Patents

Literature

67results about How to "Long heating time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System for and method of microwave annealing semiconductor material

ActiveUS20090184399A1Inhibited DiffusionLong heating timeSemiconductor/solid-state device manufacturingMicrowave heatingSusceptorSemiconductor materials

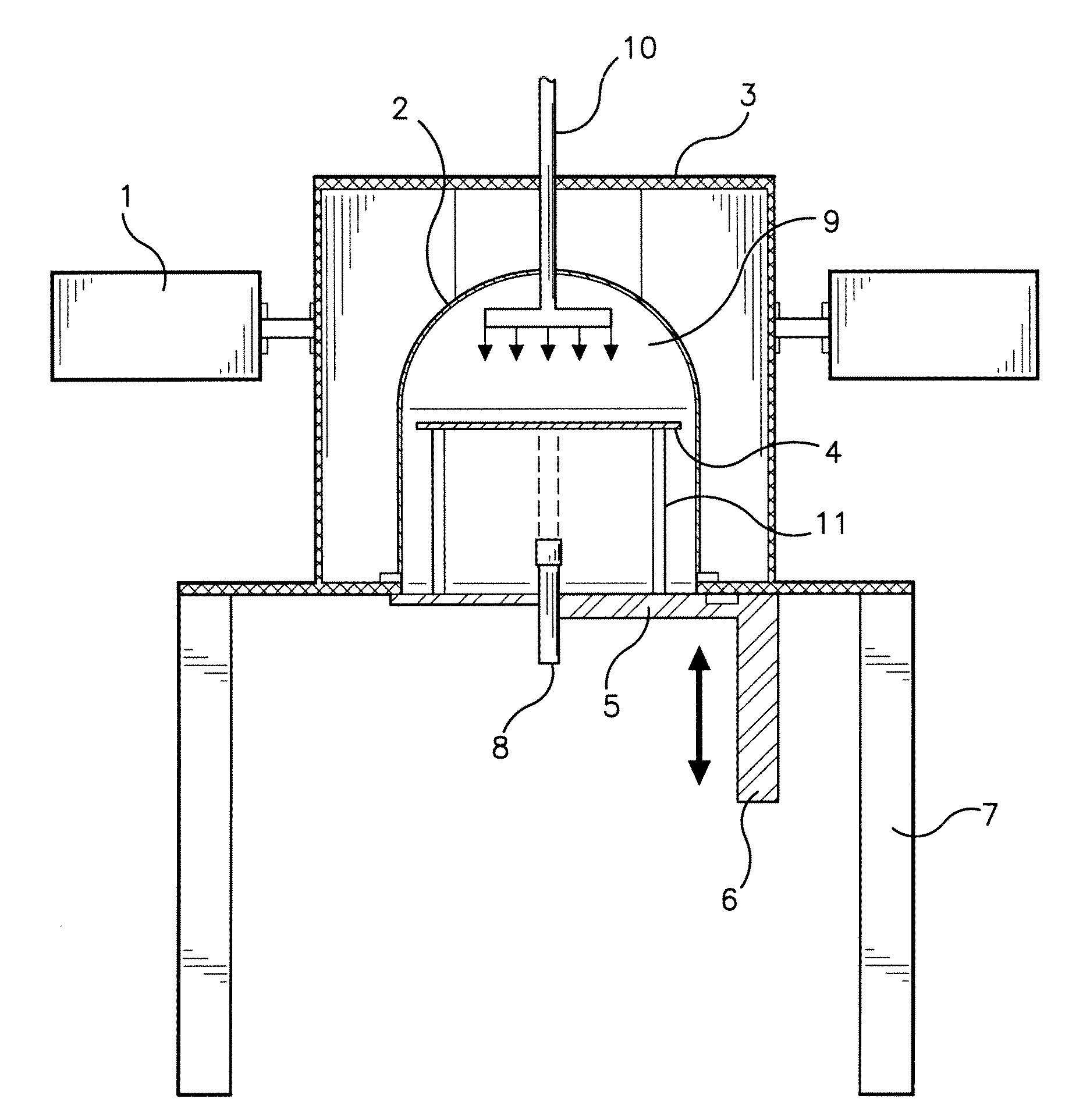

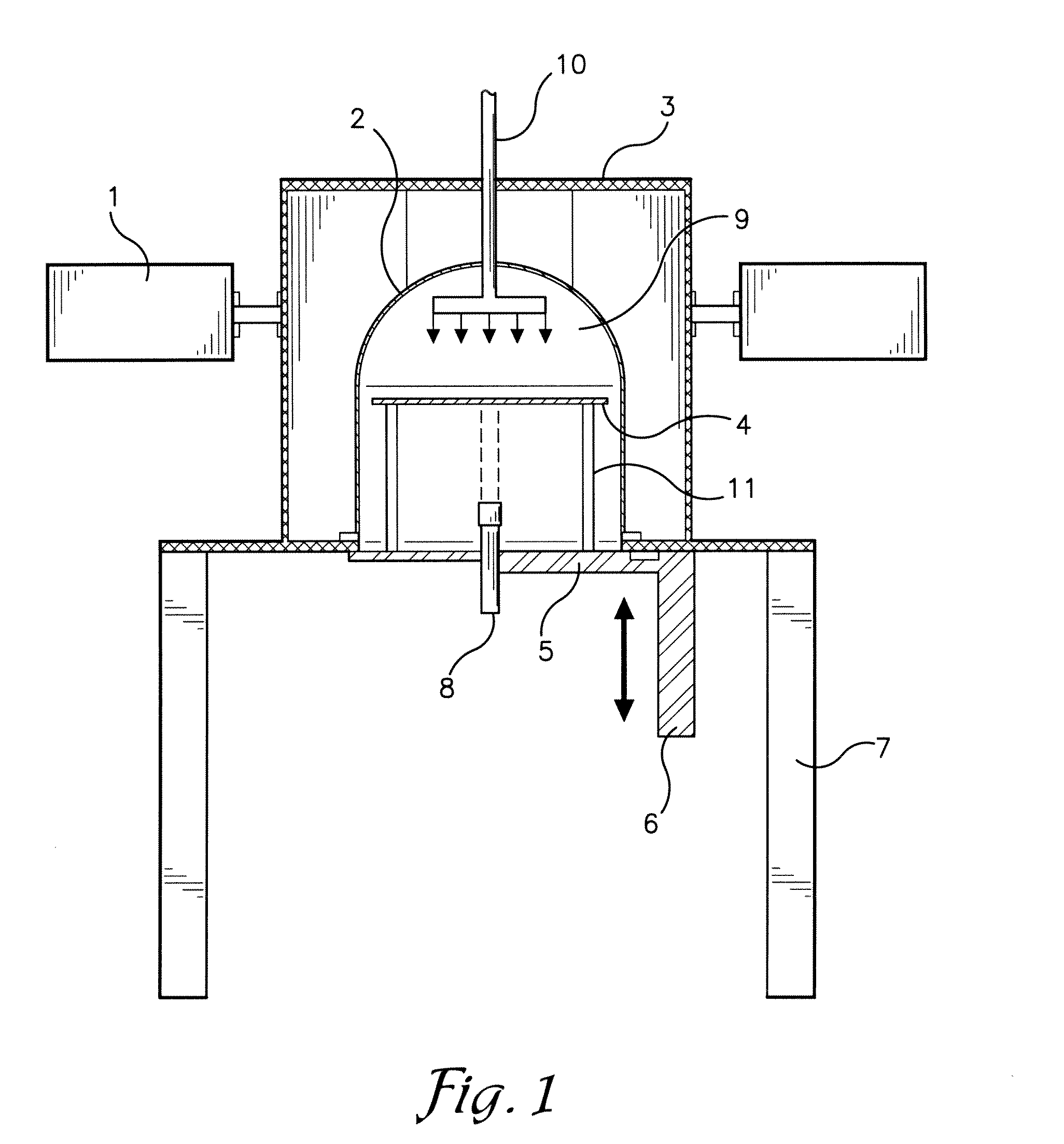

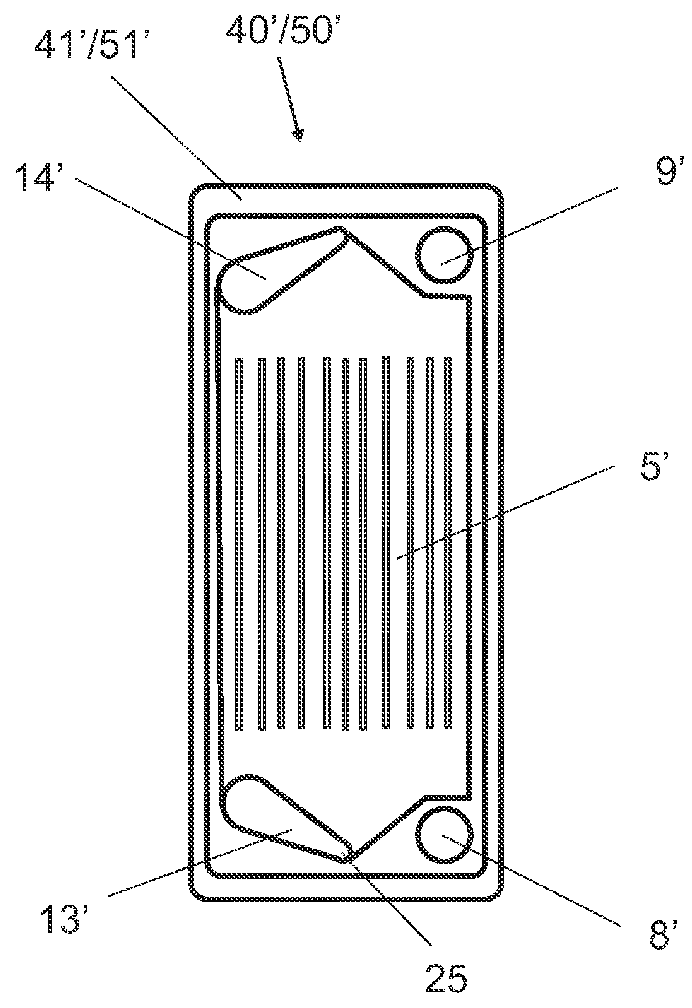

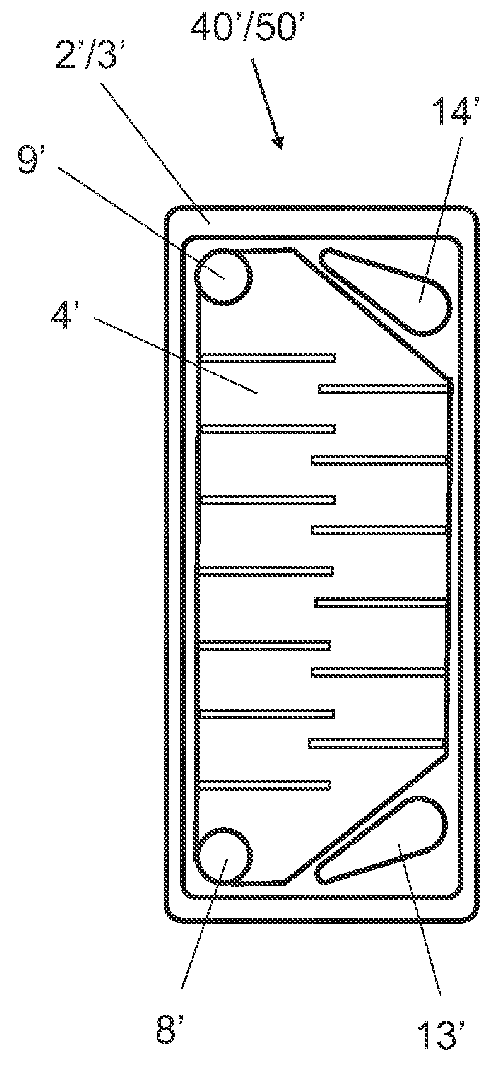

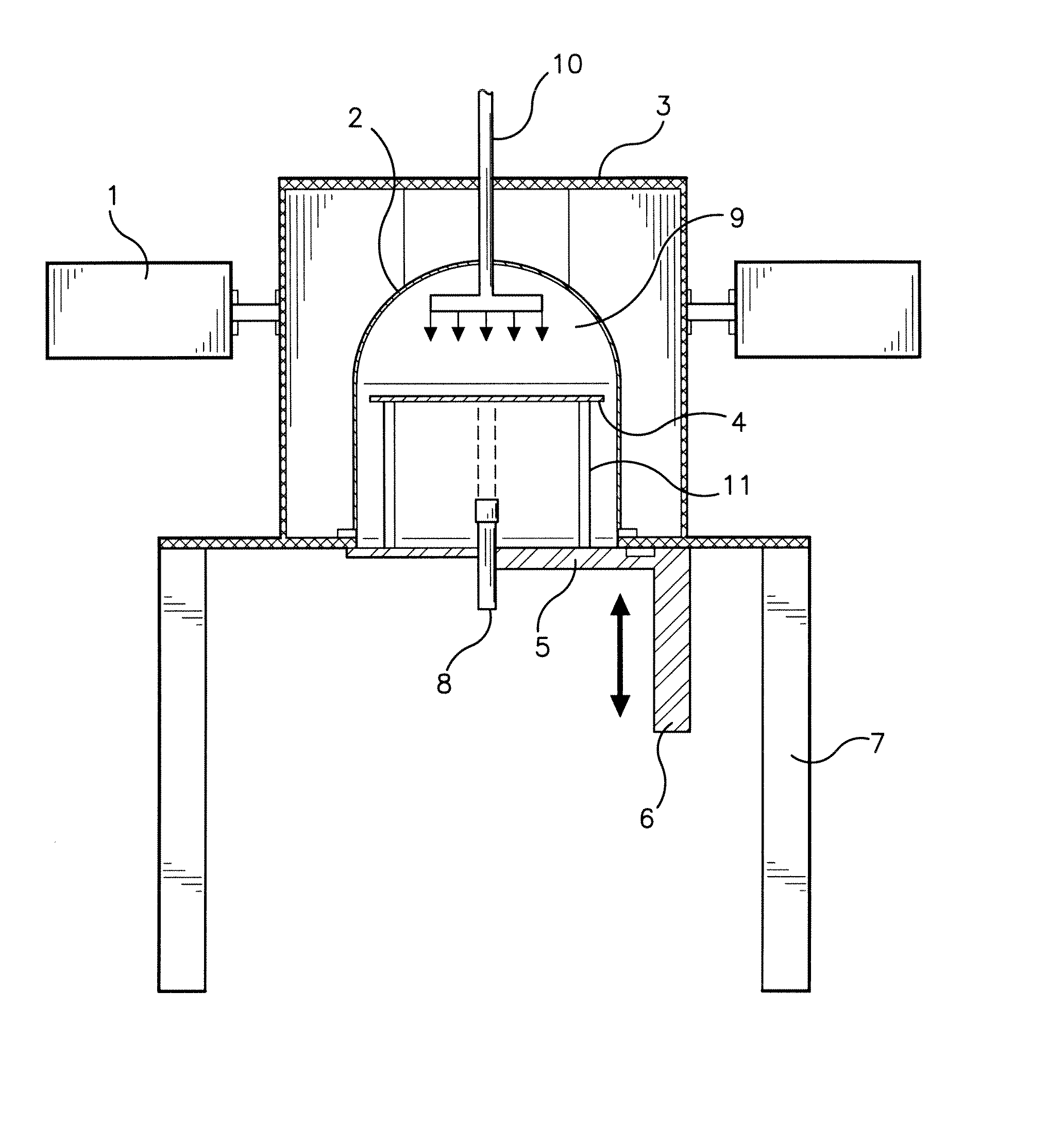

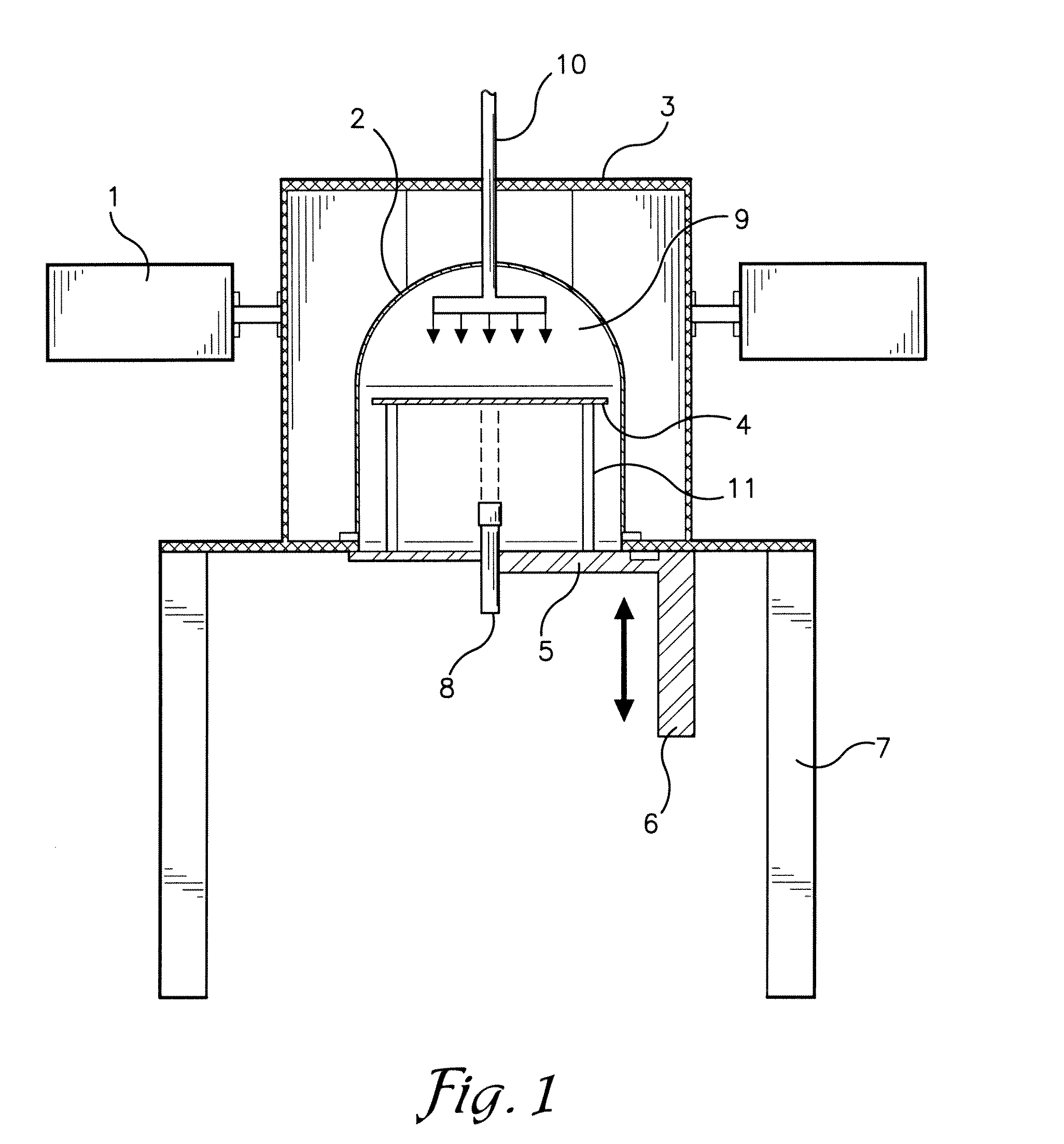

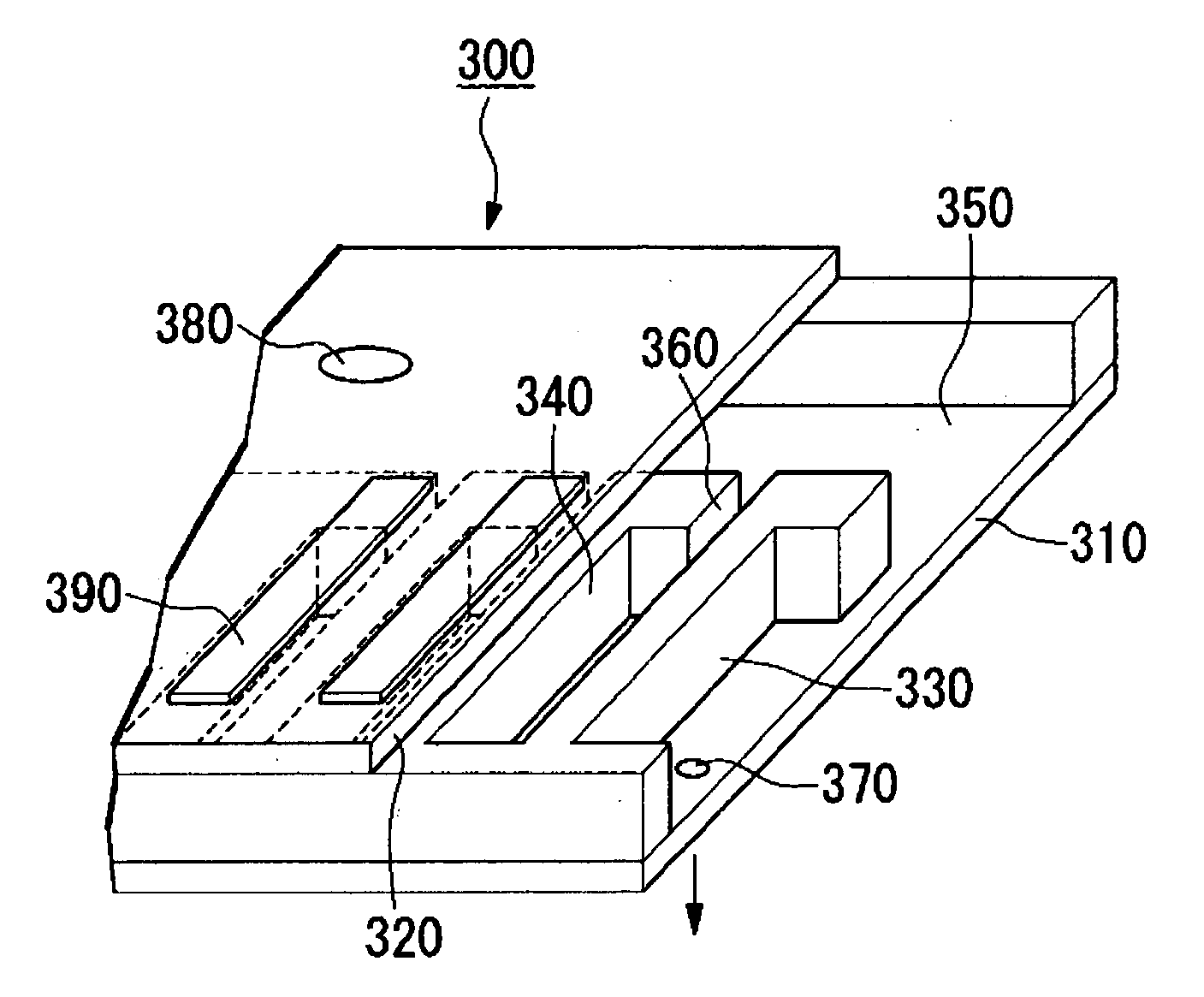

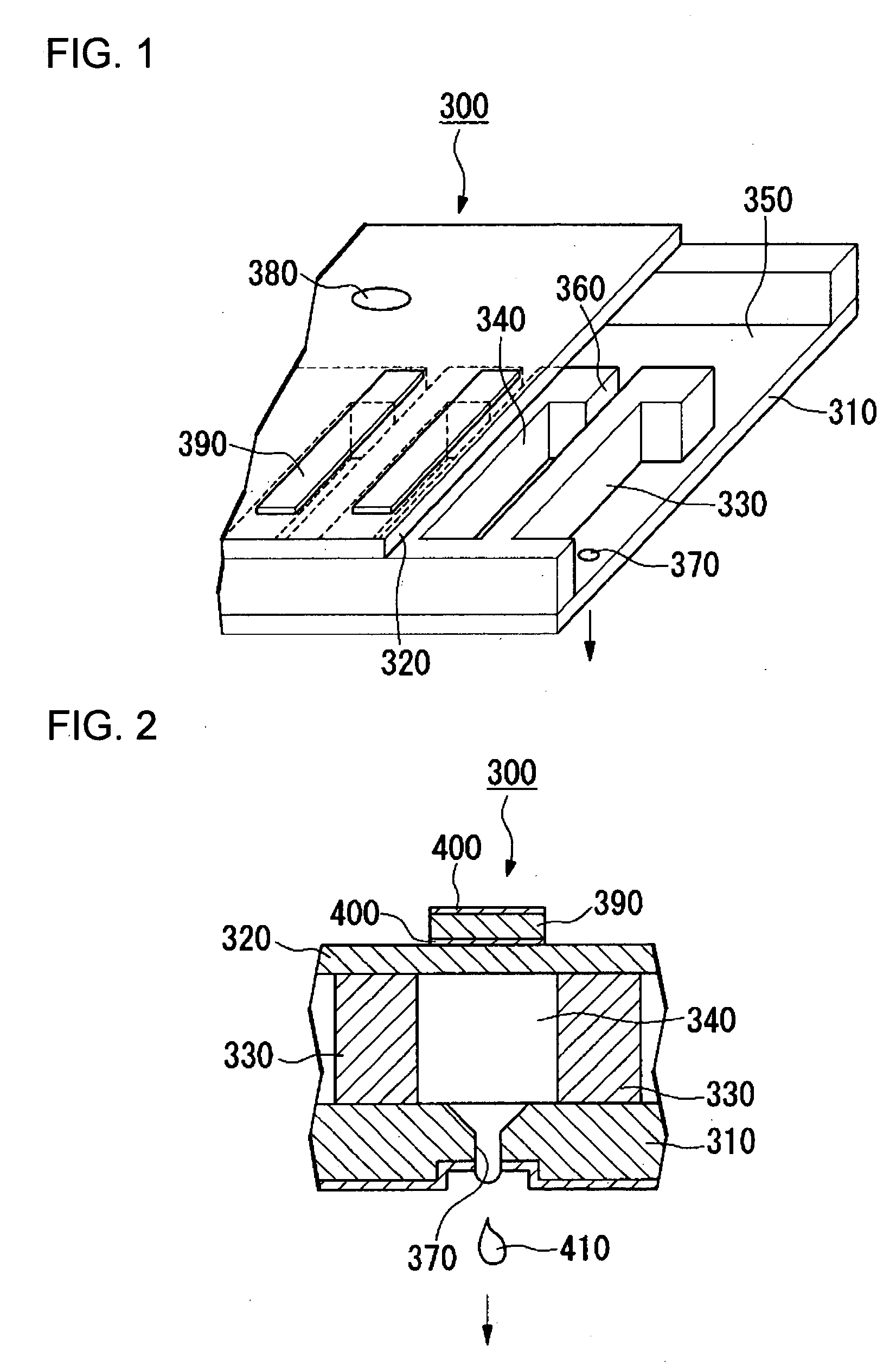

A system for and method of processing, i.e., annealing semiconductor materials. By controlling the time, frequency, variance of frequency, microwave power density, wafer boundary conditions, ambient conditions, and temperatures (including ramp rates), it is possible to repair localized damage lattices of the crystalline structure of a semiconductor material that may occur during the ion implantation of impurities into the material, electrically activate the implanted dopant, and substantially minimize further diffusion of the dopant into the silicon. The wafer boundary conditions may be controlled by utilizing susceptor plates (4) or a water chill plate (12). Ambient conditions may be controlled by gas injection (10) within the microwave chamber (3).

