Automatic separating and polishing system and processing technique for steel balls subjected to demolding

An automatic separation and steel ball technology, applied in the direction of solid separation, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of poor efficiency, incomplete treatment, time-consuming and labor-intensive manual separation of steel ball modules, etc., to reduce Production cost, effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

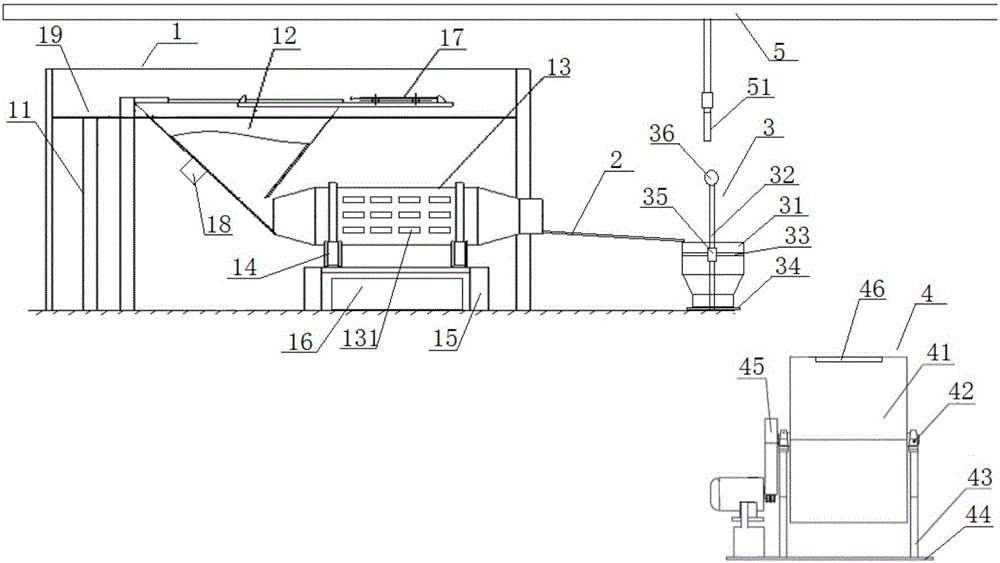

[0043] A kind of automatic separation and polishing system of the steel ball after the demoulding of the present embodiment, such as figure 1 As shown, it includes a hoisting crane 5 and a ball sand separation device 1, a selection table 2, and a polishing device 4 distributed in sequence according to the production line. Separation, selection and polishing; the hoisting crane 5 is hoisted above the production line. The ball sand separation device 1 uses the weight of the steel balls to knock each other to separate the steel ball modules, and then utilizes the gravity of the steel balls and the circular shape to roll, which is different from the riser and molding sand and automatically separates. Finally, Then use the steel ball's own gravity and circular shape to polish and polish each other.

Embodiment 2

[0045] An automatic separation and polishing system for steel balls in this embodiment after demoulding, the basic structure is the same as in Embodiment 1, the improvement is that the ball sand separation device 1 includes a bracket 11, a feeding hopper 12, a drum 13, a roller 14 and The drum support platform 15; the feeding hopper 12 is fixed above the support 11, and its bottom opening communicates with the front opening of the drum 13; the rear opening of the drum 13 is connected with the selection table 2, and the drum 13 is below the drum supporting platform 15 , between the two is the roller 14 that drives the drum 13 to rotate. The steel ball modules in the drum 13 through the rotation of the drum 13, combined with the weight of the steel ball modules, provide the impact force for the steel ball modules to knock each other, and automatically separate the steel balls, risers and molding sand. The selection table 2 is in the shape of a downward inclined table, which prov...

Embodiment 3

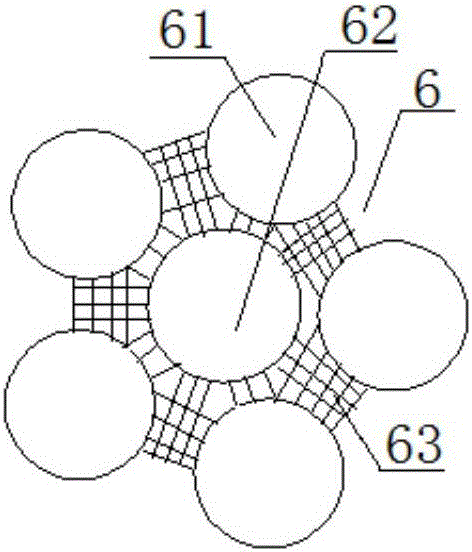

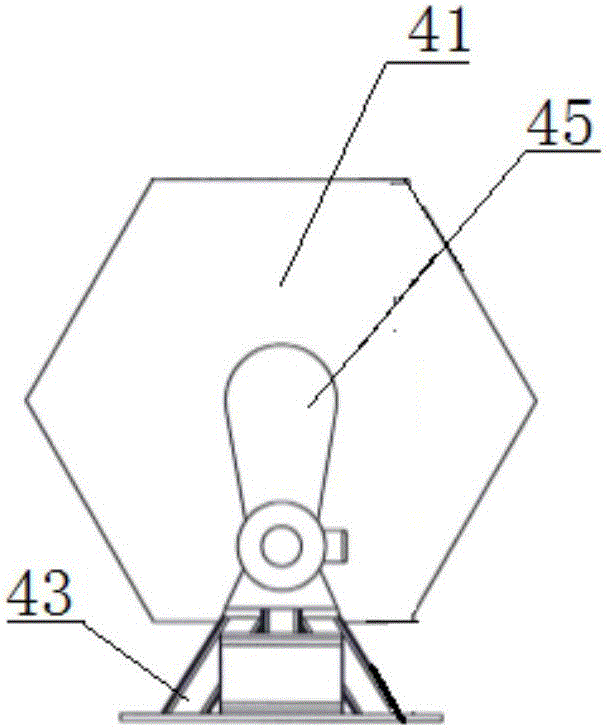

[0052] A kind of automatic separation and polishing system for steel balls in this embodiment after demoulding, the basic structure is the same as that of Embodiment 2, the improvements and differences are: the inclination angle of the selection platform 2 is 7°; the cross section of the polishing box 41 is pentagonal; A sand outlet 131 with a width of 5 mm; also includes a turnover device 3; the turnover device 3 includes a turnover bucket 31, a lifting shaft 32, a pole 33, a bottom sealing plate 34, a shaft sleeve 35 and a hanging ring 36; the turnover bucket 31 is in the shape of a barrel with both ends open; the outer side of the bushing 35 is symmetrically fixed with a support rod 33, and is fixed at the inner center of the turnover barrel 31 through the support rod 33, and one end of the lifting shaft 32 is vertically fixed to the bottom sealing plate 34 Finally, the other end passes through the axle sleeve 35 and is fixedly connected with the hanging ring 36; the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com