3D printer

A 3D printer and printer technology, applied in the direction of ceramic molding machines, manufacturing tools, additive processing, etc., can solve problems such as time-consuming and labor-intensive, physical deformation, rough outer surface, etc., and achieve comprehensive sandblasting and polishing and save work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

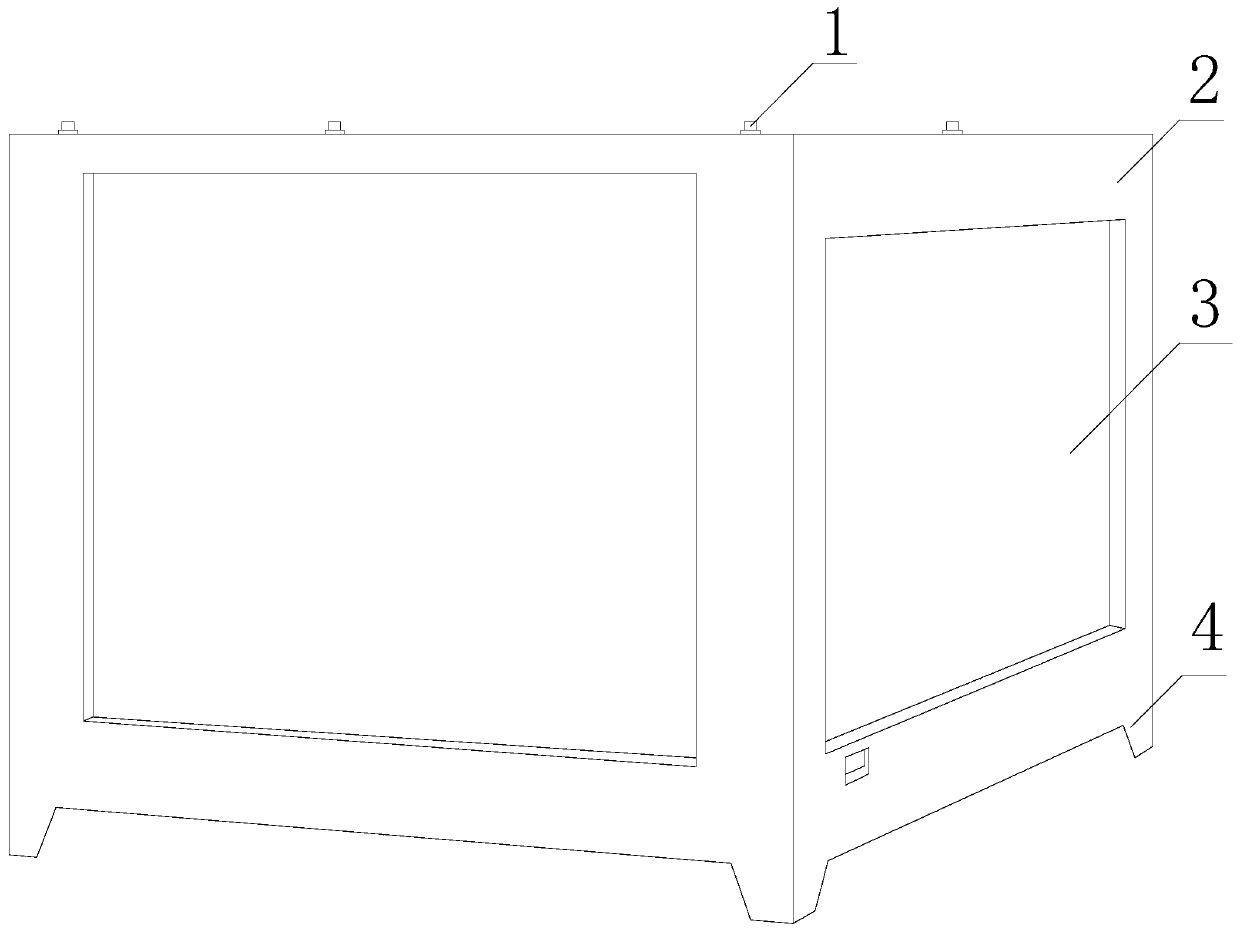

[0026] see Figure 1-Figure 6 , the present invention provides a 3D printer, the structure of which includes a fixing screw 1, a printer body 2, a window 3, and a support foot 4, the fixing screw 1 is screwed to the upper end of the printer body 2, and the window 3 is embedded in the right side of the printer body 2 There are four supporting feet 4 and the upper ends are welded to the four corners of the lower surface of the printer main body 2 .

