Aperture grinding and finishing device for hardware casting machining

A technology for dressing devices and castings, which is used in grinding drive devices, metal processing equipment, grinding/polishing safety devices, etc. Poor fit and other problems, to reduce workload, ensure processing accuracy, and save processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

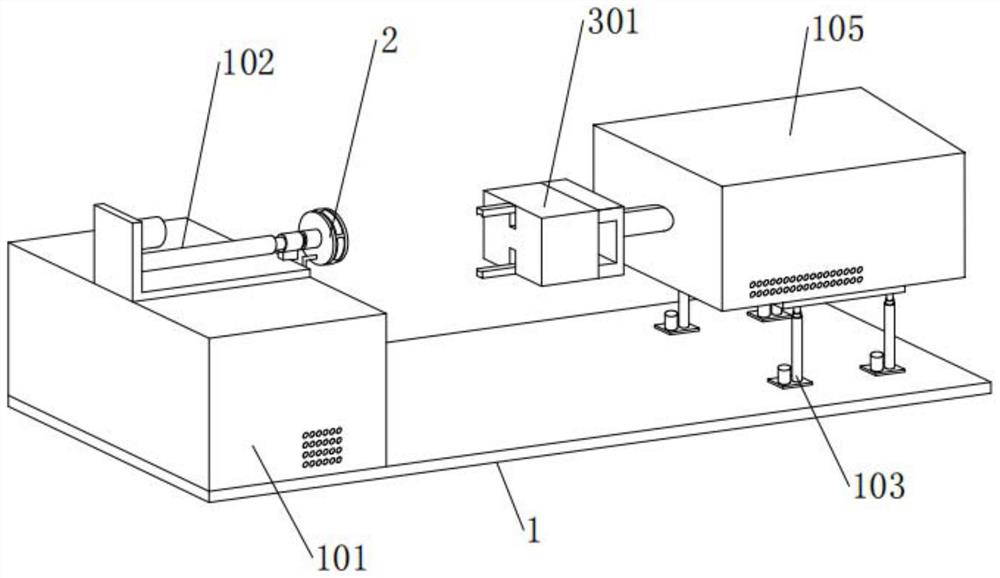

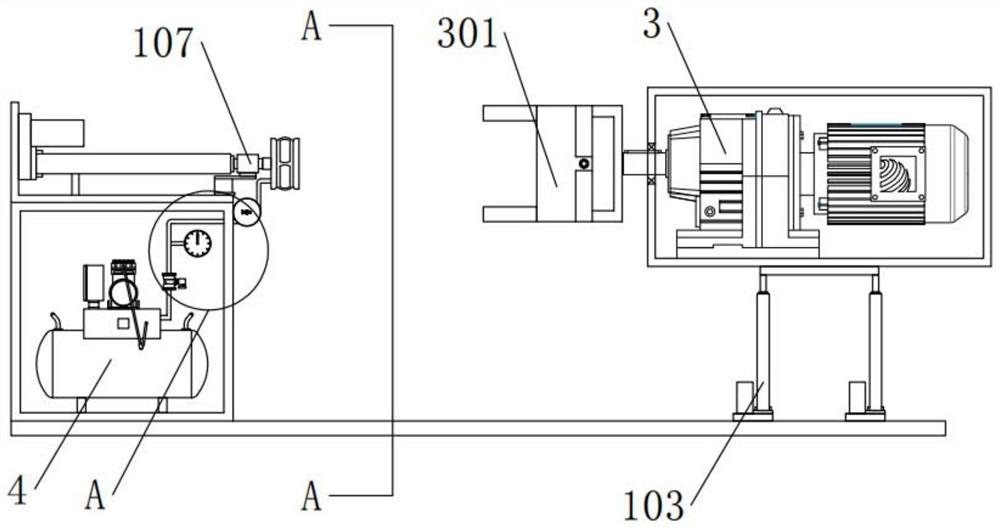

[0036] An aperture grinding and trimming device for processing metal castings, comprising a workbench 1, a protective case-101 is installed on the left side of the top of the workbench 1, and a horizontally assembled electric push rod-102 is fixedly connected to the top of the workbench 1. A grinding block 2 is fixedly installed on the side of the rod one 102 facing the vertical line in the workbench 1, and a compressor 4 is fixedly connected to the inner bottom of the protective shell one 101;

[0037] The aperture grinding and trimming device for metal casting processing also includes: the top right side of the workbench 1 is vertically equipped with an electric push rod 2 103, the top of the electric push rod 103 is fixedly connected with a support seat 104, and the top of the support seat 105 is assembled by bolts There is a protective case 2 105, the inner bottom of the protective case 105 is fixedly connected with a servo motor 3, the output shaft of the servo motor 3 run...

