Method for forming nickel silicide with microwave annealing

A nickel silicide, microwave annealing technology, applied in electrical components, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as the annealing time should not be too long, the temperature should not be too high, and the uniformity of nickel silicide is not very good. Achieving the effect of promoting rearrangement, improving performance, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

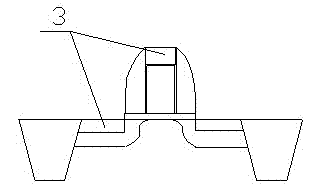

[0028] The present invention will be further described below in combination with principle diagrams and specific operation examples.

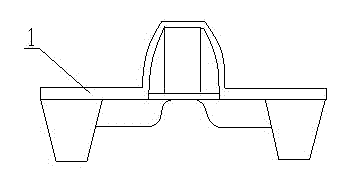

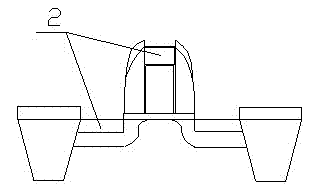

[0029] Such as image 3 Shown, the microwave annealing method of the present invention forms nickel silicide, wherein, comprises the following steps:

[0030] S1. Perform pre-cleaning on the exposed silicon surface to remove natural oxides; the step of pre-cleaning to remove natural oxides is completed by cleaning in a SiCoNi chamber or HF immersion, and removing a silicon surface layer with a thickness of 15A-50A. Nickel or nickel alloys are deposited on the cleaned silicon surface by physical vapor deposition.

[0031] S2. Deposit nickel or nickel alloy on the cleaned silicon surface, and cover a barrier layer on the surface of nickel or nickel alloy.

[0032] S3. During the process of heating the wafer to the first temperature, microwave radiation is used at the same time to make a part of nickel or nickel alloy react with silicon to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com