Owner:DSGI

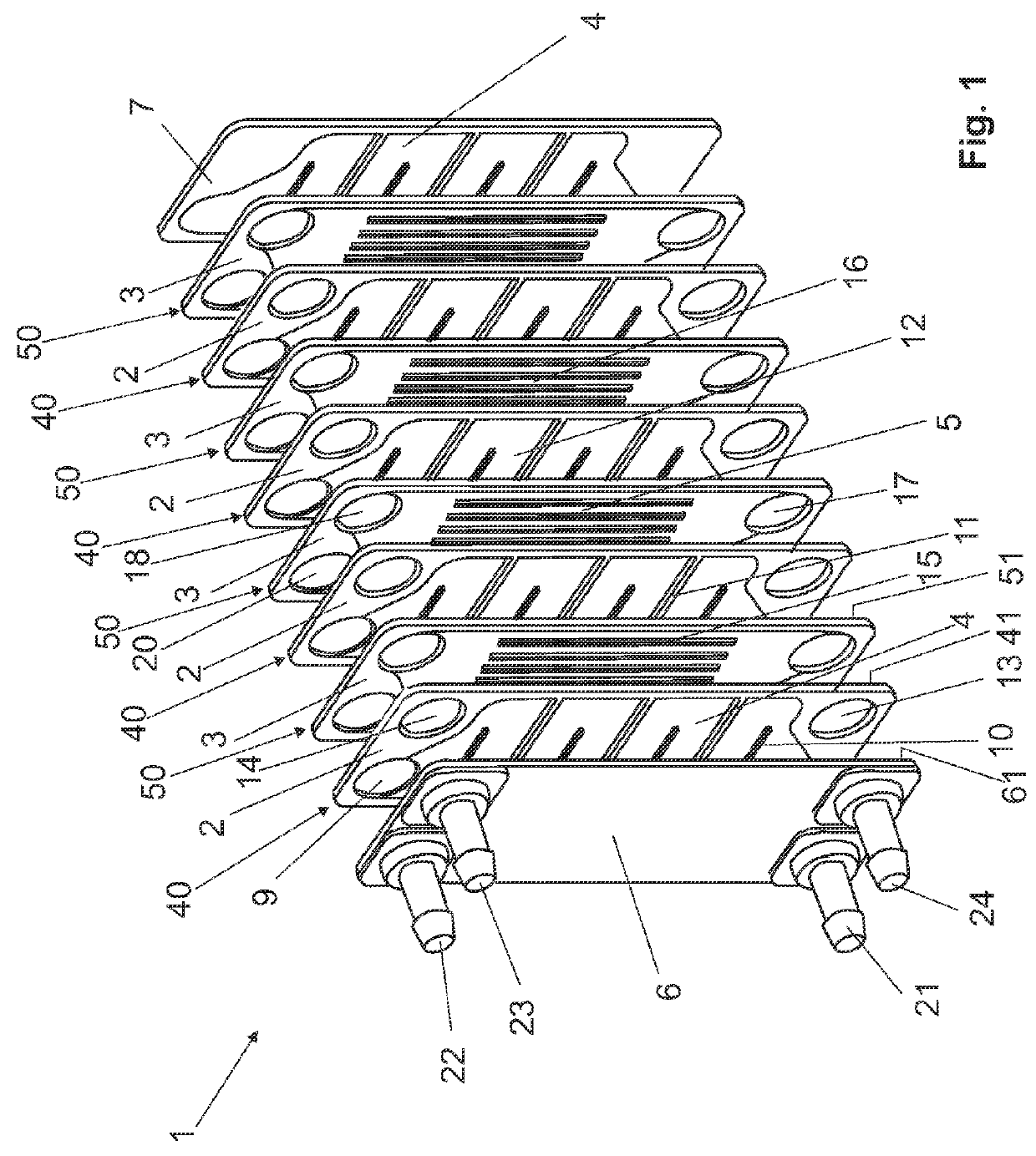

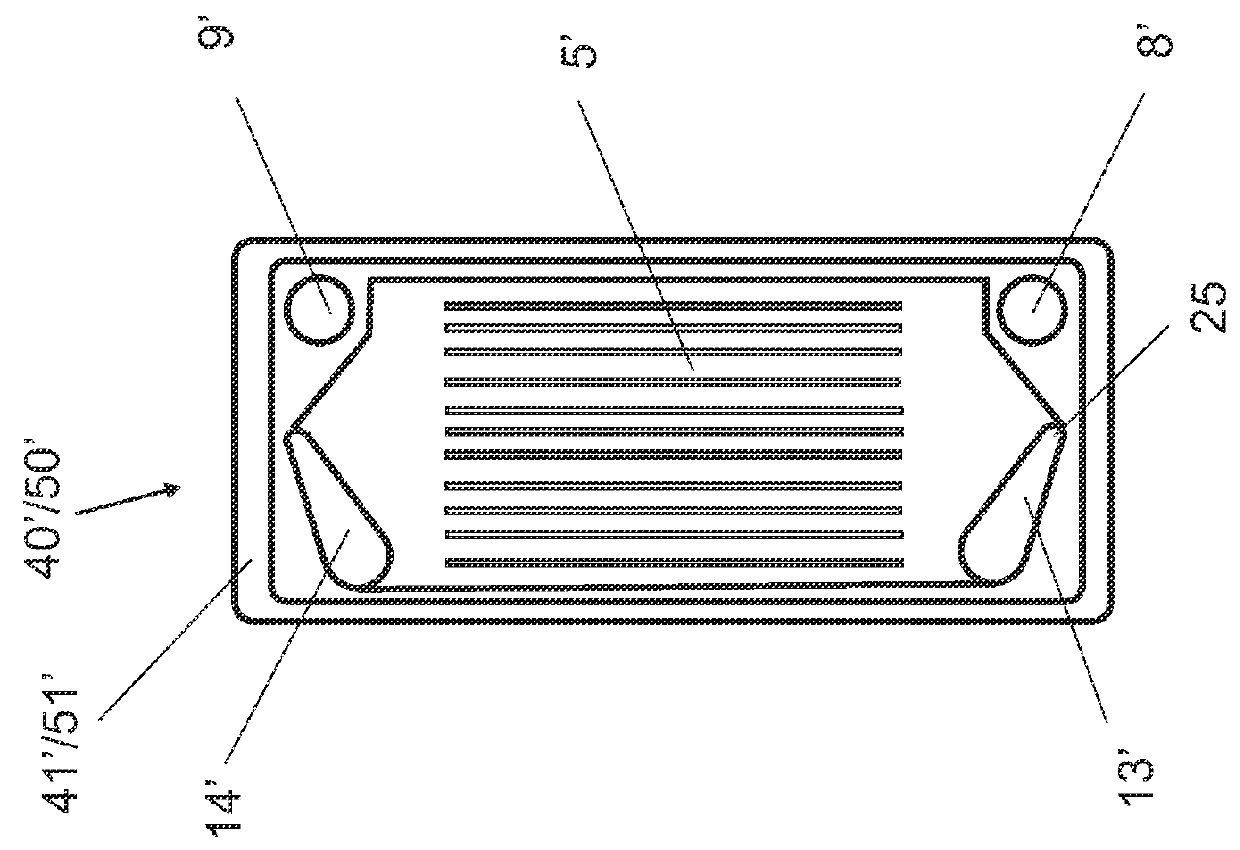

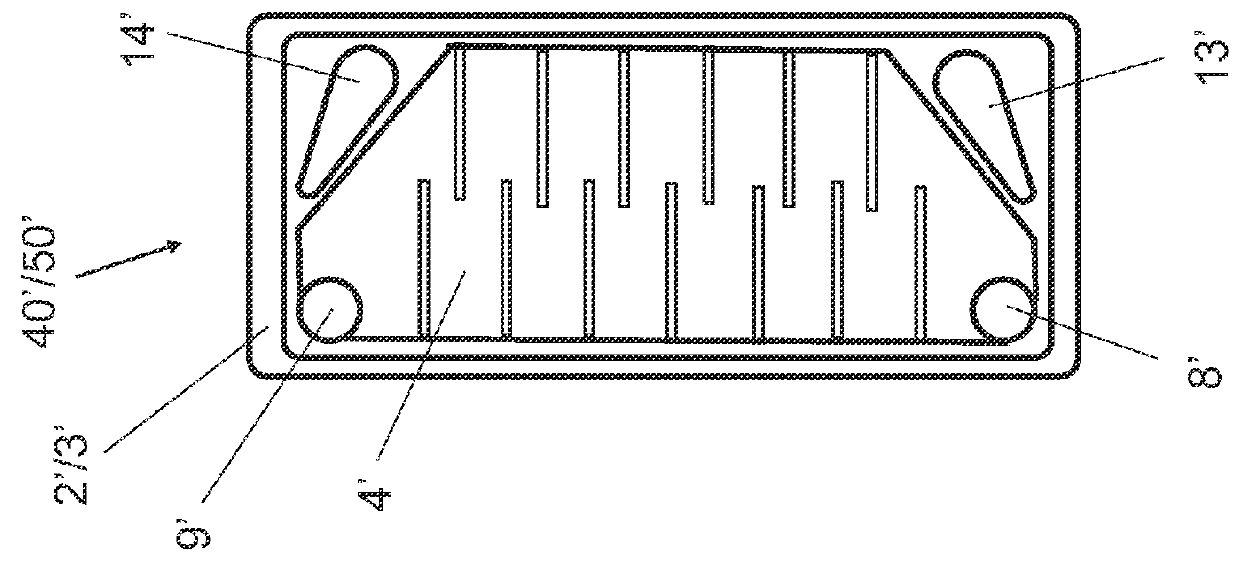

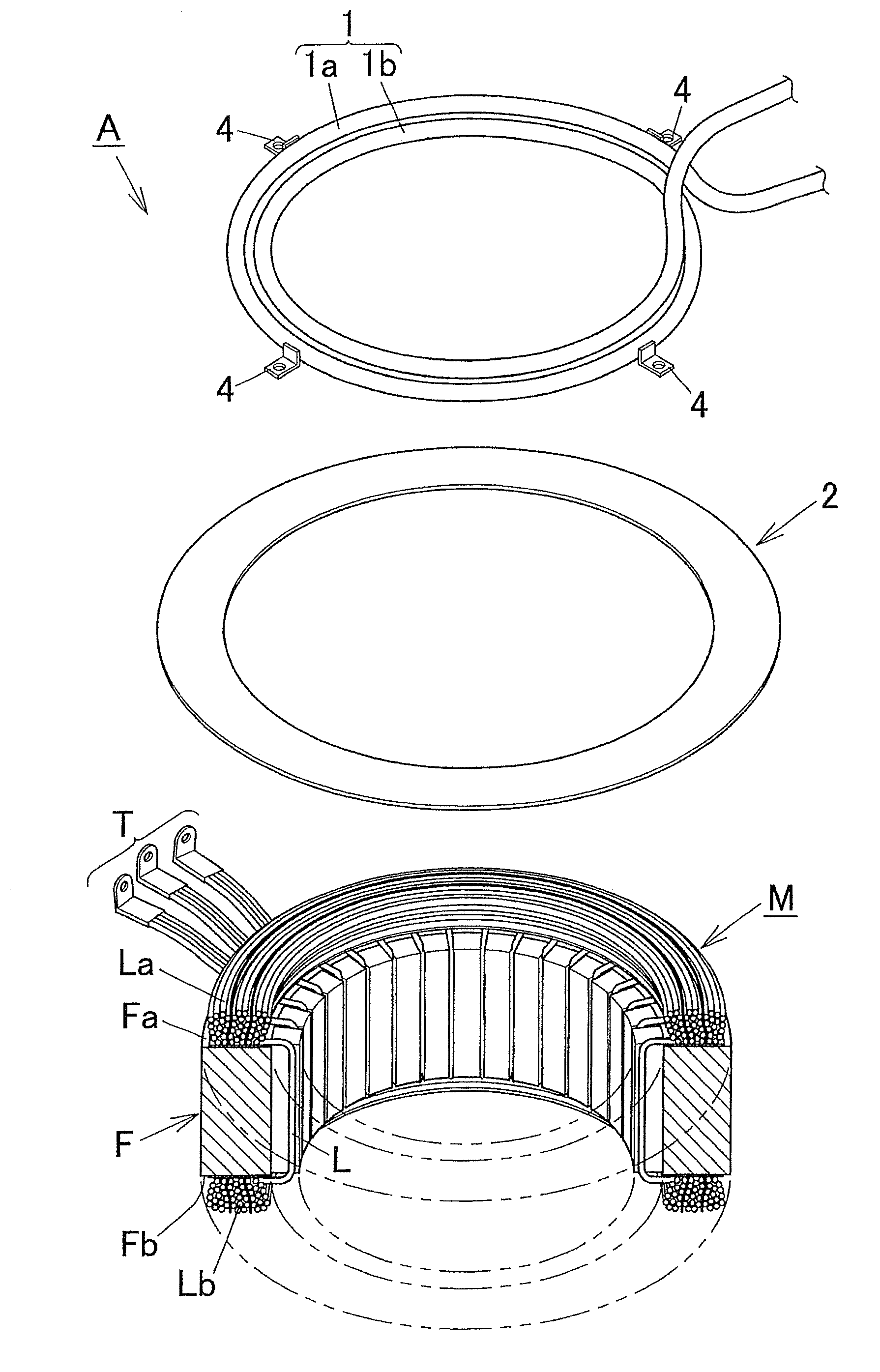

Plate heat exchanger

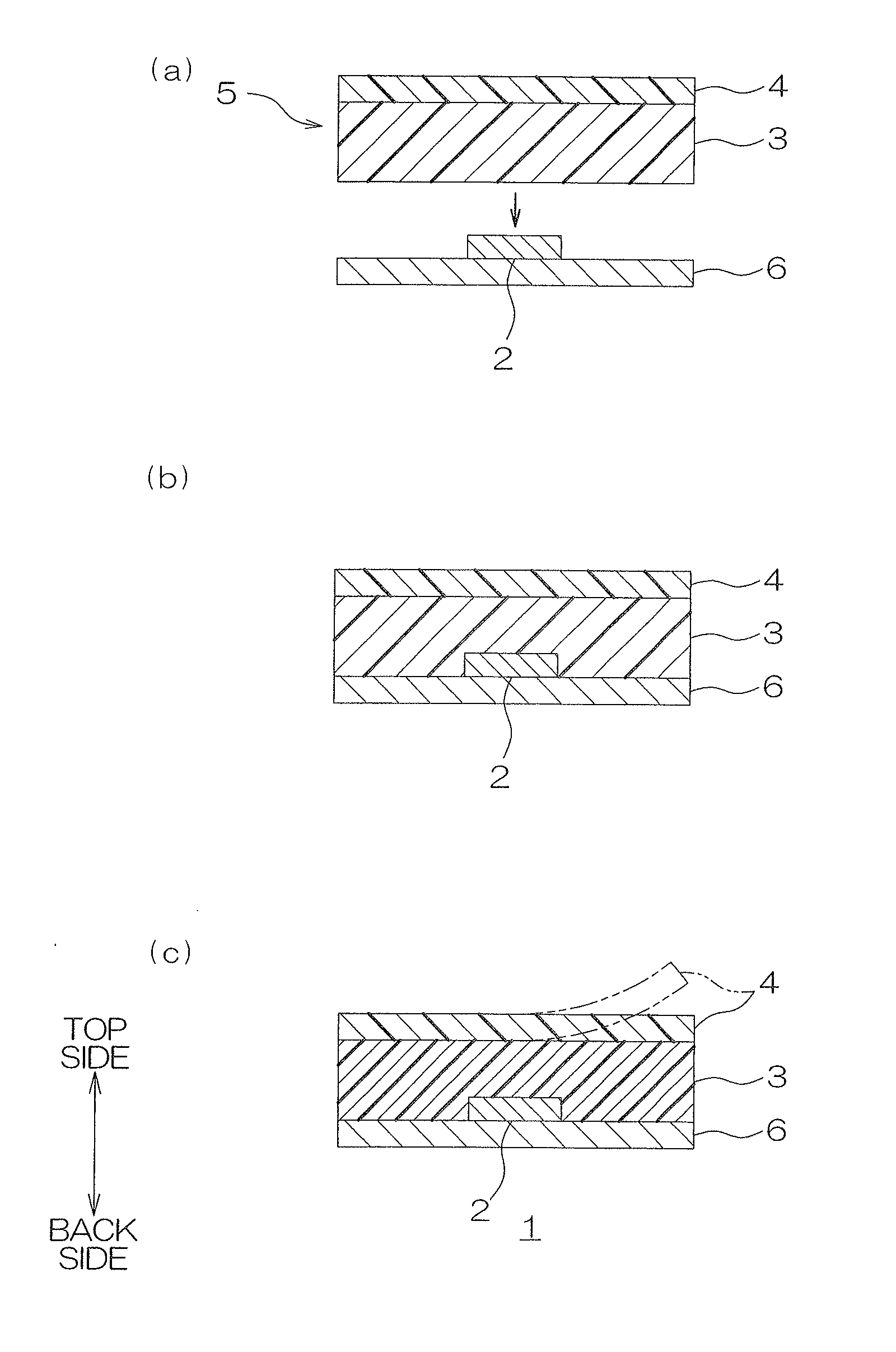

ActiveUS20120103579A1Easy to manufactureFacilitate heat exchangeIce removalMountingPlate heat exchangerEngineering

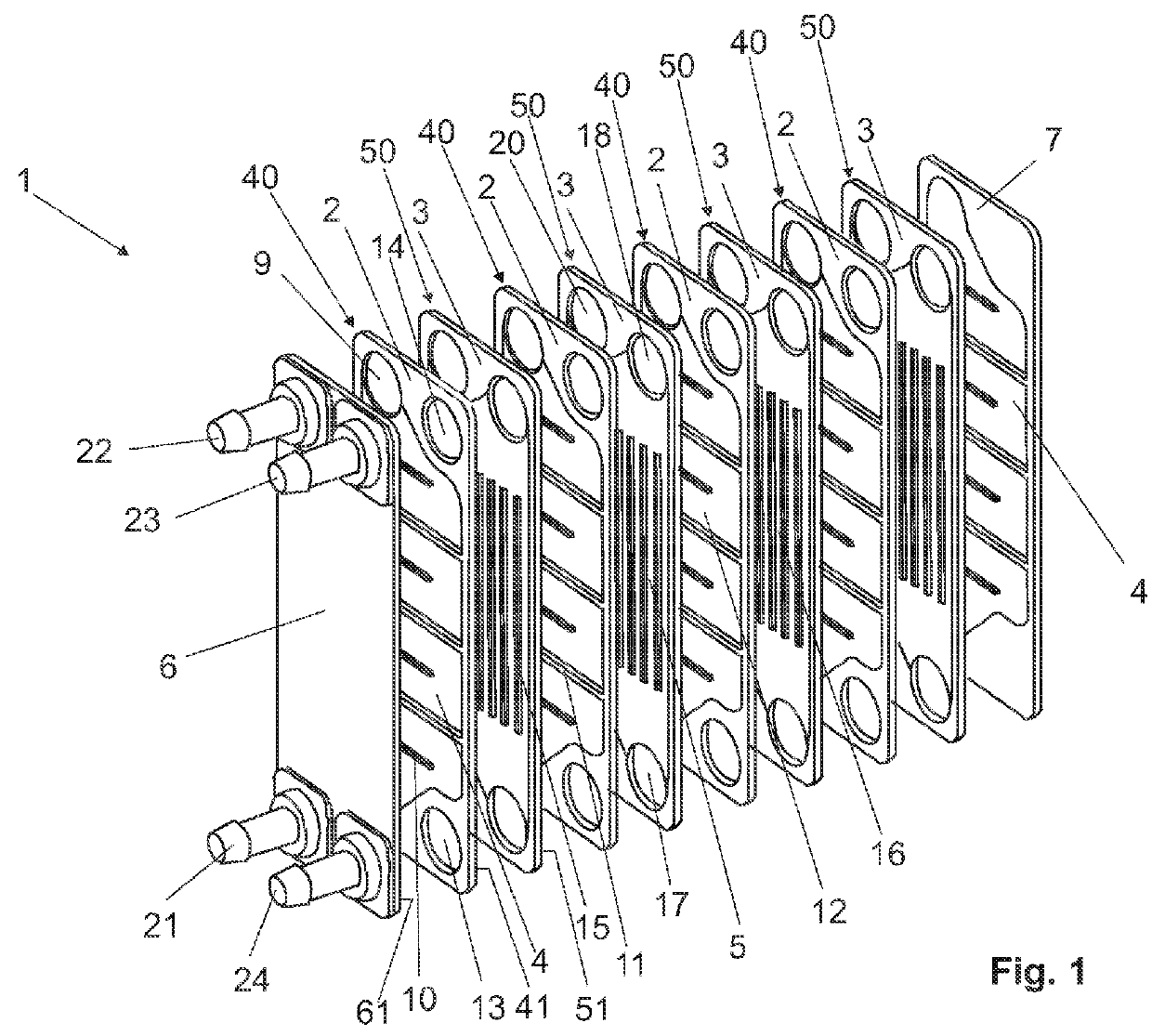

The invention relates to a plate heat exchanger comprising a plurality of plates having flow channels, wherein a first plate has a front side having at least one flow channel for a first fluid and a second plate has a front side having at least one flow channel for a second fluid, and wherein the plates have through openings via which the flow channels for the same fluid are respectively connected to one another, wherein a front plate, which is placed in front of the front side of the first plate, has ports for the first fluid and for the second fluid, wherein an end plate forms the end of the aligned plates, wherein the plates and ports are formed from plastic, and wherein the plates are bonded or welded tightly together.

Owner:SARTORIUS STEDIM BIOTECH GMBH

System for and method of microwave annealing semiconductor material

ActiveUS7928021B2Inhibited DiffusionLong heating timeSemiconductor/solid-state device manufacturingElectricityDopant

A system for and method of processing, i.e., annealing semiconductor materials. By controlling the time, frequency, variance of frequency, microwave power density, wafer boundary conditions, ambient conditions, and temperatures (including ramp rates), it is possible to repair localized damage lattices of the crystalline structure of a semiconductor material that may occur during the ion implantation of impurities into the material, electrically activate the implanted dopant, and substantially minimize further diffusion of the dopant into the silicon. The wafer boundary conditions may be controlled by utilizing susceptor plates (4) or a water chill plate (12). Ambient conditions may be controlled by gas injection (10) within the microwave chamber (3).

Owner:DSGI

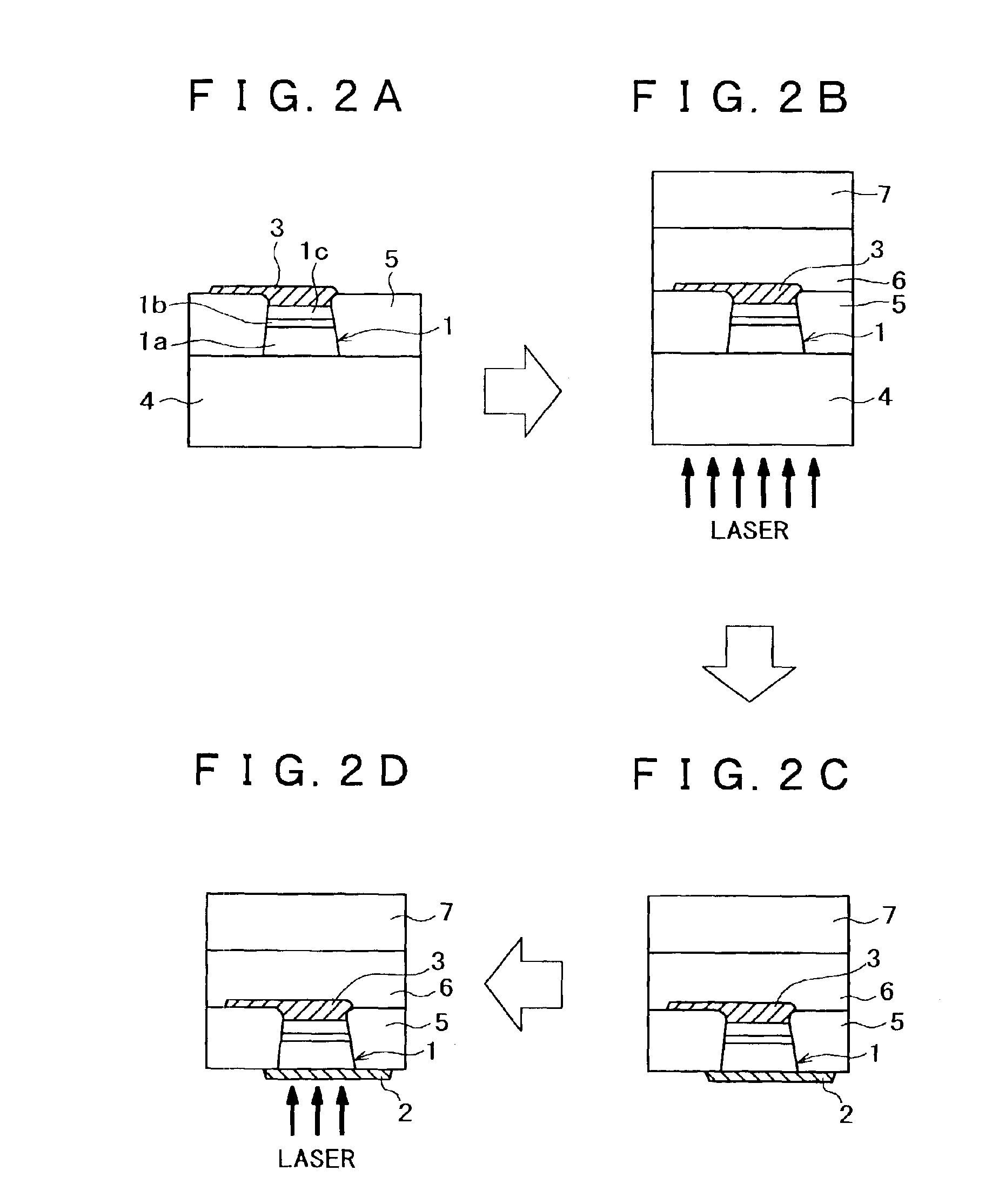

Alloying method, and wiring forming method, display device forming method, and image unit fabricating method

InactiveUS20050176190A1Without degrading characteristicImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingDevice materialDisplay device

Owner:SONY CORP

Clean pulping technology for high-polymerization-degree bamboo pulp

InactiveCN103382671ASolve difficult governance problemsReduce shockPretreatment with alkaline reacting compoundsPulp de-wateringMaterials preparationDissolving pulp

The invention belongs to the field of paper pulp manufacturing and particularly relates to a method for utilizing a bamboo raw material to produce high-polymerization-degree dissolving pulp. The method is characterized by comprising the steps of material preparation, prehydrolysis, hot alkali extraction, alkaline method cooking, oxygen bleaching, bleaching and acid treatment and the like, and the clean pulping method for the high-polymerization-degree bamboo pulp solves the problems that existing production raw materials for the high-polymerization-degree dissolving pulp is sufficient, the technology falls behind, and pollution is severe, and the like. The polymerization degree of the manufactured bleached bamboo pulp is over 2000, the whiteness is over (90+ / -2)%ISO, a-cellulose is over 96%, the ash content is below 0.1%, the Fe ion is below 20ppm, S18 is below 3%, S10 is below 4%, and (S10-S18) is below 2%.

