Fluid sweeping and polishing machine

A sweeping machine and fluid technology, applied in surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc., can solve the complex structure of the machine, cumbersome operation process, and debris on the surface of the glass screen Many problems, to prevent external environmental interference, improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

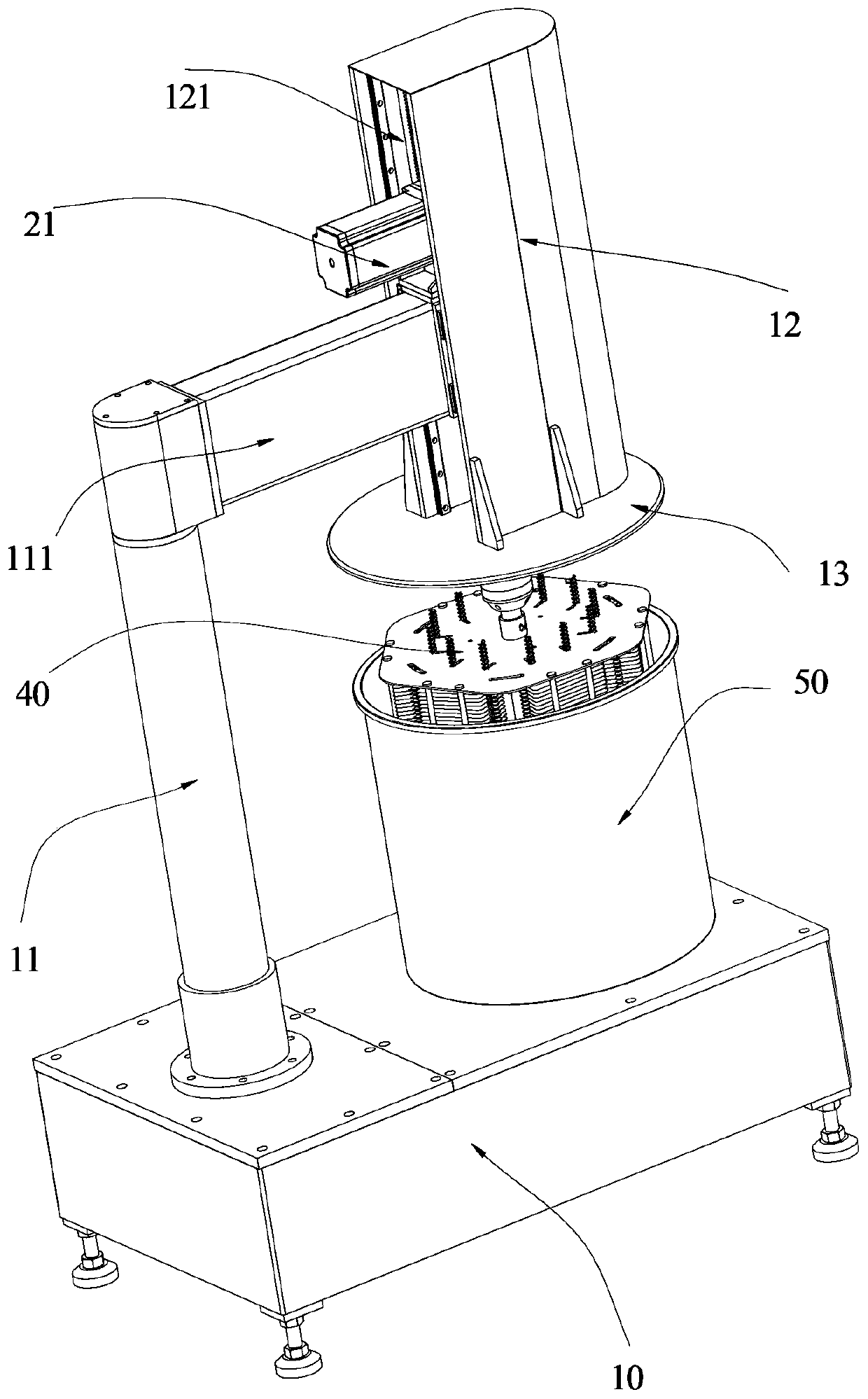

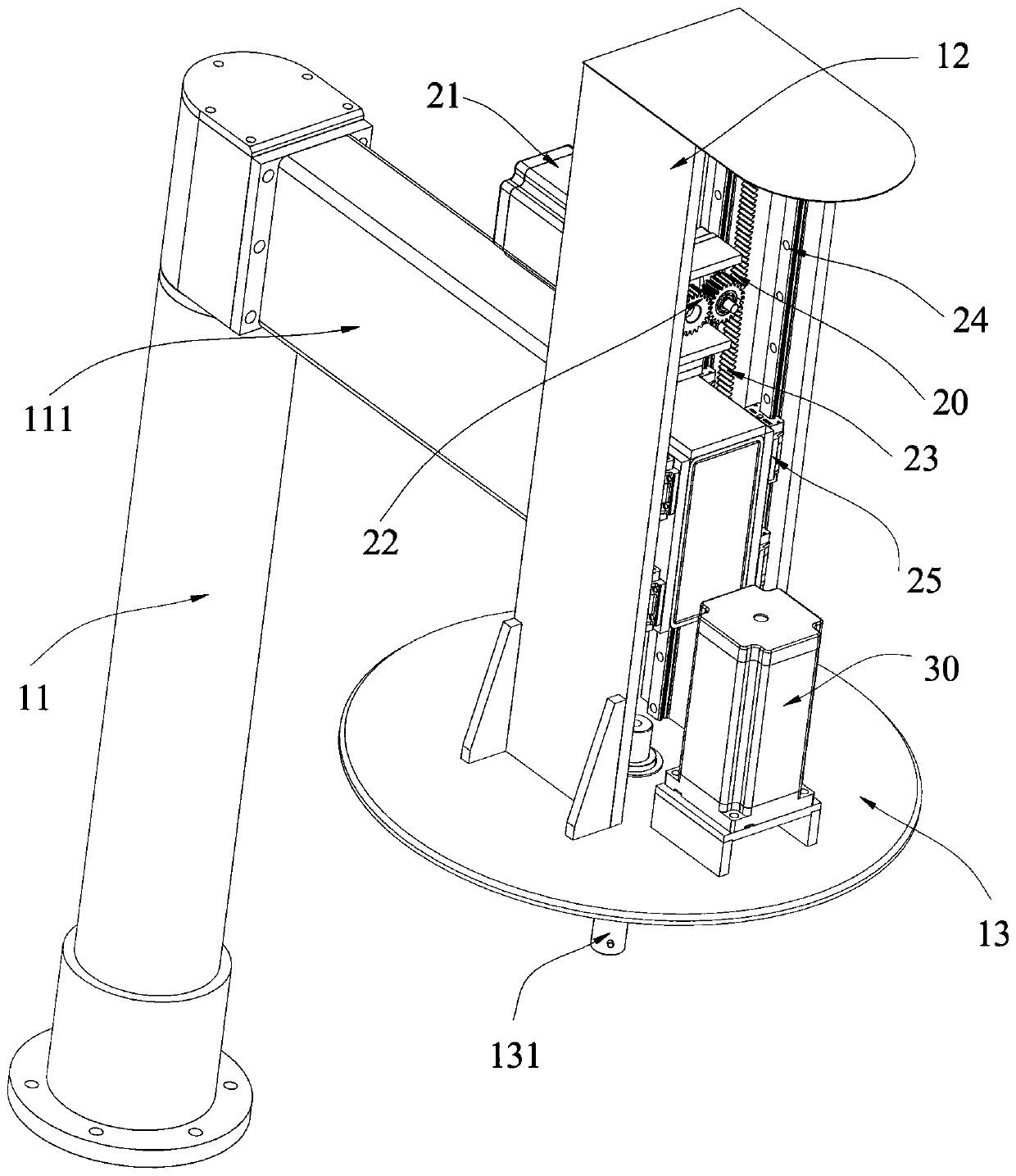

[0030] Such as Figure 1-6 A kind of fluid sweeping machine shown, comprises body 10, workpiece insert frame 40, polishing tube 50 and the 3rd driving mechanism, is provided with mounting column 11 on body 10, is provided with movable seat 12 and on this mounting column 11 The first driving mechanism 20 , the movable base 12 can move along the height direction of the mounting column 11 driven by the first driving mechanism 20 . In addition, the inside of the movable seat 12 is formed as an installation cavity 121, and a second driving mechanism and a connecting shaft 131 are arranged in the installing cavity 121; the connecting shaft 131 is pivotally connected to the movable seat 12, and is connected under the drive of the second driving mechanism. Shaft 131 rotates.

