the workpiece inserting frame is fixedly connected with the connecting shaft in a detachable mode, a plurality of ultrasonic generators and a rotary part are disposed in the polishing barrel, the rotary part is in pivot joint with the bottom end of the polishing barrel, and a third driving mechanism is disposed on the machine body; the conveying line is used for conveying the workpiece inserting frames; and the transferring manipulator is used for clamping the workpiece inserting frames to reciprocate between the connecting shafts and the conveying line. By means of the automatic feeding and discharging fluid polisher automatic line, polishing can be performed through a polishingsolution which rotates at high speed, and automatic feeding and discharging are achieved.

Owner:江西宇瀚智慧装备科技有限公司

Current ratio color pool

InactiveCN1746656ACorrosion resistanceWith material compactnessMaterial analysis by optical meansTitanium alloyMaterials science

Owner:张爱荔

Aperture grinding and finishing device for hardware casting machining

PendingCN114346781AReduce workloadTo achieve a polished effectRevolution surface grinding machinesGrinding drivesBristlePolishing

According to the hole diameter grinding and finishing device for hardware casting machining, a second electric push rod is vertically assembled on the right side of the top of a workbench, a supporting seat is fixedly connected to the top of the second electric push rod, a second protective shell is assembled to the top of the supporting seat through bolts, and a servo motor is fixedly connected to the bottom end in the second protective shell; an output shaft of the servo motor penetrates through the left side wall of the second protective shell, and the output end of the servo motor is fixedly connected with a clamp. According to the polishing device, the polishing block is matched with the lantern ring, burrs on the surface of a blank workpiece are removed through friction between the polishing block and the blank workpiece, the polishing effect is achieved, the workpiece can be cleaned through the quick disassembly design of the lantern ring and the polishing block and friction between bristles on the outer side face of the lantern ring and the blank workpiece, and therefore the workload of workers is effectively reduced, and the polishing efficiency is improved. And the whole device is convenient to use.

Owner:徐州全达金属制品有限公司

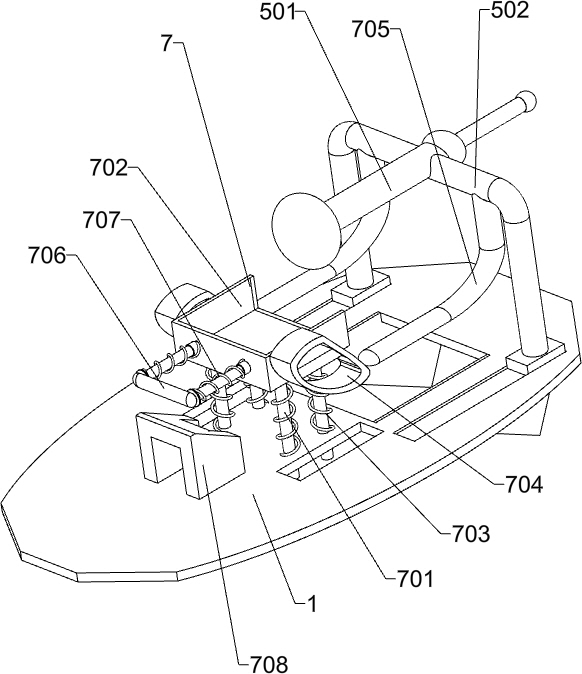

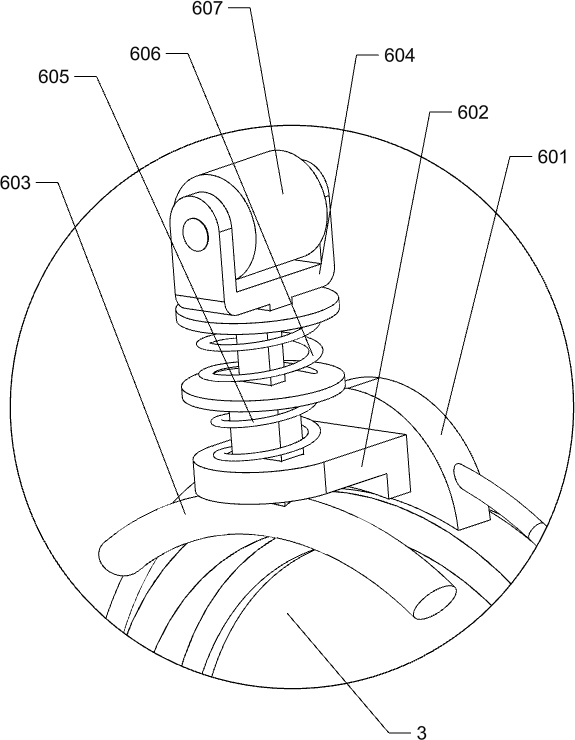

Self-adaptive polishing device for special-shaped surface of iron art

ActiveCN112518532ATo achieve a polished effectGuaranteed polishing efficiencyPolishing machinesGrinding drivesPolishingMaterials science