Owner:SICHUAN KANGQI BIOTECH CO LTD

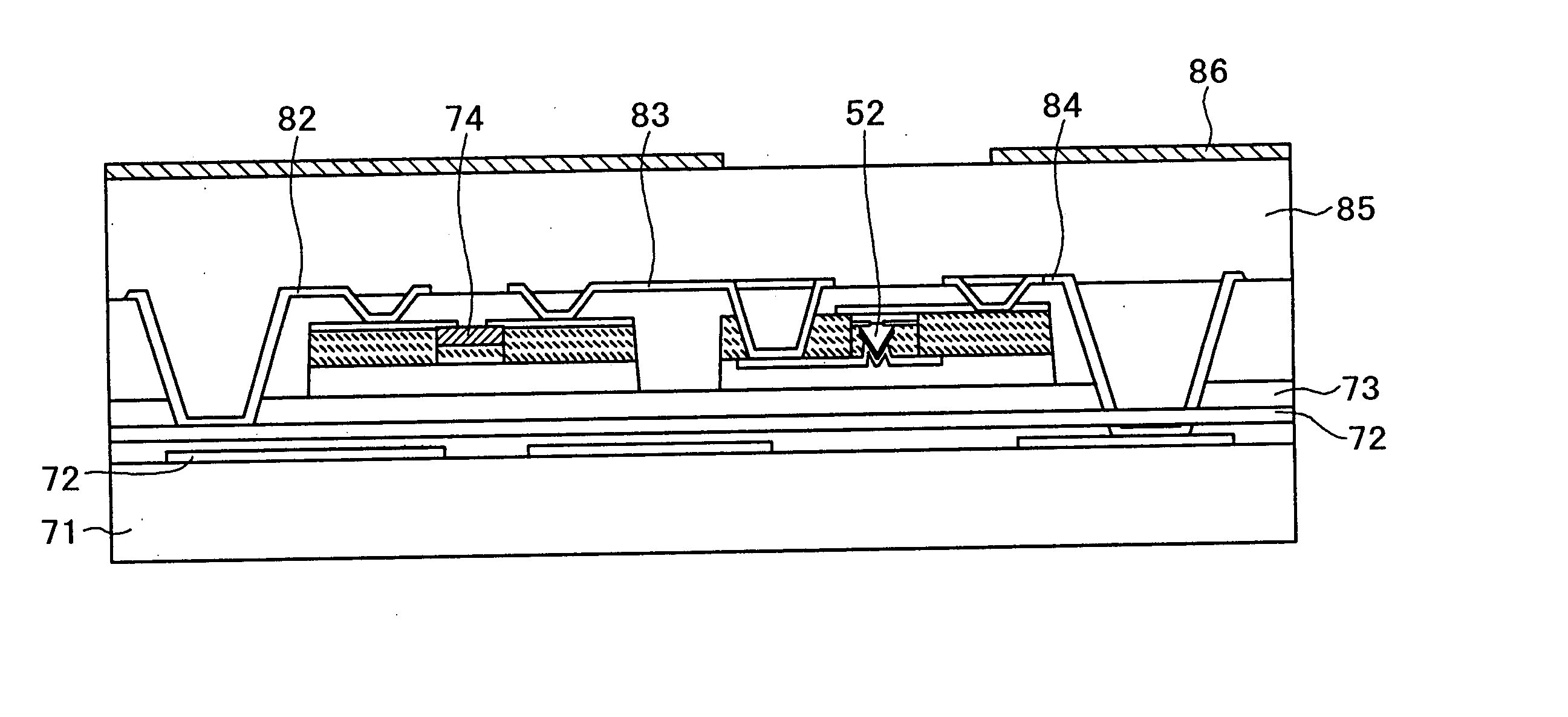

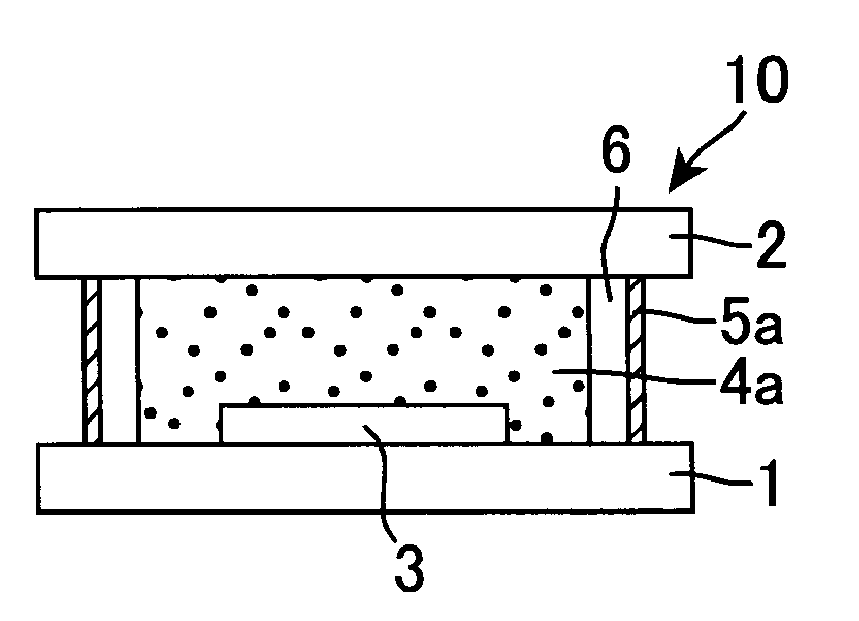

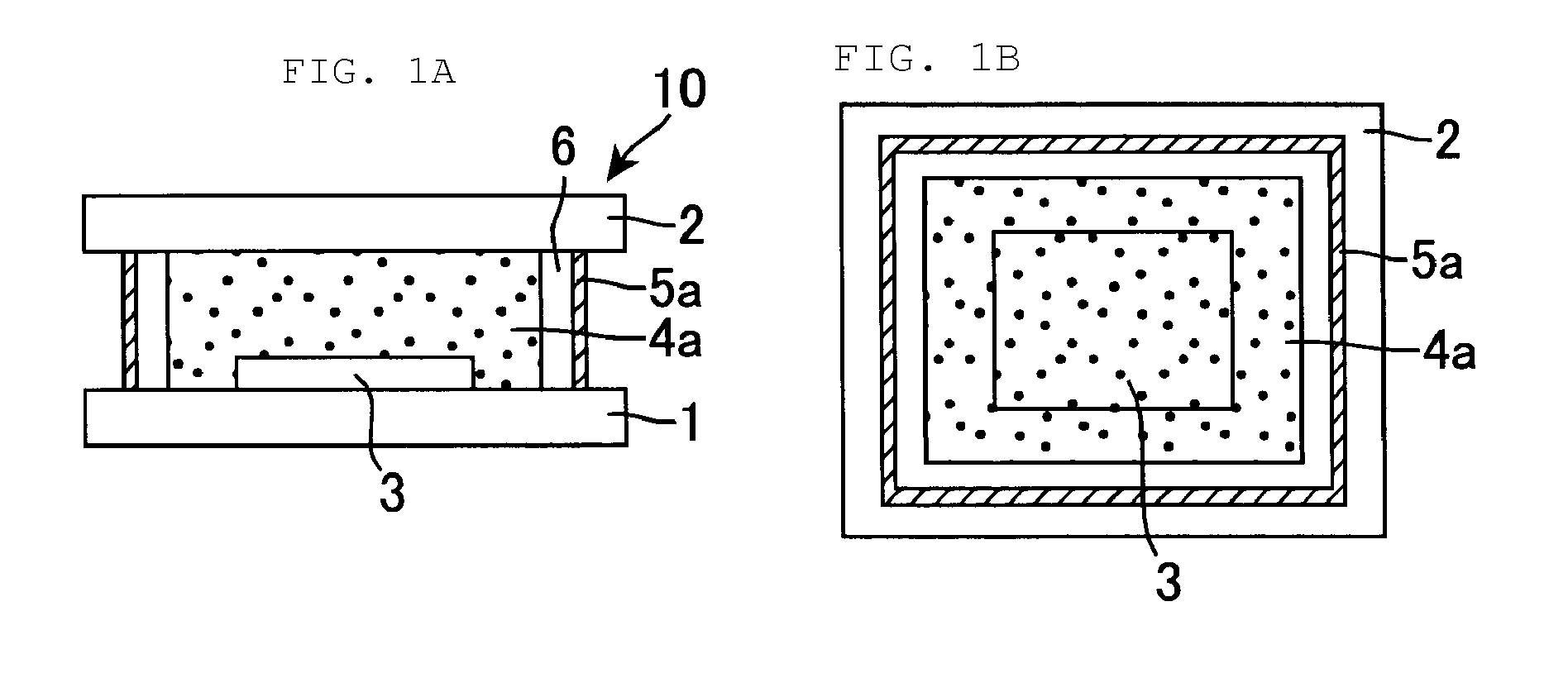

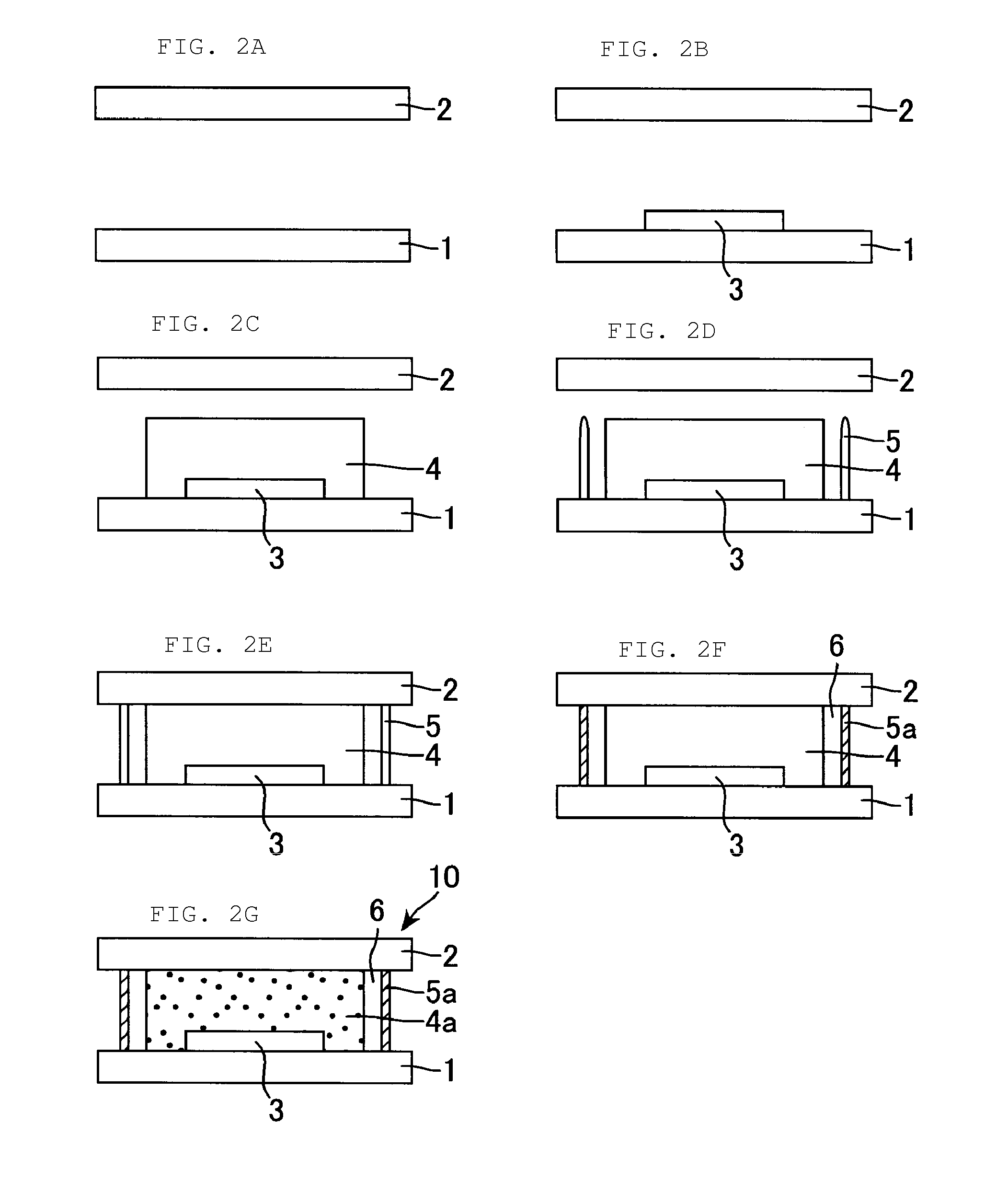

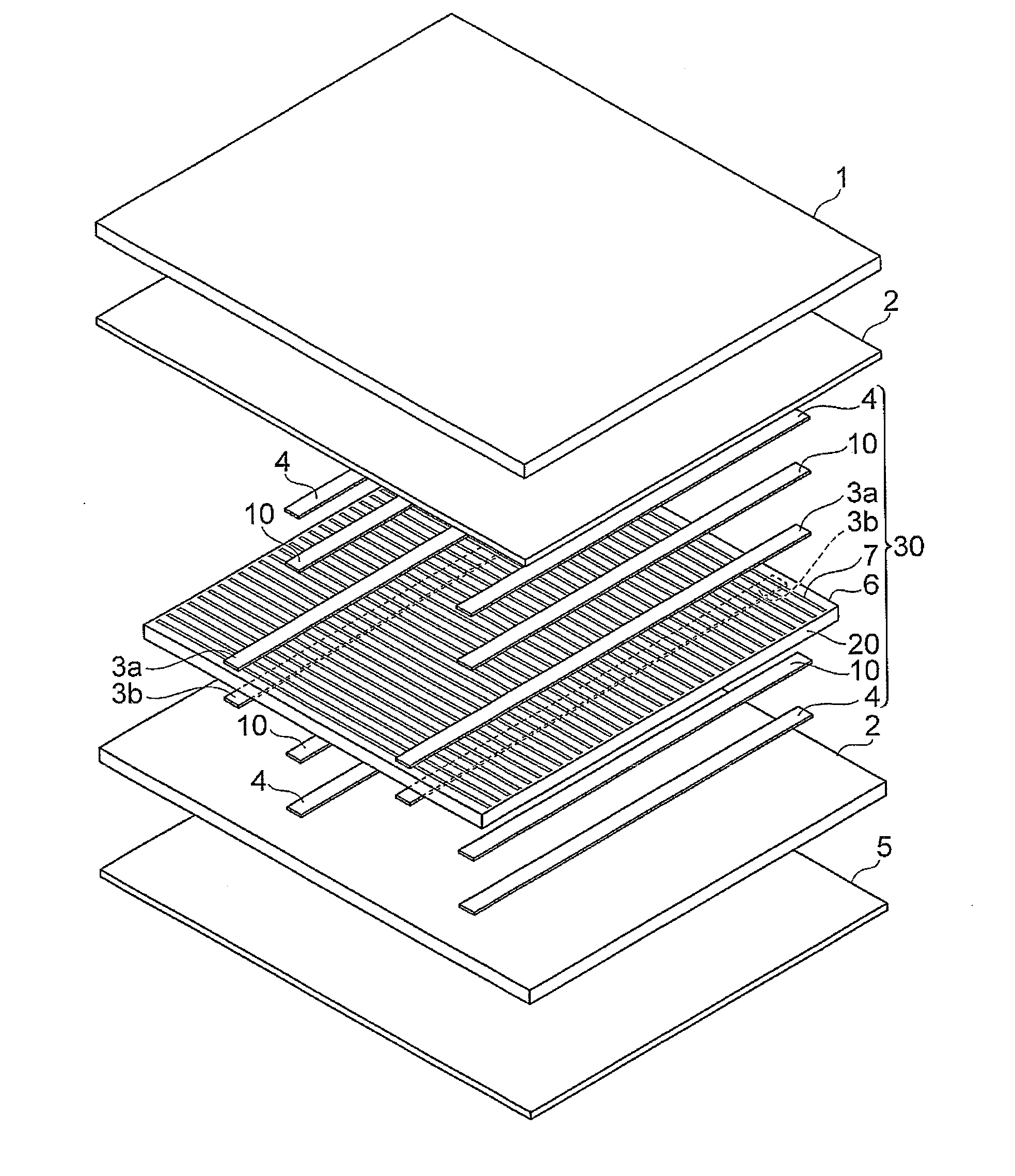

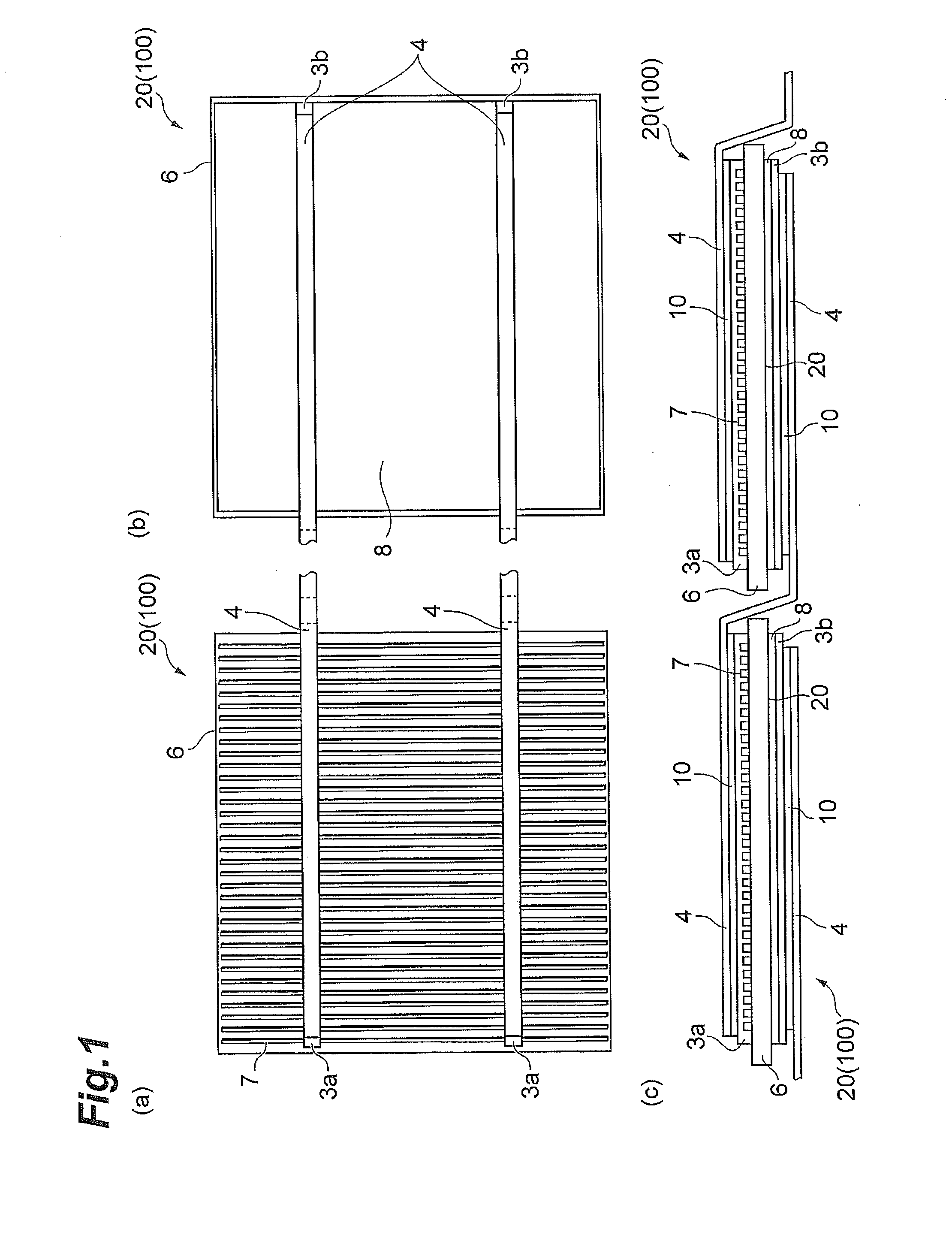

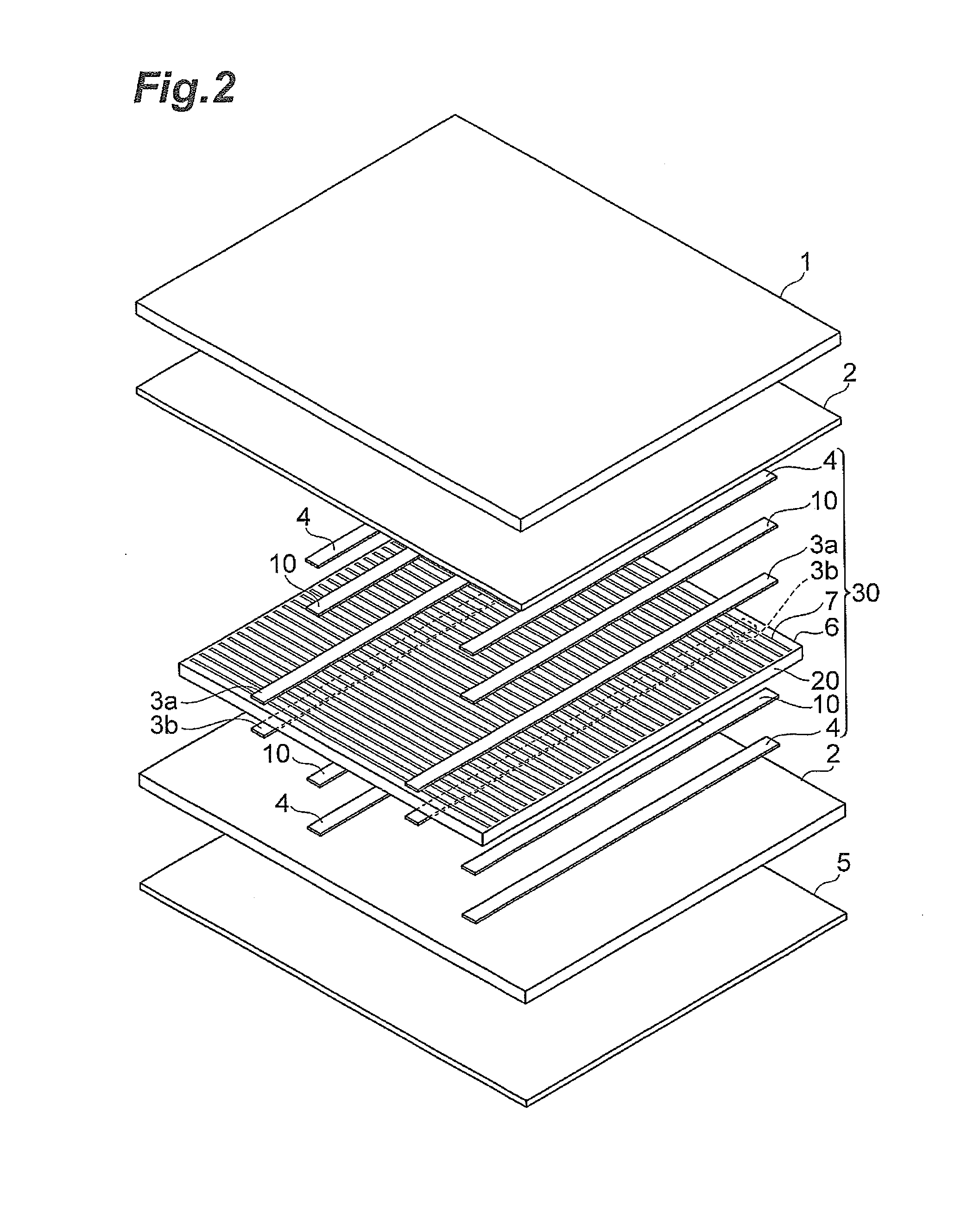

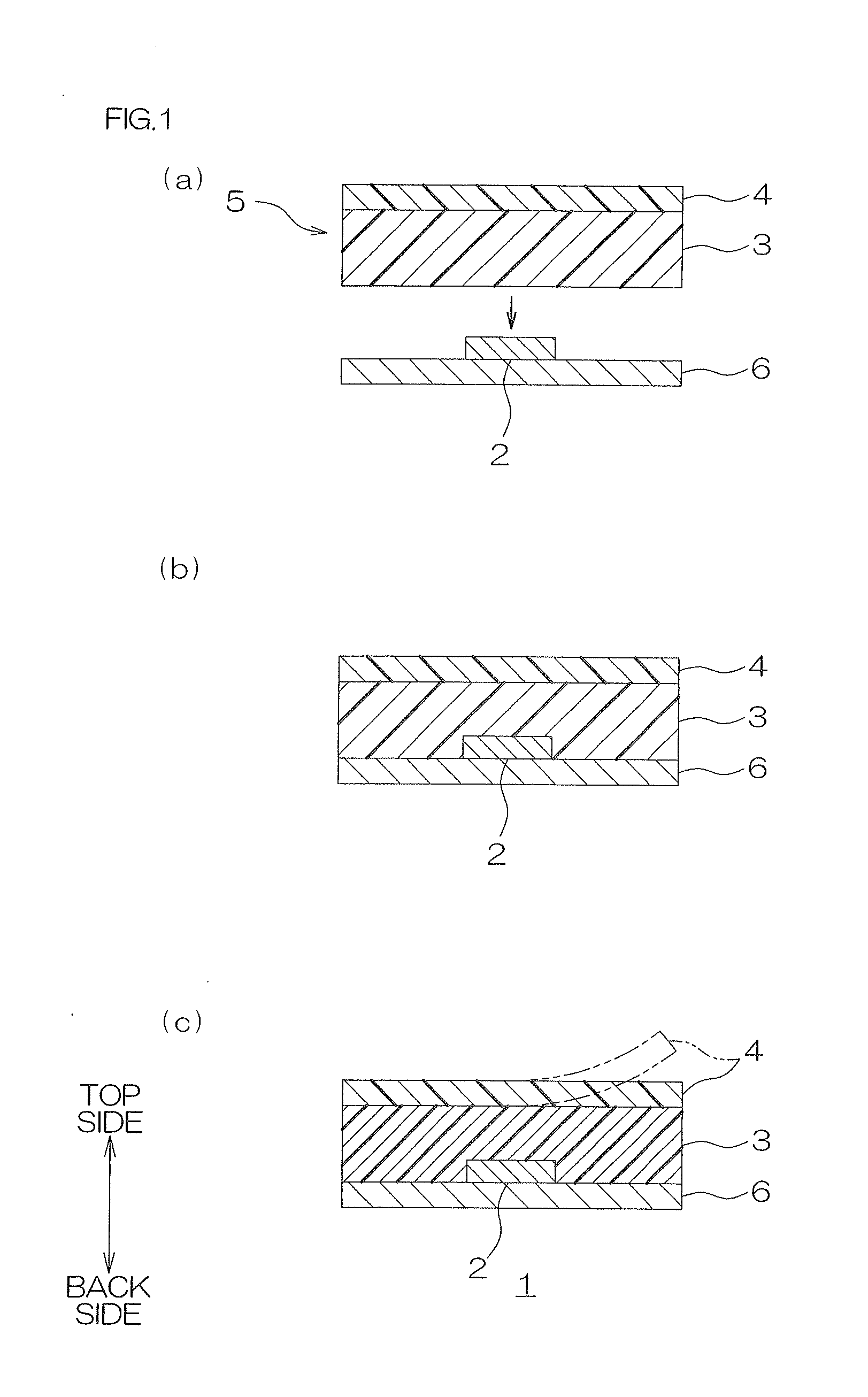

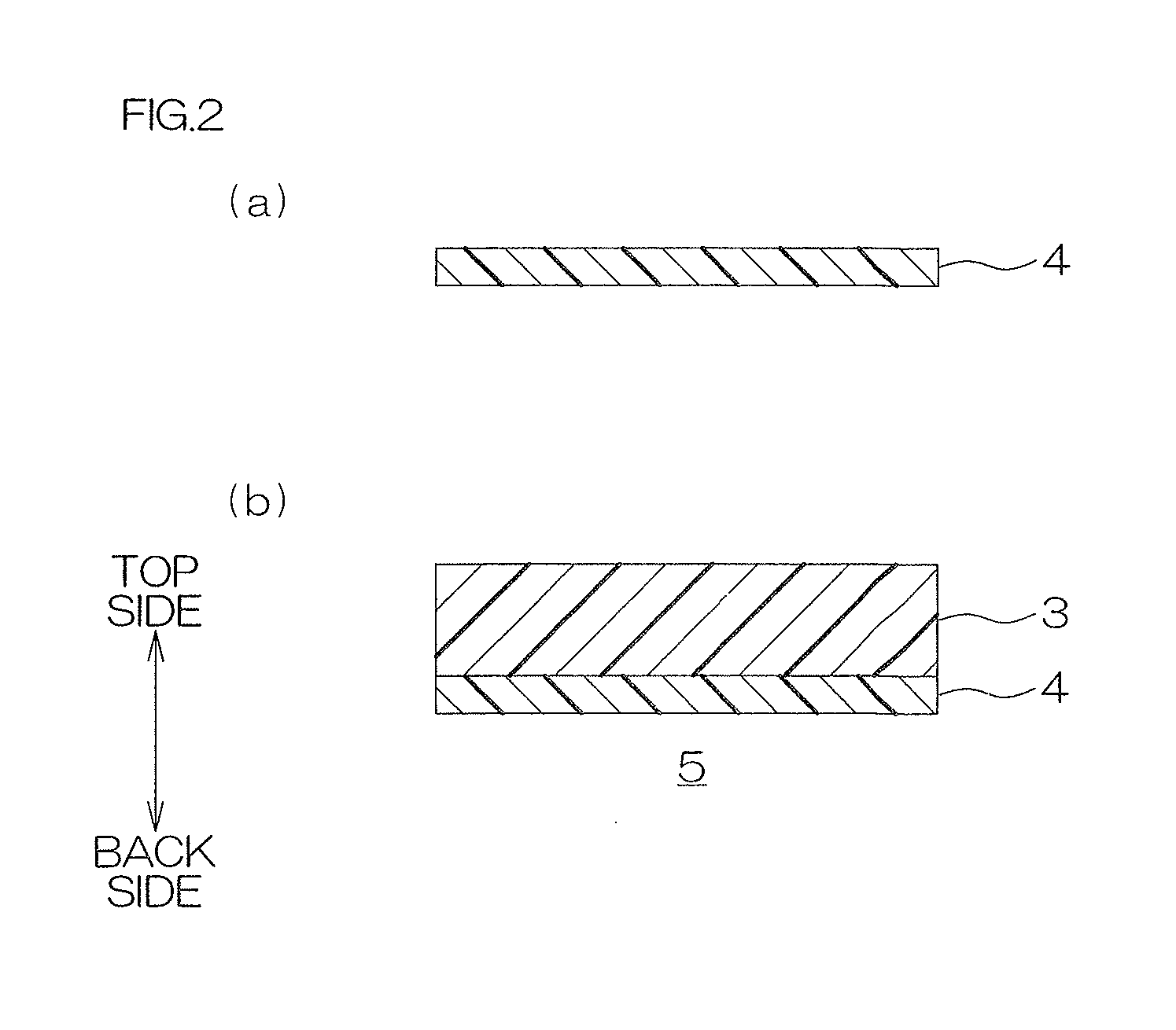

Organic electroluminescent panel, organic electroluminescent display, organic electroluminescent lighting device, and production methods thereof

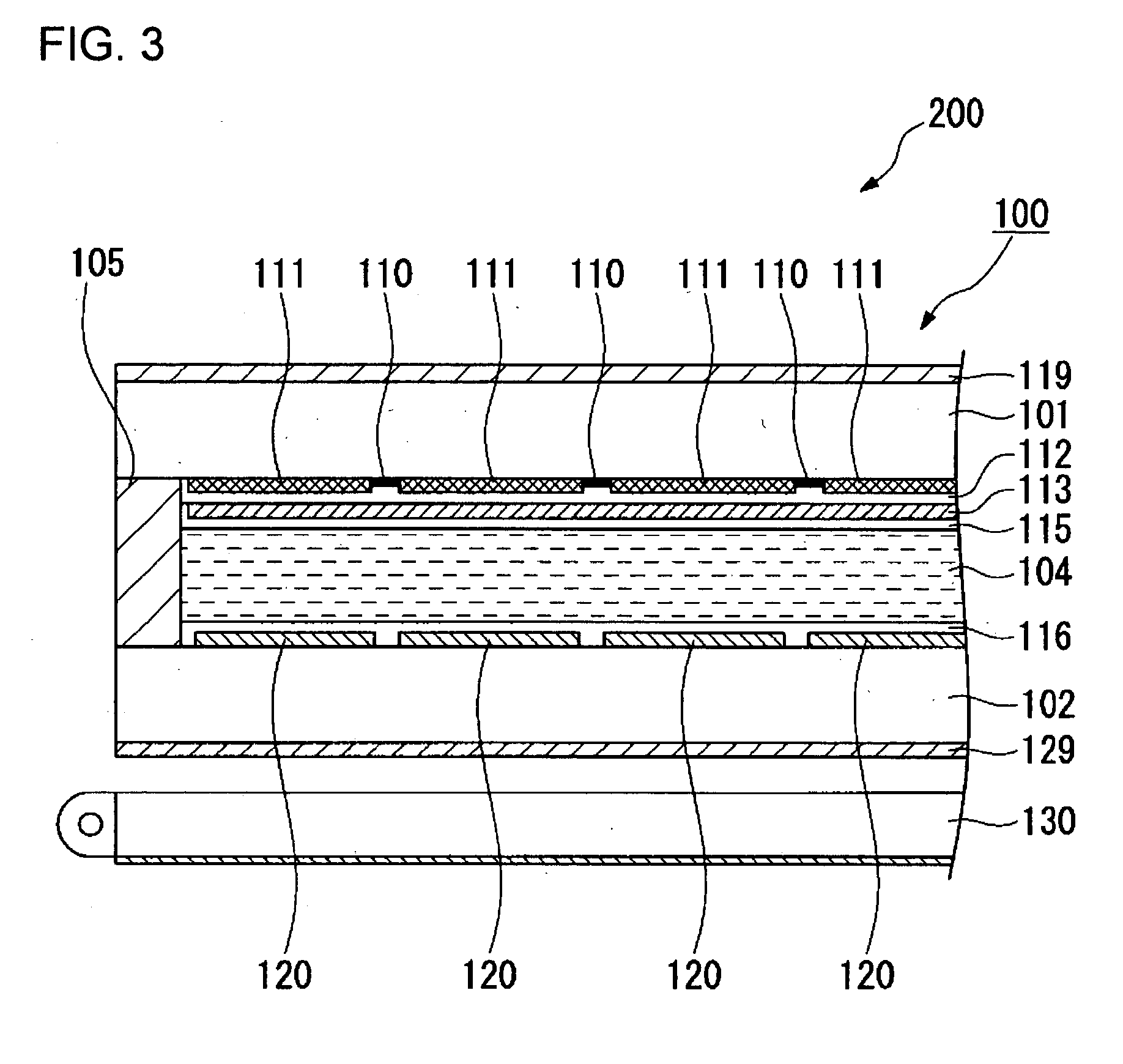

ActiveUS20100090596A1Shorten heating timeShorten takt timeDischarge tube luminescnet screensLamp detailsEngineeringOrganic electroluminescence

An organic electroluminescent panel, an organic electroluminescent display, an organic electroluminescent lighting device, each include an organic electroluminescent element that maintains stable light emission characteristics for a long period of time. The organic electroluminescent panel includes an element substrate; a sealing substrate facing the element substrate; and an organic electroluminescent element disposed on a sealing substrate side of the element substrate, wherein the organic electroluminescent panel further includes a first sealing member and a second sealing member, the first sealing member sealing a gap between the element substrate and the sealing substrate, the second sealing member covering the organic electroluminescent element, the first sealing member and the second sealing member being arranged with a space therebetween, the space is in a vacuum or reduced pressure state.