Embodiment 2

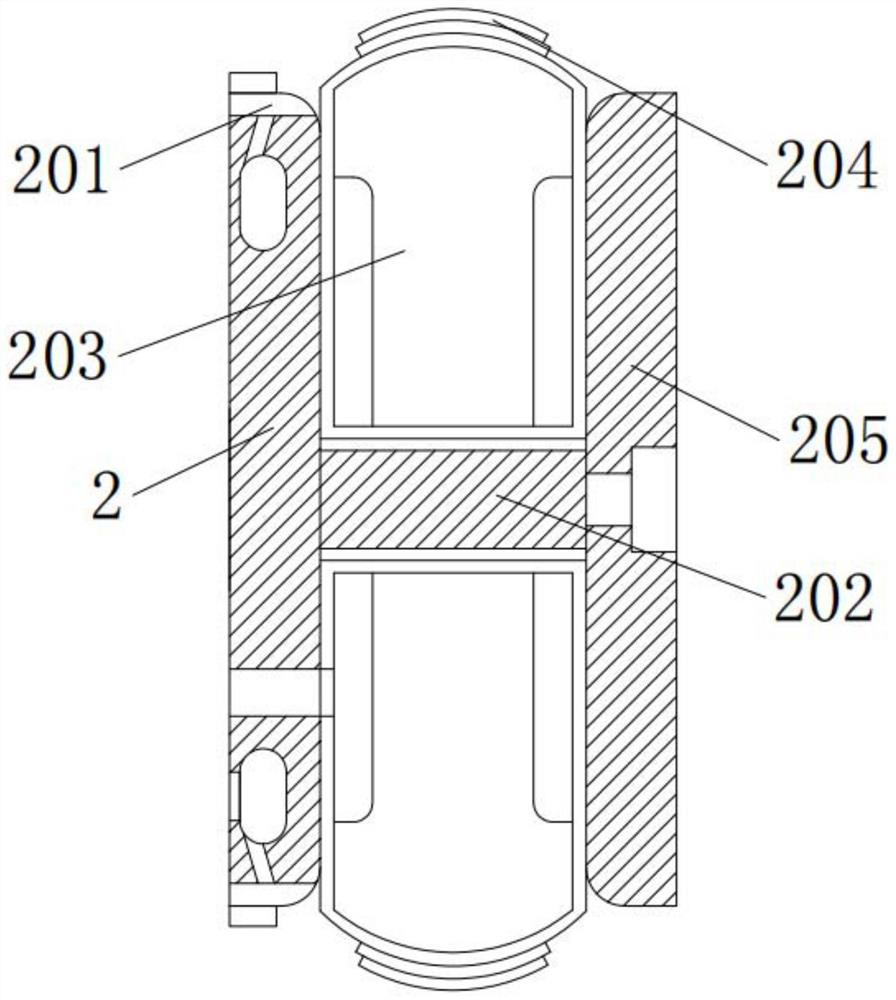

[0043] The difference between this embodiment and Embodiment 1 is that the grinding block 2 includes: a collar 201, a connecting shaft 202, an air bag 203, sandpaper 204 and a block 205, the collar 201 is sleeved on the outside of the grinding block 2, and the collar 201 is Made of white plastic steel, the outer side of the collar 201 is provided with bristles;

[0044] The collar 201 and the grinding block 2 are designed to be detachable. The servo motor 3 drives the clamp 301 to rotate, and the collar 201 contacts the blank workpiece. The bristles clean up the debris adhering to the surface of the workpiece, which is convenient for subsequent grinding of the blank workpiece.

[0045] The connecting shaft 202 is fixedly connected to the center of the right side of the grinding block 2, the air bag 203 is sleeved on the outside of the connecting shaft 202, the air bag 203 is closely attached to the grinding block 2, the outer side of the air bag 203 is fixed with a glue layer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com