The invention relates to the field of iron art polishing equipment, and particularly relates to a self-adaptive polishing device for a special-shaped surface of an iron art. The self-adaptive polishing device comprises a device main body, wherein a recycling device is fixedly mounted at the lower end of the device main body; a water adding cavity is fixedly mounted outside the device main body; alaminating device is movably mounted inside the water adding cavity; a resisting plate is movably mounted at the outer side of the laminating device; one end of the laminating device penetrates through the water adding cavity and enters the device main body; a plurality of laminating devices which are arranged in the same way are uniformly mounted inside the water adding cavity at equal distance,so that pressure intensity in the water adding cavity is increased, and water enters the device main body at a relatively high speed, and therefore, the laminating device is driven to move towards theiron art inside the device main body; laminating contact is performed according to the shape of the outer side of the iron art; and a rotary plate is arranged inside the water adding cavity, so thatwhen a drive rotary rod rotates, the rotary plate is driven to rotate together, and the laminating device can be driven to rotate at the outer side of the iron art, and as a result, the effect of polishing the special-shaped surface is achieved.

Owner:浙江江山福鑫工艺品有限公司

Polishing device for indium phosphide substrate

PendingCN112847114AChange selection rangeMeet technical requirementsPolishing machinesGrinding drivesGraphite electrodeMaterials science