Owner:SHARP KK

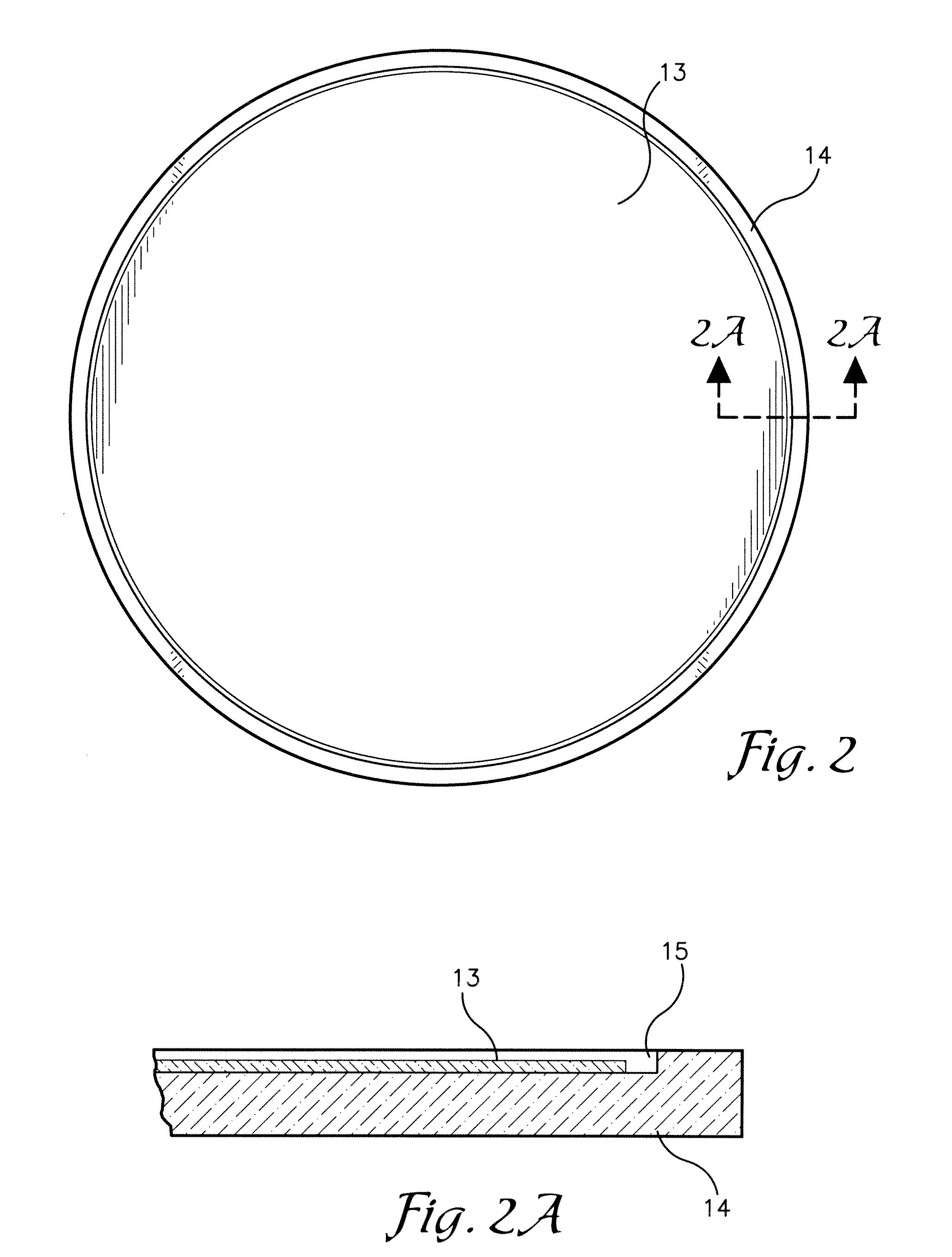

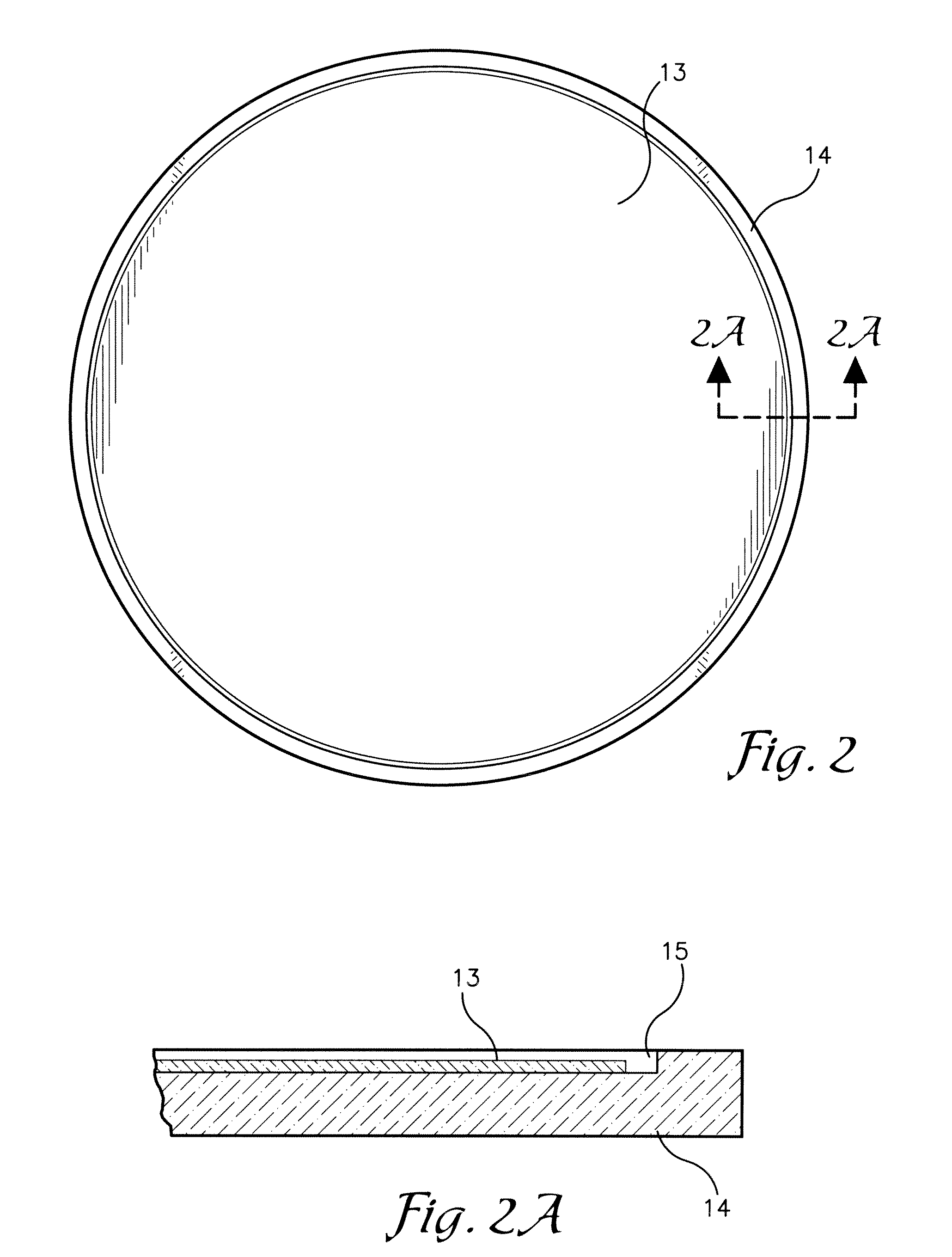

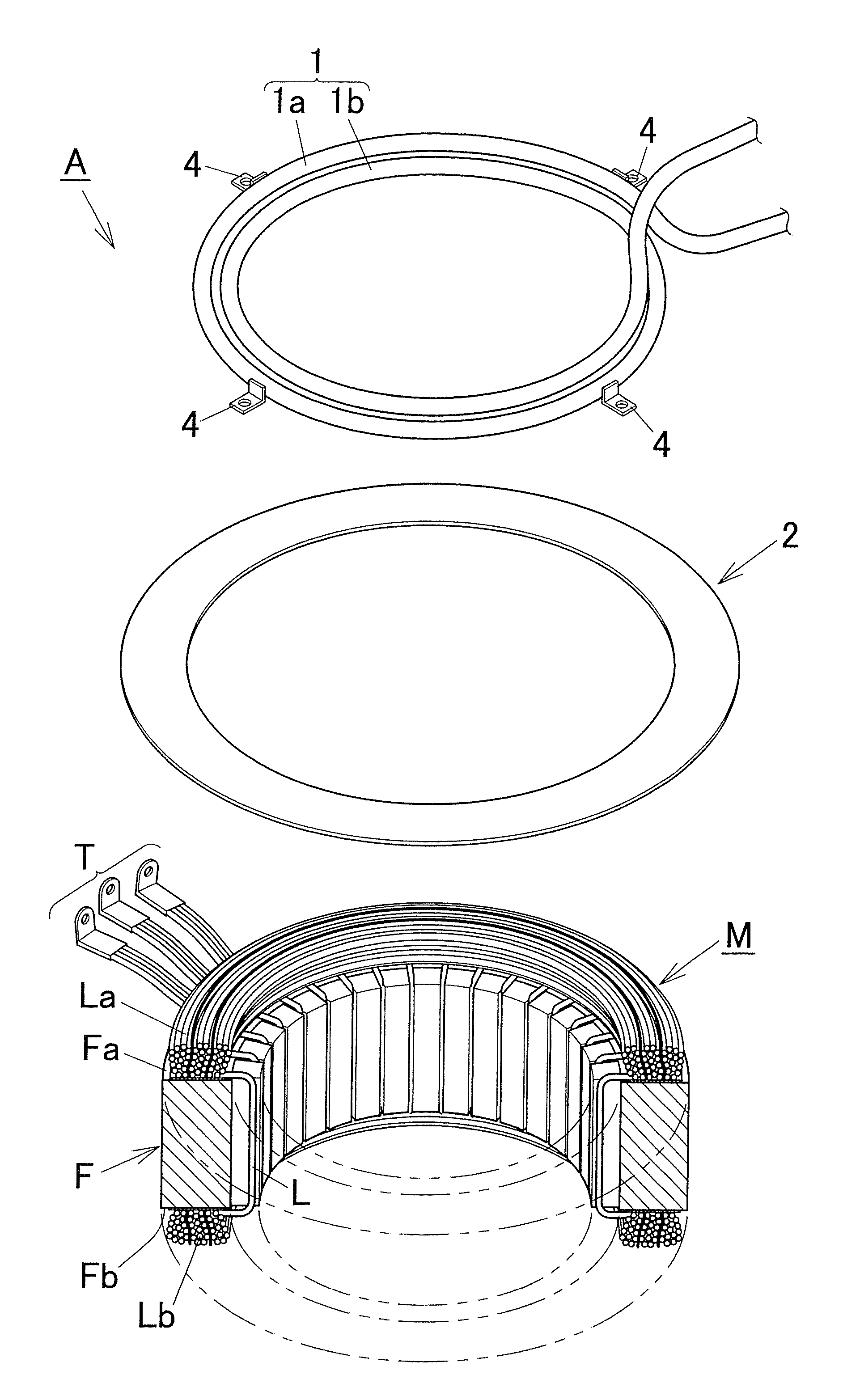

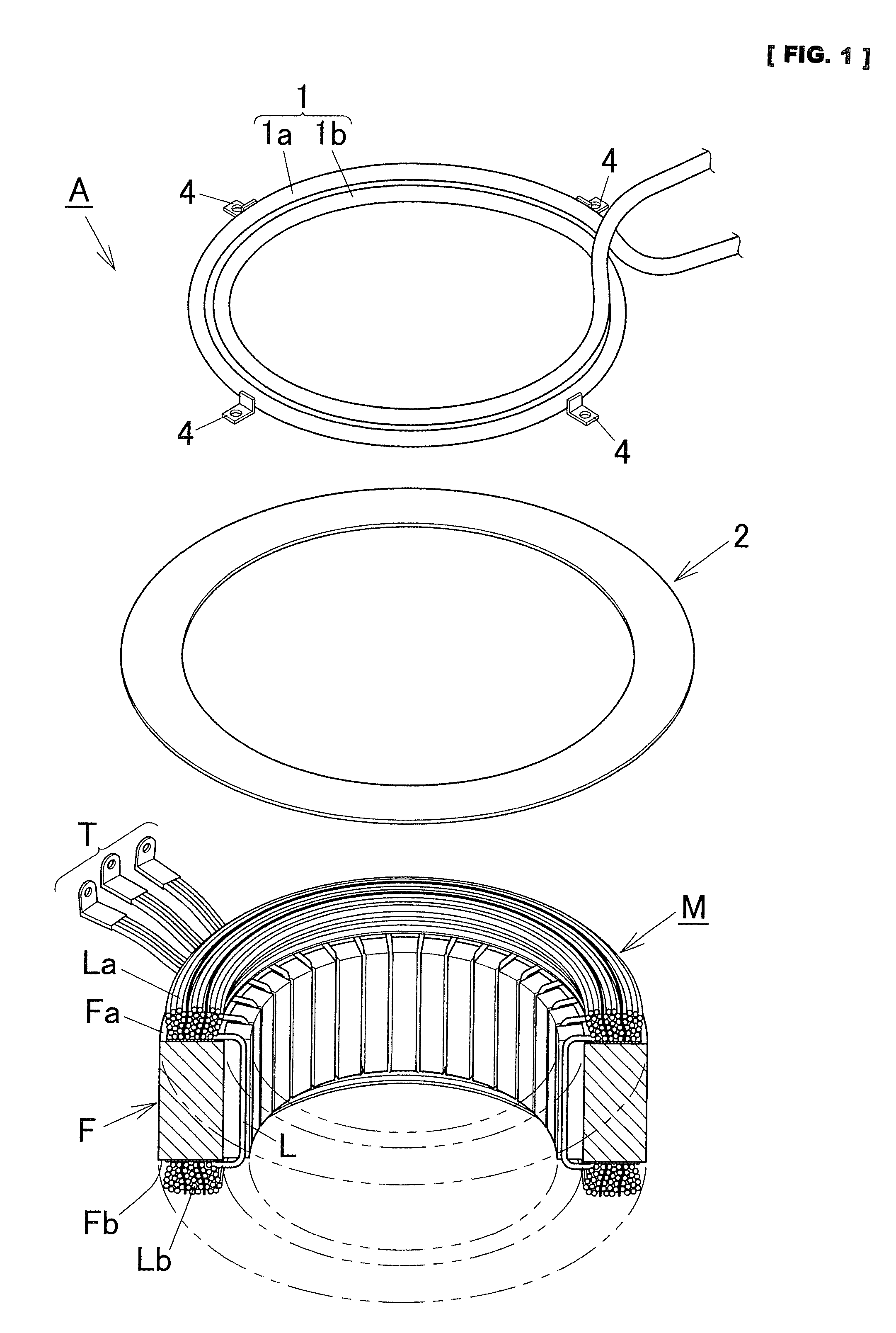

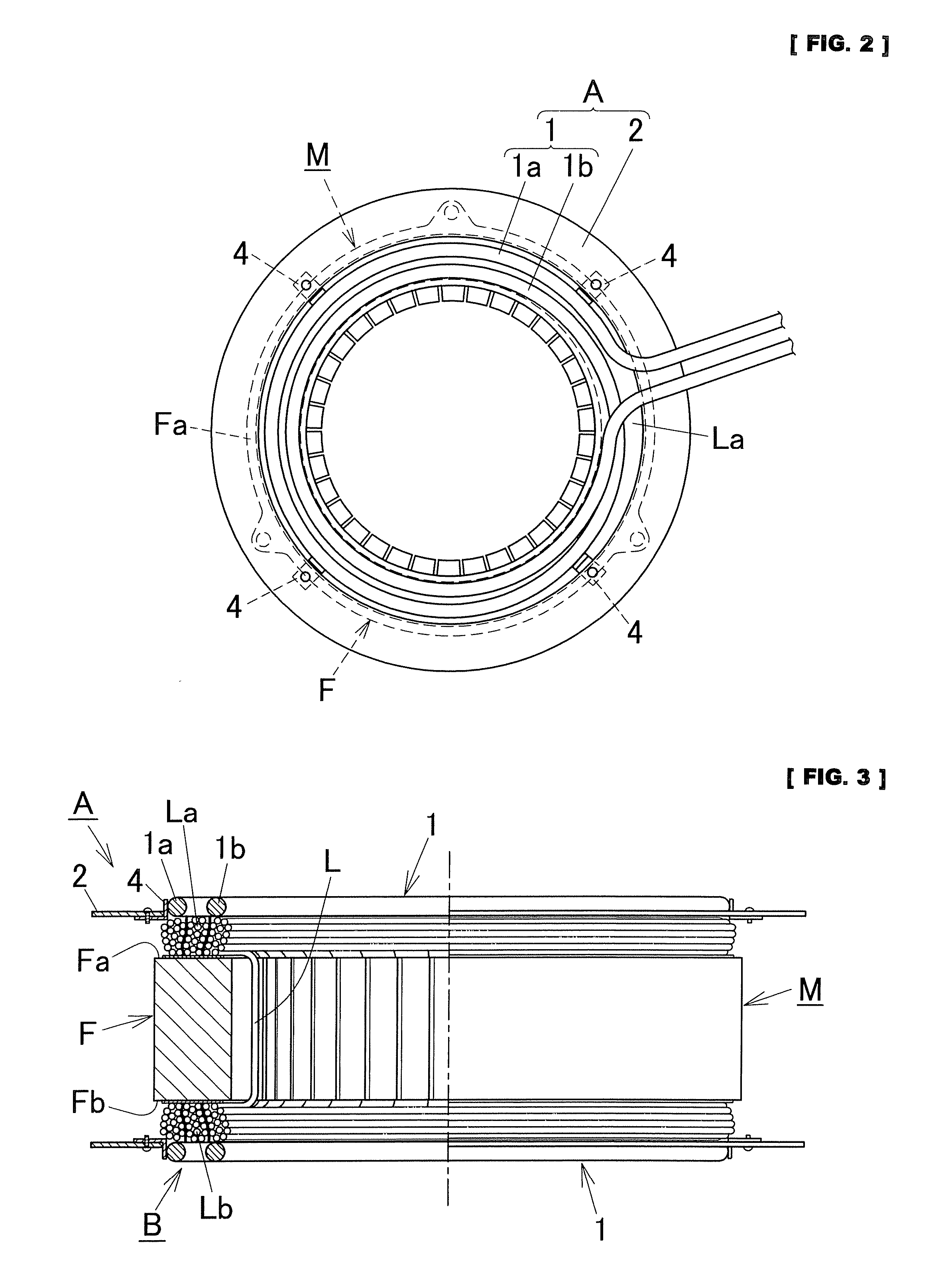

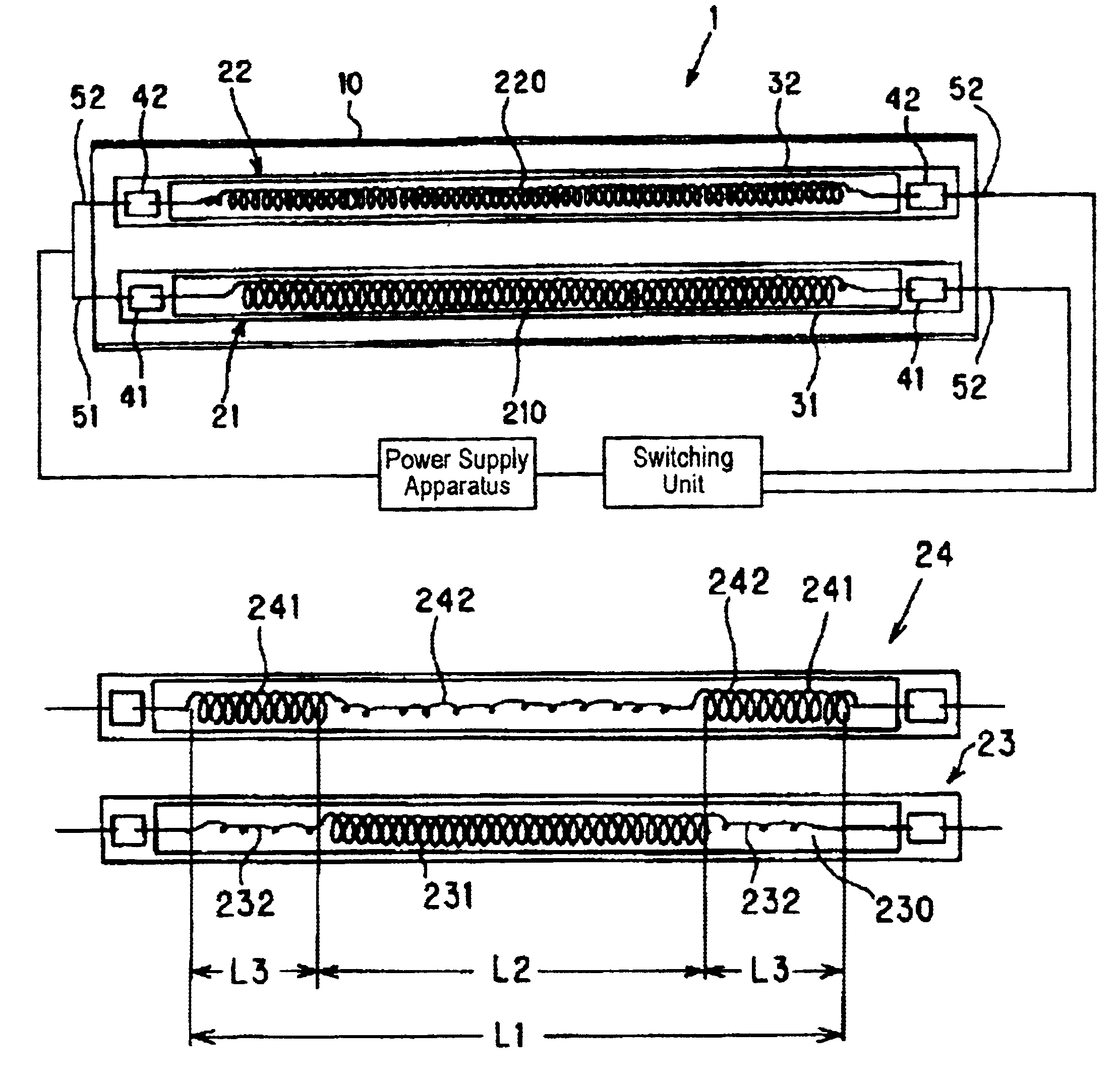

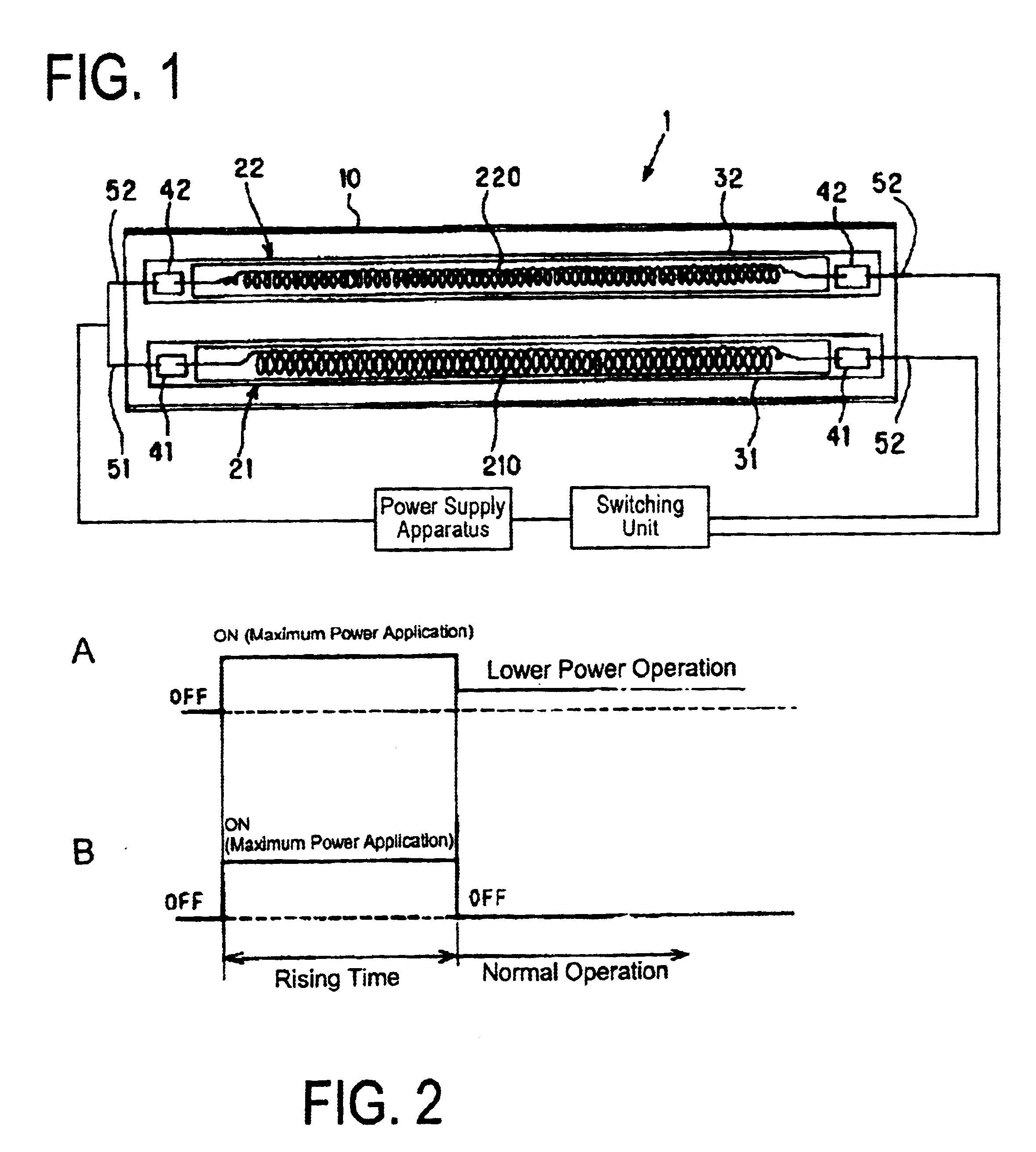

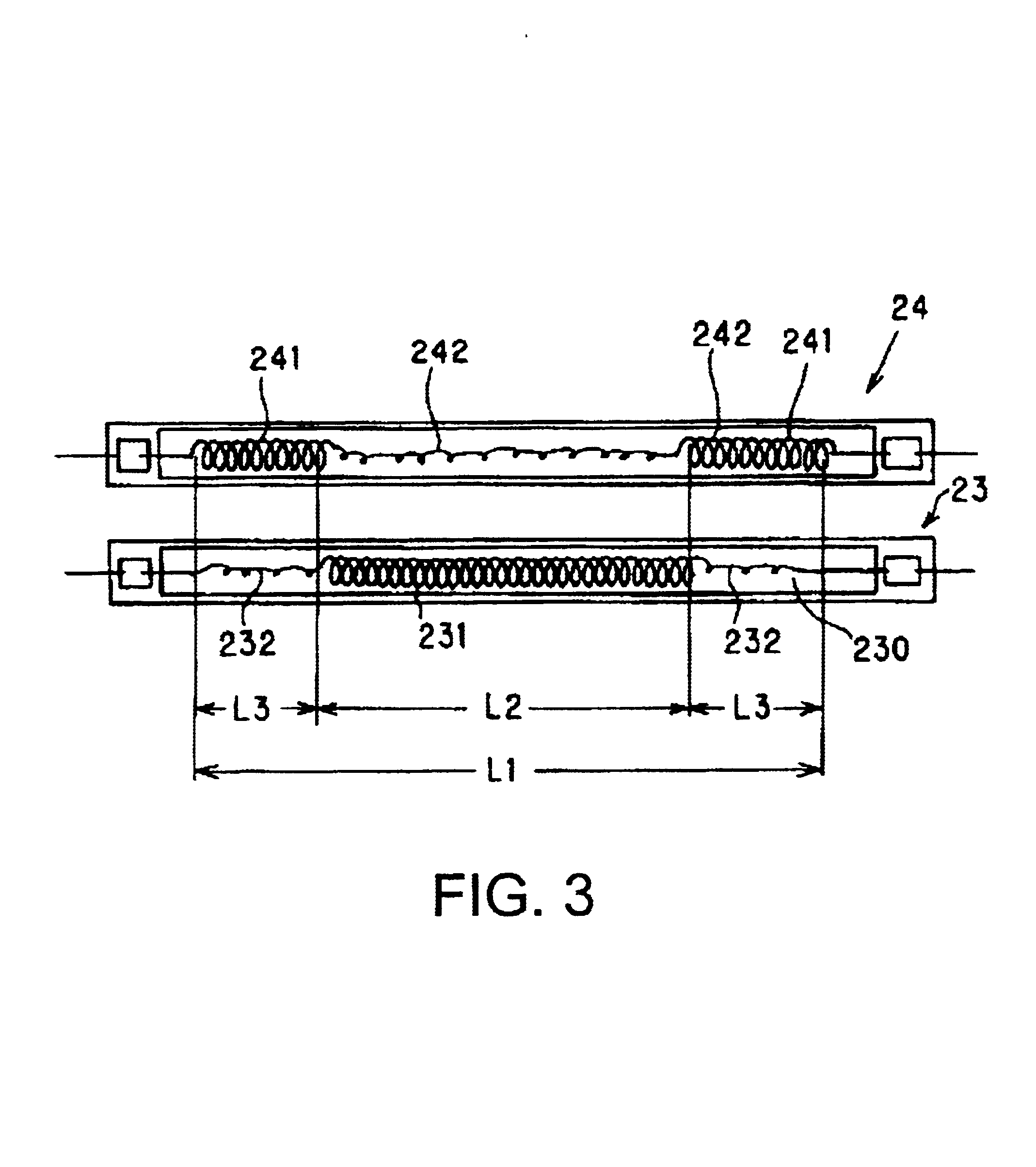

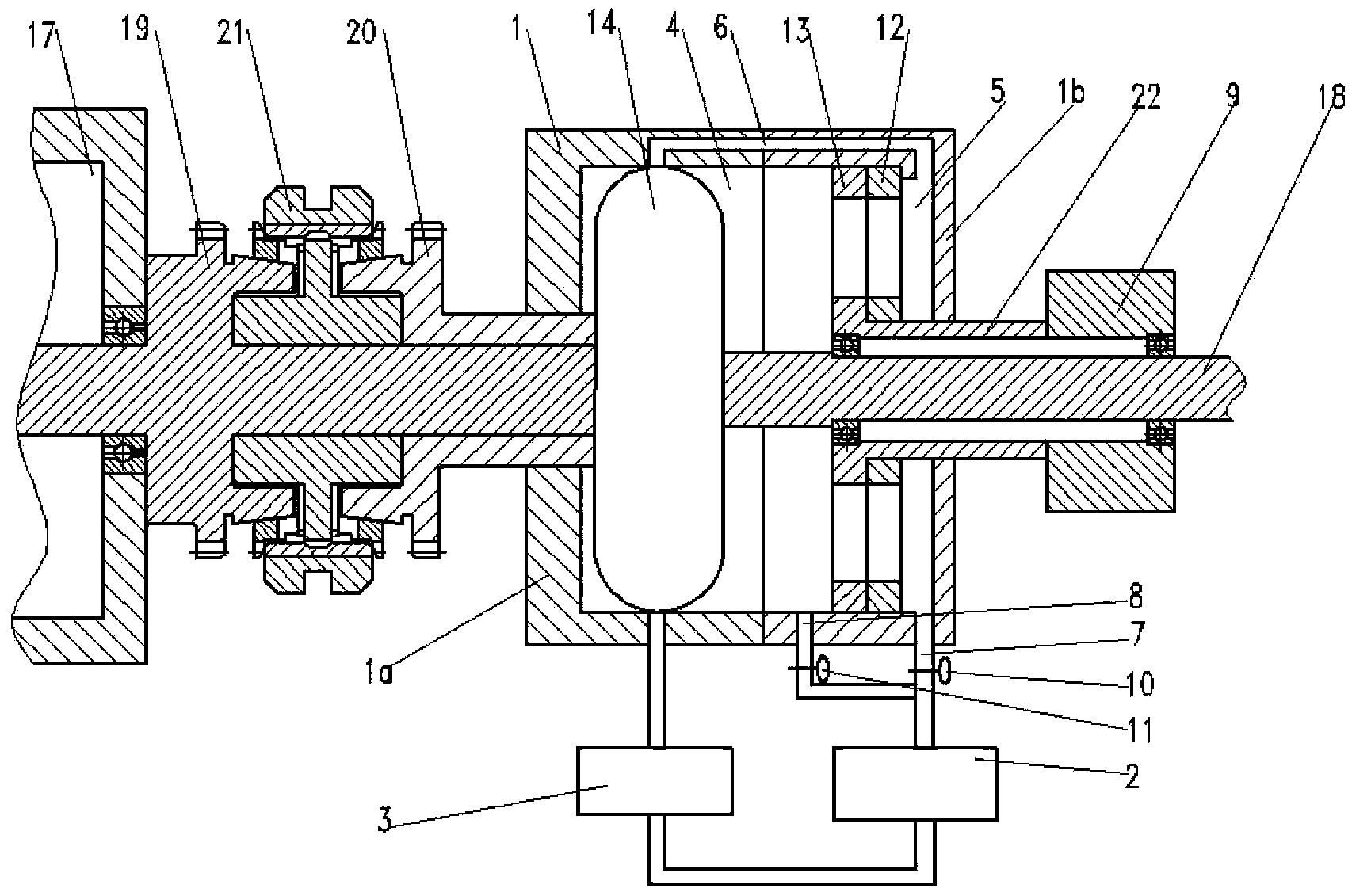

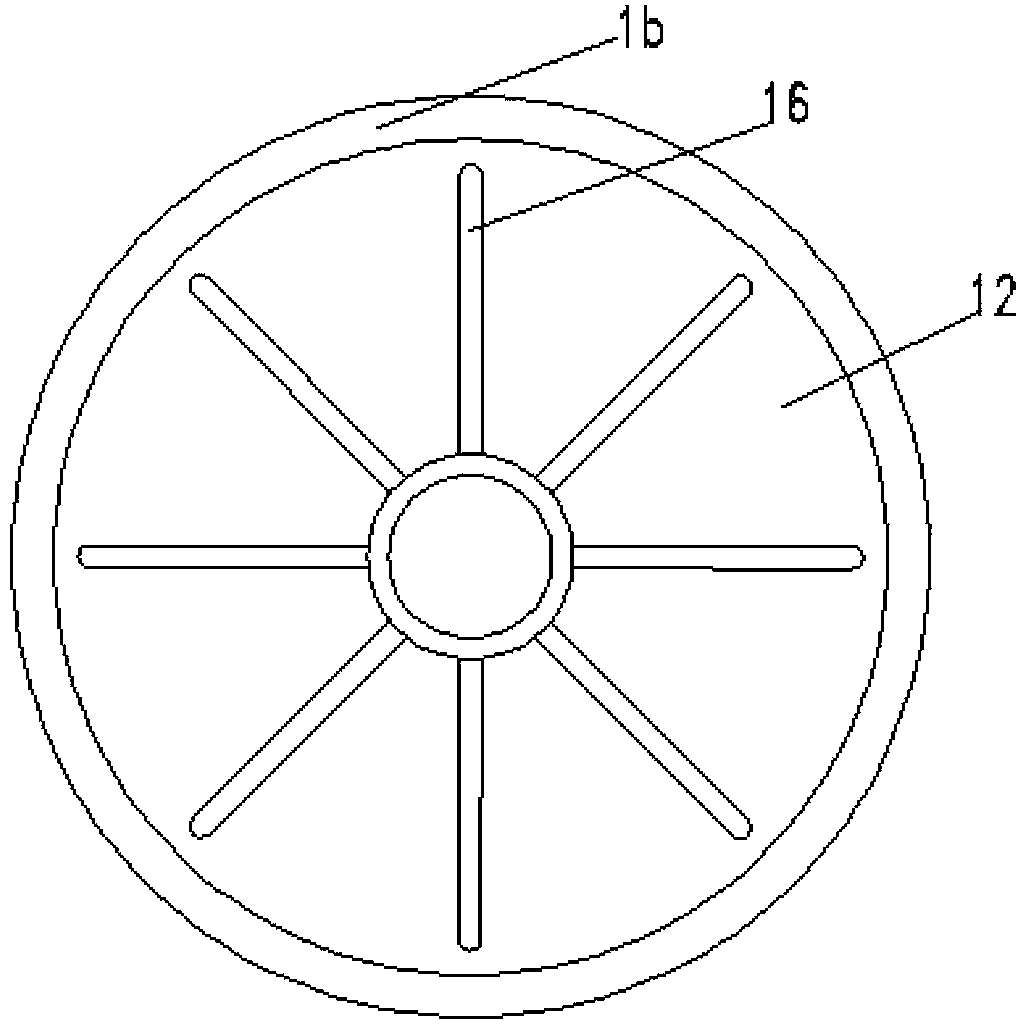

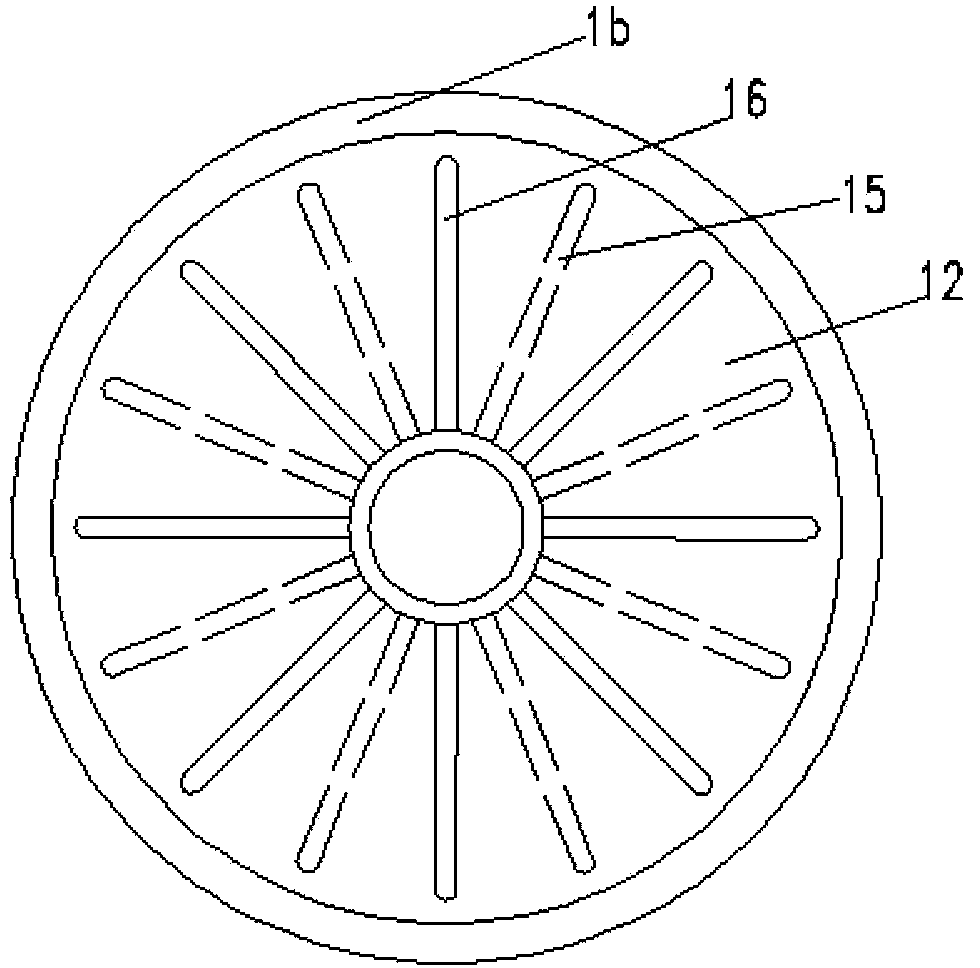

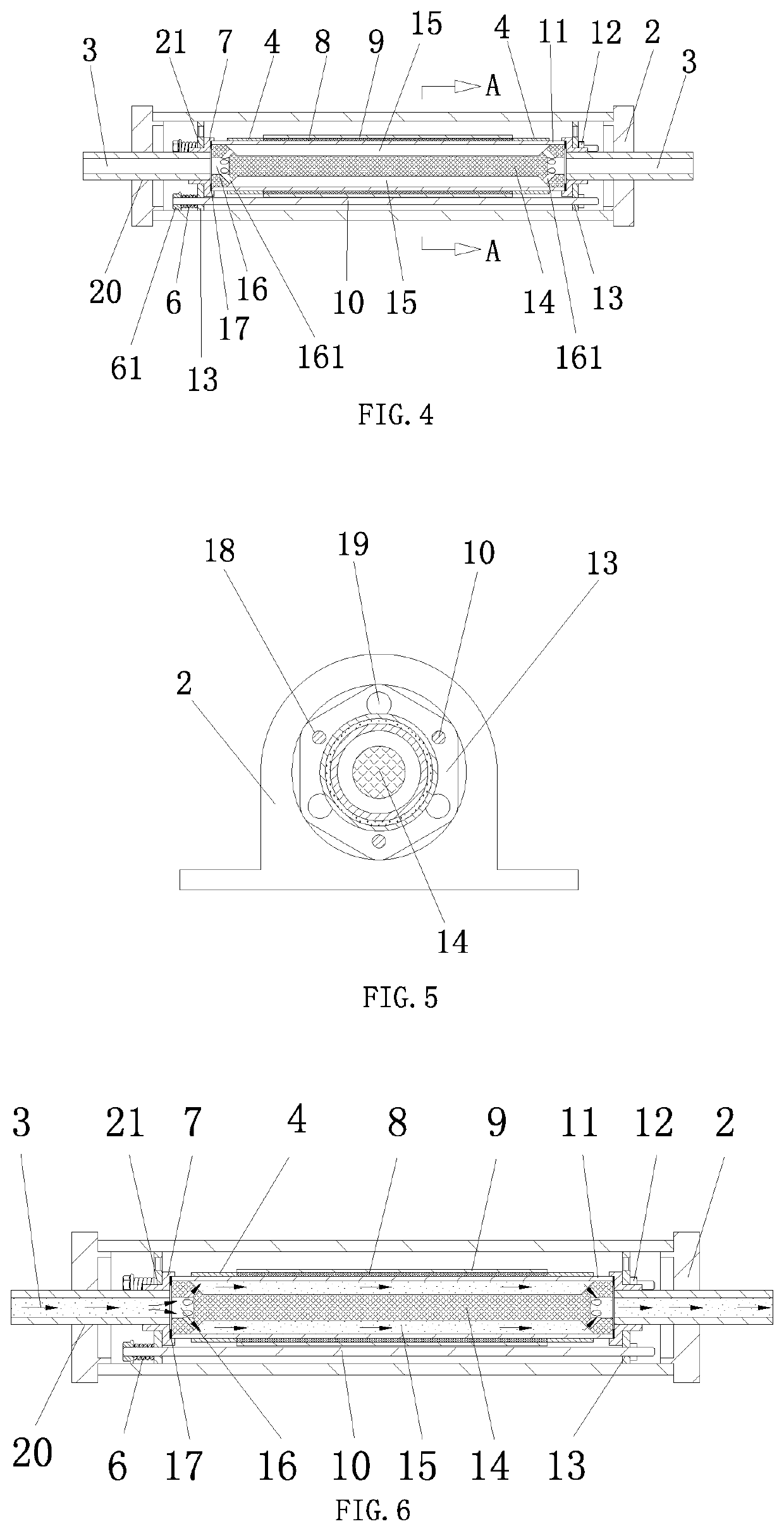

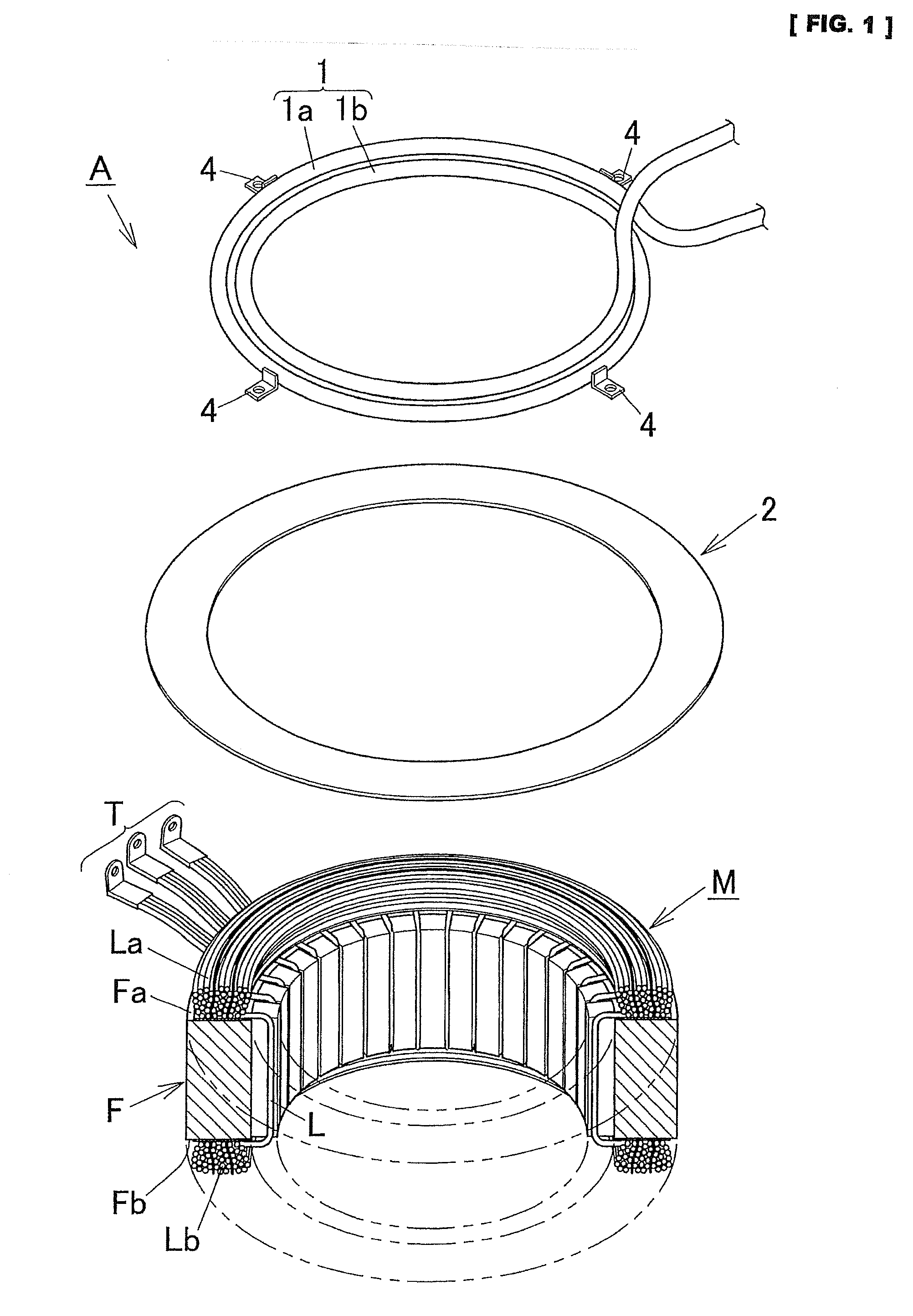

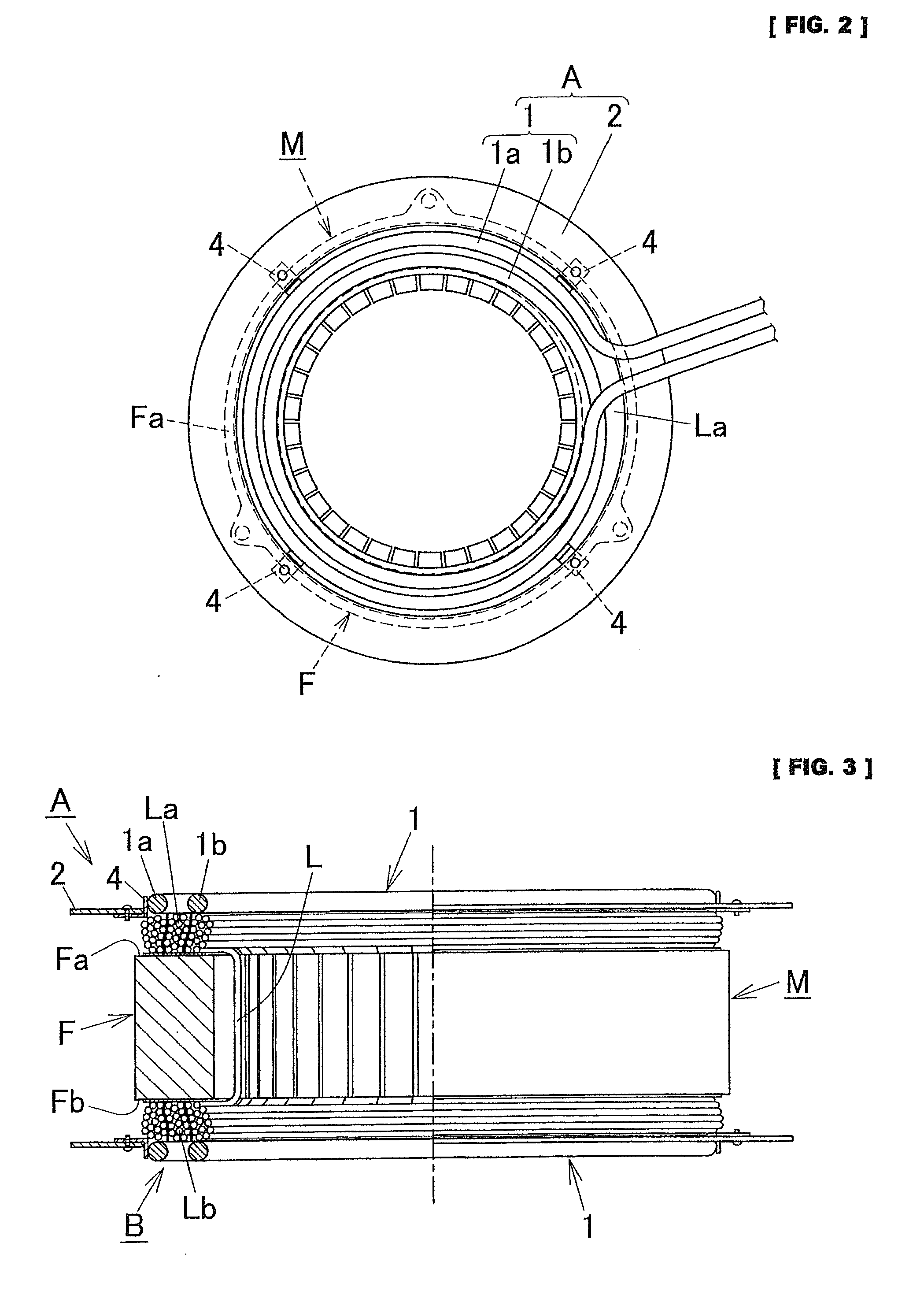

Stator coil heating apparatus and stator coil heating method

InactiveUS20100295412A1Heat processingLow costCoil arrangementsManufacturing dynamo-electric machinesConductor CoilMagnetic flux

A stator coil heating apparatus and a stator coil heating method that are capable of effectively preventing a core from thermal deformation particularly caused due to a magnetic flux generated by a coil head, without the problem of heating temperature variation, and also shortening a time for the process of heating a stator coil, are provided.A stator coil heating apparatus A to heat a stator coil L wound around a circular core F, comprises: induction heating coil heads 1 and 11 that heat the circular coil L by generating an inductive effect acting from outside in the thickness direction of the core F, against circular winding coil bases La and Lb that are sticking out of end faces Fa and Fb of the core F in the thickness direction thereof; and shields 2 and 12 that block a magnetic flux generated by the coil heads 1 and 11, out of the end faces Fa and Fb of the core F in the thickness direction thereof.

