Polishing machine device

A polishing machine and polishing liquid technology, which is applied in the direction of explosion generating devices, grinding/polishing equipment, abrasive jet machine tools, etc., can solve the problem of limited polishing position, achieve the effect of increasing wear resistance and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

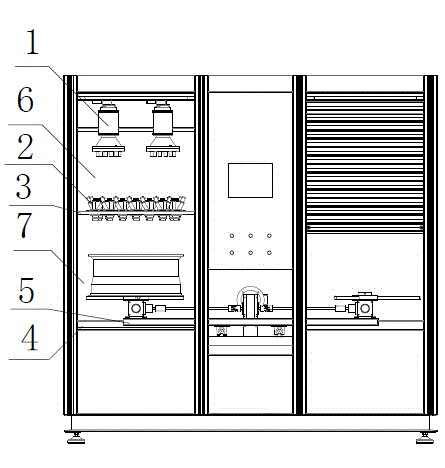

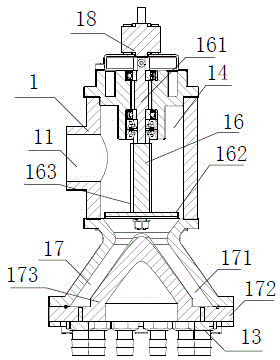

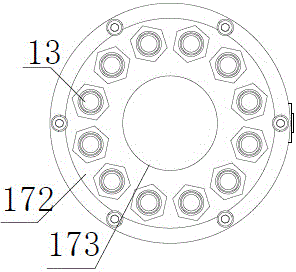

[0037] Example 1, such as figure 1 — Figure 5 Shown: a polishing machine device, comprising a frame 4 with an inner cavity, the inner cavity is provided with a mixing and distributing chamber 6 and a polishing chamber 7 below the mixing and distributing chamber 6 Dividing plate 3, this kind of polishing machine also comprises and is positioned at described mixing distributing chamber 6 and is used for the polishing material distributor 1 that is used to mix polishing liquid polishing material uniformly, a plurality of being located on described dividing plate 3 and / or all The polishing chamber 7 is connected with the polishing compound distributor 1 and has an adjustable angle mixing spray gun 2 and a conveying device 5 for placing the object to be polished and sending the object to be polished into or out of the polishing position. Described polishing material distributor 1 comprises the inlet port 11 of input polishing material and a plurality of discharge ports 13 for out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com