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

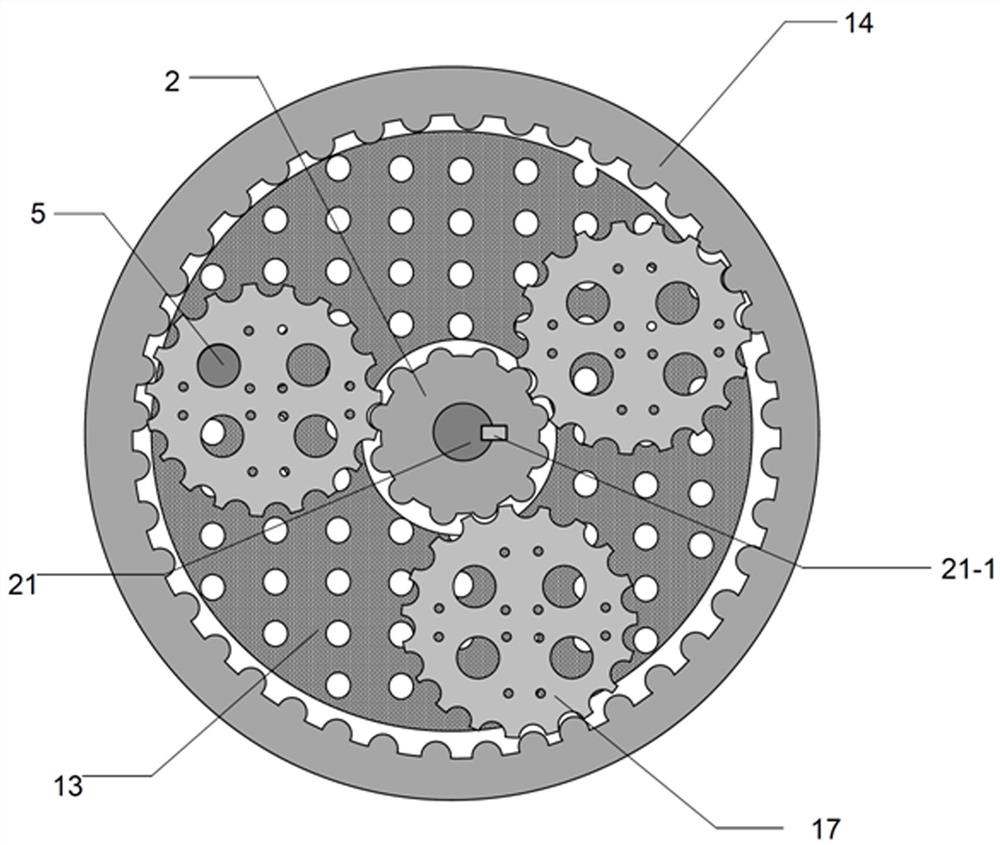

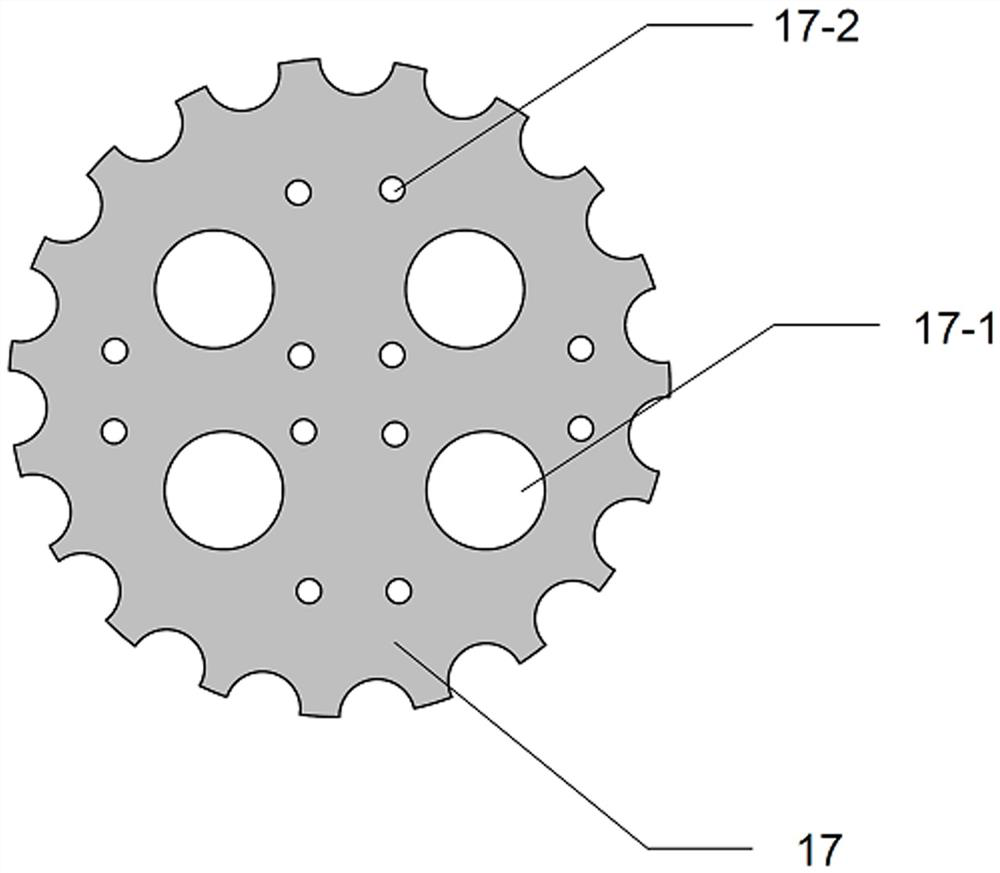

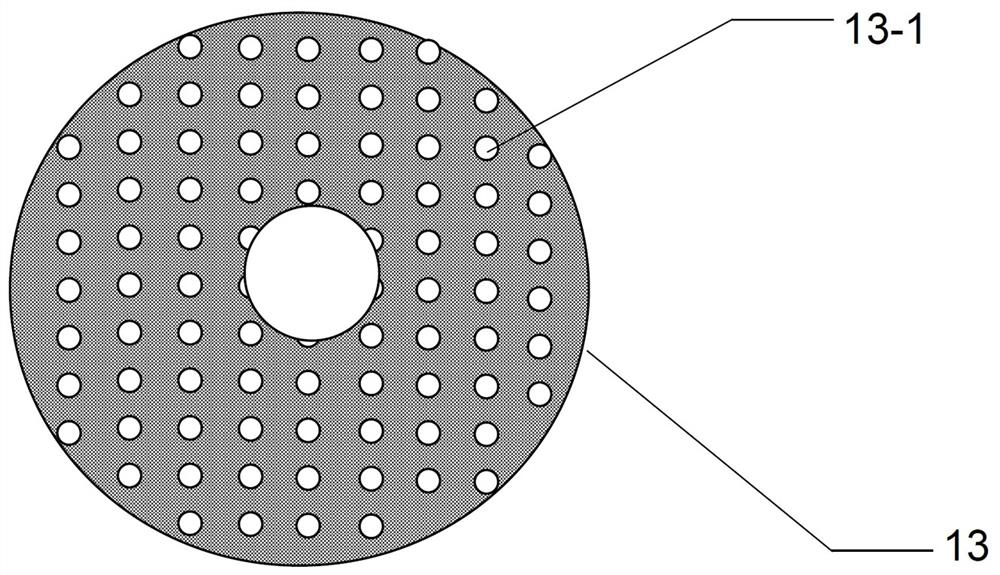

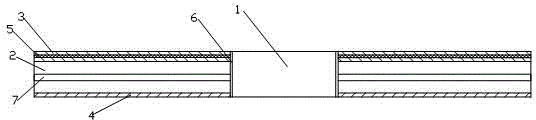

Multifunctional grinding wheel

InactiveCN105014562AAchieve grindingTo achieve a polished effectBonded abrasive wheelsEngineeringGrinding wheel

The invention relates to a multifunctional grinding wheel and belongs to a grinding tool. According to the technical scheme, the multifunctional grinding wheel comprises an annular base body with a central installation hole; the surface of one side of the annular base body is provided with at least two grinding wheel grinding material layers made of grinding materials, and the surface of the other side of the annular base body is provided with a polishing layer; and a transition layer is arranged between every two adjacent grinding material layers. The multifunctional grinding wheel has the beneficial effects of reasonable structure, good use effect and high durability.