Owner:TOYOTA JIDOSHA KK

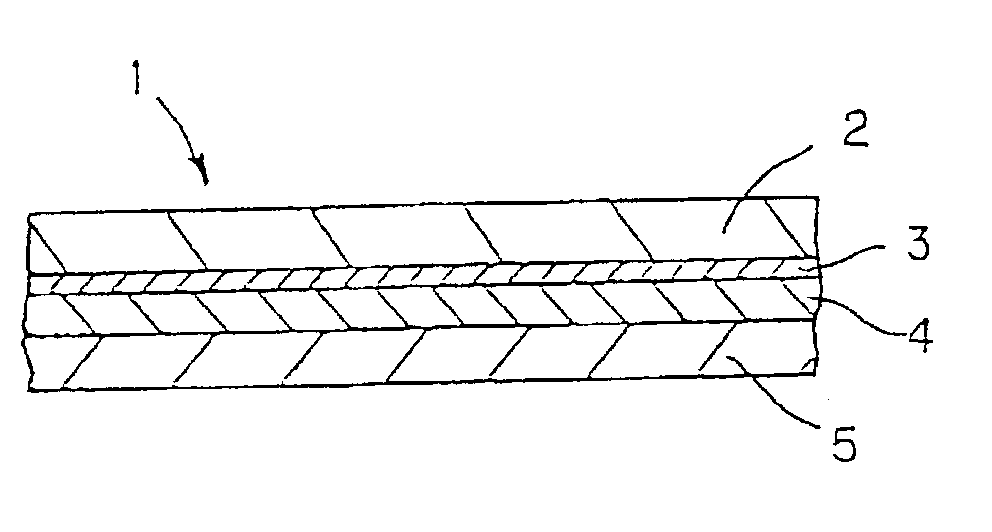

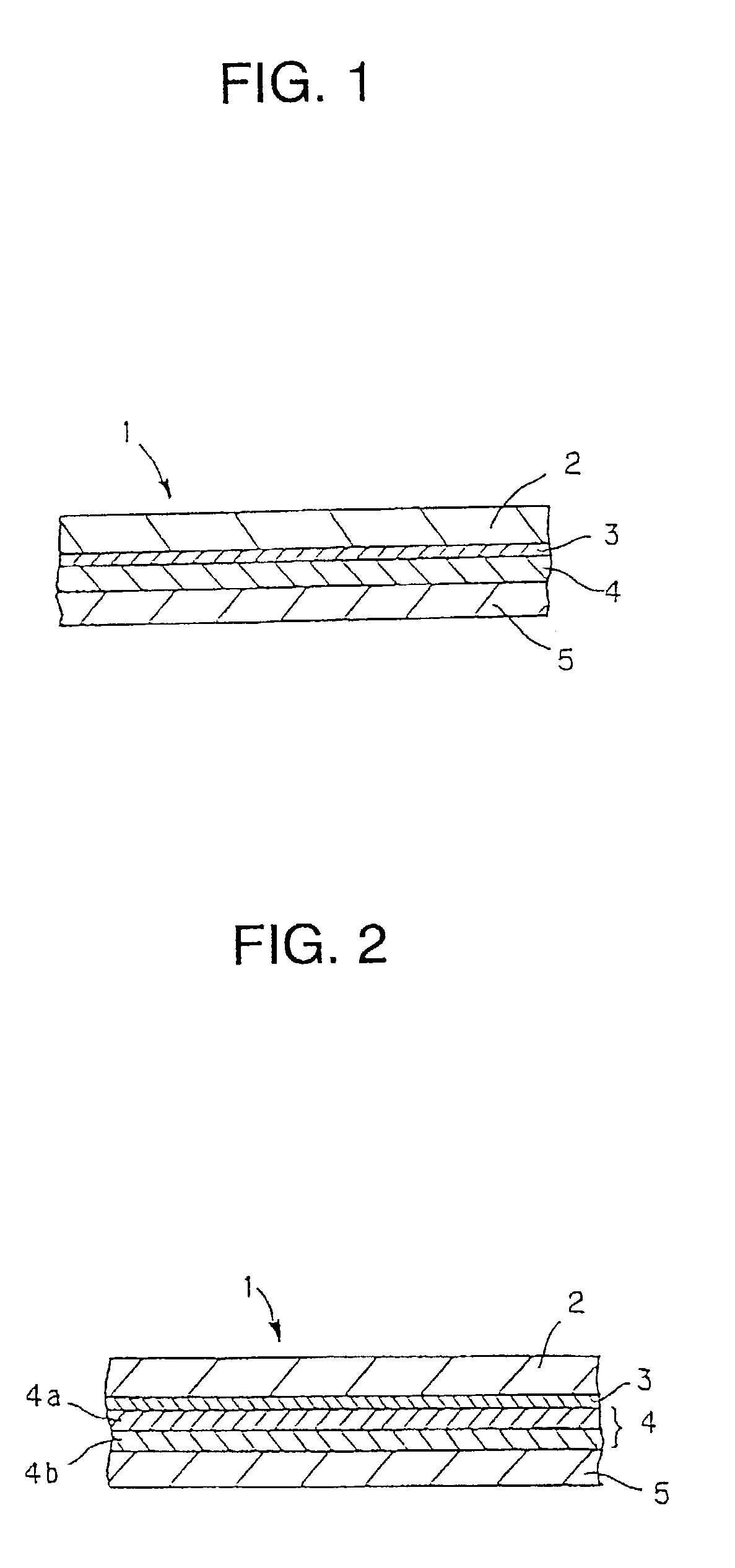

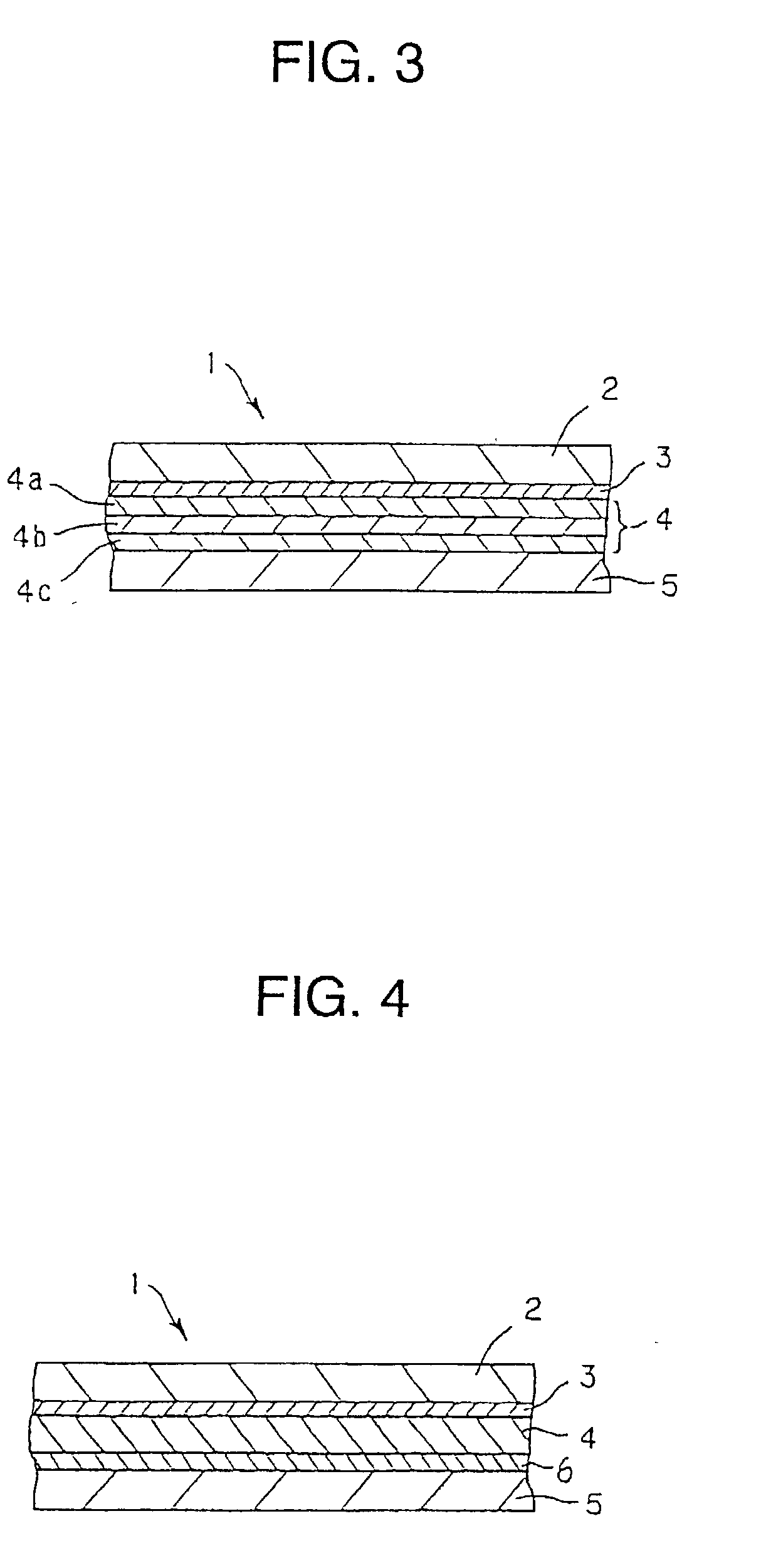

Transparent, electrically conductive and heat-sealable material and lidded container for carrier tape using the same

InactiveUS20030017328A1Peel strengthHigh heat sealing strengthSynthetic resin layered productsConjugated diene hydrocarbon coatingsVisual recognitionSynthetic resin

The present invention has a main object to provide a transparent conductive heat sealing material of which antistatic property does not deteriorates even at a low humidity, and has a transparency to an extent of permitting visual recognition of the contents and a carrier tape lid using the same. To achieve this object, the transparent conductive heat sealing material of the invention is characterized by a heat-sealable synthetic resin, and conductive fine particle having a 50% particle size of up to 1.0 mum.

Owner:DAI NIPPON PRINTING CO LTD

Electrically conductive adhesive composition, connection structure, solar battery module, and method for producing same

ActiveUS20150255633A1Improve connection reliabilityImprove connection strengthConductive materialSemiconductor/solid-state device manufacturingCationic polymerizationSolar battery

An electrically conductive adhesive composition comprising electrically conductive particles containing a metal of which melting point is 220° C. or less, a thermosetting resin, and a thermal cationic polymerization initiator.

Owner:RESONAC CORP

Plate heat exchanger

ActiveUS9228784B2Easy constructionCost-effectivelyIce removalMountingPlate heat exchangerEngineering

The invention relates to a plate heat exchanger comprising a plurality of plates having flow channels, wherein a first plate has a front side having at least one flow channel for a first fluid and a second plate has a front side having at least one flow channel for a second fluid, and wherein the plates have through openings via which the flow channels for the same fluid are respectively connected to one another, wherein a front plate, which is placed in front of the front side of the first plate, has ports for the first fluid and for the second fluid, wherein an end plate forms the end of the aligned plates, wherein the plates and ports are formed from plastic, and wherein the plates are bonded or welded tightly together.

Owner:SARTORIUS STEDIM BIOTECH GMBH

Method for preparing ultra-fine crystal grain pure molybdenum block material

A method for preparing ultra-fine crystal grain pure molybdenum block material belongs to the technical field of high-melting-point metal and metal-based heat sink material. The invention is characterized in that firstly the molybdenum powder with granularity which is smaller than 10mum and larger than 1mum is selected for executing the vacuum hot pressing pre-burning of green body. Then the pre-burned green body is placed in a pyrauxite mold and is placed into a press for exerting pressure of 1-10GPa on the sample. Then the 10-25 kW alternating current is exerted on two ends of the sample for sintering. The energized current is 1000A-3000A and lasts for 15 seconds to 3 minutes. After energizing and sintering, pressure is continuously maintained for 30 seconds to 3 minutes; then the sintered body is milled and polished. The relative density is 96-99.9% and the grain size is smaller than or equal to the initial powder size of used raw material. The pre-burning is executed under the following conditions: 20-50MPa of pressure, 10<-2>-10<-3>Pa of vacuum degree, 800-1000 DEG C of temperature and 30min-60min of time. The ultra-fine crystal grain pure molybdenum block material prepared by the invention has better mechanical performance and thermal-shock resistance and is suitable for electronic packaging materials, hot sink materials, electrical contact materials and fire-resistant plasma scouring components, such as divertor materials in nuclear fusion devices.

Owner:UNIV OF SCI & TECH BEIJING

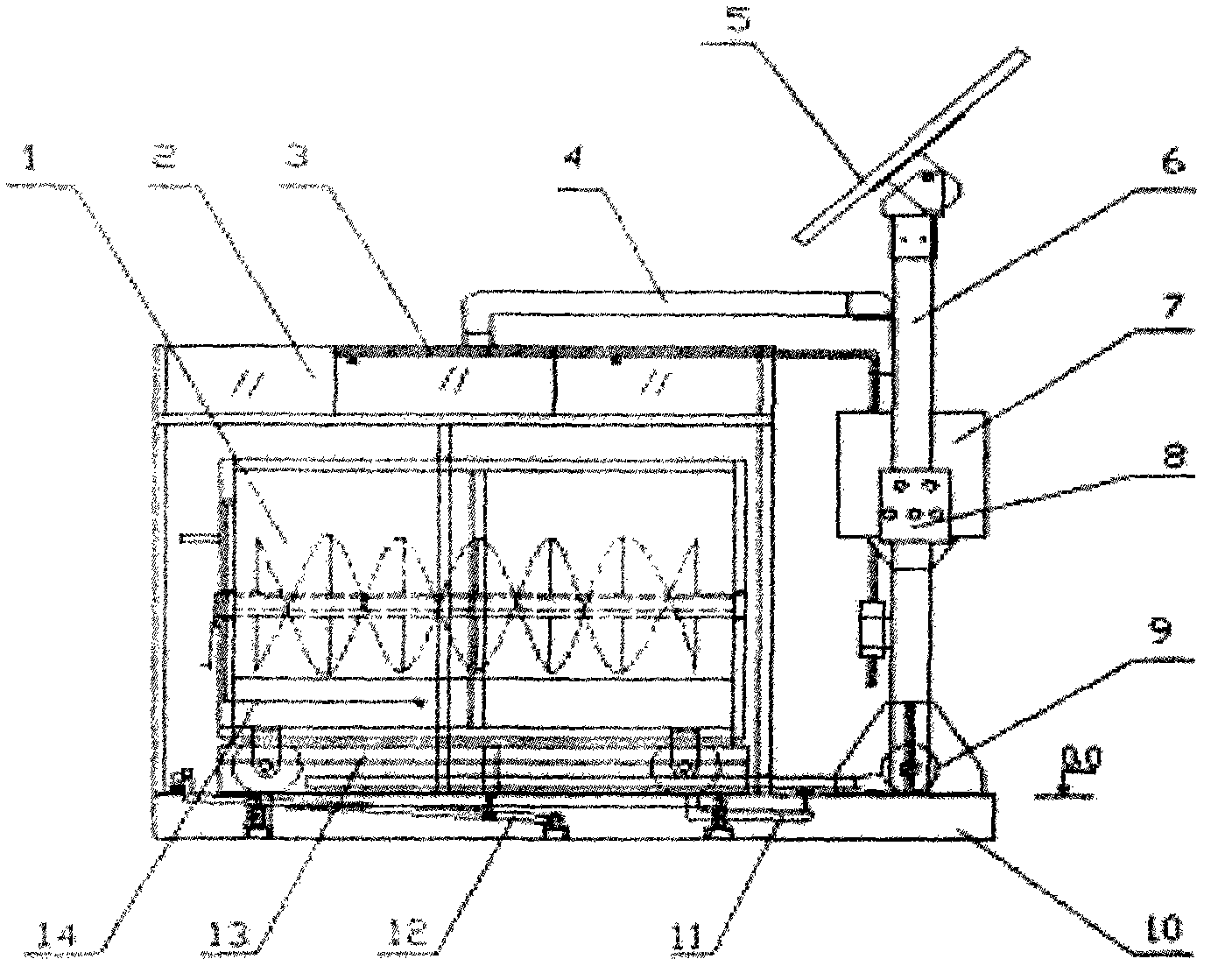

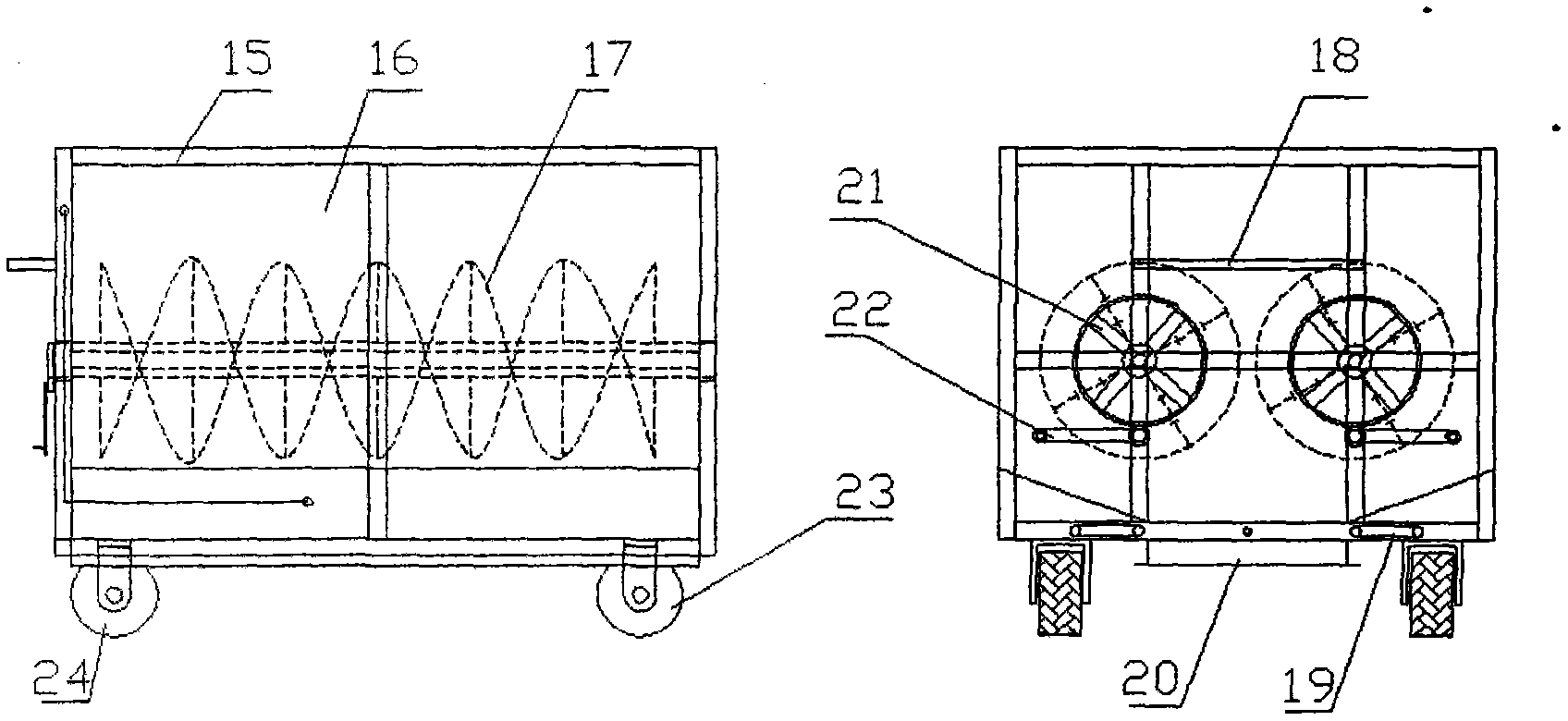

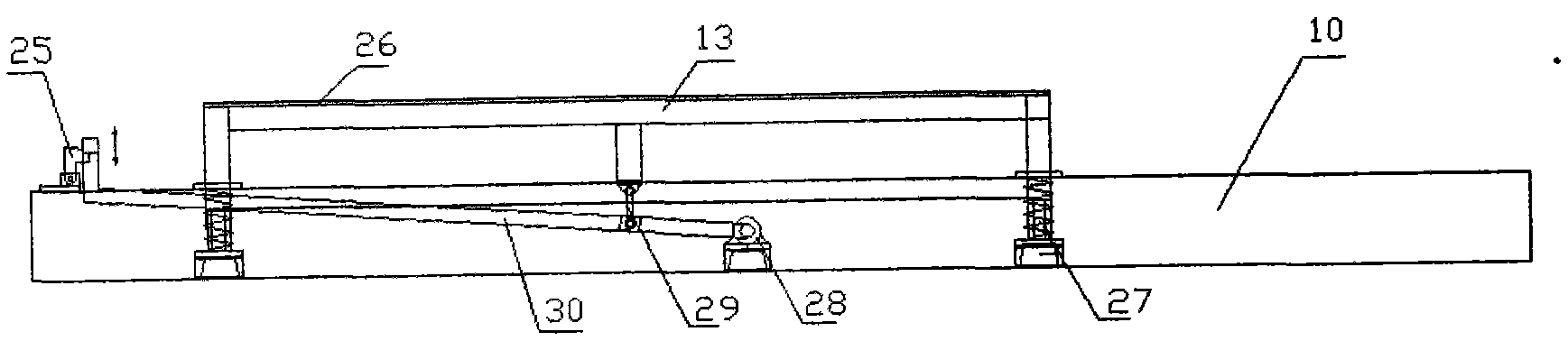

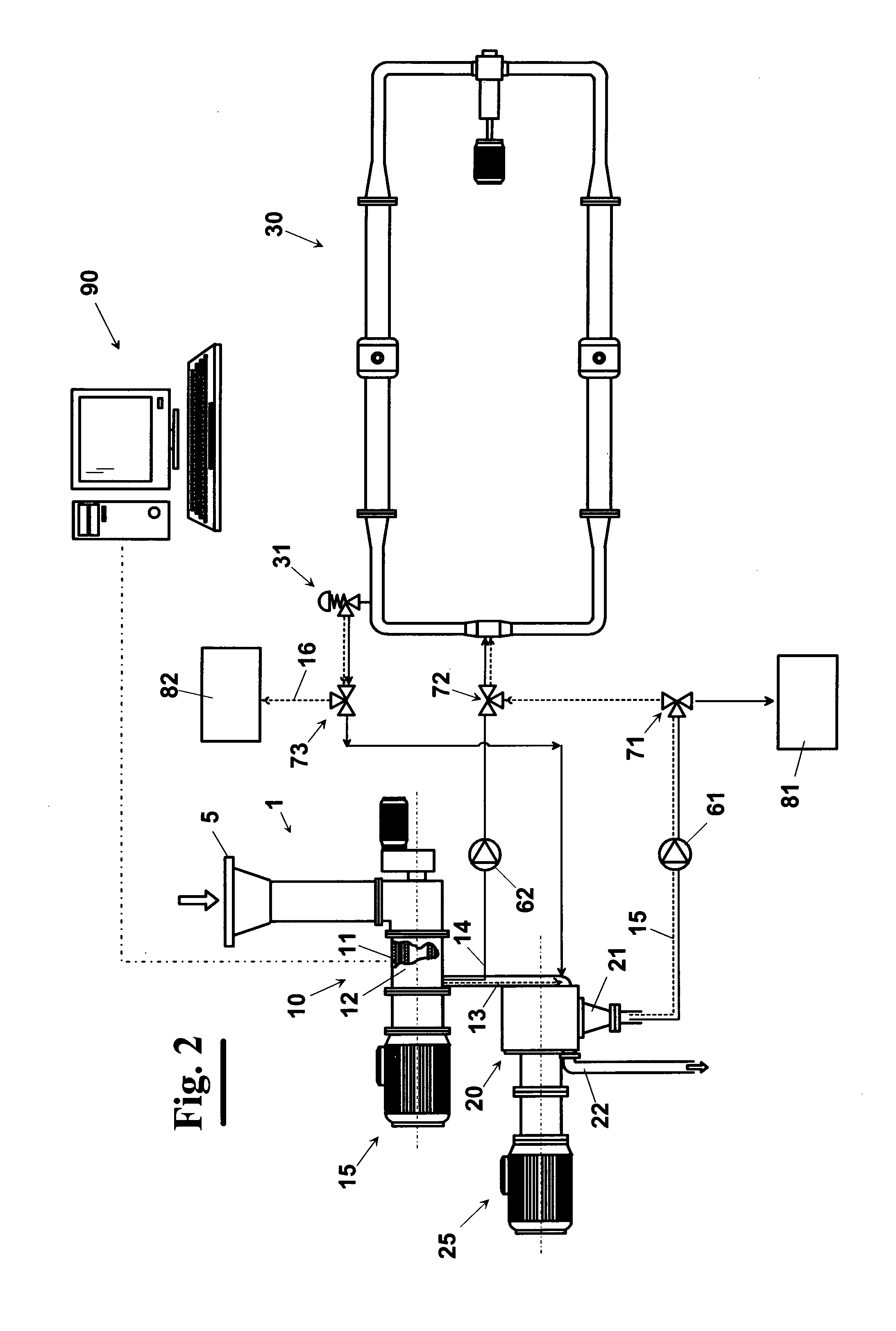

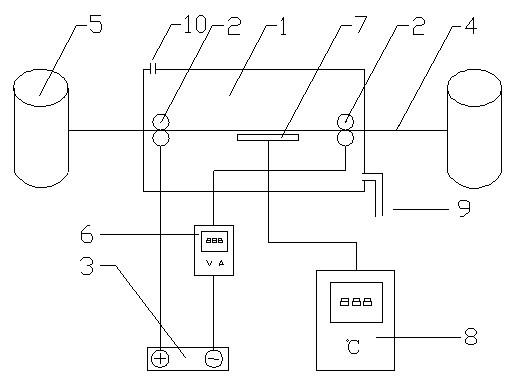

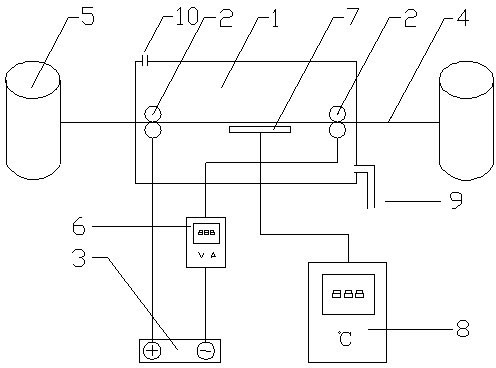

Convenient energy-saving static OAR (Organics Aerobic oxidation Resources) treatment device

ActiveCN104016746AIncrease profitSolve shipping problemsClimate change adaptationEnergy inputCartWater pipe

The invention provides a convenient energy-saving static OAR (Organics Aerobic oxidation Resources) treatment device, belonging to the field of the technical equipment for solid waste organics resource utilization. The device is composed of a transfer fermentation cart, a base, an aeration system, a heat preservation chamber, a solar power generation system, a control system, a spraying system, an exhaust system and a filtrate pipe. The transfer fermentation cart is a movable part; after the transfer fermentation cart is loaded with materials, the transfer fermentation cart is pushed into the heat preservation chamber; the heat preservation chamber is connected with the base; the aeration system is powered by the solar power generation system; the solar power generation system is mounted on a cross beam of two upright columns; the control system comprises a temperature sensor, an overall control cabinet and the like; the temperature sensor is mounted on a side part of the transfer fermentation cart, and the overall control cabinet is mounted on the side surfaces of the upright columns; the spraying system is connected with a tap water pipe and is capable of adjusting the moisture content of materials; the exhaust system is mounted at the top of the heat preservation chamber so as to discharge stink generated in the fermentation process. The device is simple in structure, low in energy consumption, high in efficiency, simple and convenient to operate, and suitable for treating solid waste organics.

