Polishing method and polishing equipment for 3D sapphire

A sapphire and 3D technology, applied in metal processing equipment, used abrasive processing devices, abrasive feeding devices, etc., can solve problems such as high safety risks, difficult polishing, and easy buffering by water glass gel. , to achieve uniform polishing and good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

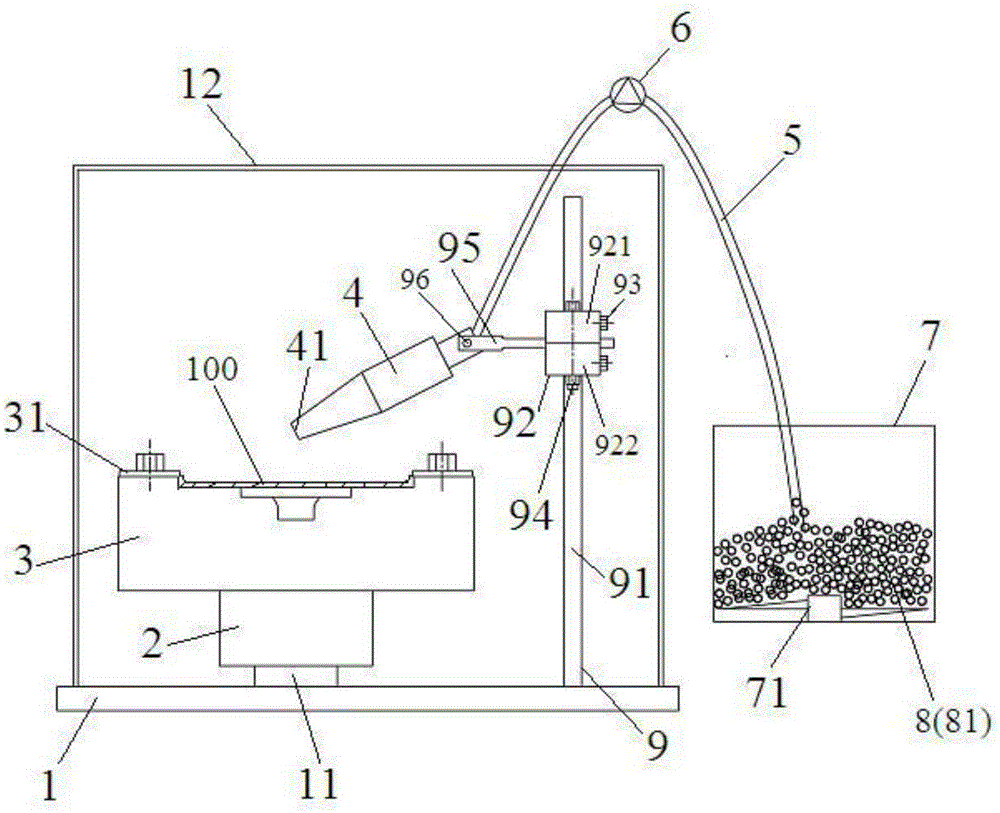

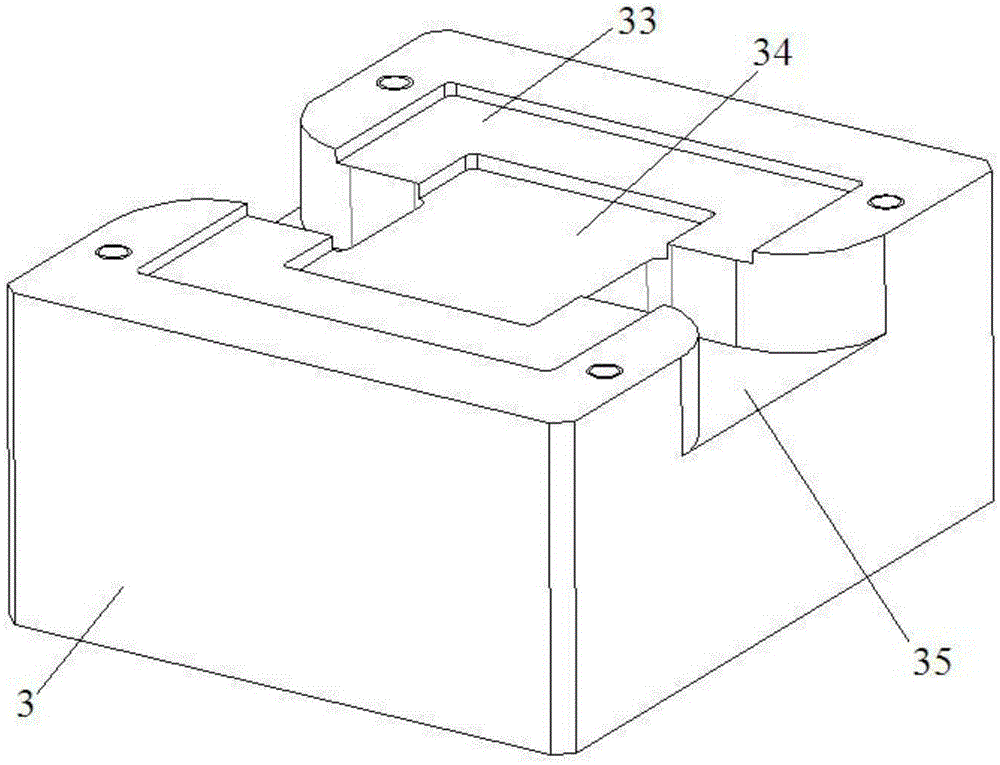

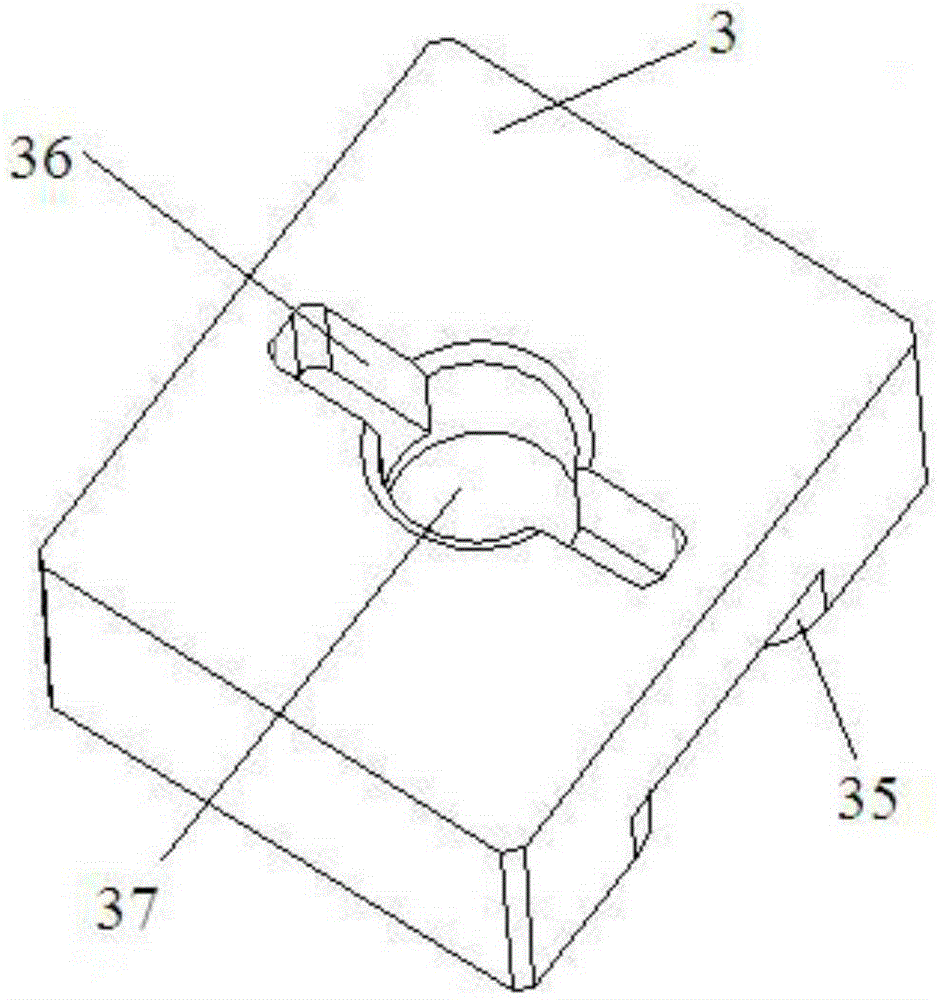

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

[0034] A polishing method for 3D sapphire, comprising the steps of:

[0035] 1) Abrasive preparation process: select diamond micropowder and rubber balls and pour them into the material making equipment to prepare materials, so that the rubber balls adhere to the diamond micropowder, and transfer the rubber balls adhering to the diamond micropowder to the container for standby;

[0036] 2) The preparation process of the spray tool: connect the spray tool with the air pump with the gas pipeline, and place the air inlet of the gas pipeline in a container filled with abrasives;

[0037] 3) Polishing process: the nozzle of the spray tool is aimed at the 3D sapphire part, the air pump is started, and the abrasive is sprayed onto the processed surface of the 3D ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com