Cambered surface polishing device for ceramic processing

A polishing device and ceramic processing technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of manual repeated friction, low work efficiency, cumbersome operation process, etc., to improve work efficiency, save manpower, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

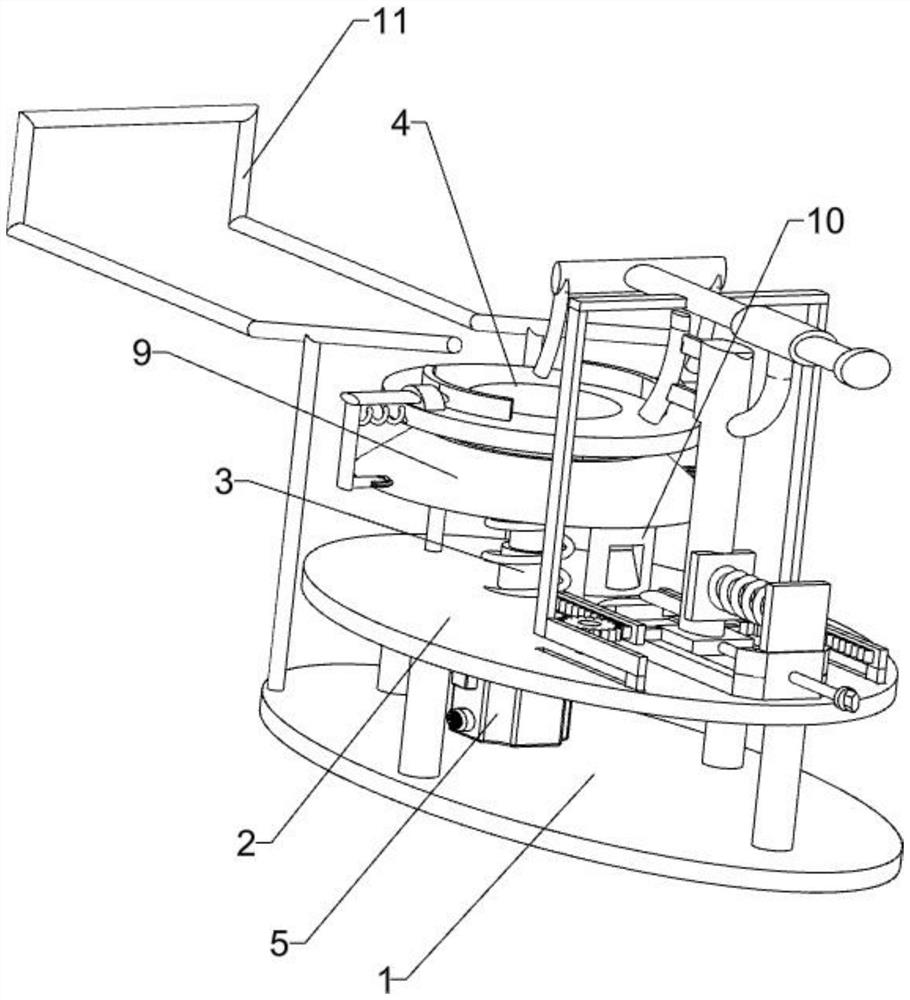

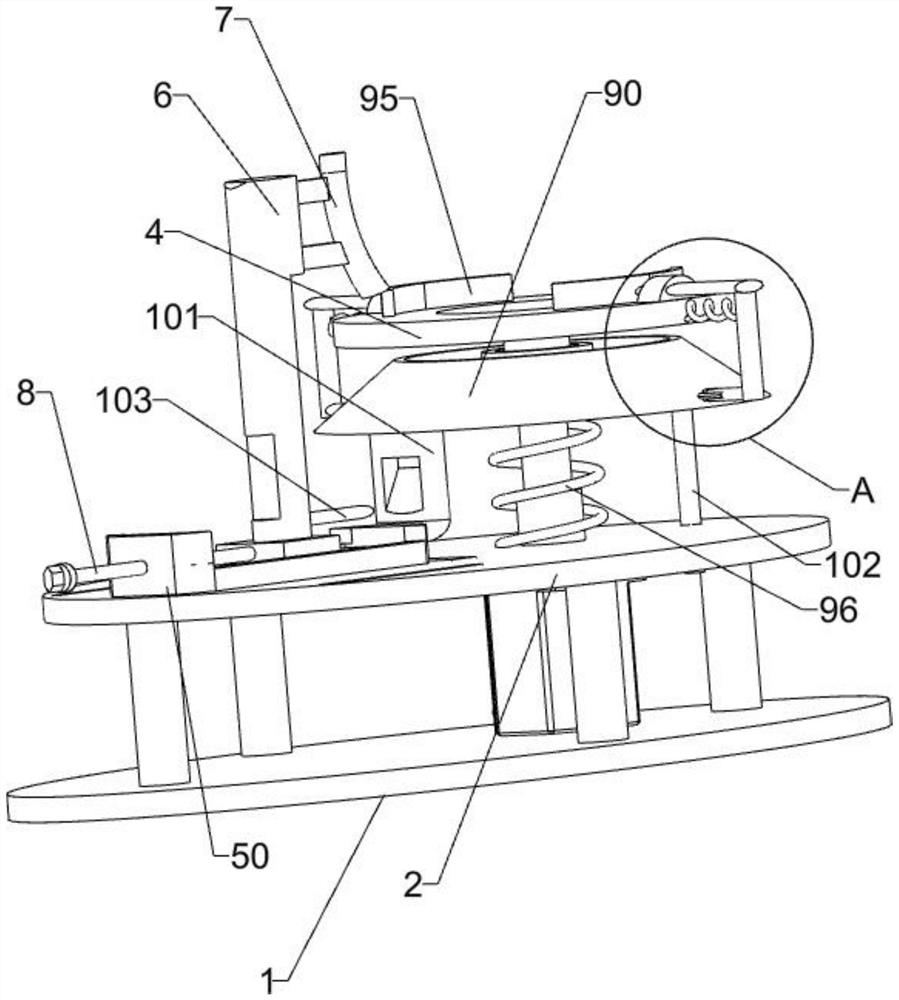

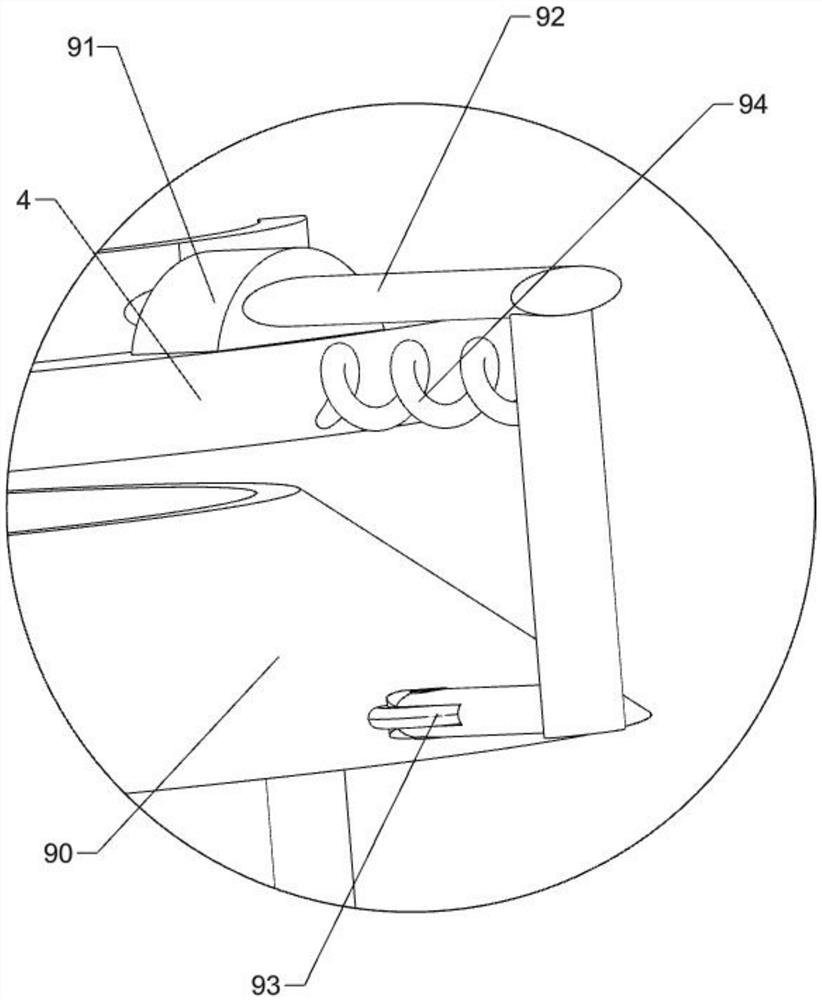

[0022] A kind of curved surface polishing device for ceramic processing, such as Figure 1-3 As shown, it includes a bottom plate 1, a mounting plate 2, a spindle 3, a disc 4, a motor 5, a sliding seat 50, a sliding rod 6, an arc scraper 7, and a pull rod 8. The top of the bottom plate 1 is connected with a mounting plate 2, and the mounting plate 2 The rear side is rotatably connected to the main shaft 3, the top of the main shaft 3 is connected to the disc 4, the motor 5 is installed on the top of the bottom plate 1, the output shaft of the motor 5 is connected to the main shaft 3, and the front side of the top of the bottom plate 1 is connected to a sliding seat 50, and the sliding seat 50 The top is slidingly connected with a slide bar 6, and the rear side of the slide bar 6 is connected with an arc-shaped scraper 7, and the slide bar 6 is connected with a pull rod 8, which slides and cooperates with the slide seat 50, and also includes a clamping mechanism 9 and a transmis...

Embodiment 2

[0027] On the basis of Example 1, such as Figure 4 As shown, it also includes a blanking mechanism 11. The blanking mechanism 11 includes a sleeve 111, a pulling rod 112, a transmission rack 113, a gear 114, an L-shaped rack 115 and a placement frame 116, and the upper part of the slide bar 6 is connected with a sleeve. The sleeve 111 is slidably connected with a puller 112 in the sleeve 111, the left and right sides of the slide bar 6 are connected with a transmission rack 113, and the left and right sides of the top of the mounting plate 2 are rotatably connected with a gear 114, and the gears 114 on both sides are connected to the two sides respectively. The side transmission rack 113 is meshed, and the left and right sides of the pulling rod 112 are connected with an L-shaped rack 115, and the L-shaped racks 115 on both sides are respectively meshed with the gears 114 on both sides, and the rear side of the top of the base plate 1 is connected with a placement frame 116. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com