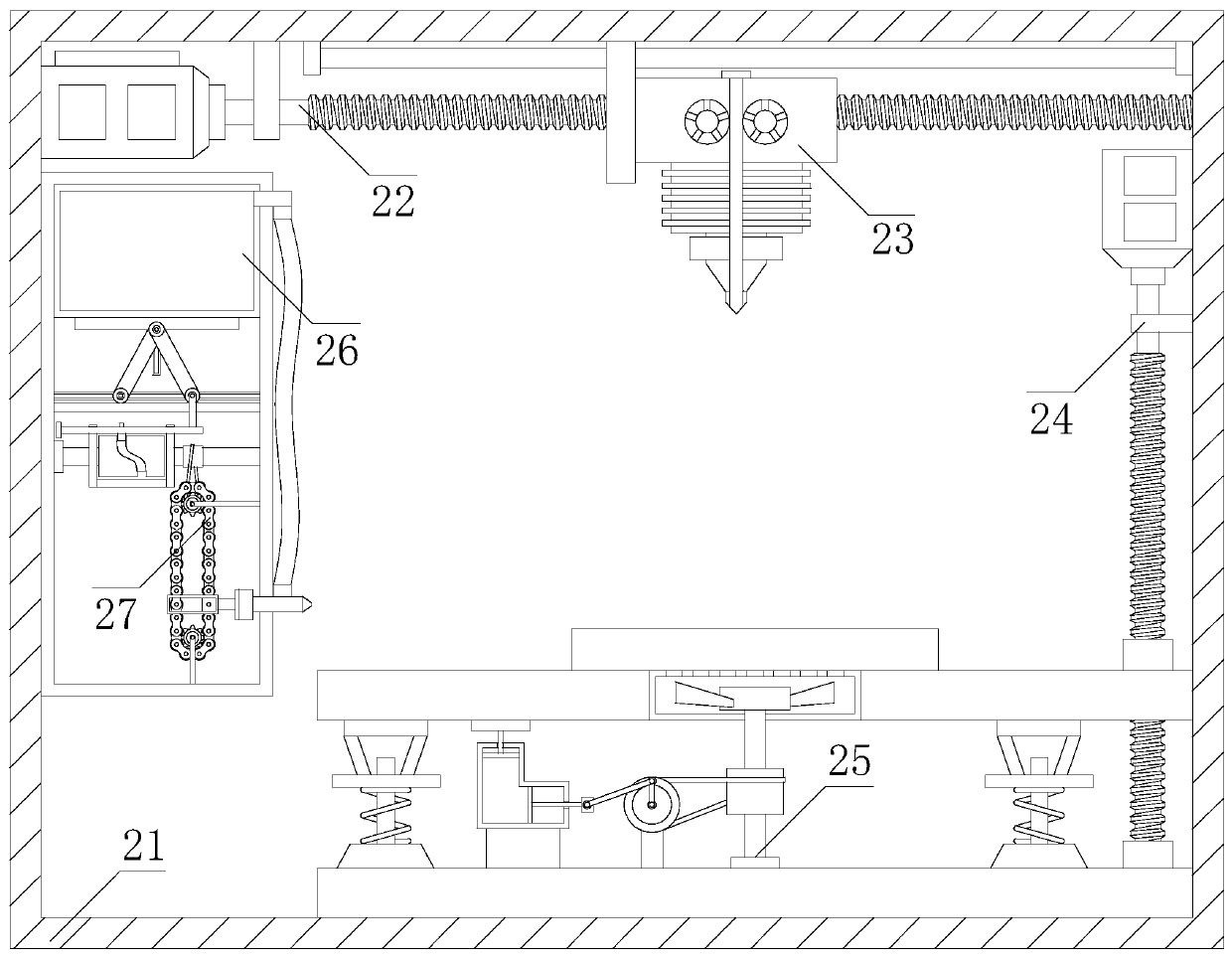

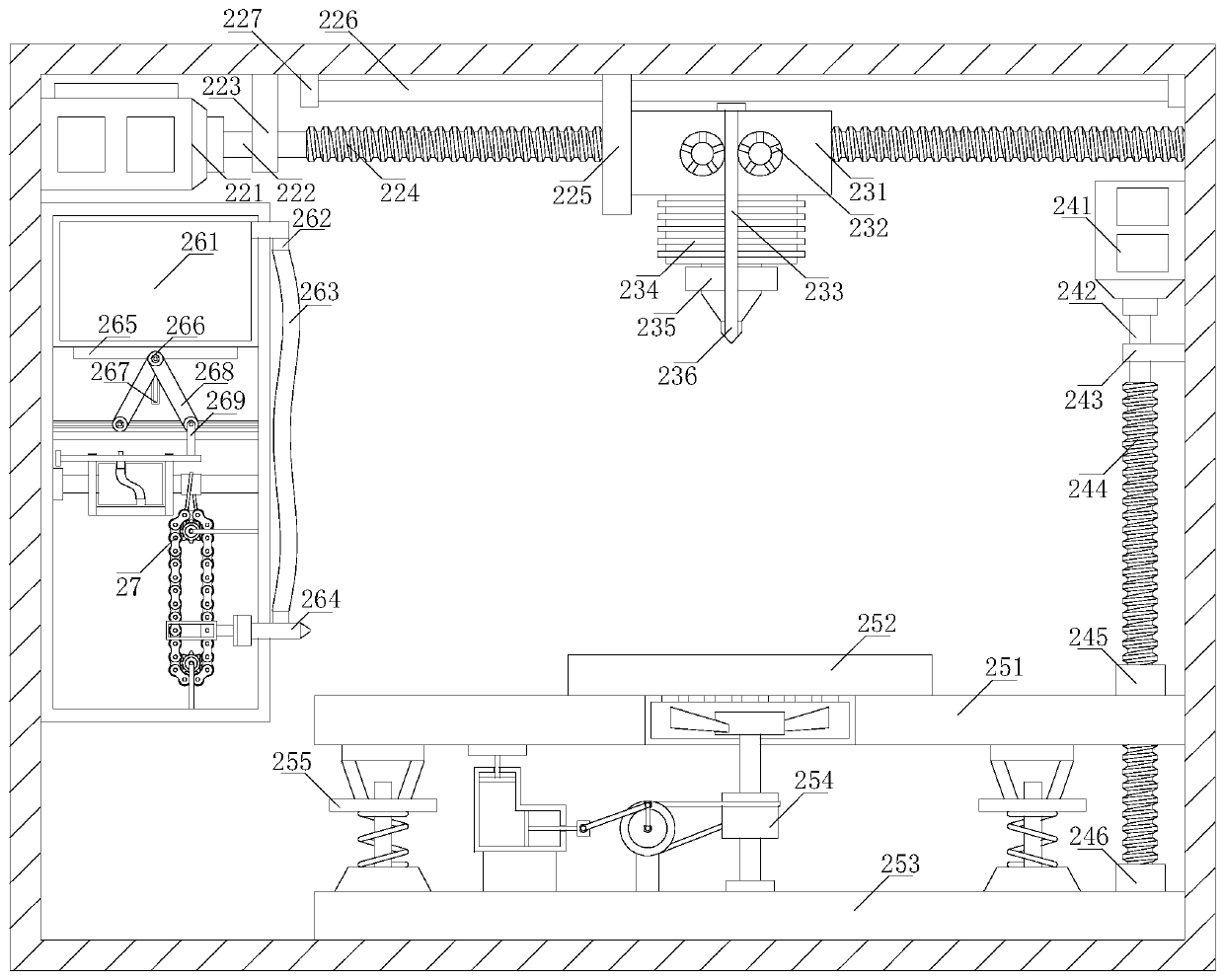

[0027] The main body of the printer 2 includes a host shell 21, a horizontal drive mechanism 22, a print head mechanism 23, a vertical drive mechanism 24, a placement mechanism 25, a sandblasting and polishing mechanism 26, and a vertical movement mechanism 27. 4. The upper ends are welded together. The horizontal driving mechanism 22 is fixedly installed on the upper end of the host casing 21. The printing nozzle mechanism 23 is installed on the horizontal driving mechanism 22 and connected flexibly. The printing nozzle mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com