Owner:北京圣海林生态环境科技股份有限公司 +2

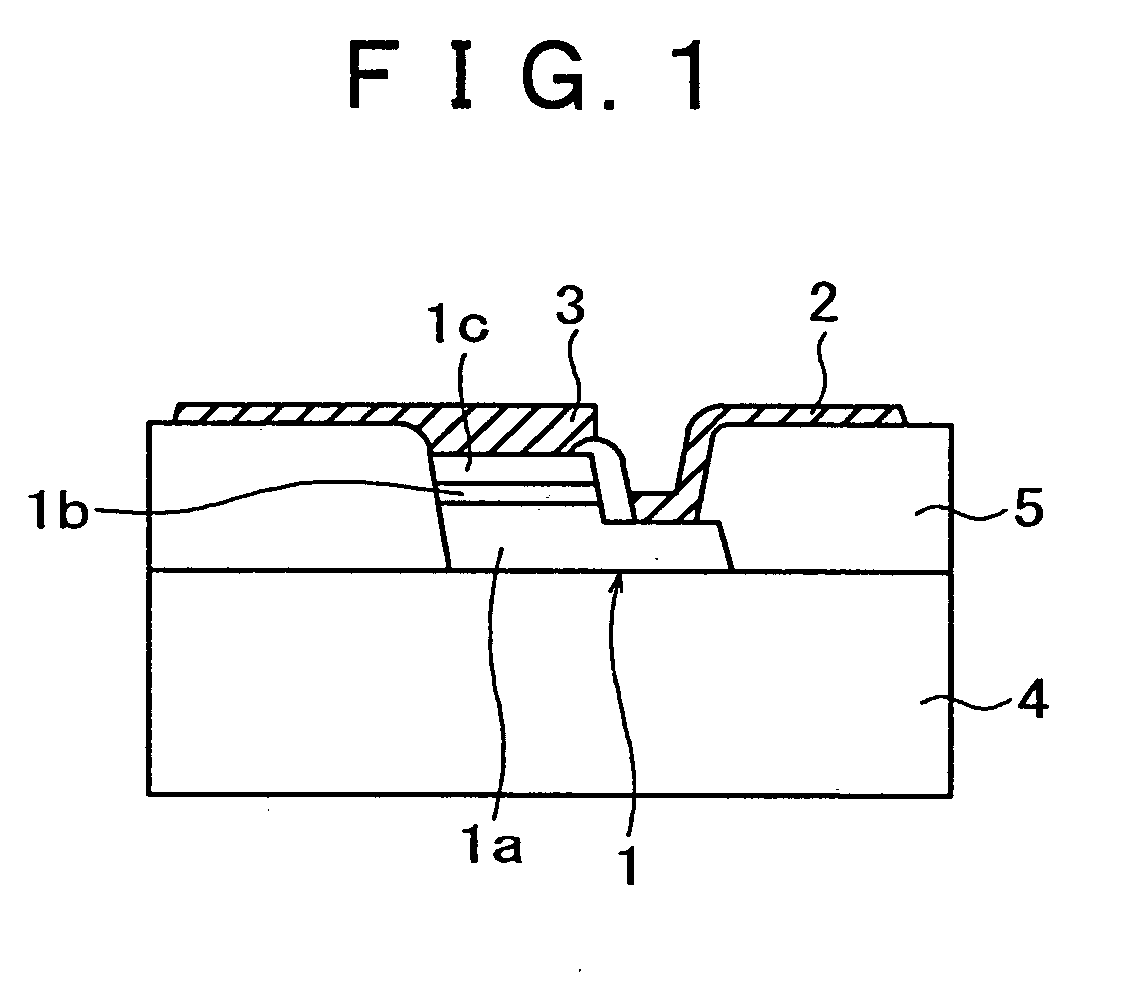

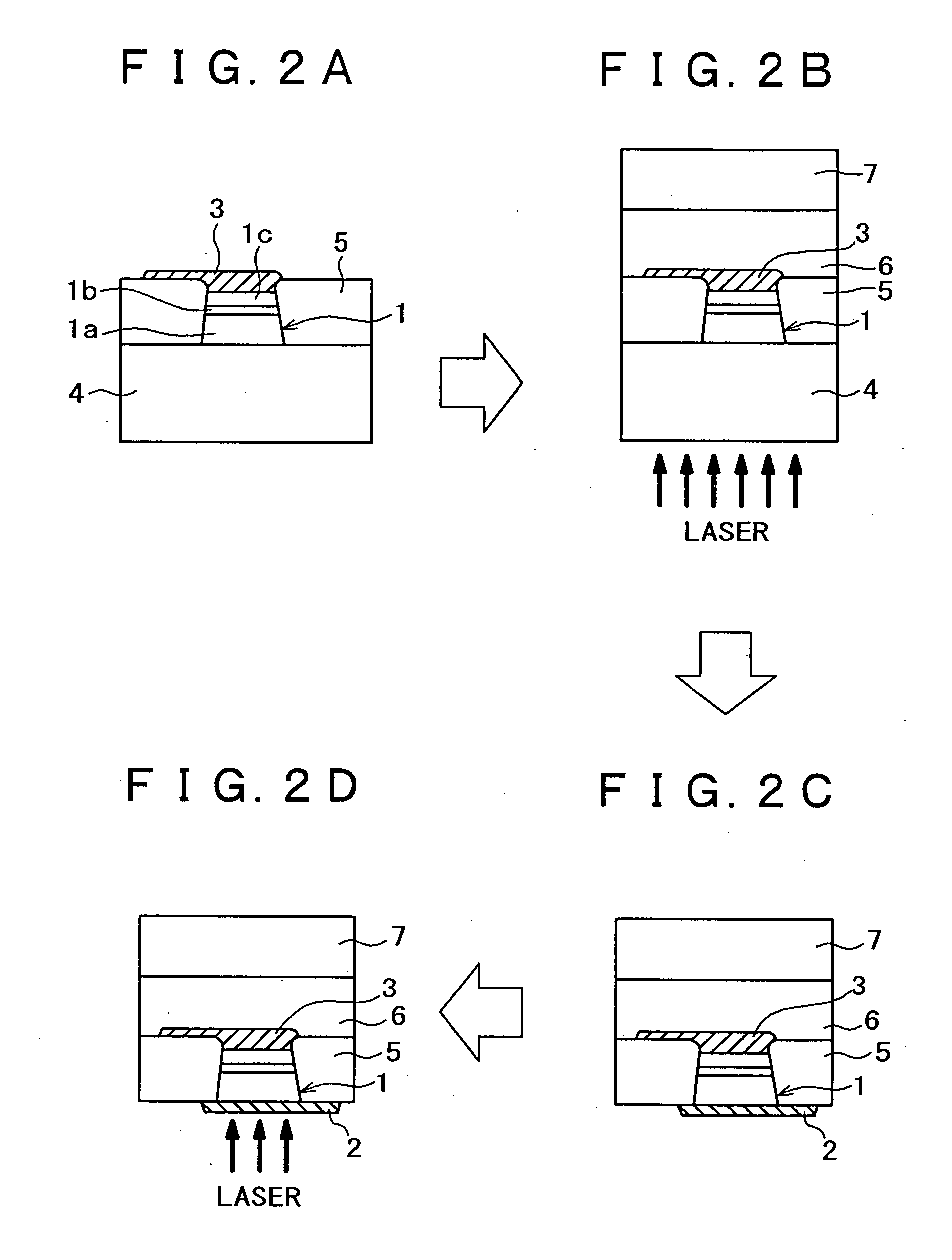

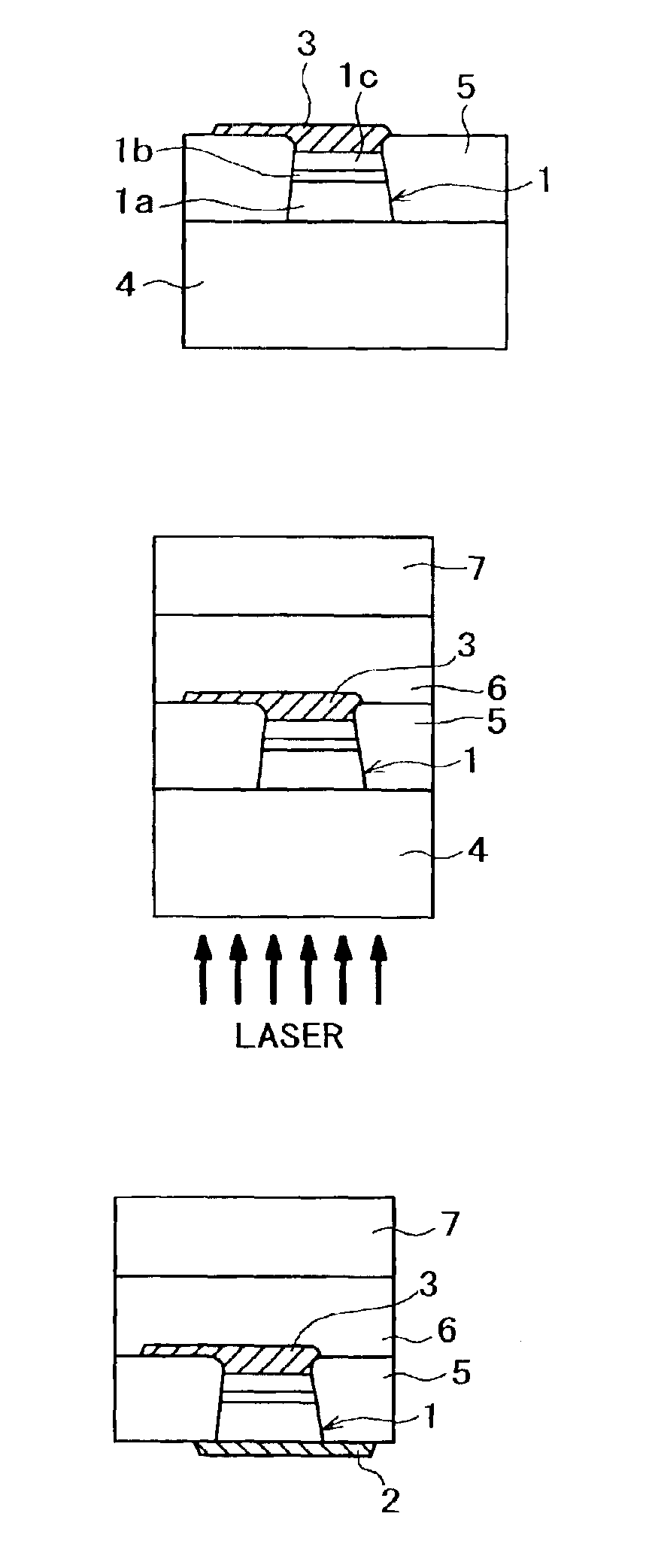

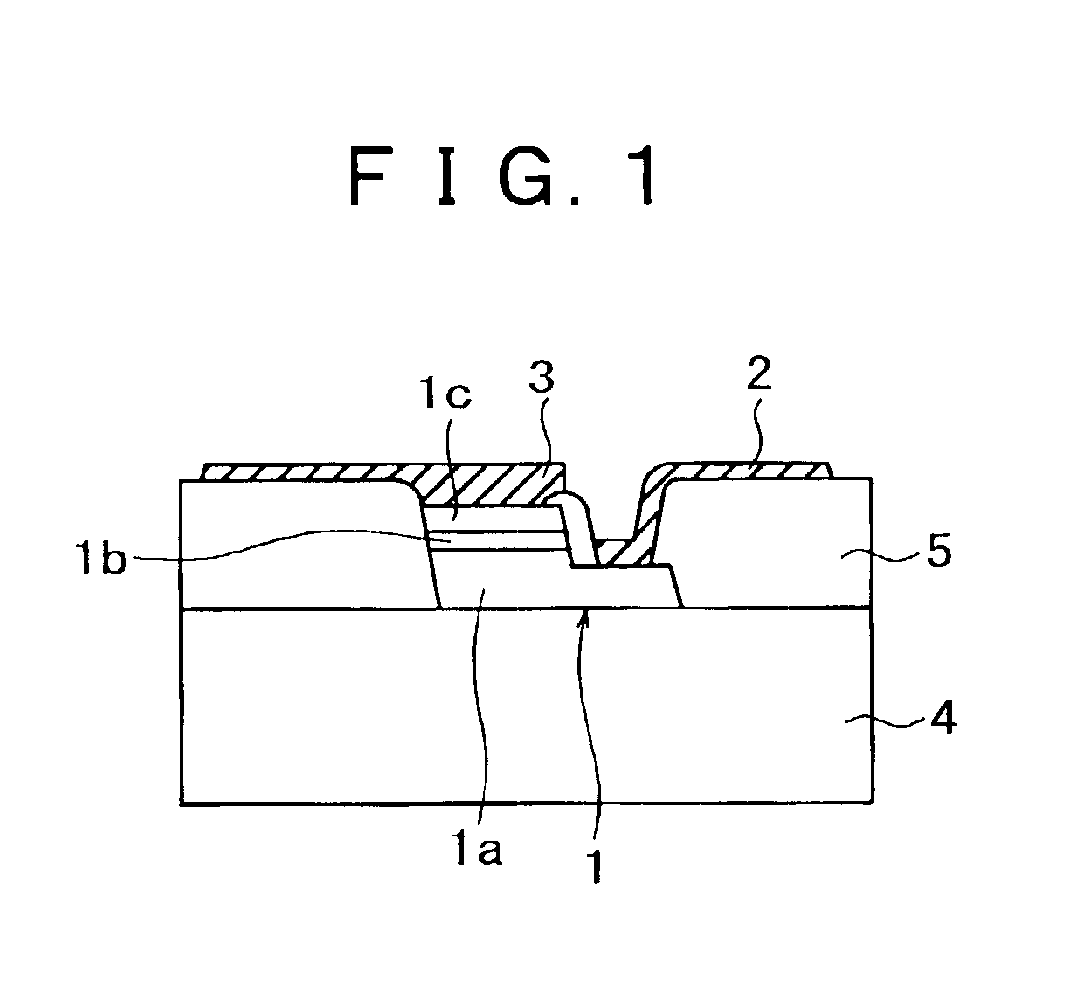

Alloying method for a image display device using laser irradiation

InactiveUS6878574B2Improve performanceWithout degrading characteristicSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceAlloy

An alloying method includes steps of forming a metal layer on a semiconductor that is then transferred to a material having a low thermal conductivity. An interface between the semiconductor and the metal layer is formed into an alloy by irradiating the interface with a laser beam having a wavelength that is absorbable in at least one of the semiconductor and the metal layer. Preferably, the material having a low thermal conductivity is a resin or amorphous silicon. Because the entire semiconductor is not heated and only a necessary portion is locally heated, the necessary portion can be readily alloyed to be converted into an ohmic contact without exerting adverse effects on the characteristics of the semiconductor device.

Owner:SONY CORP

Heating roller

InactiveUS6911625B2Convenient power supplyLong heating timeOhmic-resistance heating detailsRollsRoom temperatureEngineering

A heating roller has a first heater lamp having a first filament made of tungsten, and a second heater lamp having a second filament wherein the second filament is a heating element whose resistivity value is greater than that of tungsten at a room temperature.

Owner:USHIO DENKI KK

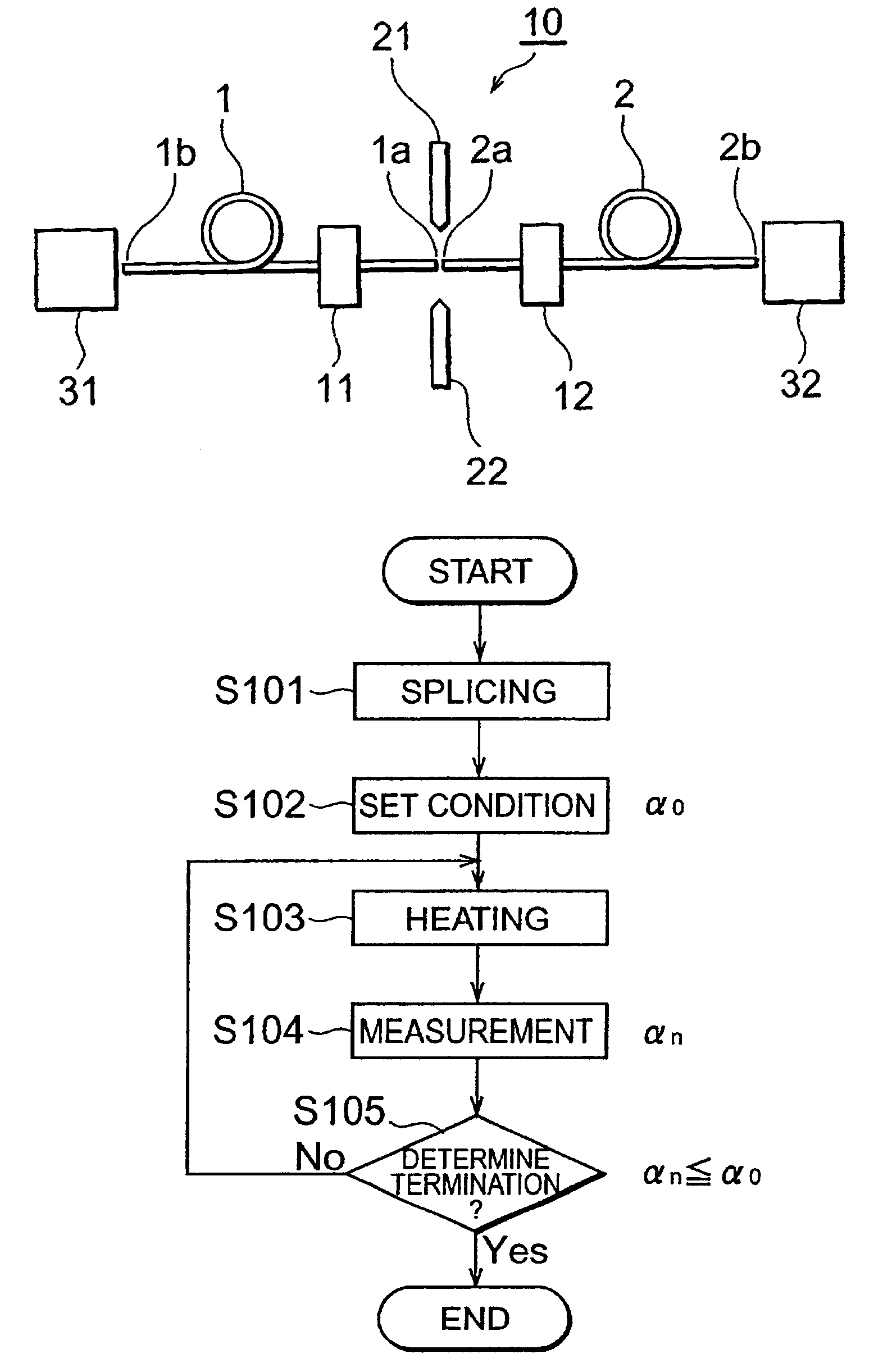

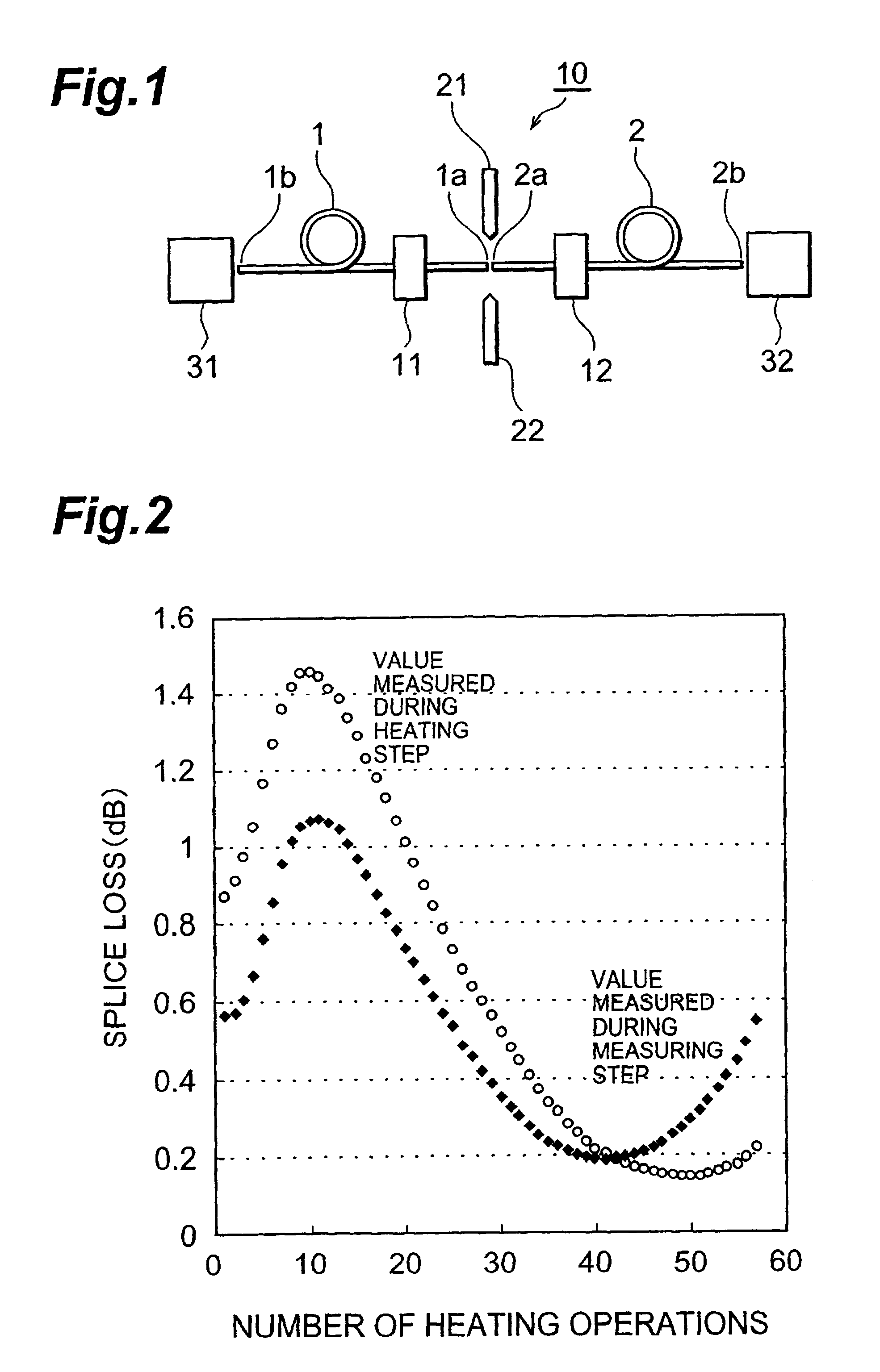

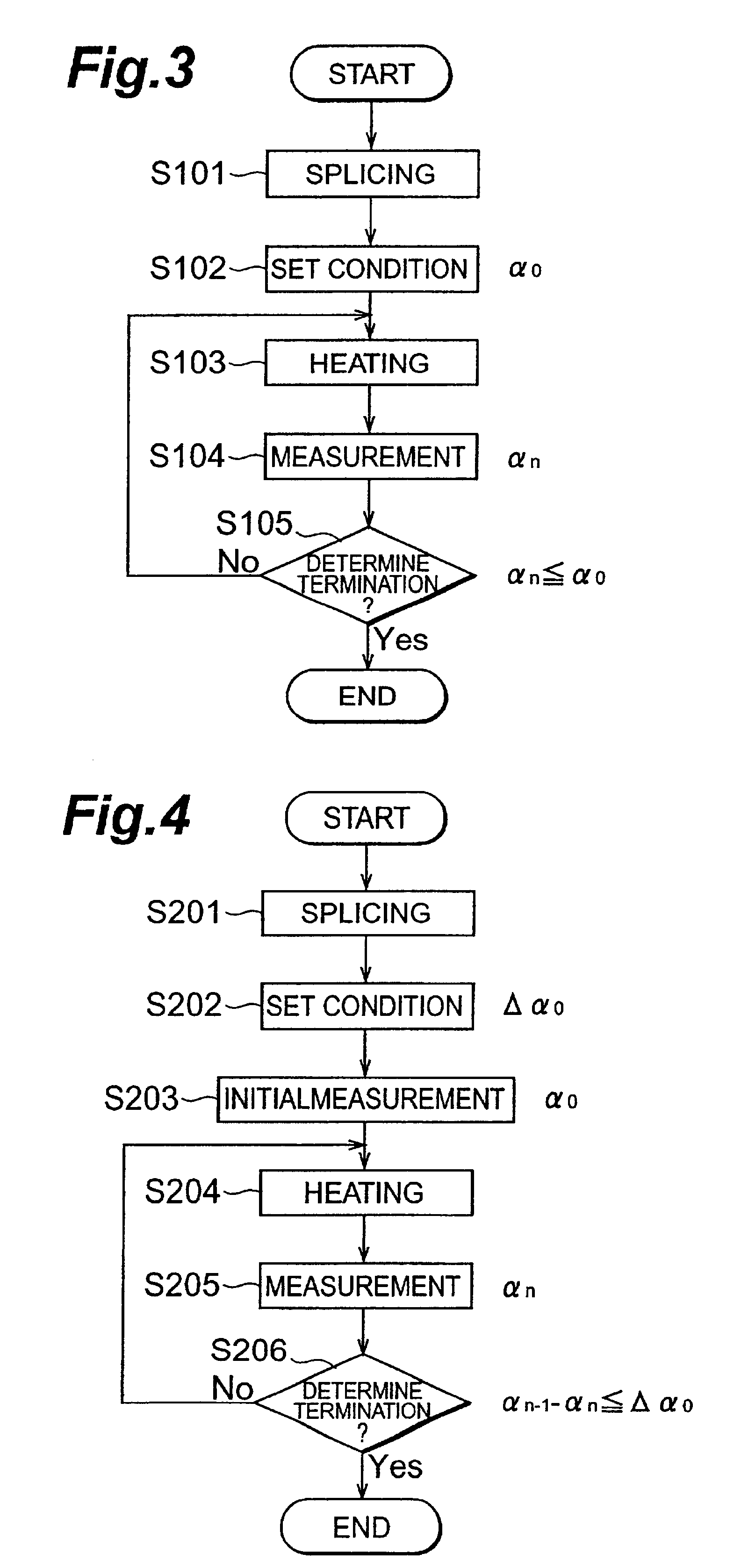

Optical fiber splicing method and optical fiber

InactiveUS6705772B2Splice loss at room temperature is fully reducedShort timeGlass making apparatusElectric discharge heatingRoom temperatureEngineering

An optical fiber splicing method capable of fully reducing the splice loss at room temperature is provided. In the optical fiber splicing method in accordance with the present invention, respective end faces of optical fibers are fused together in a splicing step (S101). In a condition setting step (S102), a set value alpha0 is set. Thereafter, a heating step (S103), a measuring step (S104), and a termination determining step (S105) are carried out repeatedly. In the heating step, a region including the fusion-spliced point is heated under a predetermined heating condition. In the measuring step, splice loss is measured. In the termination determining step, the splice loss alphan measured in the measuring step and the set value alpha0 set in the condition setting step are compared with each other in terms of magnitude. If the splice loss alphan is not greater than the set value alpha0, then it is determined that the alternation should be terminated, whereby the optical fiber connecting operation is terminated.

Owner:SUMITOMO ELECTRIC IND LTD

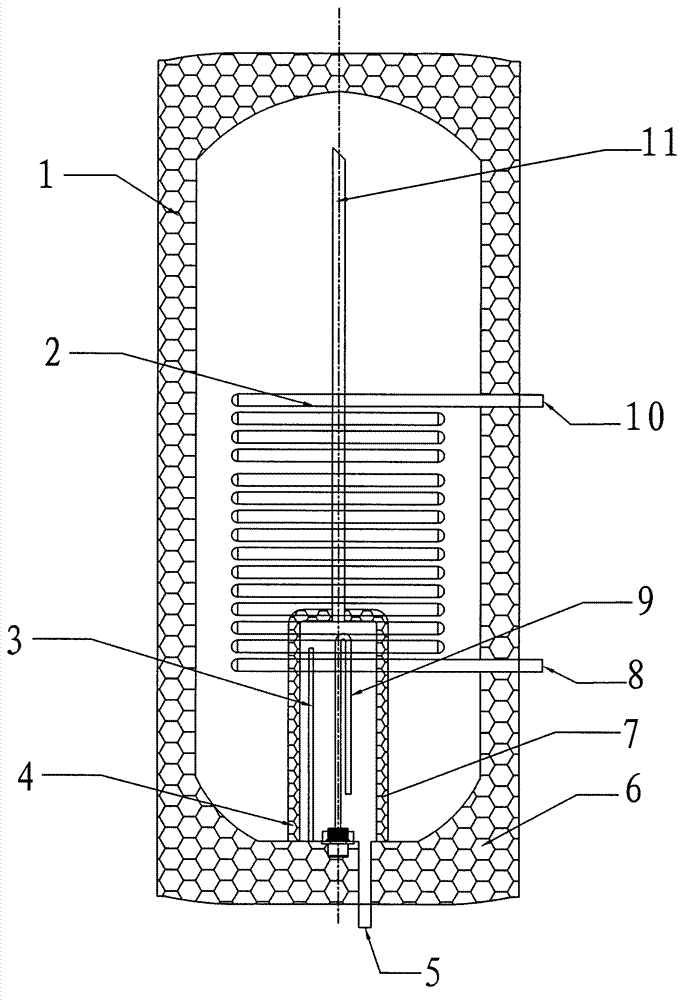

Energy saving hot water tank device

InactiveCN102809218ALong heating timeSave electricityFluid heatersSolar heat devicesElectricityHeating time

The invention discloses an energy saving hot water tank device, and relates to the technical field of hot water tanks, in particular to a hot water tank with heat source supplied by solar energy, air energy or gas-fired boiler, steam, terrestrial heat, electric heat and the like. The device comprises a water tank and a small inner container arranged inside the water tank; a heat exchange coil pipe is arranged in the water tank; a circulating inlet and a circulating outlet of the heat exchange coil pipe are respectively connected with a circulating heat source; the upper part of the small inner container is provided with a water pipe; a water inlet of the small inner container at the top end of the water pipe extends to the upper part of the water tank; the lower part of the small inner container is connected with a water outlet pipe; a hot water outlet at the end part of the water outlet pipe extends out of the water tank; and an electric heating pipe or a quartz heating pipe is arranged in the small inner container. The energy saving hot water tank device disclosed by the invention solves the problem of long heating time and large energy consumption for a traditional hot water tank caused by that the entire water tank needs to be heated up in order to achieve a required water temperature, so that the hot water can be used at any time.

Owner:嘉兴市奥华新能源科技有限公司

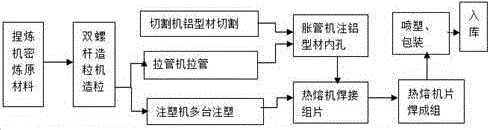

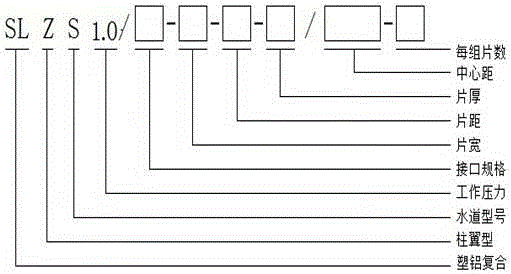

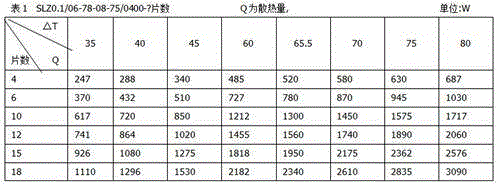

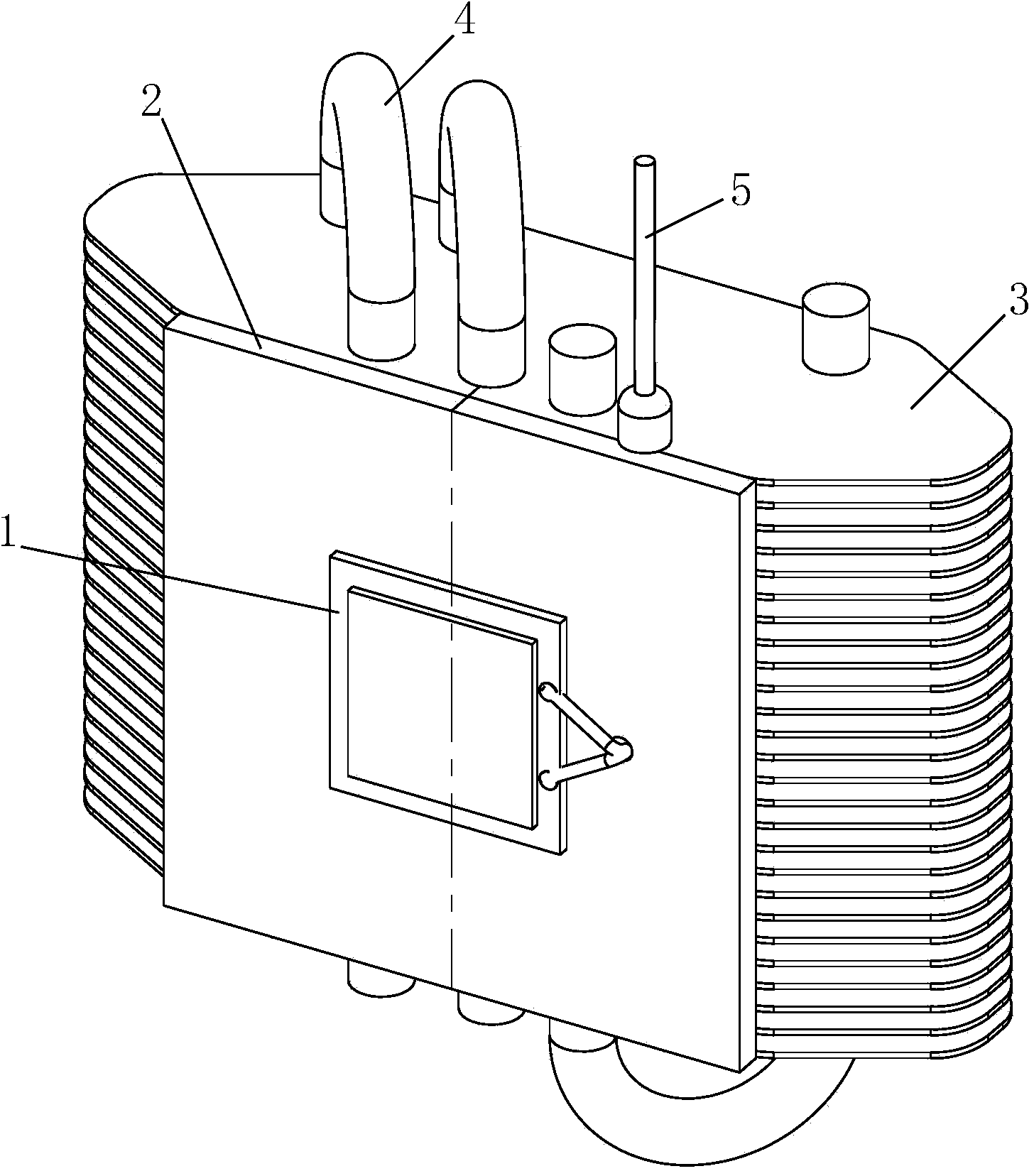

Thermal conductive plastic alloy, radiator based on alloy and preparation method

InactiveCN105175907AGood frost and heat resistanceStable molecular structureHeat exchange apparatusFiberAlloy

The invention discloses a thermal conductive plastic alloy used for a radiator, a radiator and a preparation method. The thermal conductive plastic alloy comprises polybutene or polyisobutene, polyethylene, graphite powder, carbon fiber, thermal conductive carbon black, a thermal conductive reinforcing agent, a titanate coupling agent and stearic acid. The thermal conductive plastic alloy is subjected to granulation, then pipe drawing and injection molding are carried out, an inner water channel pipe and a connecting piece of an radiator are prepared, the inner water channel pipe is expanded into an inner hole of an aluminum wing pipe of the radiator to obtain a radiator column material or sheet material, the column material or the sheet material and the connecting piece are subjected to sweat soldering to prepare a radiator single sheet, and finally the radiator single sheets are subjected to sweat soldering to compose a radiator. The thermal conductive plastic alloy and the radiator are advantaged by good environmental protection and excellent heat radiation performance, are stable and durable, and have protruding characteristics of no fouling, no rusting, no corrosion, no cracking, no pollution, no deformation, no abnormal sound and no aging.

