An edge throwing device for acrylic board processing

A technology of support seat and guide rail, used in metal processing, applications, household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

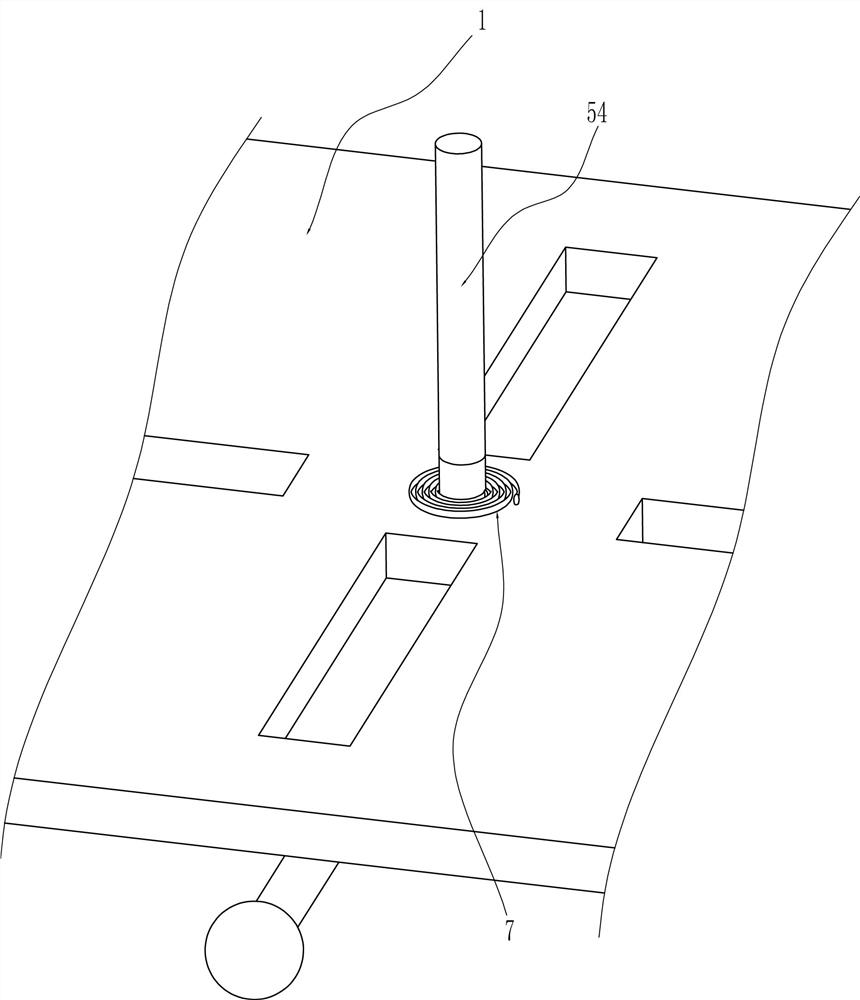

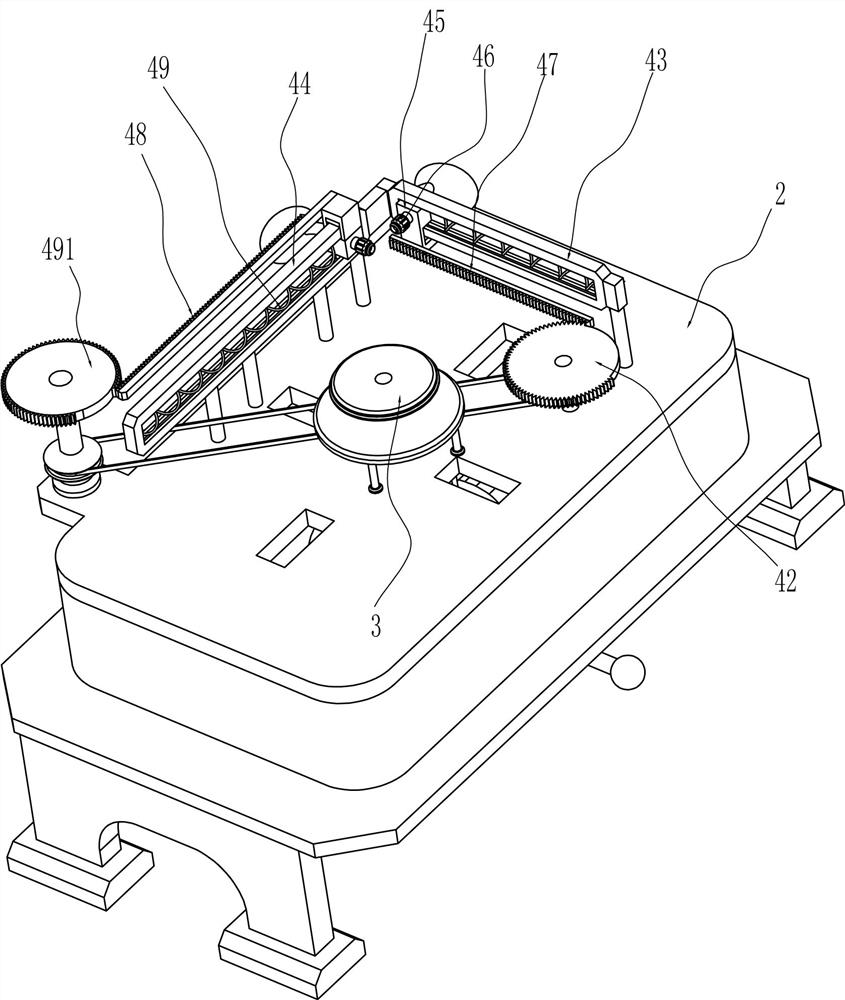

[0025] An edge throwing device for acrylic plate processing, such as Figure 1-7 As shown, it includes a support base 1 and a chassis 2. The top of the support base 1 is connected to the chassis 2, and also includes a rubber disc 3, a moving component 4 and a positioning component 5. The top of the chassis 2 is connected to the rubber disc 3 in a rotatable manner. There are four slide slots 31 evenly spaced along the circumference, a moving assembly 4 is provided between the chassis 2 and the support base 1 , and a positioning assembly 5 is provided between the slide slots 31 and the support base 1 .

[0026] The moving assembly 4 includes a drive motor 41, a first tooth-missing gear 42, a first guide rail 43, a second guide rail 44, a first slider 45, a spray gun 46, a first rack 47, a second rack 48, and a return spring 49 and the second tooth-missing gear 491, a drive motor 41 is installed on the top of the support base 1, the output shaft of the drive motor 41 passes throu...