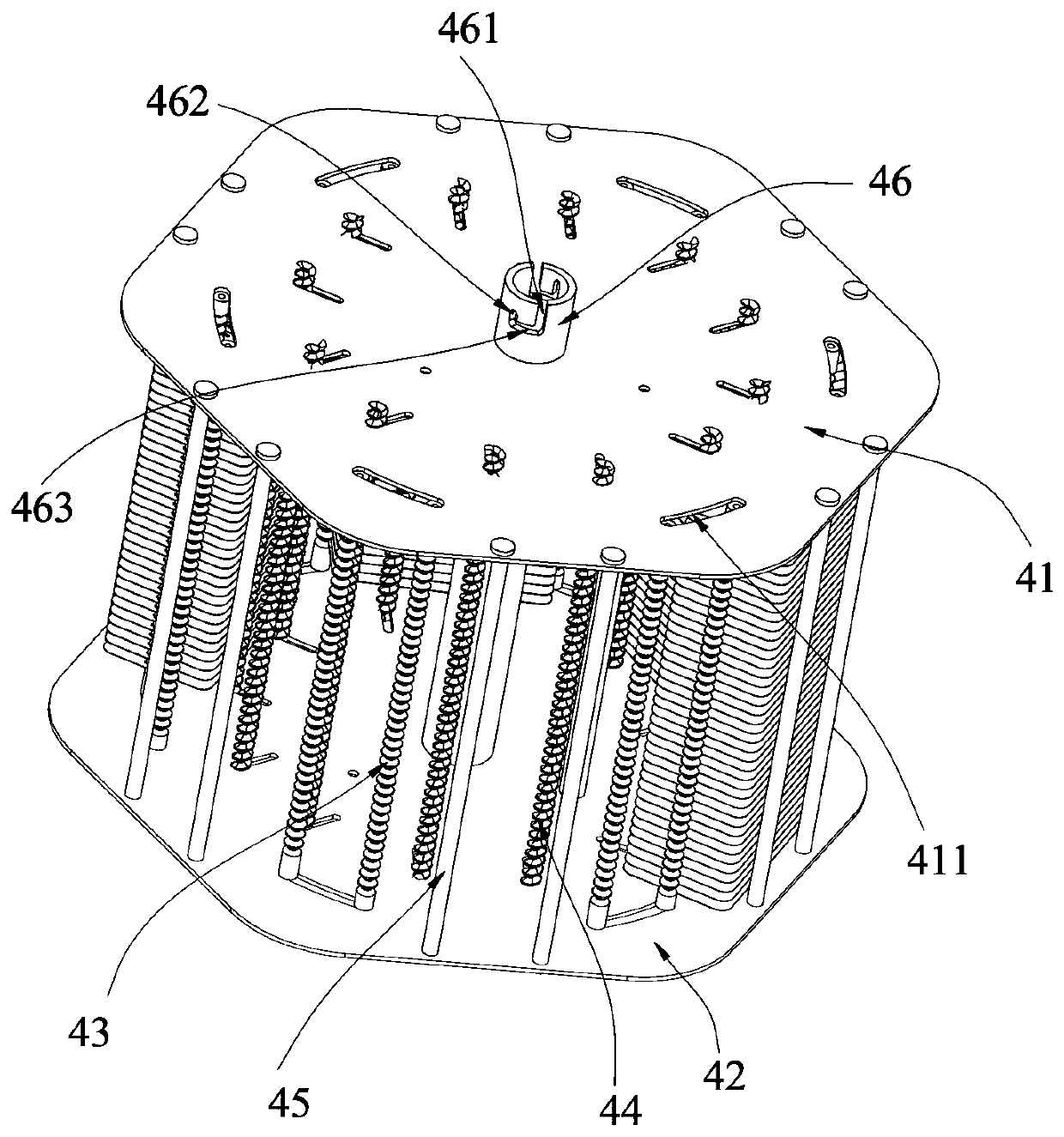

[0031] Specifically, the above-mentioned workpiece inserting frame 40 can be insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com