Owner:徐继煌

Light emitting diode device and method of producing the same

InactiveUS20130193477A1Load applied can be suppressedLong heating timeSemiconductor/solid-state device manufacturingSemiconductor devicesLight-emitting diodeDiode

A method of producing a light emitting diode device includes preparing an encapsulating resin layer; embedding a light emitting diode element in the encapsulating resin layer; and heating while pressing with gas the encapsulating resin layer having the light emitting diode element being embedded therein.

Owner:NITTO DENKO CORP

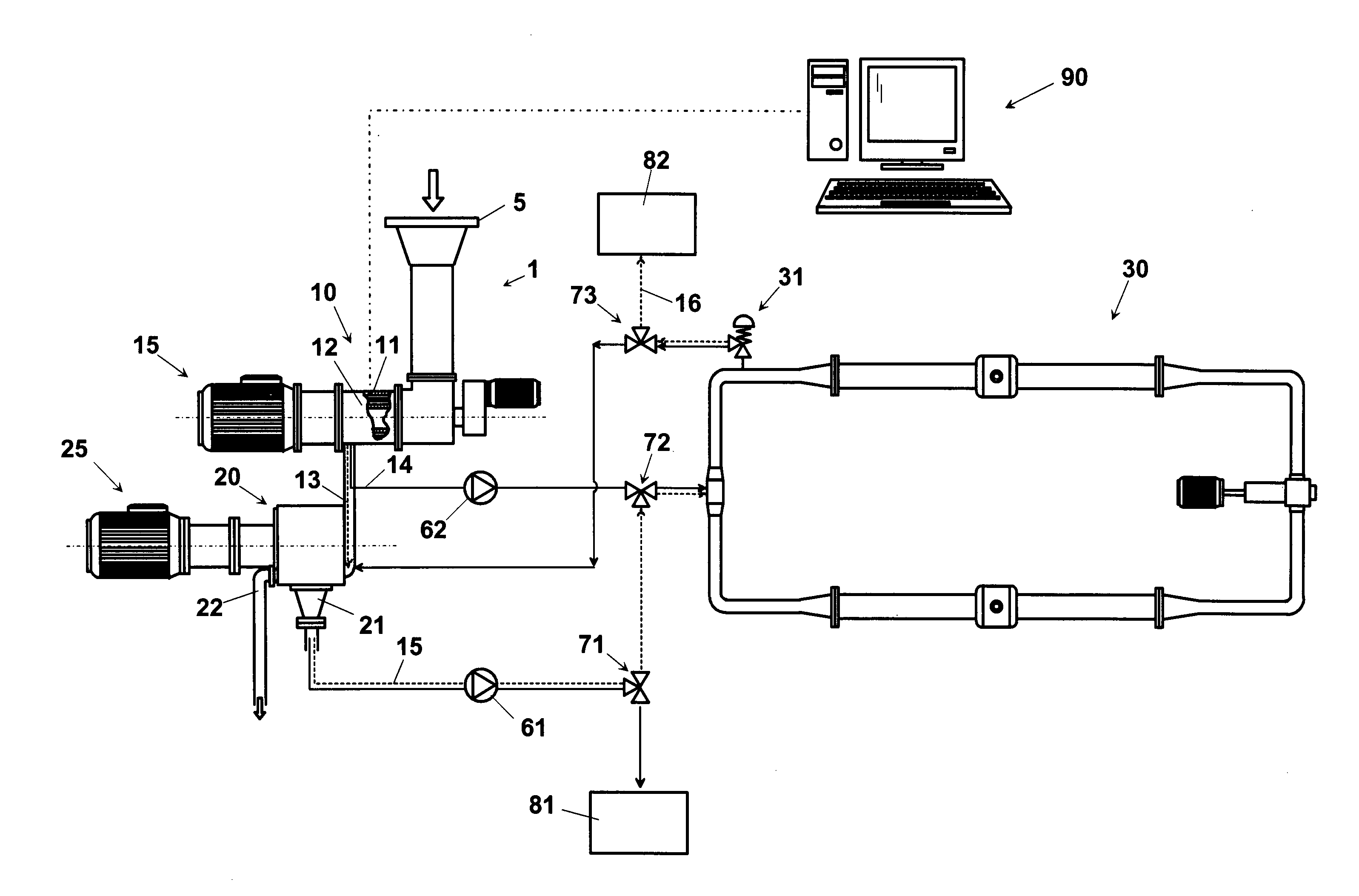

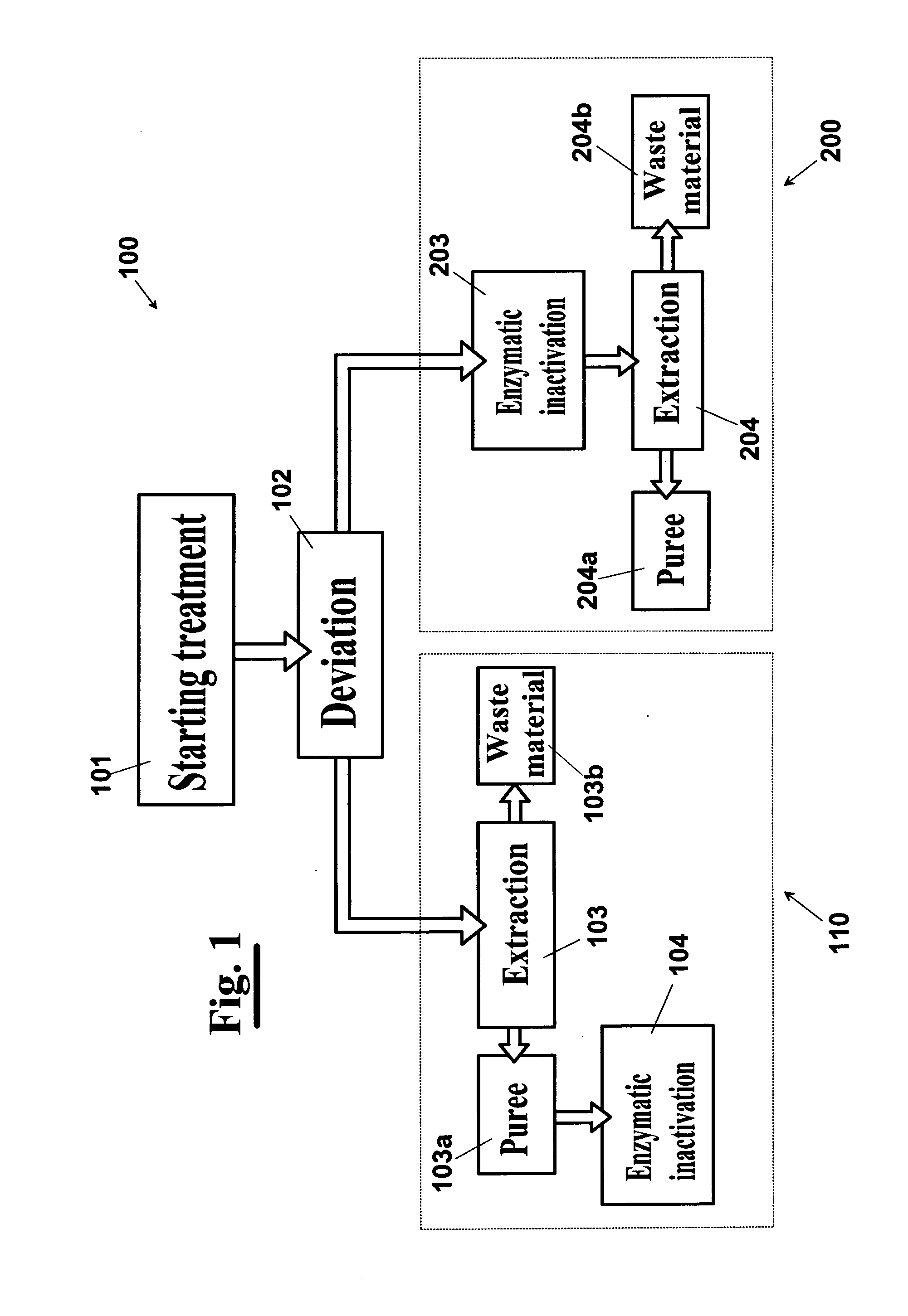

Method and apparatus for extracting puree or juice from a vegetable or animal food

ActiveUS20110244101A1Shorten speedLong heating timeJuice extractionCentrifugesFruit juiceAnimals food

Method for extracting puree, or juice, from a starting product based on vegetable or animal food comprising a starting treatment step, for example a step of softening the food product obtaining a treated product (101). A deviation step lows (102), during which the treated product is selectively directed towards a cold extraction (110), or towards a hot extraction (200). If the treated product is directed towards a cold extraction, it follows firstly an extraction step (103), in which the treated product at the inlet is separated into a main product comprising the puree, or the juice (103a) and into a waste material (103b). The main product is then subjected to an enzymatic inactivation step which provides quickly heating the treated product up to a determined temperature T (104). In case, instead, the treated product is directed towards a hot extraction, it follows firstly the enzymatic inactivation step (203), and then it follows the extraction step, from which the main product (204a) and the waste material (204b) derive.

Owner:BERTOCCHI ALESSANDRO

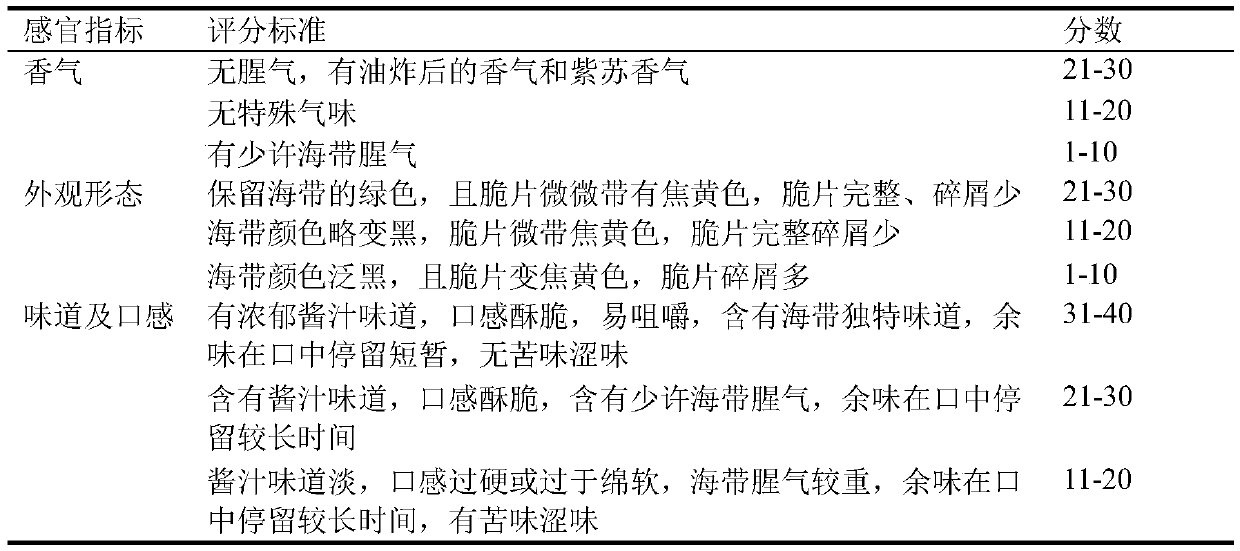

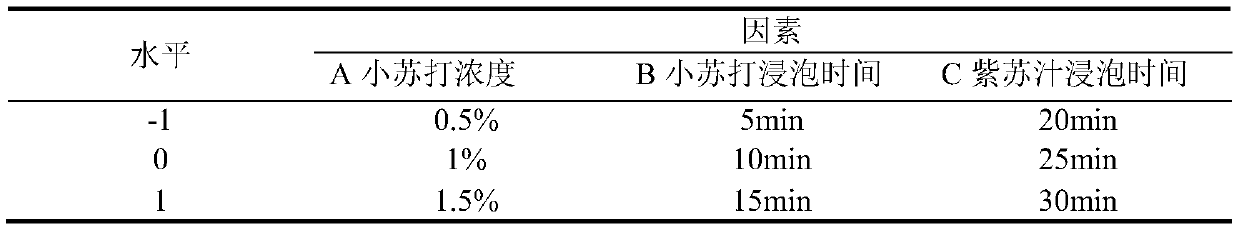

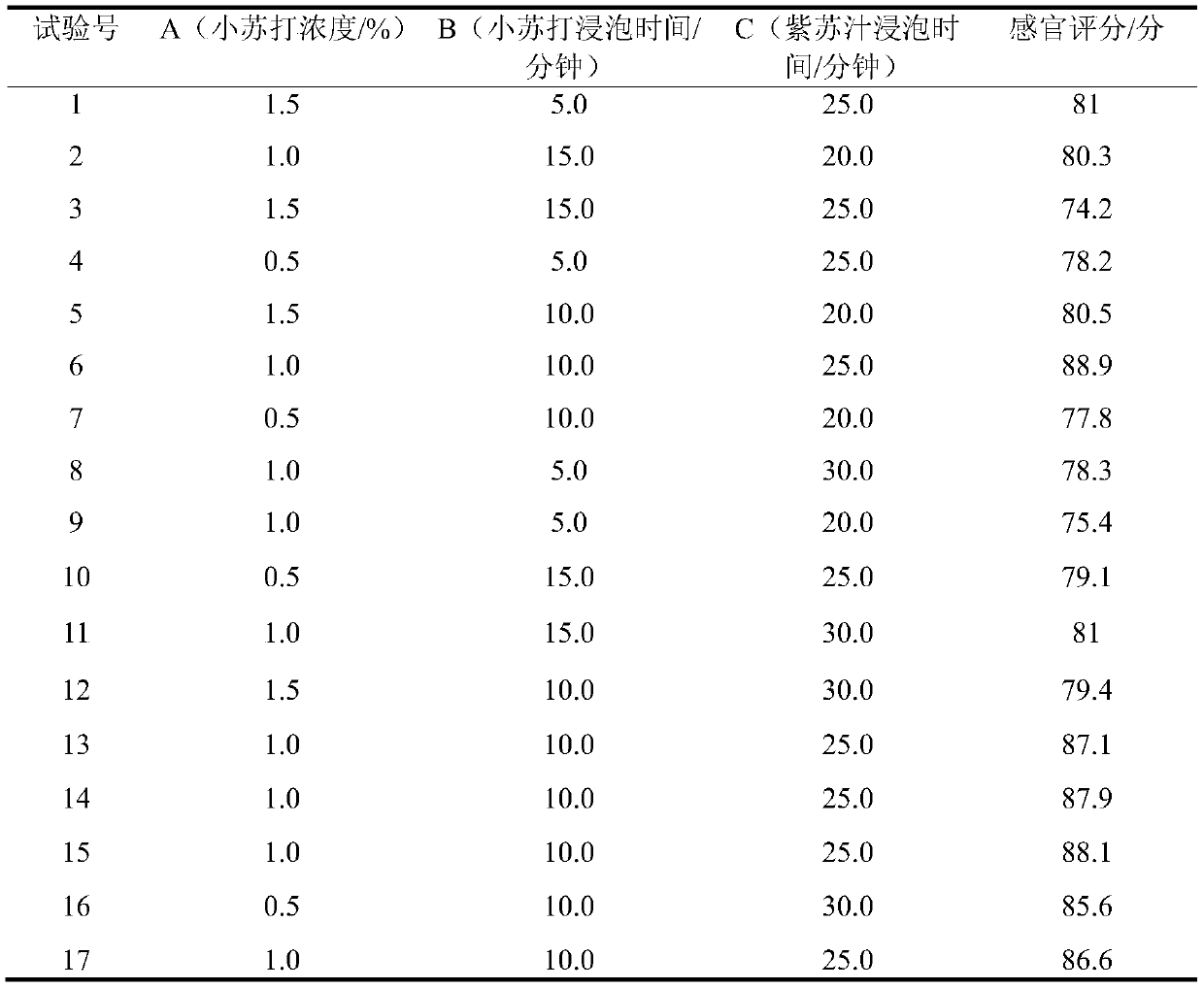

Processing method of ready-to-eat kelp chips

PendingCN110236145AControl intakeSatisfy a craving for a snackLipidic food ingredientsFood dryingReady to eatRoom temperature

The invention discloses a processing method of ready-to-eat kelp chips. The method comprises the steps of performing dry steaming on salted dry kelp, and performing cleaning so as to obtain pretreated kelp; placing the pretreated kelp in water containing perilla frutescens juice and cooking wine, and performing soaking at room temperature so as to obtain soaked kelp; then immersing the soaked kelp in a baking soda aqueous solution at room temperature, performing washing with water, performing cutting into slices, and performing seasoning so as to obtain seasoned kelp slices; and finally, drying the kelp slices in hot air of 170-190 DEG C so as to obtain the ready-to-eat kelp chips. The average fat content of the products namely the ready-to-eat kelp chips is only 1.9%, so that the desire of people for eating snack foods can be met, the taken-in heat quantity can also be controlled, and nutrients can be obtained.

Owner:ZHEJIANG UNIV OF TECH

Rare earth permanent magnet and method for preparing same

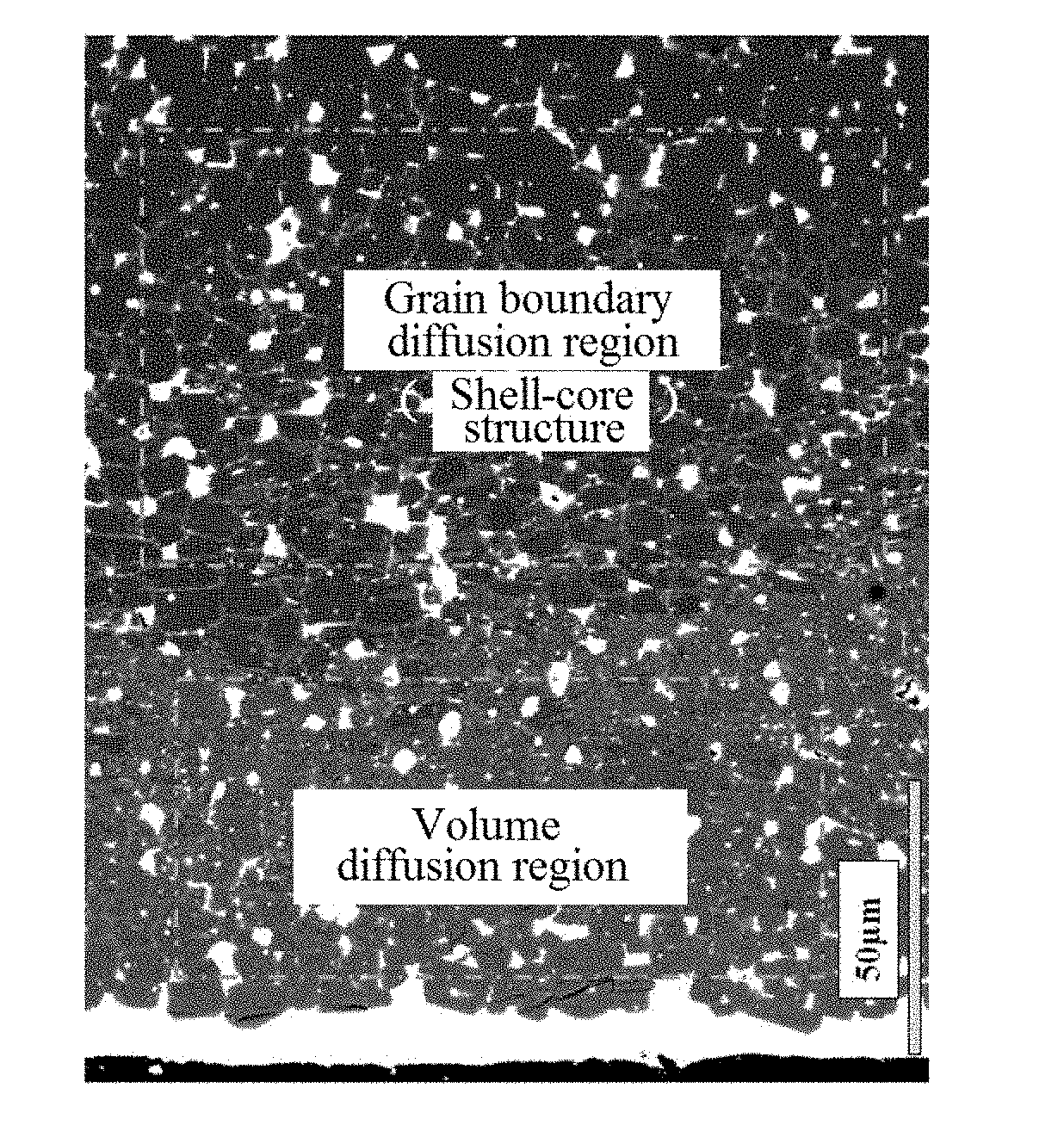

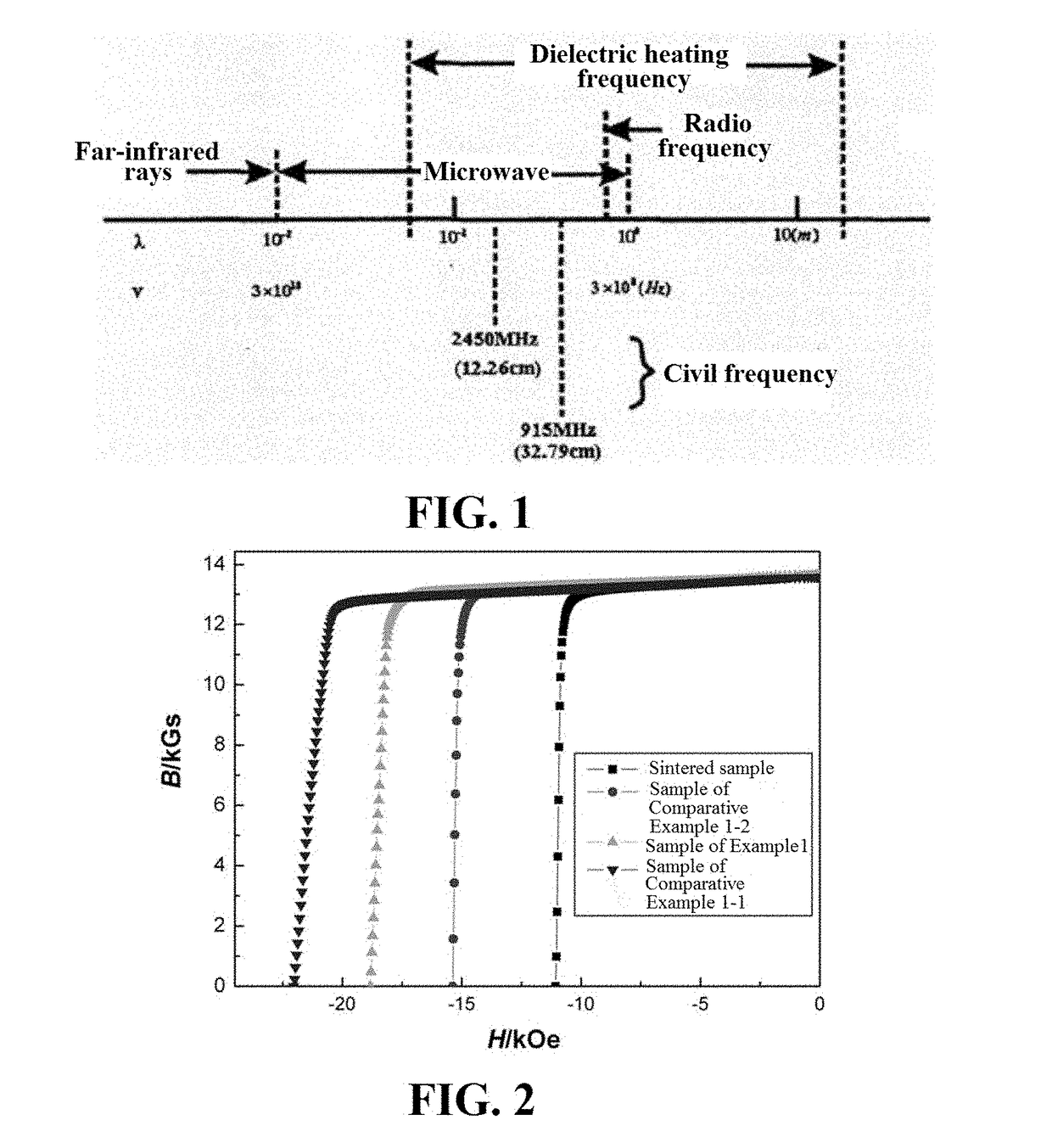

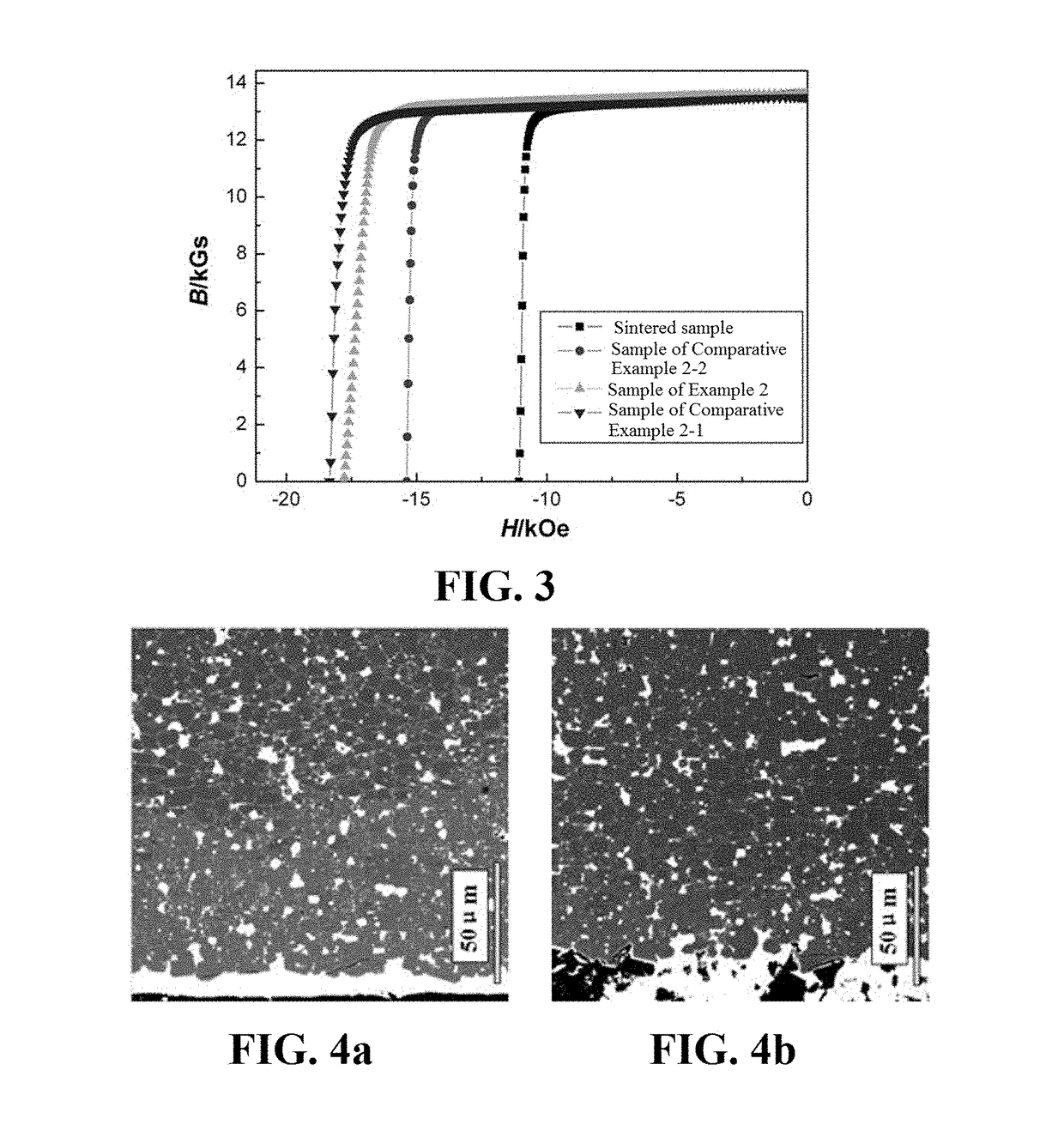

ActiveUS20170250019A1Improve heating efficiencyShorten heat treatment timePermanent magnetsSolid state diffusion coatingRare-earth elementSlurry

The present invention discloses a rare earth permanent magnet and a method for preparing same. The material of the rare earth permanent magnet has a heavy rare earth element volume diffusion phenomenon at a depth of 5μm to 100 μm from the surface of the magnet to the interior of the magnet along the magnetic field orientation direction, thereby forming a volume diffusion layer region; the volume diffusion layer region is divided into magnet units having a volume of 10*100*5 μm, and the concentration difference of the heavy rare earth elements of the magnet units at different positions in the volume diffusion layer is below 0.5 at %. The present invention provides a sintered NdFeB magnet of high intrinsic coercive force Hcj on the premise of not influencing the remanence Br and the maximum magnetic energy product (BH)max of products. In the method for preparing the rare earth permanent magnet, microwave heat treatment is performed on a blank magnet coated with heavy rare earth source slurry in a vacuum condition. This method can effectively improve the heating efficiency, reduce the heat treatment time, lower the energy consumption, and reduce the production cost of the magnet.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Method of disposing spacer and method of manufacturing electro-optic device

InactiveUS20040069364A1Proper disposalReducing and preventing and minimizing of variationSolid materialLiquid materialSolventBoiling point

The invention provides a method of disposing spacers which allows spacers to be disposed in a predetermined location more accurately, and a method of manufacturing an electro-optic device, in which the method of disposing spacers is used. A method of disposing spacers in a predetermined location on a substrate for an electro-optic device using a droplet discharge unit, includes discharging droplets onto the substrate for an electro-optic device using the droplet discharge unit. The droplets are formed from a solvent having a boiling point of 150 to 250 ° C. and a viscosity of 10 to 40 mPa.s with the spacers suspended therein.