Embodiment 2

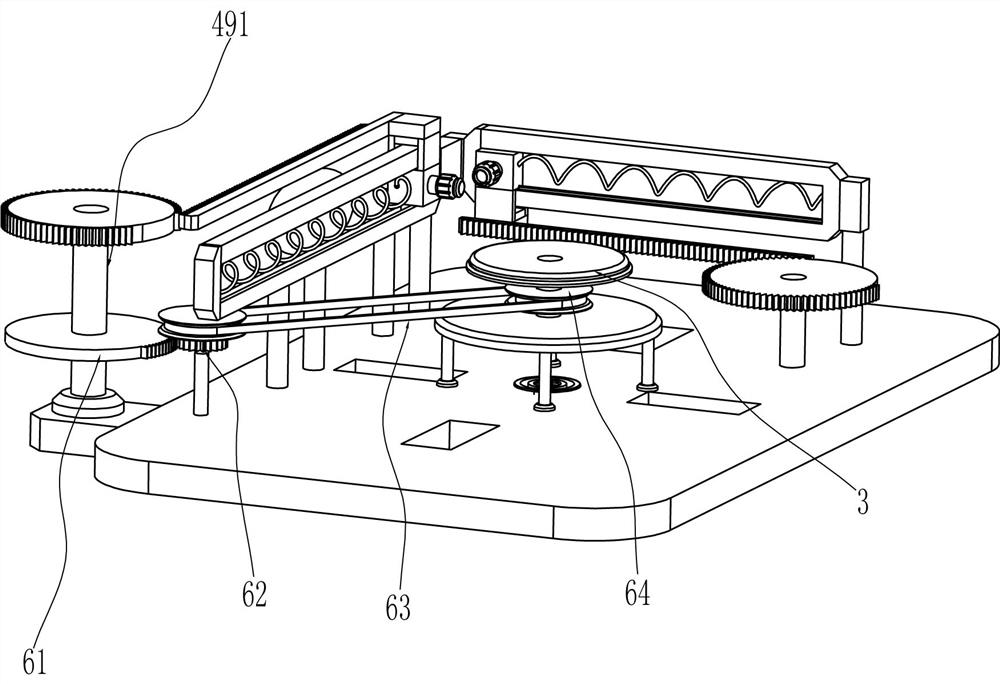

[0030] On the basis of Example 1, such as Figure 8 As shown, a rotating assembly 6 is also included, and the rotating assembly 6 includes a sector gear 61, a transmission gear 62, a flat belt 63 and a pulley 64, the sector gear 61 is connected to the second missing tooth gear 491, and the top of the support base 1 is connected in a rotational manner There is a transmission gear 62 meshing with the sector gear 61 , a pulley 64 is connected to the transmission gear 62 and the rubber disc 3 , and a flat belt 63 is wound between the two pulleys 64 .

[0031] When the second missing tooth gear 491 rotates, it drives the sector gear 61 to rotate together. When the second tooth missing gear 491 disengages from the second rack 48, the sector gear 61 meshes with the transmission gear 62. At this time, the sector gear 61 continues to rotate to drive The transmission gear 62 rotates, and the transmission gear 62 rotates through the pulley 64 and the flat belt 63 to drive the rubber disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com