Owner:JIANGSU DONGFANG GRINDING WHEEL

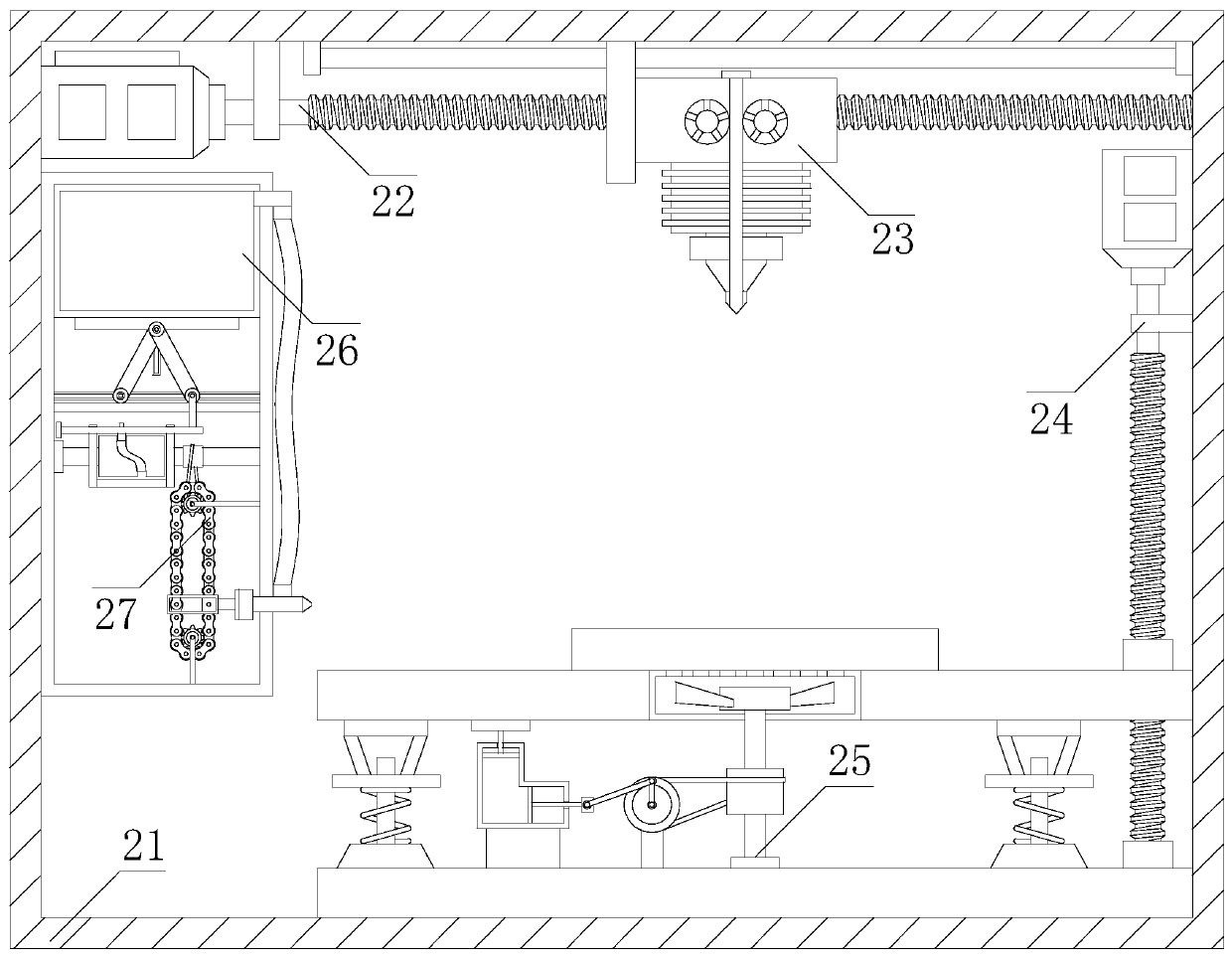

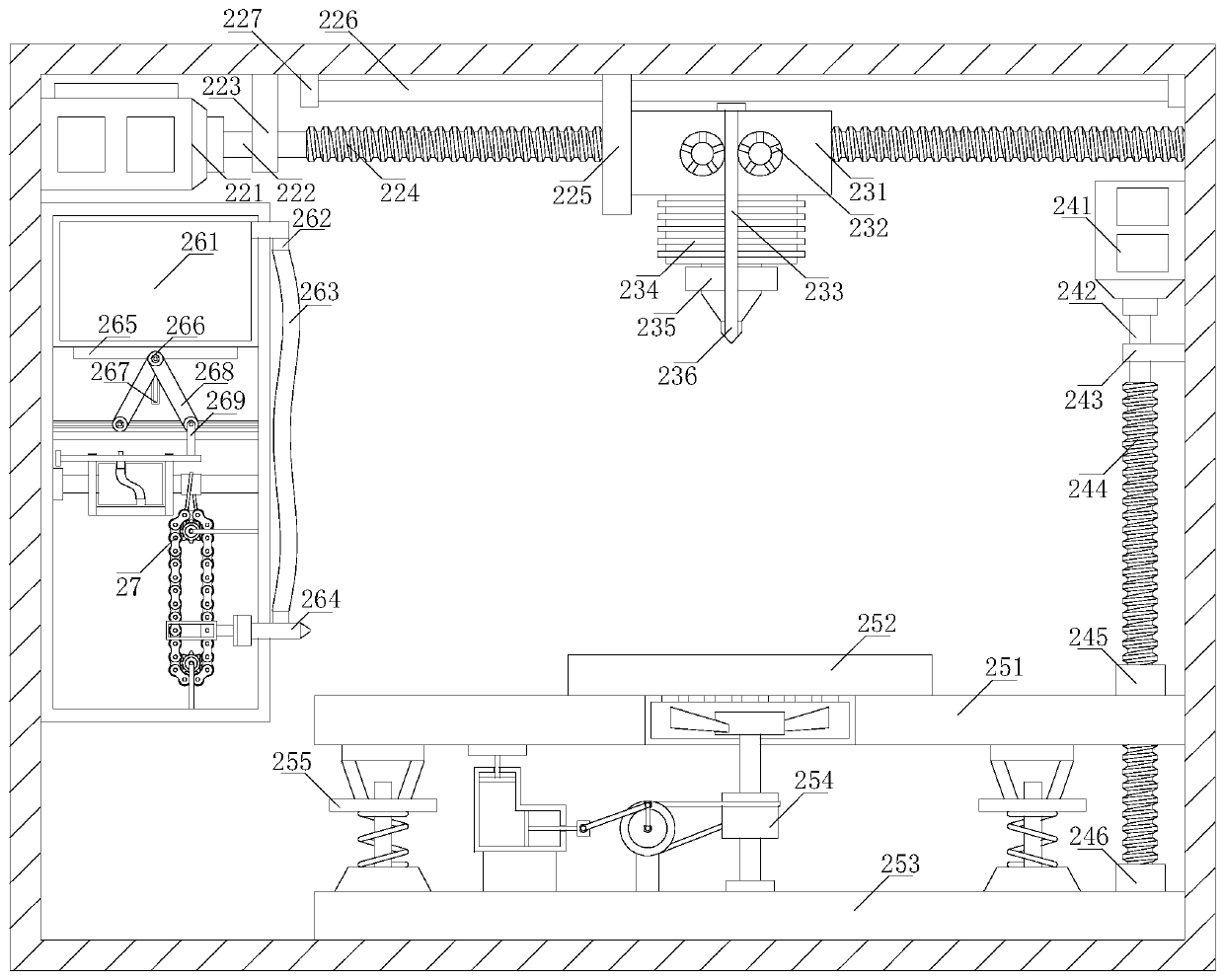

3D printer

ActiveCN110027080AWork lessEnsuring Solid FormationAdditive manufacturing apparatusCeramic shaping apparatusEngineering3d printer

The invention discloses a 3D printer. The 3D printer structurally comprises a fixing screw, a printer main body, a window and four supporting legs; the fixing screw is in threaded connection with theupper end of the printer main body; the window is embedded in the right side surface of the printer main body; the upper ends of the supporting legs are welded to the four corners of the lower surfaceof the printer main body; and the printer main body comprises a main body outer shell, a horizontal driving mechanism, a printing nozzle mechanism, a vertical driving mechanism, a placement mechanism, a sandblasting polishing mechanism and a vertical moving mechanism. A cooling mechanism is made operate to cool a printed solid body through vibration generated by movement of the placement mechanism, solid body molding is ensured, the shape is not damaged by high temperature, the polishing effect is achieved through high-speed jetting of medium beads through the sandblasting polishing mechanism, operation of operators is omitted, in addition, the outer surface of the solid body is more beautiful and smooth, and sandblasting polishing of the solid body is more thorough due to up-down movement of the sandblasting polishing mechanism through the vertical moving mechanism.

Owner:广州市力湃科技应用有限公司

Full-automatic bamboo floor waxing repairing machine

The invention discloses a full-automatic bamboo floor waxing repairing machine. The machine comprises a main body box, a wax melting box and a rotating shaft, wherein a dropping pipe is fixed on the lower end surface of the main body box through a fixing rod, a meshing plate is fixed on one side of the dropping pipe, and the inside of the meshing plate is bonded to a sponge block through an adhesive. The wax melting box is installed in the main body box, and heating pipes symmetrically distributed are installed in the wax melting box provided with a discharging pipe communicated with the dropping pipe. A first motor is mounted on one side of the wax melting box, and an output shaft of the first motor penetrates the main body box to be fixedly provided with fan blades. A motor box is installed on one side of the main body box, a second motor is fixed in the motor box, and an output shaft of the second motor is connected to the rotating shaft. The rotating shaft is mounted on the lower end surface of the motor box. The inside of the rotating shaft is sleeved with a socket shaft. The lower end of the socket shaft is fixedly provided with a meshing disc, and a woolen brush is bonded tothe inside of the meshing disc through the adhesive. The floor waxing repairing machine has the advantages of melting wax, waxing, drying paraffin wax rapidly, reducing time waste and facilitating polishing.