Owner:SEIKO EPSON CORP

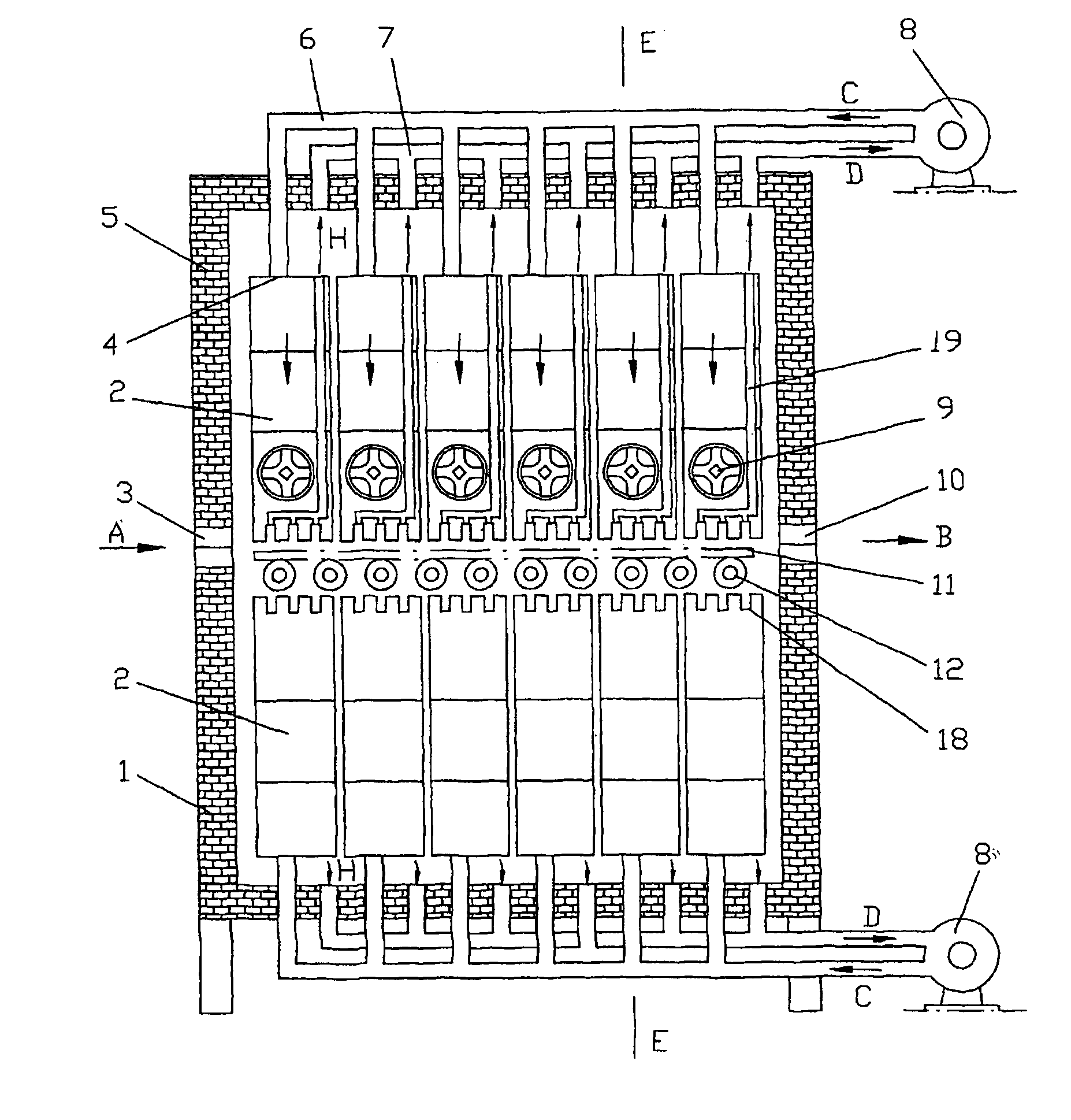

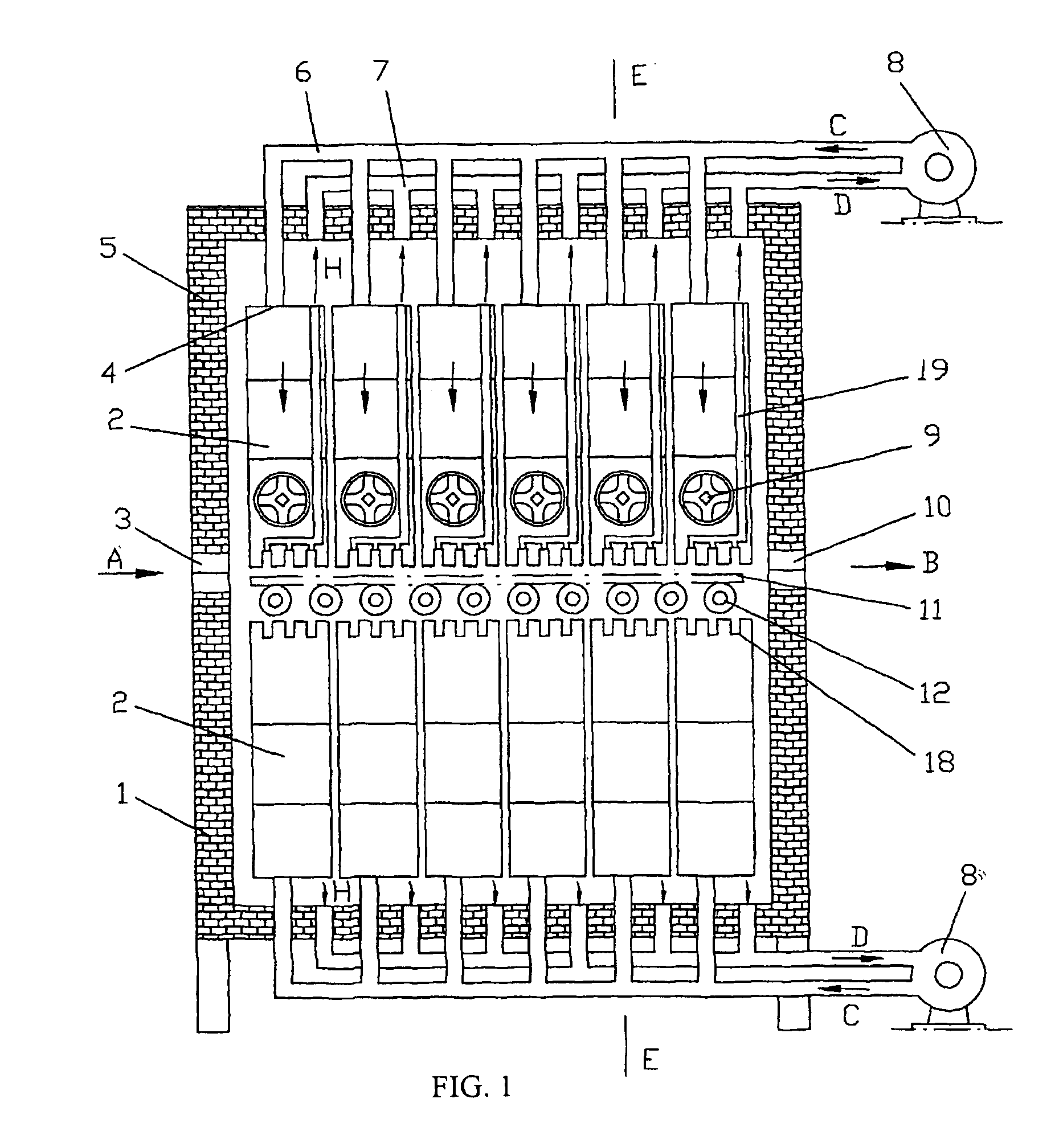

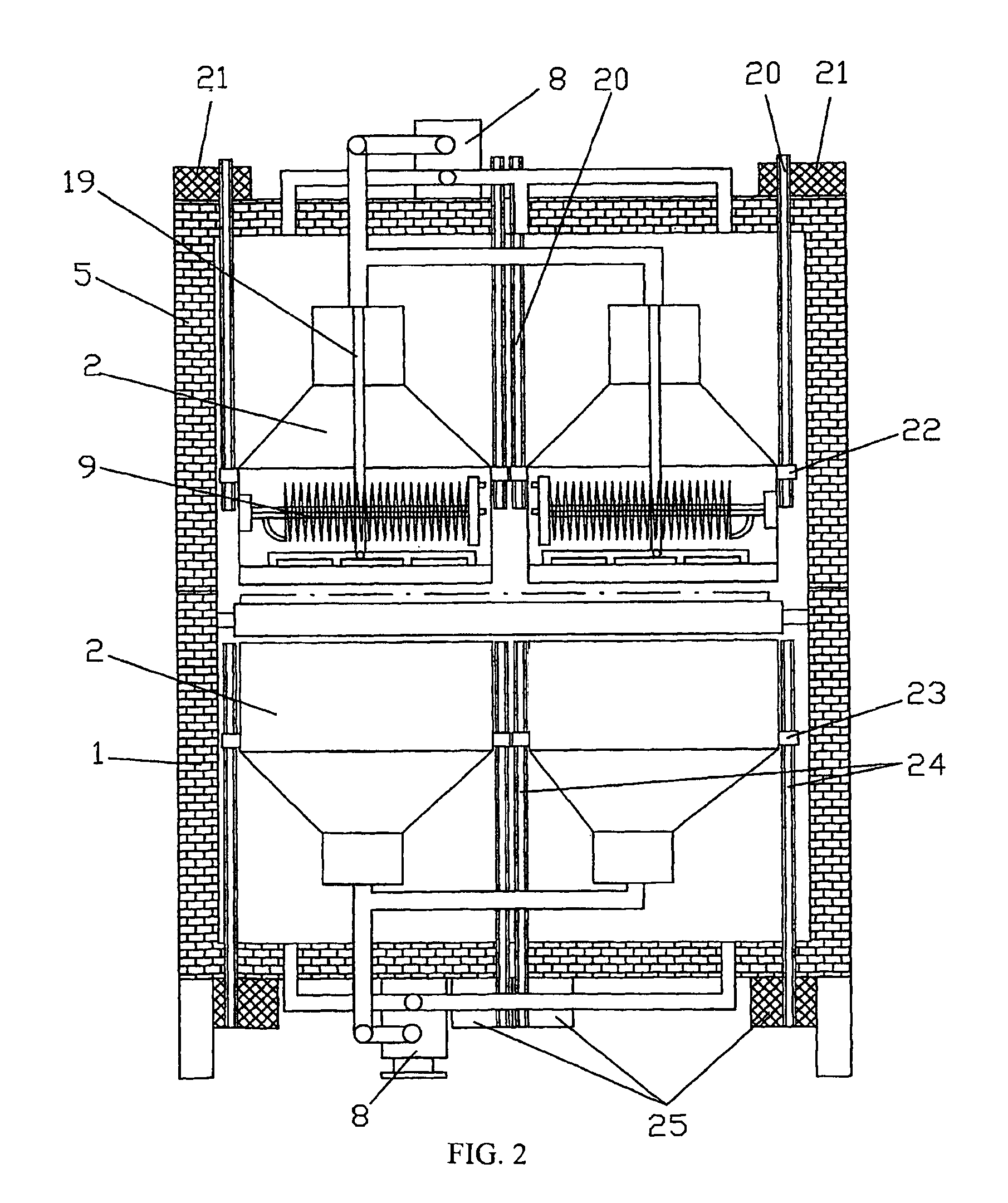

Convection glass heating furnace

ActiveUS7748237B2Lower the heatReduce defectsCharging furnaceGlass drawing apparatusHeating timeEngineering

The invention disclose a convection glass heating furnace, which includes upper and lower furnace bodies, at least one gas-collection box are set in the upper and lower furnace bodies respectively, glass inlets and outlets are setup in the gas-collection box, and a jet-flow plate is set at the gas outlets. The gas inlets of gas-collection box are connected with the exhaust port of a blower fan through pipelines. Gas heating devices are setup in the gas-collection boxes. The gas inlets of the blower fan and its upstream gas routes along with the exhaust port of the blower fan and its downstream gas route form a gas circulation loop together. Glass is heated in the heating furnace of the invention by the hot gas sprayed on its surfaces, so the deficiencies of low heating efficiency and long heating time can be effectively avoided when heating the glass with high reflectivity and transmission ratio. The power of the heating devices can be expediently selected according to the temperature and the flow rate of the hot gas needed, in particular, the hot gas sprayed on the upper and under surfaces of the glass can be set to different temperatures to make the upper and under surfaces of the glass be heated uniformly and ensure the heating quality.

Owner:LANDGLASS TECH

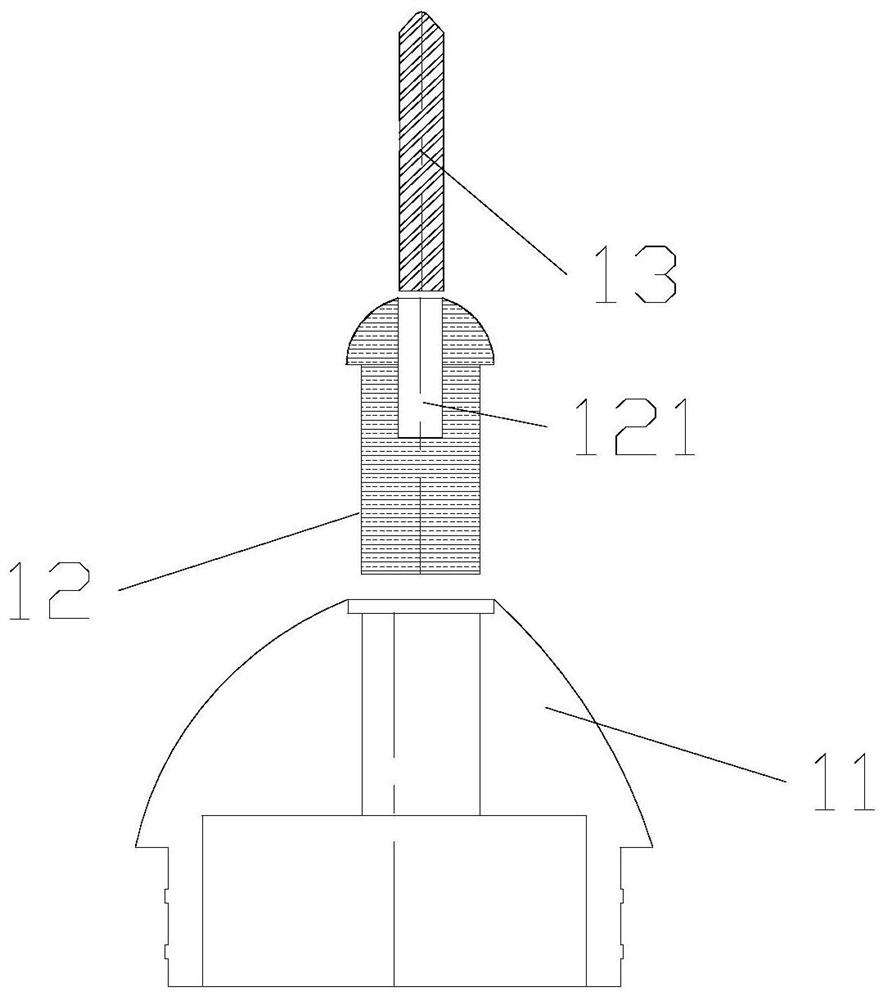

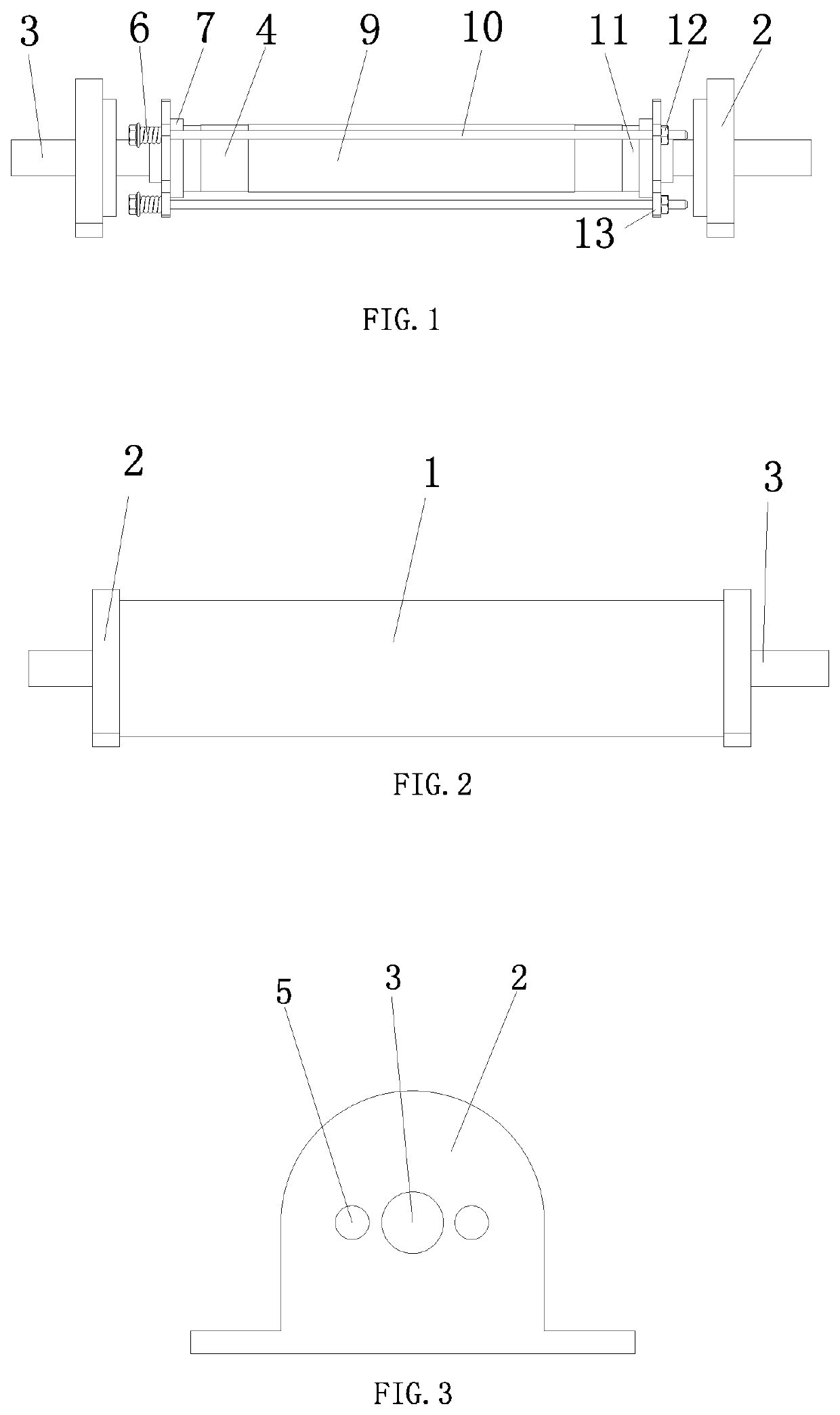

Double-acting hydraulic retarder

The invention discloses a double-acting hydraulic retarder which comprises a shell, a control system, a heat exchanger, an oil tank and a control valve. The heat exchanger is communicated with the shell, an impeller and a high-pressure oil injection device are arranged in an inner cavity of the shell, oil can be injected to the impeller by the high-pressure oil injection device during high-speed brake, the inner cavity of the shell is divided into a vacuum working cavity and an oil storage cavity by the high-pressure oil injection device, the impeller can work in the vacuum working cavity, the oil storage cavity is used for storing the high-pressure injection oil, an oil passage is arranged on the shell, the vacuum working cavity is communicated with the oil storage cavity via the oil passage, a low-speed brake oil outlet and a high-speed brake oil outlet are further formed in the shell, the low-speed brake oil outlet is communicated with the oil storage cavity, the high-speed brake oil outlet is communicated with the vacuum working cavity, and both the low-speed brake oil outlet and the high-speed brake oil outlet are communicated with the heat exchanger in a opening and closing manner; the control valve is arranged on the outside of the shell, and the high-pressure oil injection device works under the control of the control valve during high-speed brake. The double-acting hydraulic retarder has the advantages that a vehicle is braked by the aid of a working principle of a pump when the vehicle runs at a high speed and a low speed respectively, so that braking force can be relatively increased when the vehicle runs at the low speed, high braking force can be kept when the vehicle runs at the high speed, and the double-acting hydraulic retarder is high in braking efficiency.

Owner:CHONGQING JIAOTONG UNIVERSITY

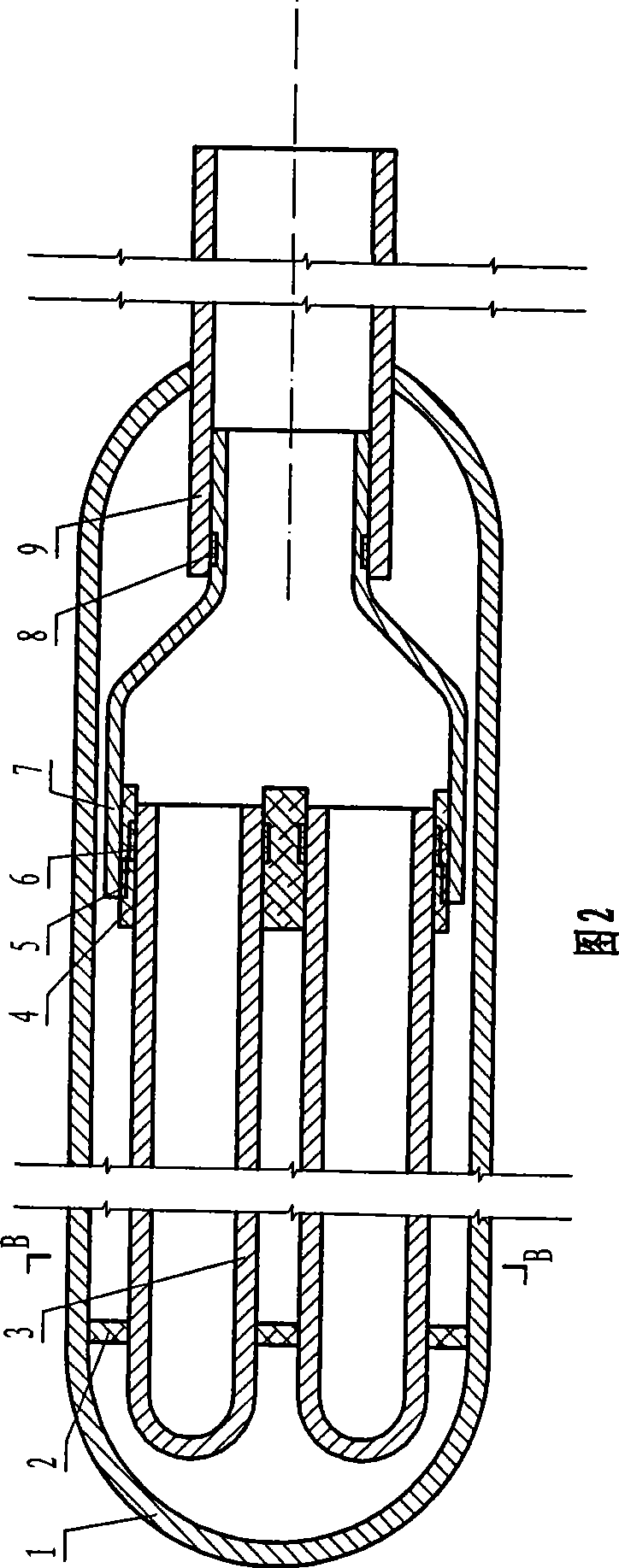

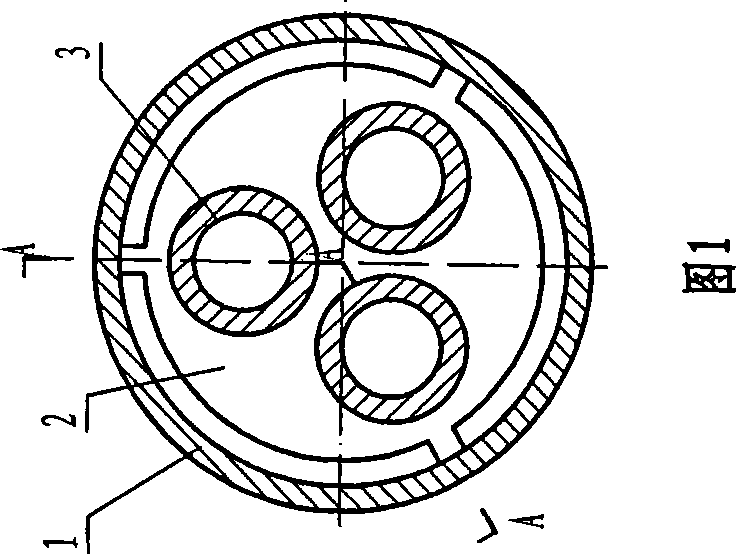

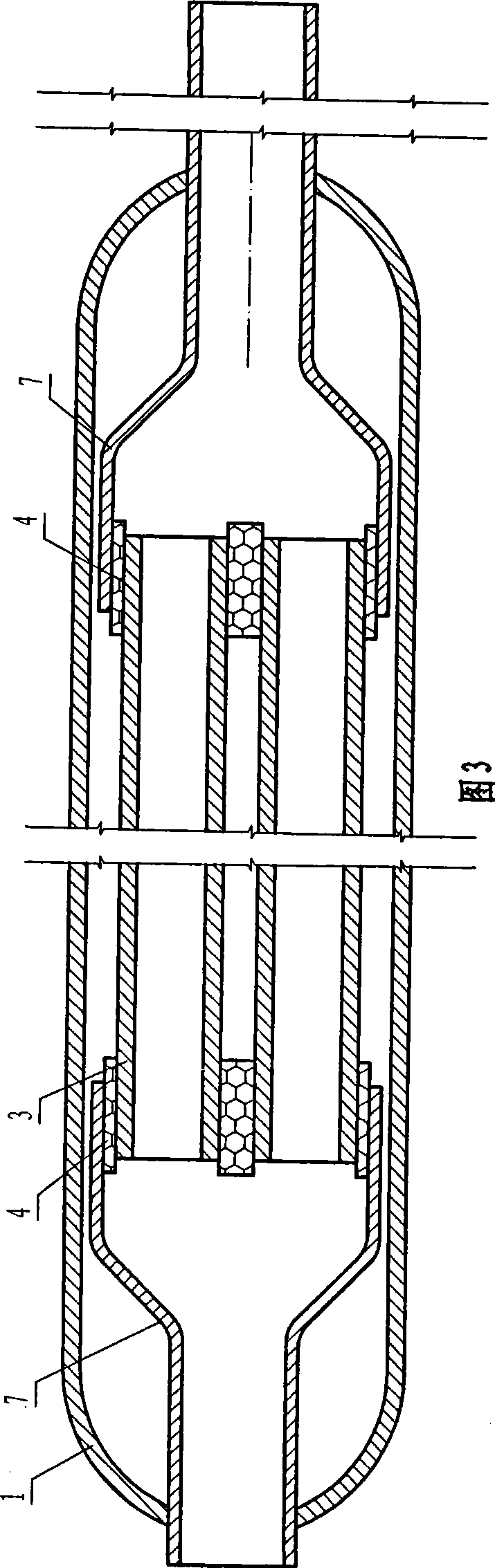

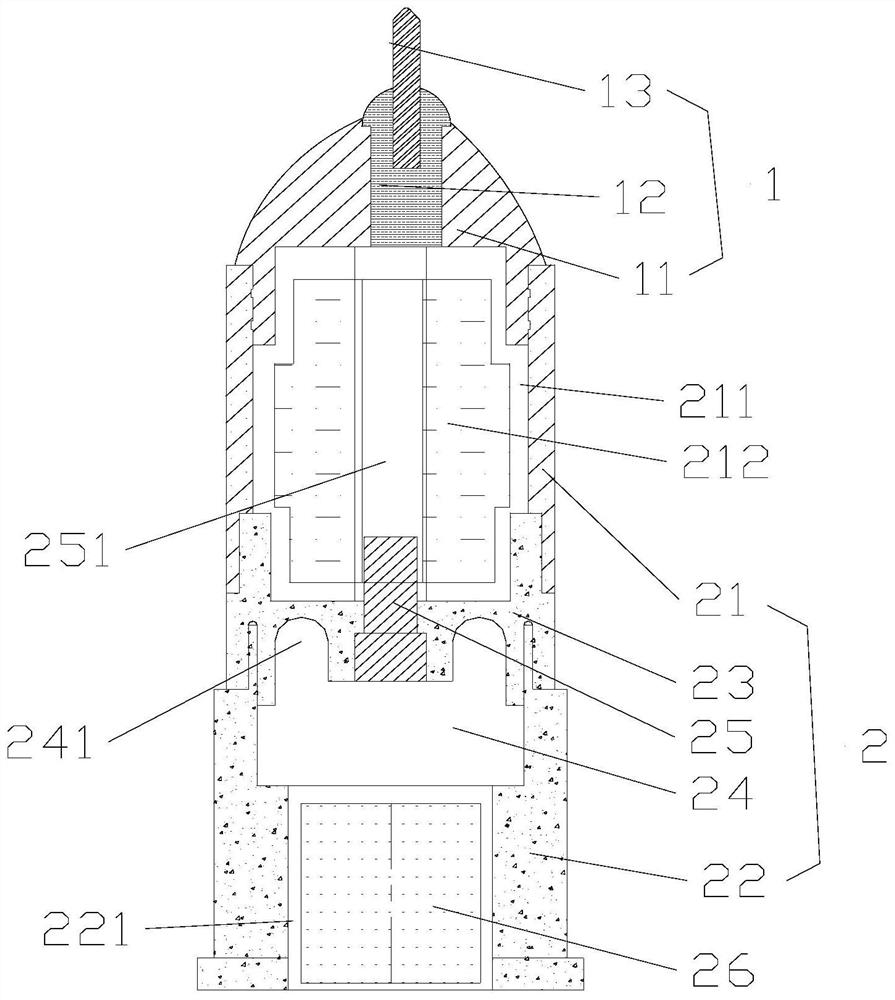

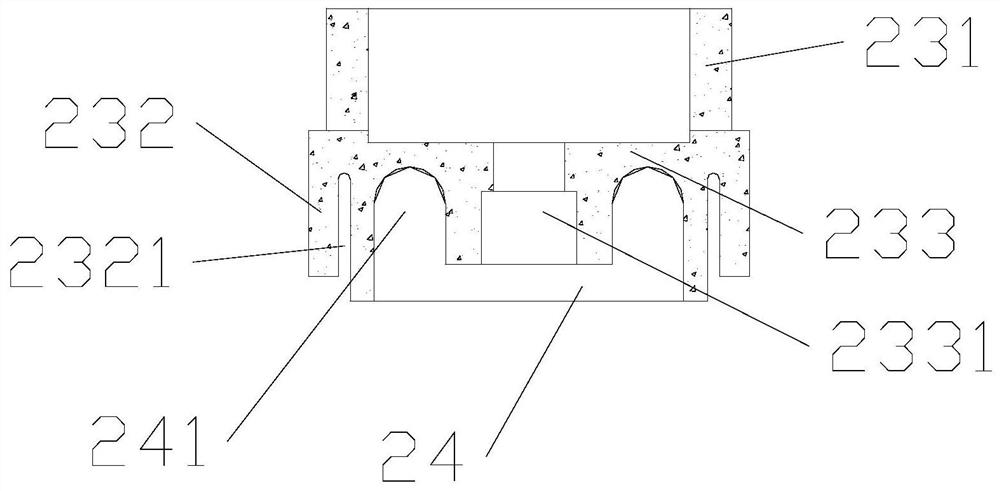

Multidimensional solar vacuum heat-collecting tube

InactiveCN101382349ALarge heat collecting surfaceLong heating timeSolar heating energySolar heat devicesCollection TimeEngineering

The invention provides a multi-dimensional solar vacuum heat collecting tube which belongs to a heat exchange part, in particular to a part which utilizes the solar energy for heating. The multi-dimensional solar vacuum heat collecting tube comprises an outer tube and inner tubes, wherein, the inner tubes are suspended in the outer tube, a vacuum cavity is arranged between the outer tube and the inner tubes; the multi-dimensional solar vacuum heat collecting tube is characterized in that: the vacuum heat collecting tube comprises one outer tube and a plurality of inner tubes. As a plurality of inner tubes are arranged in the outer tube, the heat collection area is larger, the heat collection time efficiency is longer and the heating speed is faster; the production cost of the outer tube is simultaneously saved, so the multi-dimensional solar vacuum heat collecting tube has the advantages of high thermal efficiency and low production cost.

Owner:陈忠

Fin type LED lamp radiator

InactiveCN104165333AExtend your lifeSpeed up exportPoint-like light sourceLighting heating/cooling arrangementsJunction temperatureEngineering

The invention discloses a fin type LED lamp radiator which comprises an LED light-emitting panel, a fixed substrate and cooling fins. The LED light-emitting panel is arranged on one side of the fixed substrate, the cooling fins are arranged on the other side of the fixed substrate, and a plurality of cooling fins are regularly arrayed to constitute an intensive cooling fin set. Heat conduction tubes are further arranged in the intensive cooling fin set in a penetrating mode, and refrigerant fluid is sealed and filled in the heat conduction tubes. According to the fin type LED lamp radiator, the LED light-emitting panel is arranged on the fixed substrate which is made of a high heat-conducting property material, heat generated in the working process of an LED light source can be led out quickly, the heat is transmitted to the intensive cooling fin set which is connected to the fixed substrate in an inserting mode, the heat can be transmitted between the adjacent cooling fins through the heat conduction tubes, large-area radiating can be conducted through the cooling fins, the internal temperature rising time of the LED light source can be prolonged, the internal junction temperature of the LED light source can be lowered, and the service life of the light source can be prolonged relatively.

Owner:JIANGSU DEMANDS OPTOELECTRONICS TECH

Colloid quick removing method for carbon fiber

InactiveCN102330326AAvoid surface damageSmall mechanical propertiesPhysical treatmentFiberCarbon fibers

The invention discloses a colloid quick removing method for a carbon fiber, comprising the following steps of: a, connecting two ends of the carbon fiber, which is needed to remove the colloid, to the anode and the cathode of a power supply; b, electrifying the carbon fiber to emit heat; c, measuring the surface temperature of the carbon fiber via a temperature sensor; d, controlling the current so as to control the surface temperature of the carbon fiber, thereby enabling the temperature to satisfy a condition of quickly melting and volatilizing the surface colloid without reducing the mechanical properties of the carbon fiber; e, controlling the colloid removing time, and rolling up the carbon fiber after removing the colloid. On one hand, the surface colloid is melted and volatilized by the heat emitted by the carbon fiber, which solves the defects of long temperature rise time, low colloid removing efficiency, energy wastage and the like of the conventional gaseous oxidation colloid removing mode in which a heat source is arranged at outside of the heated carbon fiber and the heat transfer is finished by convection, radiation and conduction, and is economic and environmentally friendly; on the other hand, the carbon fiber is heated under protective atmosphere, the heating temperature is high, the colloid is removed completely, simultaneously, damage on the surface of the carbon fiber is avoided, the mechanical properties of the carbon fiber are not changed greatly, and strength of the carbon fiber used as a composite material reinforcement is guaranteed.

Owner:CHINA ZHONGWANG

Window breaking bullet launched by unmanned aerial vehicle

PendingCN111811337AEasy accessShorten ignition timeAmmunition projectilesProjectilesUncrewed vehicleFiring pin

The invention provides a window breaking bullet launched by an unmanned aerial vehicle. The window breaking bullet comprises a bullet body and a hitting unit fixedly arranged at the front end of the bullet body, wherein the hitting unit comprises a hitting hammer, a firing pin base and a firing pin fixedly arranged on the firing pin base; the firing pin base is fixedly arranged on the hitting hammer; and the firing pin and the hitting hammer are arranged in an eccentric mode. The window breaking bullet utilizes the firing pin, and can utilize impact force of the bullet body and the firing pinto damage point of a window while being just in contact with a window; the firing pin and the hitting hammer are arranged in the eccentric mode, so that the bullet deviates towards one side while thefiring pin is in contact with the window; and the size of the bullet is utilized, and impact force generated during bullet launching is utilized to break the window on a large area, so that staff conveniently goes in and out.

Owner:北斗安泽防务科技有限公司 +2

Film type liquid heater and uniform heating method thereof

PendingUS20220136733A1High precisionLong heating timeHeater elementsHeating element shapesHeating filmThin membrane

The present invention discloses a film type liquid heater and a uniform heating method thereof. End fixation plates are arranged at two ends of a barrel. A heating pipe is arranged in the barrel. Pipe ports run through the two end fixation plates, respectively. Connecting pipes are arranged in the pipe ports. Sealing connection components are arranged at inner ends of the two connecting pipes. A heating film layer is coated outside the heating pipe. Electrode layers are connected left and right sides of the heating film layer, and the electrode layers are connected to an external power supply. An insulating layer is coated outside the heating film layer. A flow splitting column is fixedly connected in the heating pipe. A heating chamber is formed between an inner side of the heating pipe and the flow splitting column. Flow splitting grooves are formed at left and right ends and on the inner side of the flow splitting column. Two outer ends of the flow splitting grooves are communicated with the connecting pipes, and the flow splitting grooves are communicated with the heating chamber. The heating film layer is electrified to generate heat. The heat is conducted inward to the heating pipe and the flow splitting column, and conducted outward to the barrel. Liquid flows into the heating chamber through the connecting pipes and the flow splitting grooves, so that the heating uniformity of the liquid flow flowing through the heating chamber is improved.

Owner:ZHEJIANG CHEER TECH CO LTD

Stator coil heating apparatus and stator coil heating method

ActiveUS20140091084A1Heat processingLow costCoil arrangementsManufacturing dynamo-electric machinesThermal deformationStator coil

A stator coil heating apparatus and a stator coil heating method that are capable of effectively preventing a core from thermal deformation particularly caused due to a magnetic flux generated by a coil head, without the problem of heating temperature variation, and also shortening a time for the process of heating a stator coil, are provided.A stator coil heating apparatus A to heat a stator coil L wound around a circular core F, comprises: induction heating coil heads 1 and 11 that heat the circular coil L by generating an inductive effect acting from outside in the thickness direction of the core F, against circular winding coil bases La and Lb that are sticking out of end faces Fa and Fb of the core F in the thickness direction thereof; and shields 2 and 12 that block a magnetic flux generated by the coil heads 1 and 11, out of the end faces Fa and Fb of the core F in the thickness direction thereof.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com