Colloid quick removing method for carbon fiber

A carbon fiber, fast technology, applied in fiber processing, textiles and papermaking, physical treatment, etc., can solve the problems of high cost, complex degumming process, low degumming efficiency, etc., achieve fast heating speed, high degumming efficiency, avoid The effect of surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

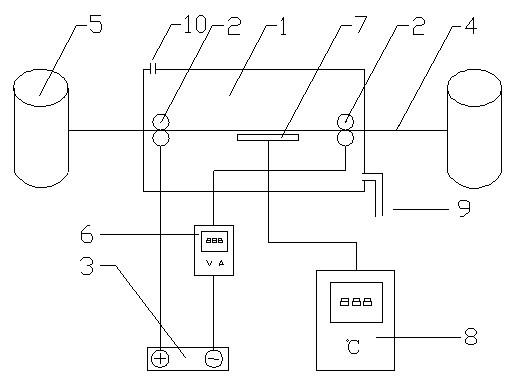

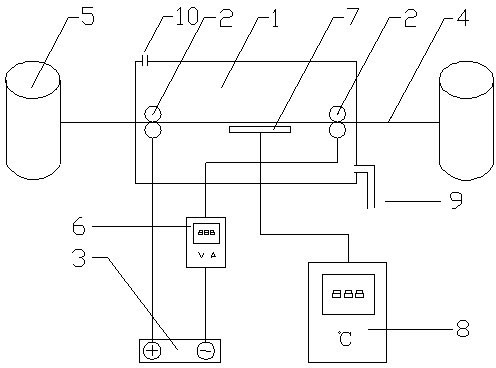

[0019] figure 1 It is a system structure diagram of the quick glue removal method of carbon fiber in the present invention. As shown in the figure, the system includes two pairs of conveying rollers 2 for conveying carbon fibers 4 , and the two pairs of conveying rollers 2 are respectively electrically connected to the positive and negative poles of the power supply 3 . When in use, electrify the carbon fiber located between the conveying rollers. Since the carbon fiber itself has resistance, it will generate heat after electrification. When the surface of the carbon fiber rises to a certain temperature, the colloid will start to melt and volatilize rapidly, and at the same time, the carbon fiber will move under the action of the conveying roller. , You can control the degumming time by adjusting the speed of the conveying roller, so as to achieve the purpose of completely degumming. A current controller 6 is arranged between the power supply 3 and the conveying roller 2 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com