Thin-wall special-shaped curved surface polishing device and method based on static pressure principle polishing tool

A technology for polishing tools and special-shaped surfaces, applied in manufacturing tools, optical surface grinders, grinding/polishing equipment, etc., can solve the problems of low processing efficiency, reducing edge effects, poor uniformity, etc., to improve processing efficiency and reduce abrasive tools. The number of dressing times, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

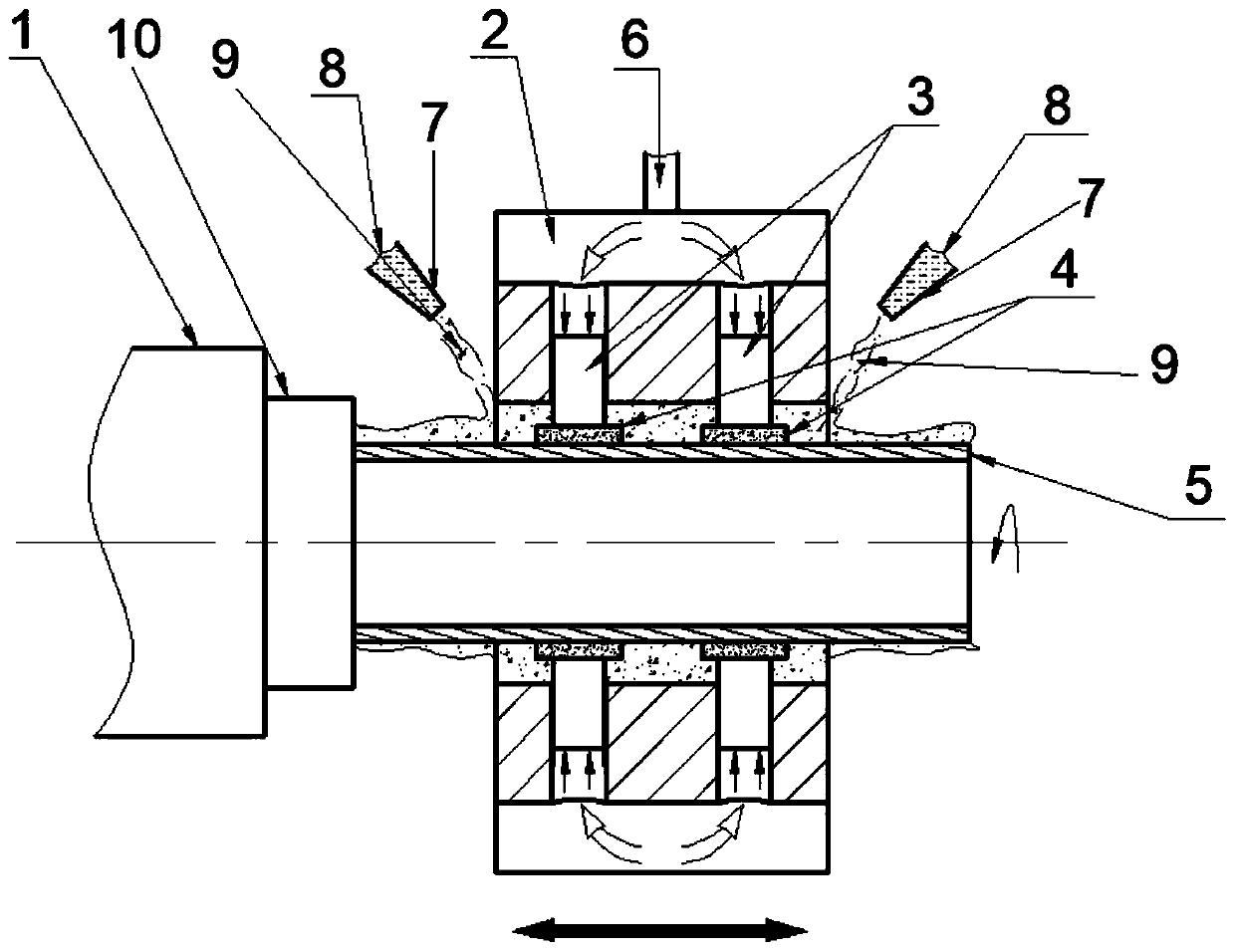

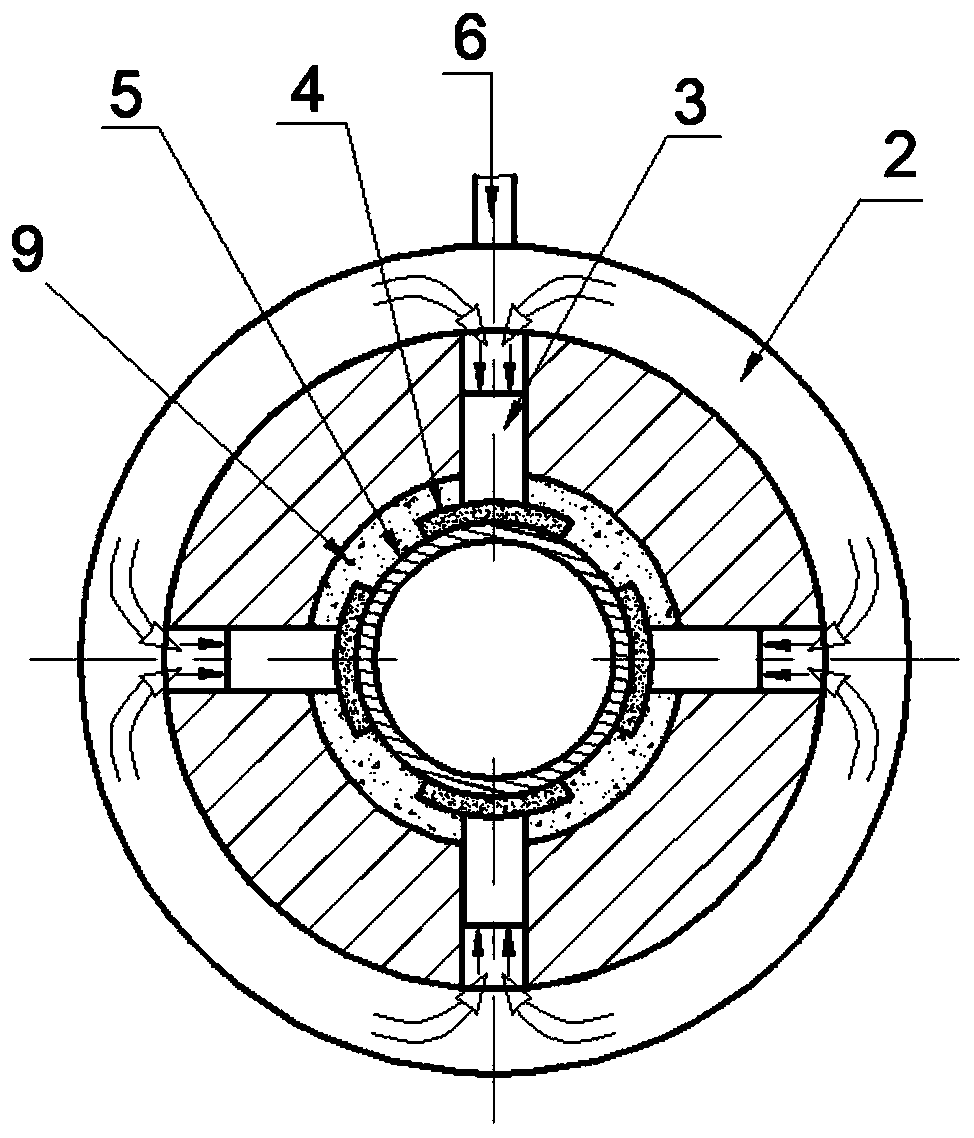

[0038] Such as figure 1 and figure 2 The shown thin-wall special-shaped curved surface polishing device based on the principle of static pressure polishing tool is used for polishing the outer circle of a thin-wall cylinder, including a nozzle 7 for ejecting polishing liquid 8, and also includes a fluid cylinder 2 connected to A plurality of pistons 3, the movement direction of the pistons 3 is towards the curved surface to be polished, and the output end of the pistons 3 is provided with a polishing abrasive 4, and the polishing abrasive 4 matches the curved surface to be polished.

[0039] The fluid cylinder 2 in this embodiment is an air cylinder, which specifically includes a main shaft, a cylinder, a piston 3, a polishing abrasive 4, a workpiece 5, a compressed gas 6, a polishing liquid nozzle 7, a polishing liquid 8, abrasive grains 9, and a clamp 10. The entire cylindrical polishing tool is mainly composed of two parts: the main part is the cylinder, the main function...