Owner:王盈

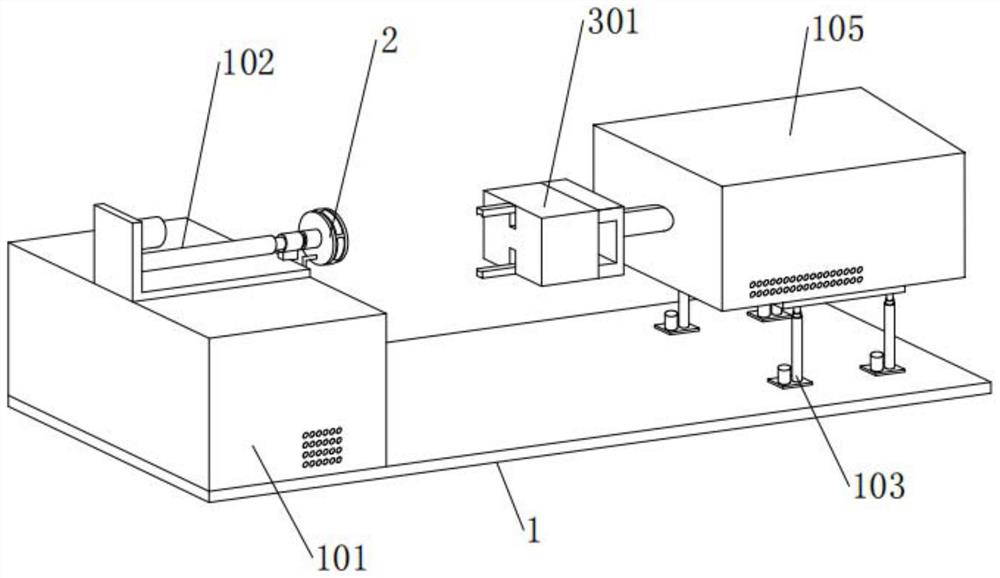

Fluid sweeping and polishing machine

PendingCN110026832ATo achieve a polished effectAvoid interferenceEdge grinding machinesPolishing machinesEngineeringMechanical engineering

The invention discloses a fluid sweeping and polishing machine. A machine body, a workpiece sheet inserting frame, a polishing barrel for loading polishing liquid and a third drive mechanism are included. The rack is provided with an installing column. The installing column is provided with a movable base and a first drive mechanism. The first drive mechanism is used for driving the movable base to move in the height direction of the machine body. An installing cavity is formed in the movable base. A second drive mechanism and a connecting shaft are arranged in the installing cavity. The connecting shaft is in pin joint to the movable base and is driven by the second drive mechanism to rotate. The workpiece sheet inserting frame is used for inserting multiple workpieces and fixedly connected with the connecting shaft in a detachable manner. A plurality of ultrasonic generators and a rotation piece are arranged in the polishing barrel, and the rotation piece is in pin joint to the bottom end of the polishing barrel through a rotation shaft. The third drive mechanism is arranged on the machine body and used for driving the rotation piece to rotate. According to the fluid sweeping andpolishing machine, polishing particles in the polishing liquid run at a high speed and constantly collides with the surface of glass in multiple directions many times, and accordingly the polishing effect is achieved.

Owner:江西宇瀚智慧装备科技有限公司

A capsule polishing device

InactiveCN105170501BTo achieve a polished effectReasonable structureGas current separationCleaning using toolsDust controlElectric machinery

The invention discloses a capsule polishing device, which includes a chassis, a polishing mechanism, a feeding hopper, a rotating shaft, a first dust removal device, a second dust removal device, a control device, a motor, a discharge hopper and a speed measuring device. The control device is electrically connected A rotating shaft, a motor and a speed measuring device. The speed measuring device includes a Hall sensor and an alarm. The first dust removal device includes a first fan, a first filter and a first brush. The second dust removal device includes a second fan. , a second filter screen and a second brush. The chassis is provided with a waste storage tank. Compared with the existing technology, the present invention provides a capsule polishing device with a reasonable structure. The capsule rotates 360° on the rotating shaft and the brush function Down, through the first dust removal device and the second dust removal device, the dust can be effectively separated to achieve the effect of capsule polishing. The speed measuring device monitors the capsule polishing device in real time. When the speed exceeds the set range, the alarm starts the alarm system.

Owner:SHAOXING ZHONGYA CAPSULE

Wing rib stamping micro-contact grinding device in aircraft manufacturing

InactiveCN113547425ATo achieve a polished effectEasy to polishEdge grinding machinesGrinding carriagesStampingElectric machinery

The invention relates to the technical field of aircraft manufacturing and discloses a wing rib stamping micro-contact grinding device in the aircraft manufacturing. The wing rib stamping micro-contact grinding device comprises a fixed shell, a fixed block is fixedly connected to the middle of the inner wall of the fixed shell, a motor is fixedly embedded in the middle of the fixed block, the lower end of an output rod of the motor penetrates through the bottom of the fixed shell to be fixedly connected with a grinding block, a first rotating rod is connected to the inner wall of the bottom of the fixed shell in an inserted manner, the left end of the first rotating rod is connected to the inner wall of the bottom of the fixed block in an inserted manner, in use, first air bags are extruded through extrusion plates, gases in the first air bags are extruded into buffer boxes through first air pipes, the buffer boxes convey the gases into sliding grooves through the sliding grooves, rubber blocks are pushed by the gases to move rightwards, second springs are stretched and deformed, the rubber blocks move towards the outer side of a hollow clamping plate to clamp a wing rib plate, a whole machine body cannot shake left and right relative to the wing rib plate, the stable effect is achieved, and the wing rib plate can be conveniently ground through the grind block.

