Low-temperature microwave annealing method for improving optical-electrical characteristic of silicon superlattice film

A technology of microwave annealing and photoelectric characteristics, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as high temperature and damage to silicon superlattice structure, and achieve high yield, low annealing temperature, and strong repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

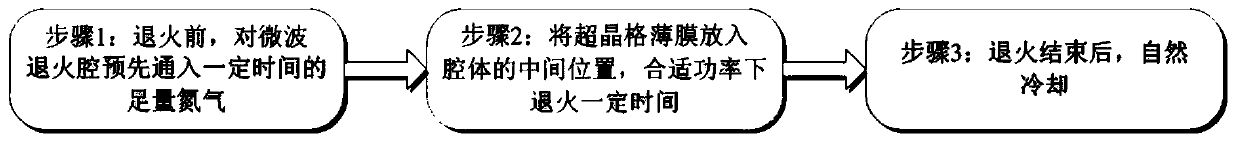

[0027] A method for improving SiO 2 / SiN x Process flow of low-temperature microwave annealing method for photoelectric properties of silicon superlattice thin films (such as figure 1 shown), including the following steps:

[0028] Step 1: RCA standard cleaning process cleans a p-type 4-inch silicon wafer with a thickness of about 250 μm and a crystal orientation of (100) and blows it dry with high-purity nitrogen.

[0029] Step 2, Deposit SiO with a thickness of 105 nm on the Si wafer substrate by ALD technology 2 / SiN x Laminated thin films, where SiN in each lamination cycle x Layer thickness about 2 nm, SiO 2 The layer thickness is about 3 nm, and the total number of lamination cycles is 20.

[0030] Step 3, before annealing, nitrogen gas with a flow rate of 20 sccm was preliminarily passed into the microwave annealing chamber for 20 minutes.

[0031] Step 4, continue to flow into the nitrogen gas with a flow rate of 20 sccm as the annealing atmosphere, and SiO on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com