Inboard plate high strength steel and production method thereof

A technology of high-strength steel and mass percentage, applied in high-strength steel for ship inner plates and its production field, can solve the problems of high cost and insufficient yield strength of high-strength steel for ship inner plates, and achieve low production cost, good welding and processing performance , the effect of good plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

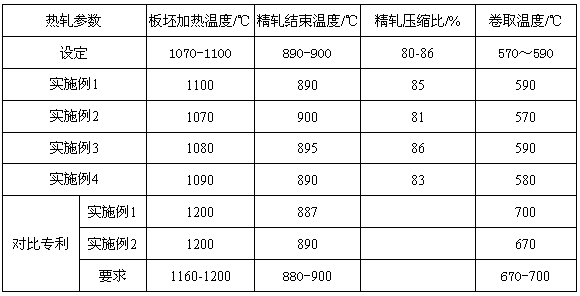

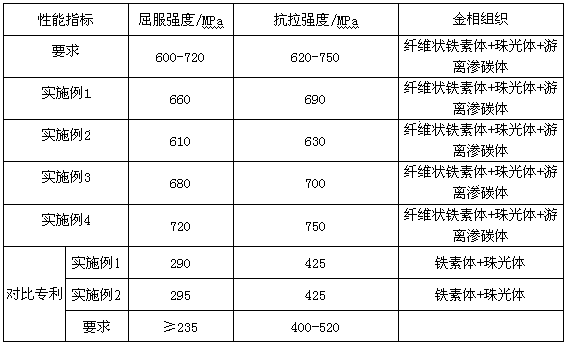

[0030] The present invention will be further described below in conjunction with Examples 1-4, and a comparative analysis has been carried out with similar invention patents. The comparative patent application number is CN201210219005.4, and the name is "a kind of normalized ship plate steel and its production method" .

[0031] Examples and comparative patent chemical composition control are shown in Table 1.

[0032] Table 1 Example 1-4 chemical composition (% by weight), the balance is Fe and unavoidable impurities.

[0033]

[0034]It can be seen from Table 1 that: (1) the composition design of the steel of the present invention is simple, low-silicon and low-manganese designs are adopted in order to reduce the cost of the alloy, and the design values of P and S content are moderately controlled under the premise of meeting the requirements for the use of steel. Industrial production control: through hot continuous rolling temperature control and cold rolling reducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com