Owner:何怀彬

An edge throwing device for acrylic board processing

ActiveCN111906978BTo achieve a polished effectSolve technical problemsFlat articlesMetal working apparatusEngineeringPhysics

The invention relates to an edge throwing device, in particular to an edge throwing device for processing acrylic boards. The technical problem of the present invention is how to design an edge polishing device for acrylic plate processing that can automatically adjust the acrylic plate and position the acrylic plate so that the position of the acrylic plate to be polished is aligned with the polishing equipment. An edge throwing device for acrylic board processing, including a support base, the top of which is connected to an organic case, and four slide grooves are evenly spaced along the circumference of the case; a rubber disc is rotatably connected to the top of the case; The component is installed between the chassis and the support base. The invention can clean the burrs on the side of the acrylic plate through the operation of the moving component, thereby achieving the effect of polishing the acrylic plate.

Owner:四川渝拓橡塑工程有限公司

A kind of silicon block polishing device and silicon block polishing method

ActiveCN103722480BReduce invisible cracksTo achieve a polished effectPolishing machinesPlane surface grinding machinesBristleEngineering

The invention discloses a silicon block polishing device which comprises a first polishing unit and a second polishing unit. A grinding part of the first polishing unit is a carborundum grinding stone, and a grinding part of the second polishing unit is a hairbrush. The hairbrush is a combined hairbrush and comprises a first hairbrush body and a second hairbrush body, the first hairbrush body is located inside the hairbrush, the second hairbrush body is located on the outer side of the first hairbrush body, and the number and the lengths of brush bristles of the second hairbrush body are both larger than the number and the lengths of brush bristles of the first hairbrush body. According to the silicon block polishing device, a silicon block is polished in two working procedures through the carborundum grinding stone and the hairbrush in sequence, the silicon block polishing effect can be remarkably improved, and therefore the silicon block cutting quality is guaranteed. The invention further discloses a method for polishing the silicon block through the silicon block polishing device.

Owner:TIANJIN YINGLI NEW ENERGY RESOURCES

Preparation method of liquid metal polishing agent

The invention relates to the technical field of polishing agent preparation, in particular to a method for preparing a liquid metal polishing agent. After the liquid polishing agent prepared by the present invention is used, the concentrated solution rich in nitrogen, phosphorus and sulfur will produce a layer of chemical extreme pressure film on the surface of the metal substrate to prevent the mutual abrasion between the metal substrates to produce large polishing scratches, while the fatty alcohol The compound can stabilize the foam, increase the consistency of the liquid polishing agent, and produce a viscous effect on the metal surface. The viscous liquid and the nitrogen, phosphorus, and sulfur extreme pressure film together provide a protective film for the metal surface to buffer the polishing process. Mutual friction produces large wear marks, and the protective film produced by viscous action is not static, but the dynamic balance in motion, the sliding friction produced by the sliding between the viscous liquid and the surface of the metal substrate, this friction is more uniform , more detailed, so it can achieve lower roughness, and has broad application prospects.

Owner:常州市宇科不绣钢有限公司

Polishing machine device

ActiveCN104589219AImprove wear resistanceExtended service lifeBlast gunsAbrasive blasting machinesEngineeringHigh pressure

The invention relates to the field of mechanical polishing equipment and particularly relates to a polishing machine device. The following scheme is adopted: the polishing machine device comprises a rack with an inner cavity, wherein the inner cavity is internally provided with a separation plate for separating the inner cavity into a mixed distribution cavity and a polishing cavity which is located under the mixed distribution cavity; the polishing machine further comprises a polishing material distributor which is located in the mixed distribution cavity and is used for uniformly mixing polishing liquid and polishing materials, and a plurality of mixed spraying guns which are arranged on the separation plate and / or in the polishing cavity, are connected with the polishing material distributor and have adjustable angles. The invention aims at providing the polishing machine device; and a part to be polished is put on a pushing-out device, and the polishing materials can be automatically distributed and mixed and are sprayed on the part to be polished under the action of the high-pressure polishing liquid, so that a polishing process is finished and the spraying angles are adjustable.

Owner:佛山市顺德区罗氏五金制品实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com