Automatic feeding and discharging fluid polisher automatic line

An automatic loading and unloading and sweeping machine technology, which is applied in the direction of conveyor objects, grinding feed movement, grinding machine parts, etc., can solve the complicated operation process, complex overall structure of the machine, and many debris on the surface of the glass screen, etc. problem, to achieve the effect of improving processing efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

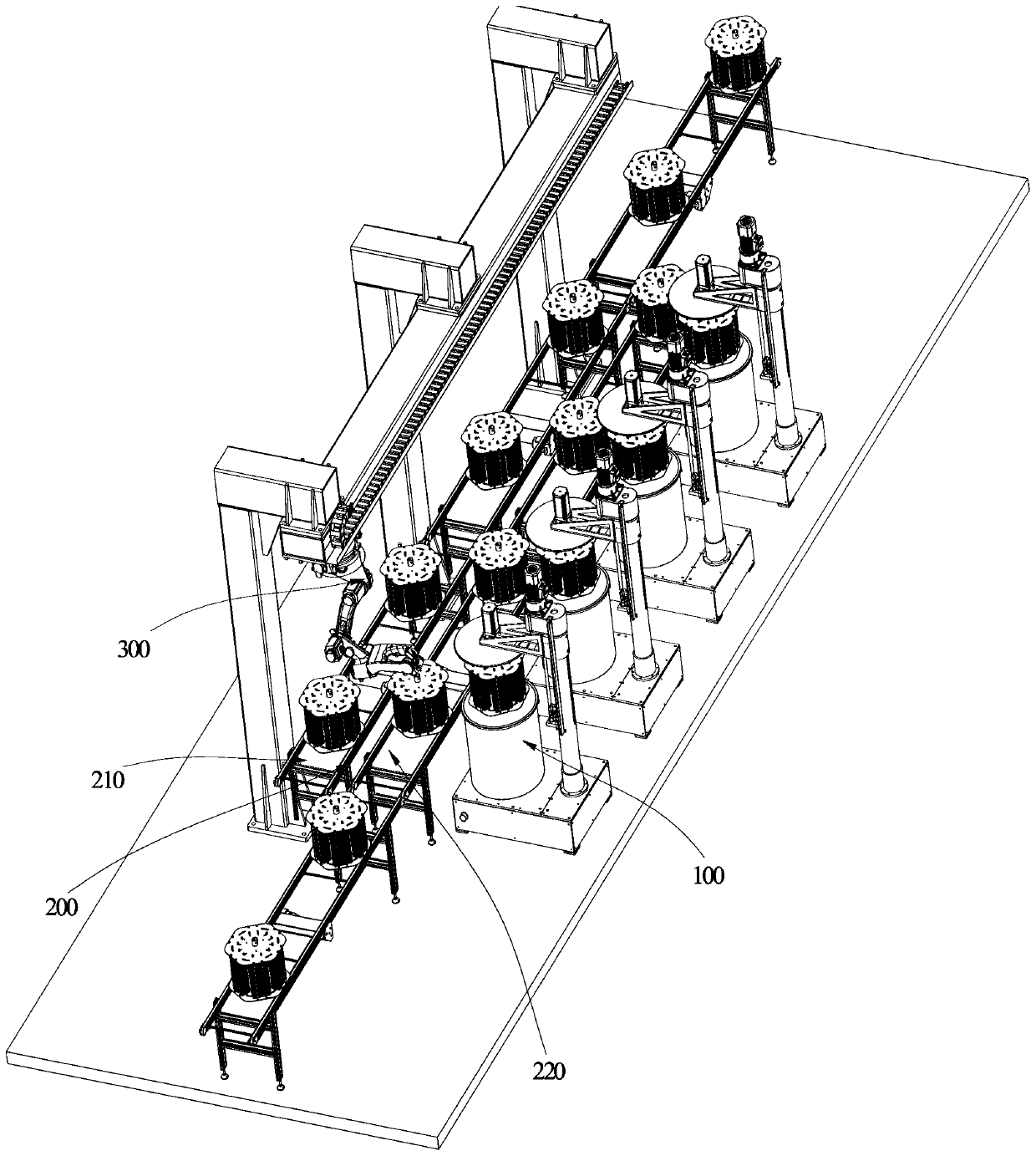

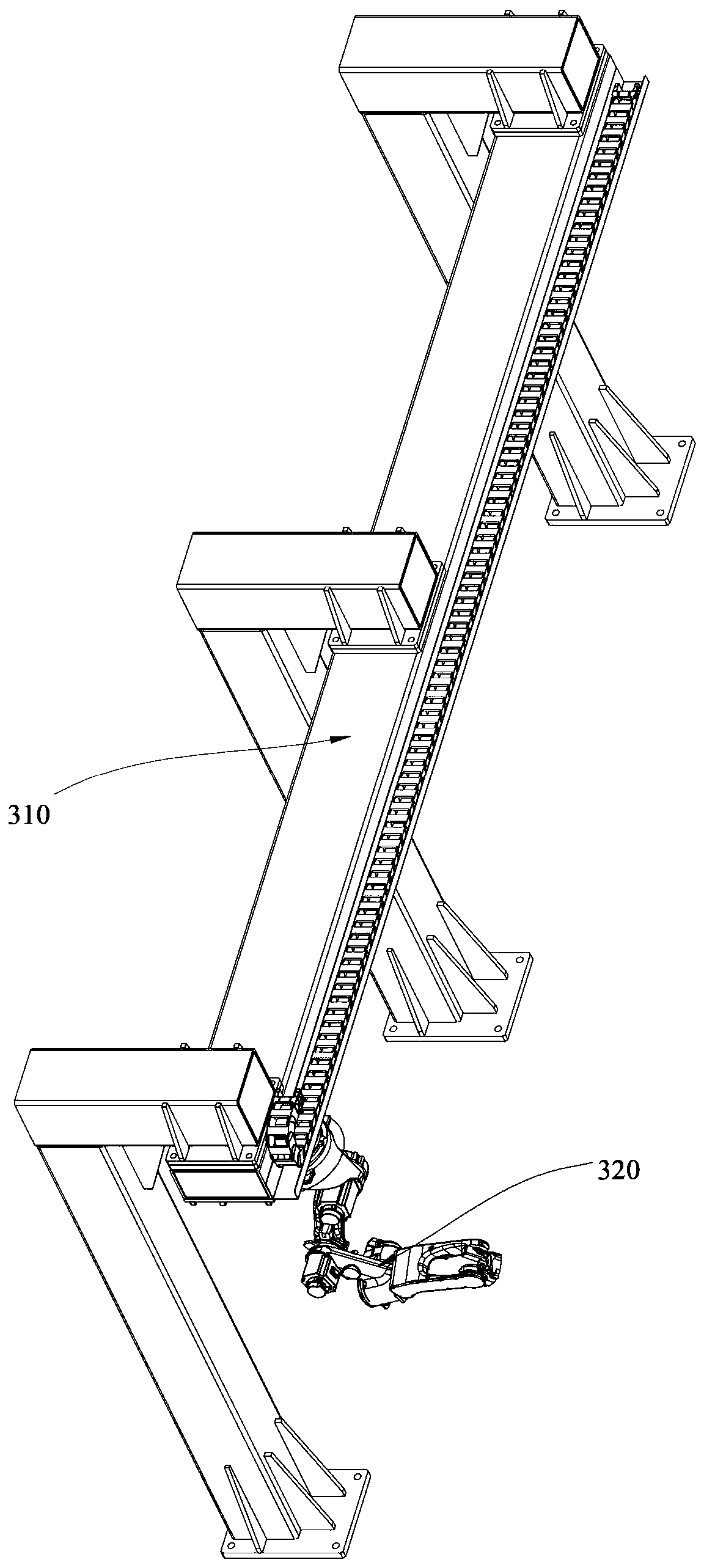

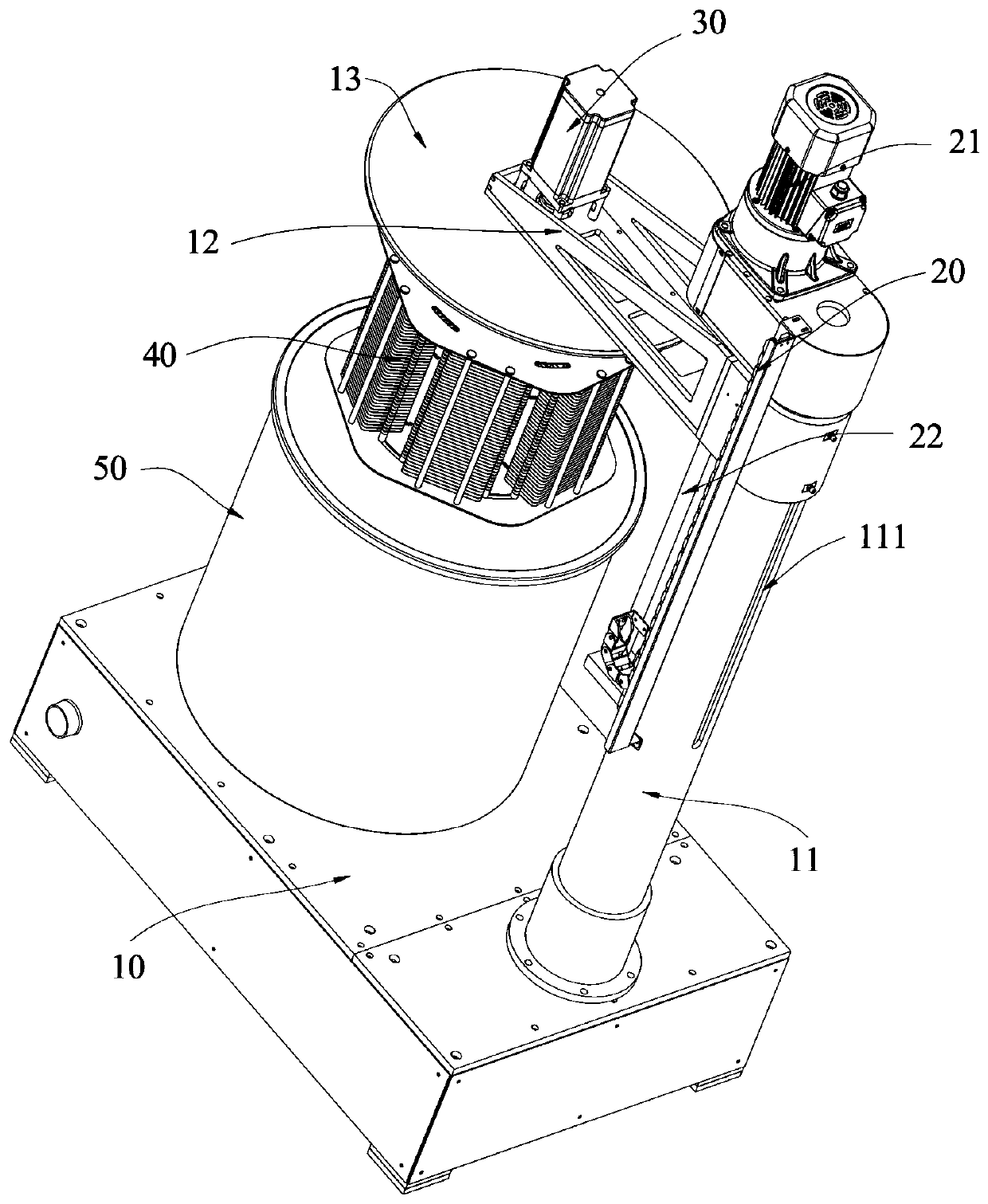

[0032] Such as Figure 1-8 The shown automatic line of automatic loading and unloading fluid sweeping machine includes a fluid sweeping machine 100, a conveying line 200 and a transfer manipulator 300. Specifically, the fluid sweeping machine 100 includes a body 10, a workpiece insert rack 40, a polishing cylinder 50 and a third The driving mechanism is provided with a mounting column 11 on the body 10. The mounting column 11 is provided with a mounting frame 12 and a first driving mechanism 20. The mounting frame 12 can be driven by the first driving mechanism 20 along the height of the mounting column 11. direction movement. In addition, the mounting frame 12 is provided with a second driving mechanism and a connecting shaft 131 ; the connecting shaft 131 is pivotally connected to the mounting frame 12 , and the connecting shaft 131 rotates driven by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com