Nut cracker

A shell breaking and nut crushing technology, which is applied in home appliances, applications, kitchen utensils, etc., can solve problems such as difficult to control the extrusion force, unfavorable safety, and easy damage to fruits, so as to prevent excessive pressing speed and avoid safety problems , the effect of preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

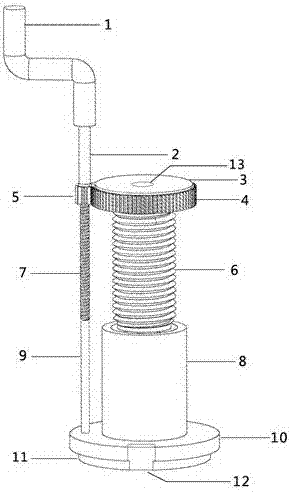

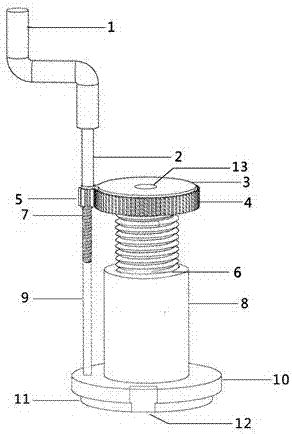

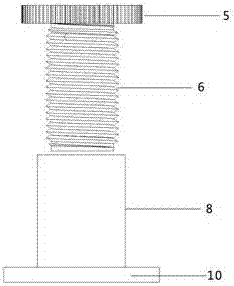

[0024] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] see Figure 1 to Figure 9 , a nut cracker, comprising a base 10, on which a storage bin 8 is arranged; a pressure stud 6 is arranged on the top of the storage bin 8, and the upper end of the pressure stud 6 is connected with a driven gear 4; the base 10 and the fixed shaft One end of A9 is connected, and the other end of the fixed shaft A9 is connected with the fixed stud 7 as a whole; the fixed stud 7 is provided with a power gear 5, and the power gear 5 meshes with the driven gear 4; the upper side of the power gear 5 passes through the power The connecting shaft links to each other with the crank 1.

[0026] The crank handle 1 is sequentially connected with the power connection shaft 2 and the power gear 5; the power connection shaft 2 and the power gear 5 are both hollow structures, and the interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com