Square tube cutting method and device

A technology of cutting device and cutting method, which is applied to sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problems of large load of saw disk and its driving device, shorten the service life of saw disk and driving device, etc. The effect of cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

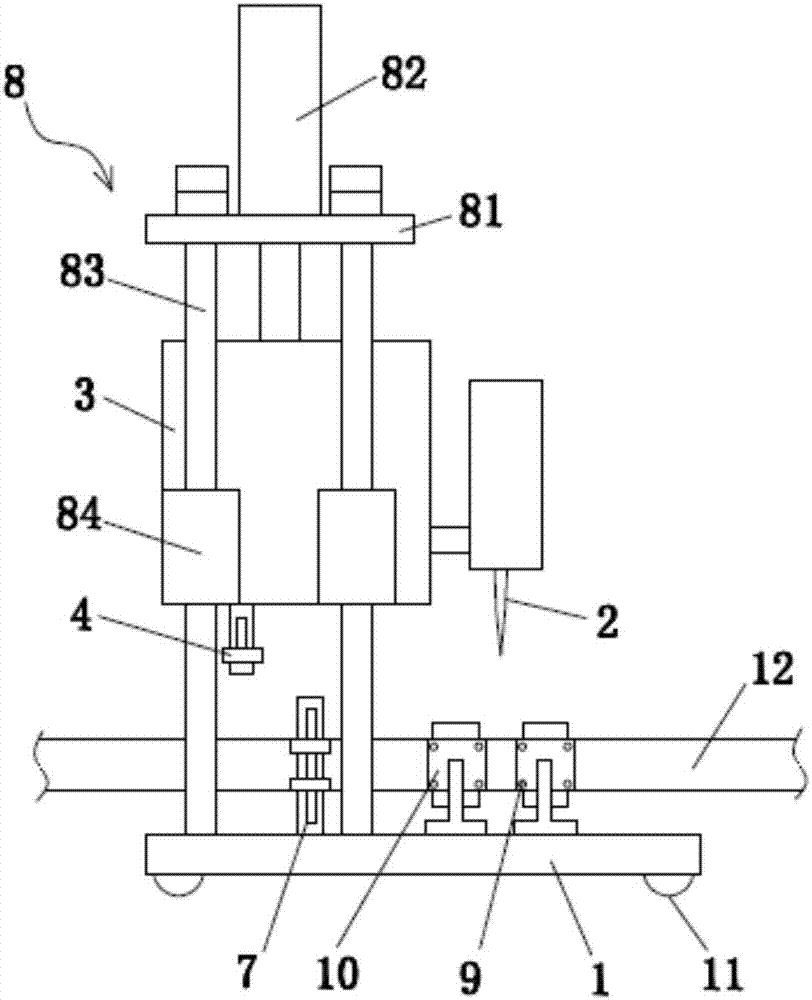

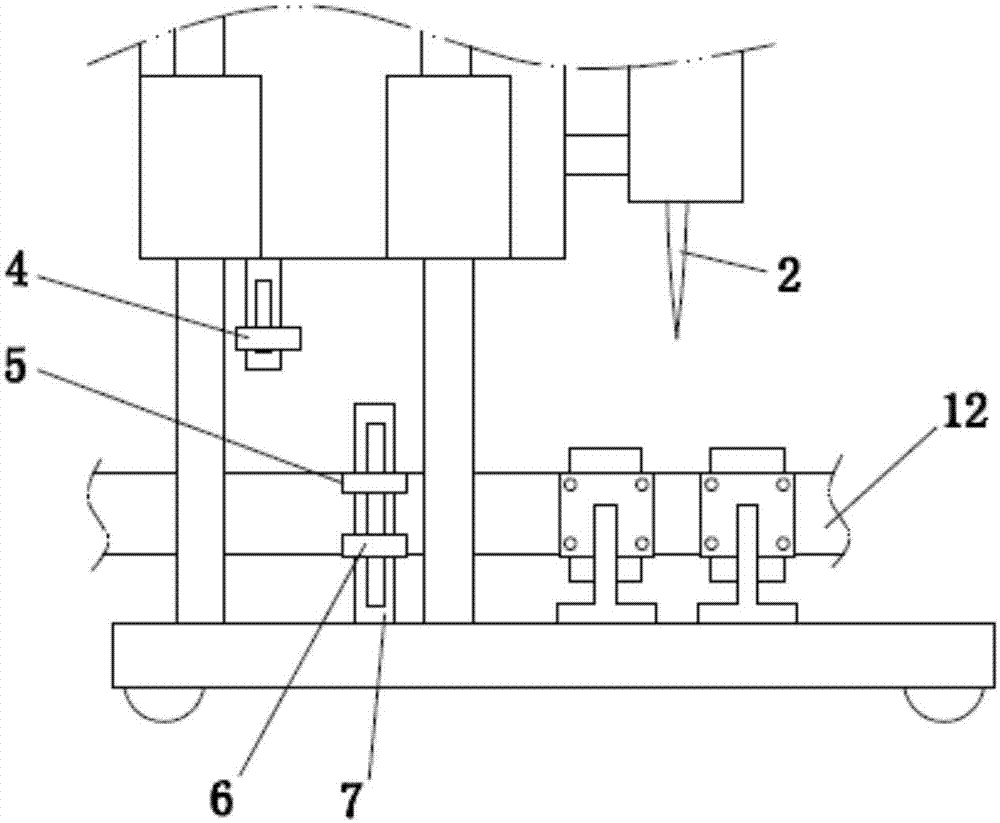

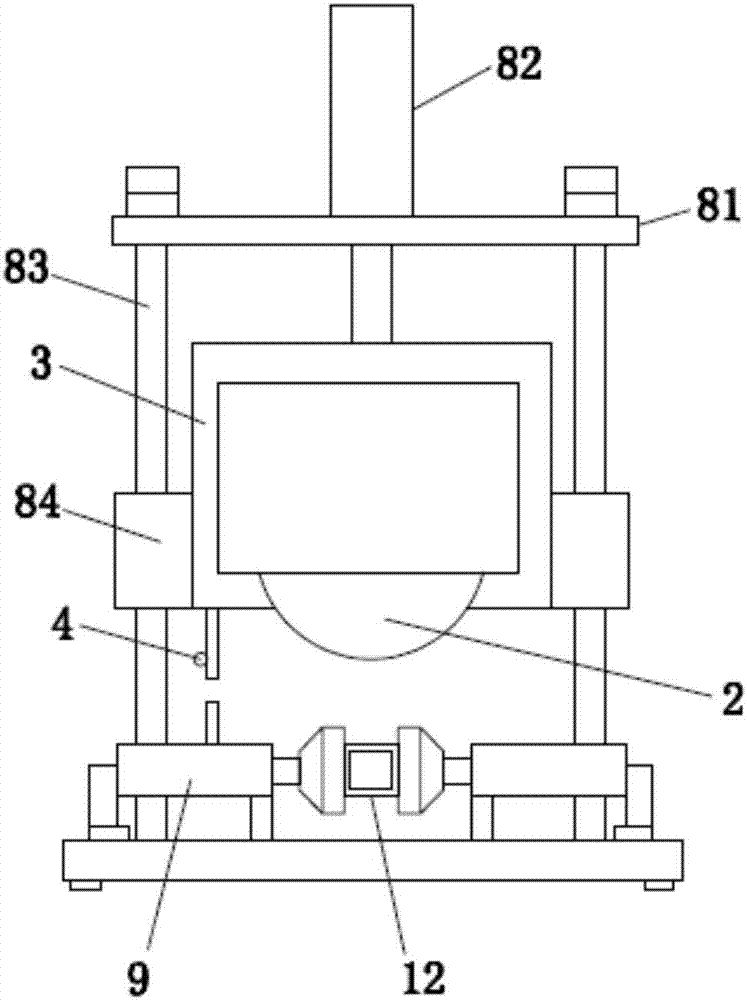

[0033] The specific embodiment of the present invention is as Figure 1 to Figure 6 As shown, a square pipe cutting device includes a base 1, the base 1 is provided with a saw disc 2 arranged vertically, the saw disc 2 is connected with a first drive mechanism 3, and the base 1 is provided with a saw The lifting device 8 of the disc 2 and the square tube fixing mechanism; the square tube cutting device also includes a speed switching device that can control the lifting device 8 to drive the saw disc 2 to cut the horizontal side wall and the vertical side wall of the square tube at two pressing speeds . The two pressing speeds are respectively the first pressing speed a and the second pressing speed b. In this embodiment, the first driving mechanism 3 is a motor, and a pulley 11 is provided at the bottom of the base 1 .

[0034] The speed switching device comprises a reference part 4 and a first sensor 5 and a second sensor 6 for detecting the height position of the reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com