Polishing device for capsules

A technology of polishing device and capsule, which is applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. It can solve the problems of large power consumption, complicated equipment structure, inconvenient movement, etc., and achieve structural reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

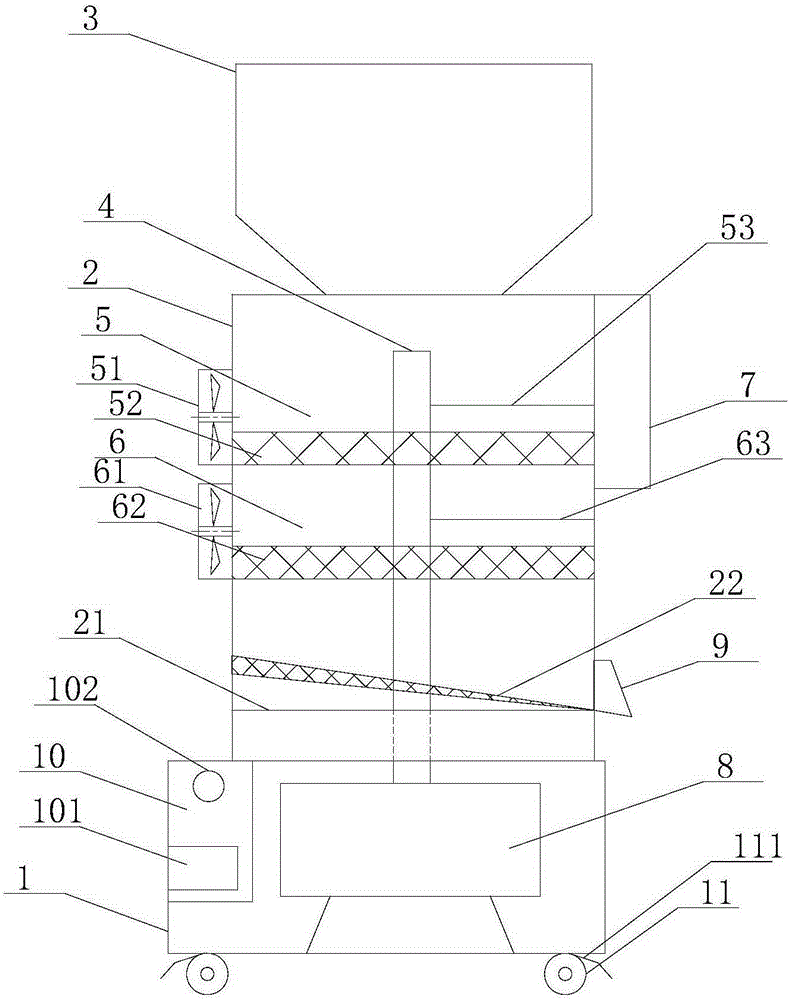

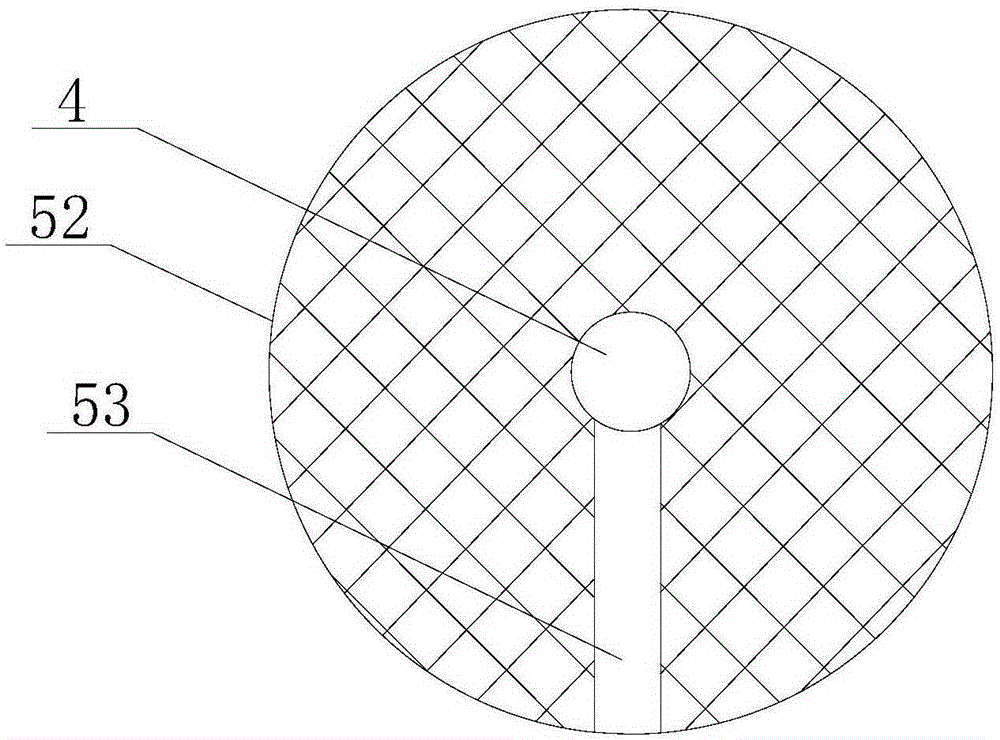

[0013] refer to figure 1 and figure 2 , the embodiment of the present invention provides a capsule polishing device, including a chassis 1, a polishing mechanism 2, a feed hopper 3, a rotating shaft 4, a first dust removal device 5, a second dust removal device 6, a control device 7, a motor 8, and a discharge hopper 9 and a speed measuring device 10, the cabinet is provided with a motor 8, a hopper 9 and a speed measuring device 10, and the polishing mechanism 2 is provided with a control device 7, and the control device 7 is electrically connected to the rotating shaft 4, the motor 8 and the speed measuring device 10 , the speed measuring device 10 includes a Hall sensor 101 and an alarm 102, the first dust removal device 5 includes a first fan 51, a first filter 52 and a first brush 53, the first filter 52 and the first brush 53 A hair brush 53 is arranged on the rotating shaft 4, and the second dust removal device 6 includes a second fan 61, a second filter screen 62 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com