Propeller dynamometer load device for measuring background noise of circulating water tank

A technology of circulating water tank and load device, applied in measurement device, measurement of ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of high forecast, different propeller dynamometer loads, underestimation of background noise, etc., to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

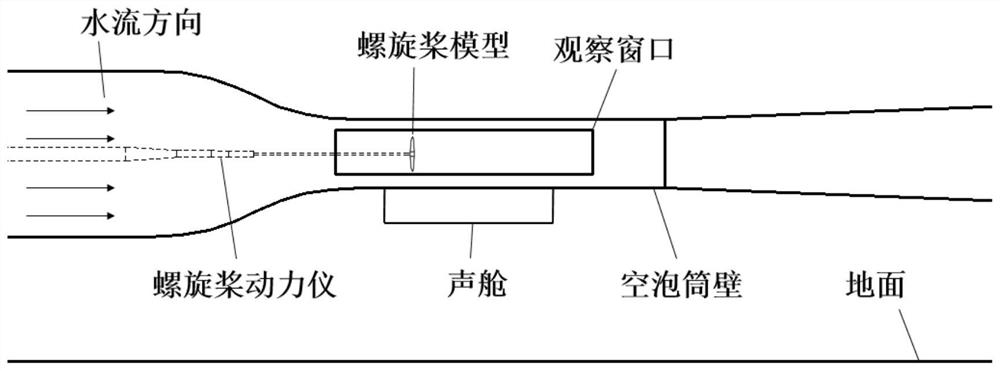

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

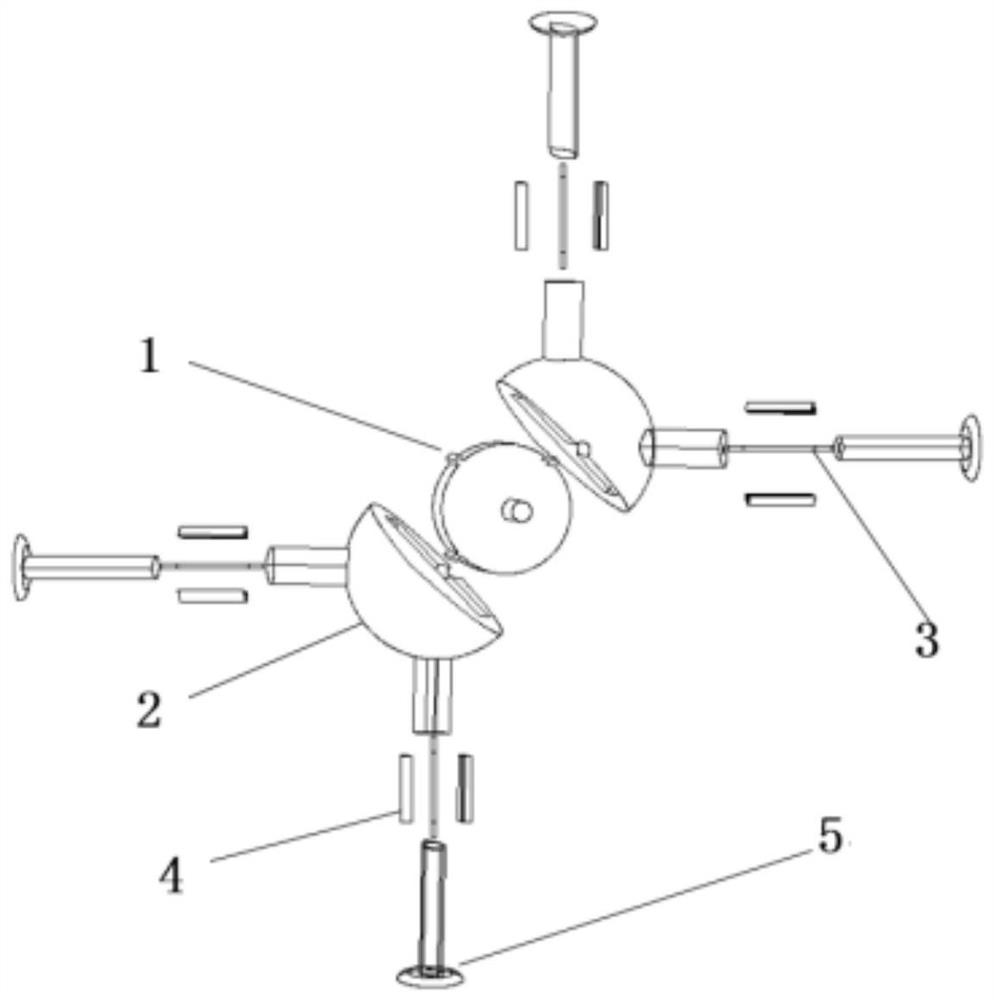

[0033] A kind of propeller dynamic instrument loading device used for measuring the background noise of circulating water tank according to the present invention, its overall structure is shown in figure 2 . It includes 5 components including magnetic powder brake 1, housing 2, screw 3, screw housing 4 and suction cup 5.

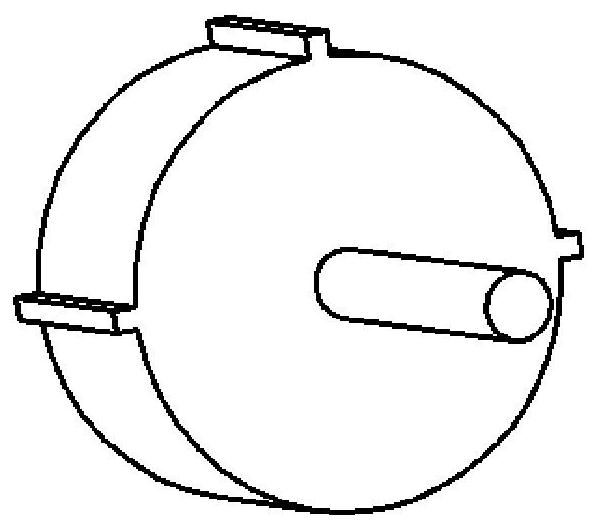

[0034] Among them, the magnetic powder brake 1 (see image 3 ) is installed on the shaft of the propeller dynamometer to provide a constant torque. The size of the torque is determined according to the test conditions of the propeller model. Determine the rotational speed of the propeller model in the test, and then adjust the inflow velocity of the circulating water tank to make the thrust coefficient of the propeller model reach the target value. At this time, the torque at which the propeller model reaches the target thrust coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com