Corn cutting device

A technology of cutting and corn, applied in metal processing and other directions, can solve the problems of uneven cutting, corn kernel damage, high labor intensity, etc., to prevent deviation and deformation, improve service life, and solve the effect of being crushed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

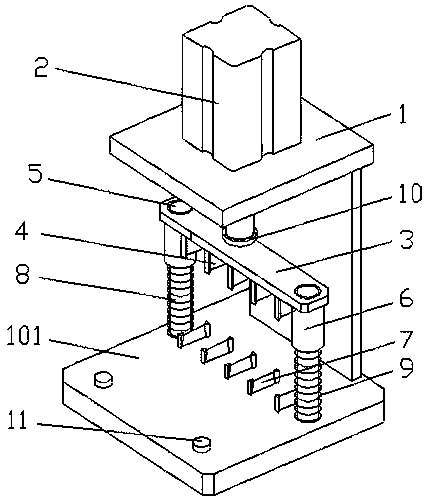

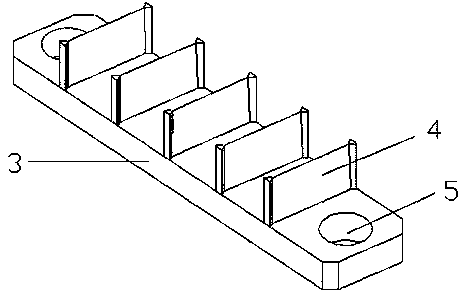

[0020] Now do further detailed explanation in conjunction with accompanying drawing.

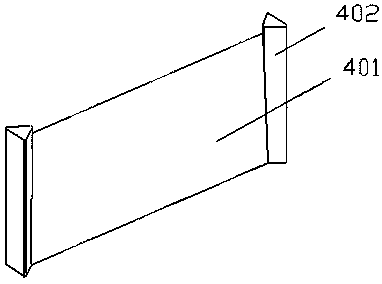

[0021] like Figure 1-4 Shown, a kind of corn sectioning device, it comprises formwork 1 and corn sectioning mould, and cylinder 2 is installed on the top of described formwork 1, and described corn sectioning mold is arranged on the base 101 of formwork 1 and is located on Below the cylinder shaft of the cylinder 2, the corn sectioning mold is provided with an upper template 3, and the bottom surface of the upper template 3 is provided with a row of cutters A4, and the two ends of the upper template 3 are provided with guide holes 5 and guide sleeves 6, and guide Cover 6 is installed on the guide hole 5, and the corn cutting mold also includes a row of cutters B7 and 2 guide pillars 8, the cutter B7 and guide pillars 8 are fixed on the base 101, and the guide pillars 8 are respectively equipped with springs 9, and the guide post 8 passes through the guide sleeve 6 and the guide hole 5 so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com