Embodiment 2

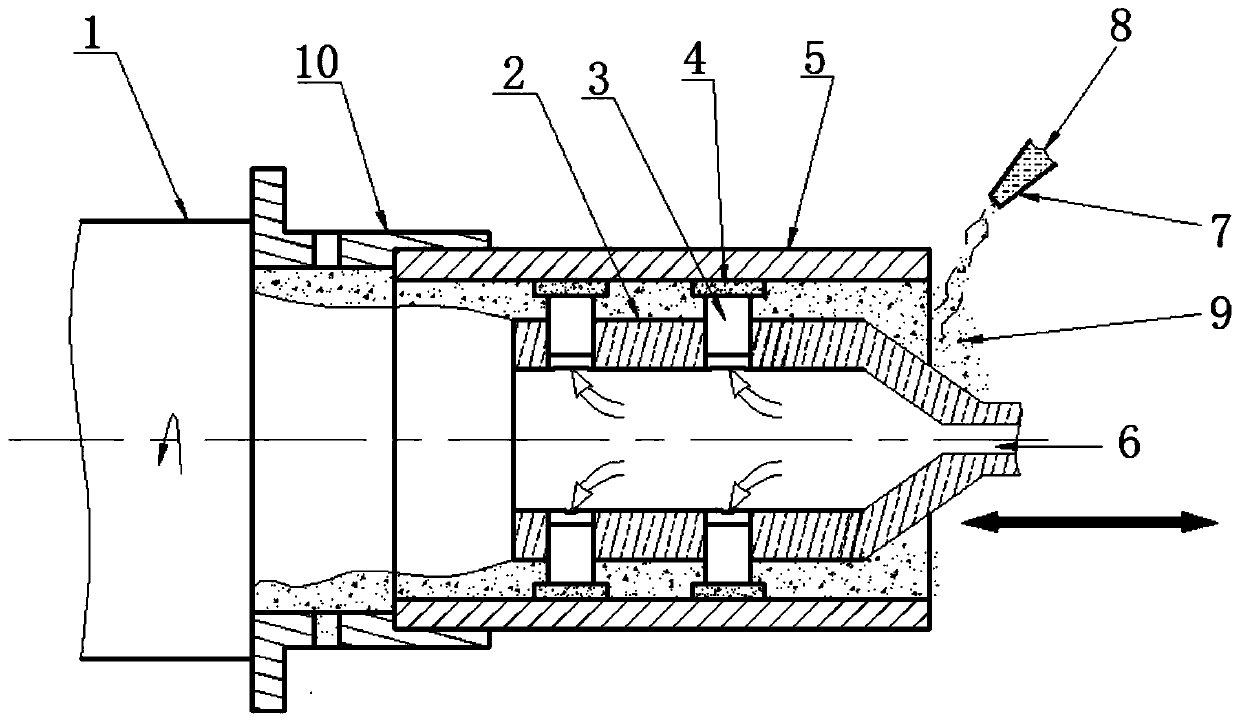

[0044] Such as image 3 and Figure 4 The shown thin-wall special-shaped curved surface polishing device based on the principle of static pressure polishing tool is used for polishing the inner circle of a thin-walled cylinder. The difference from Example 1 is that the entire polishing device is placed inside the workpiece. When the cylinder is pressurized, the piston 3 is outward. stick out.

[0045] Preferred:

[0046] In this embodiment, the polishing abrasive can be polyurethane, asphalt, or polishing cloth, which can be selected according to different processing surface quality and removal efficiency requirements.

[0047] The polishing abrasives in this embodiment can be made of polyurethane, asphalt, and polishing cloth into cylindrical, conical, and spherical abrasives, which are specifically designed according to the requirements of the rotationally symmetrical curved surface to be processed.

[0048] The number of pistons in this embodiment can be 1-20, depending ...

Embodiment 3

[0054] A method for polishing a thin-walled curved surface of a polishing tool based on the principle of static pressure, comprising the following steps:

[0055] (a) Use clamp 10 to clamp polished workpiece 5, align workpiece 5 with polishing abrasives 4 matched with the curved surface to be polished, each polishing abrasive 4 is driven by a piston 3, and all pistons 3 are driven by the same Fluid cylinder 2 drive;

[0056] (b) Fill the fluid cylinder 2 with compressed fluid of a certain pressure, so that each polishing abrasive tool 4 is in contact with the polished curved surface;

[0057] (c) The rotating fixture 10 drives the workpiece 5 to rotate, and at the same time drives all the pistons 3 and polishing abrasives 4 to perform linear reciprocating motion synchronously.

[0058] Preferably, in step (c), the nozzle 7 is moved to a suitable position of the contact part between the workpiece 5 and the polishing abrasive 4, and the polishing liquid 8 containing the abrasiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com