Patents

Literature

50results about How to "Heat thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

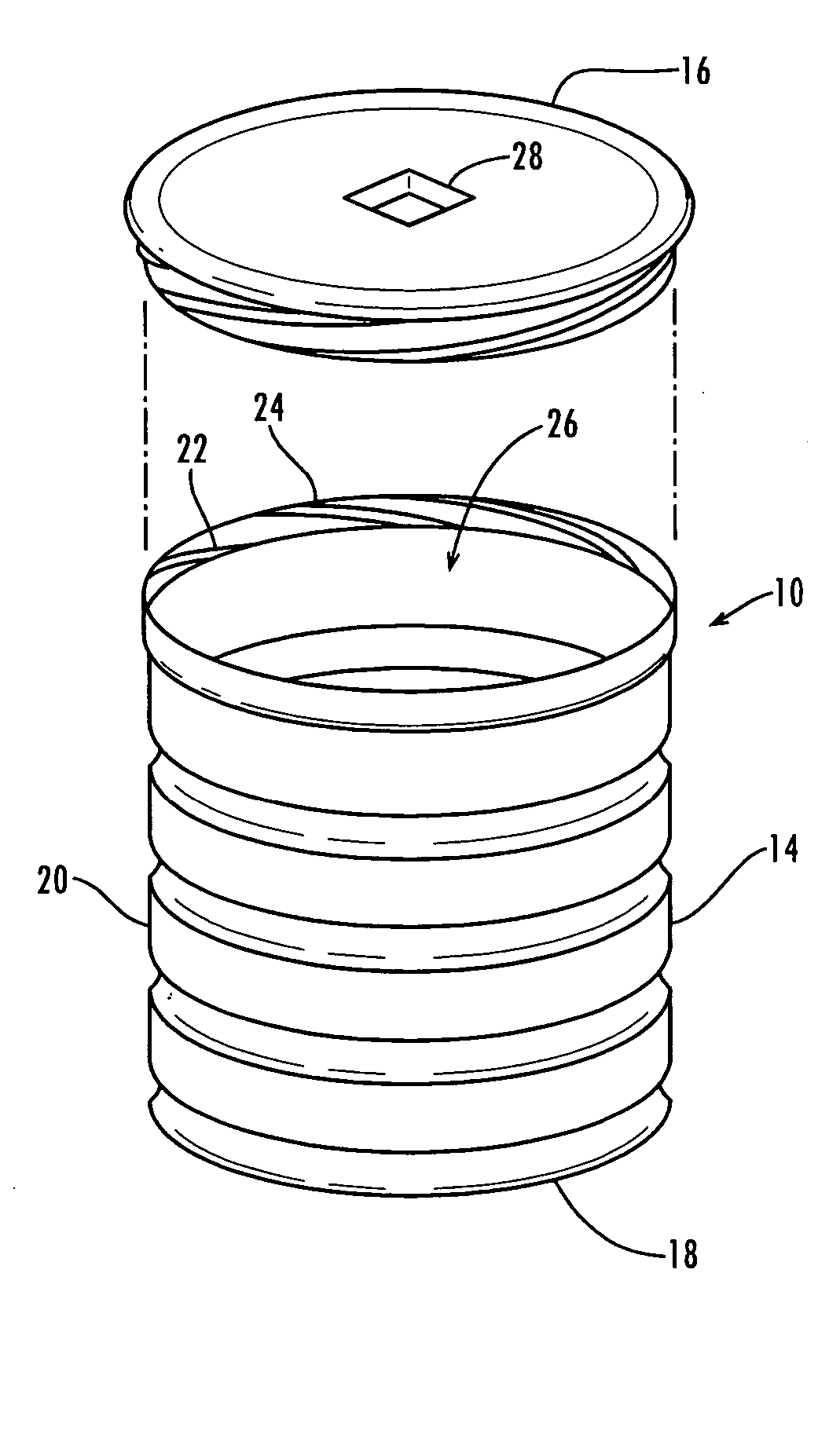

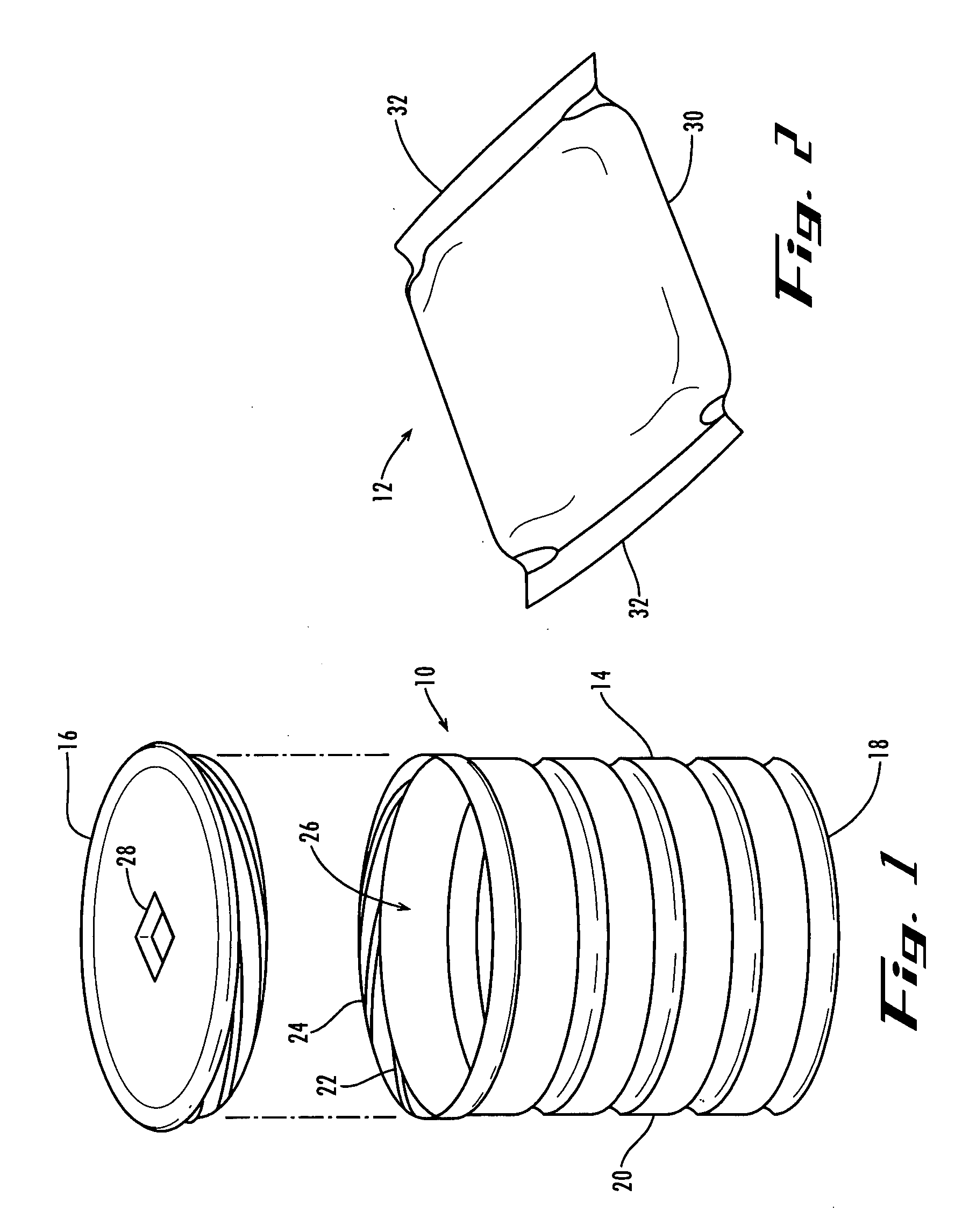

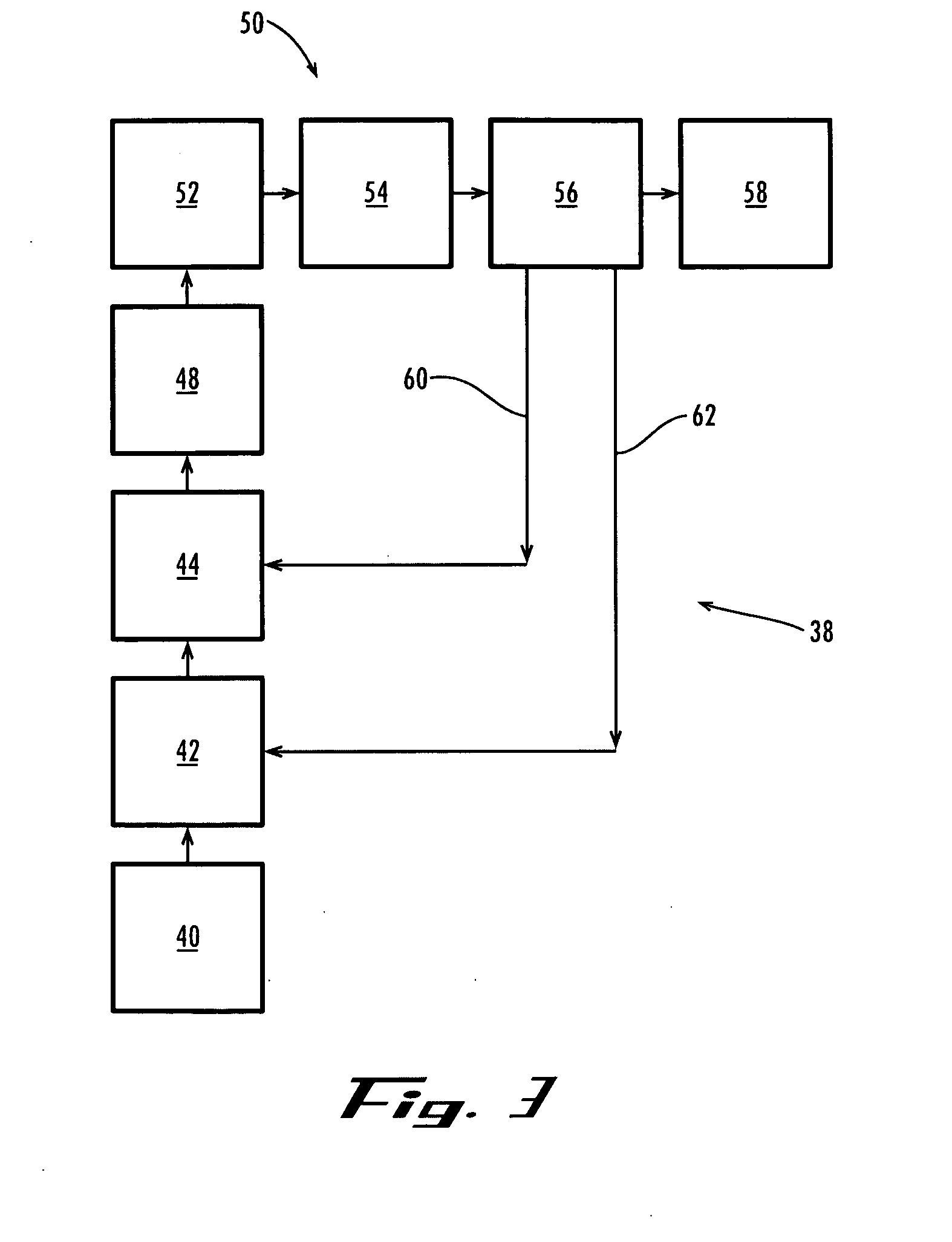

Reusable Container and Method for Retorting Flexible Packages Containing Foodstuff

InactiveUS20070082096A1Heat thoroughlyReduce packaging costsPackage sterilisationHops treatmentMechanical engineeringFood item

Method for retorting flexible packages containing foodstuff comprising retorting the flexible packages containing foodstuff in reusable, hermetically resealable, rigid retort containers. A retort container comprises a body portion including a base and outer side walls extending from the base to a mouth portion defining an opening and a resealable lid for selectively hermetically sealing the opening in the container and alternatively opening the container for removal of the flexible packages containing foodstuff.

Owner:PRINTPACK ILLINOIS

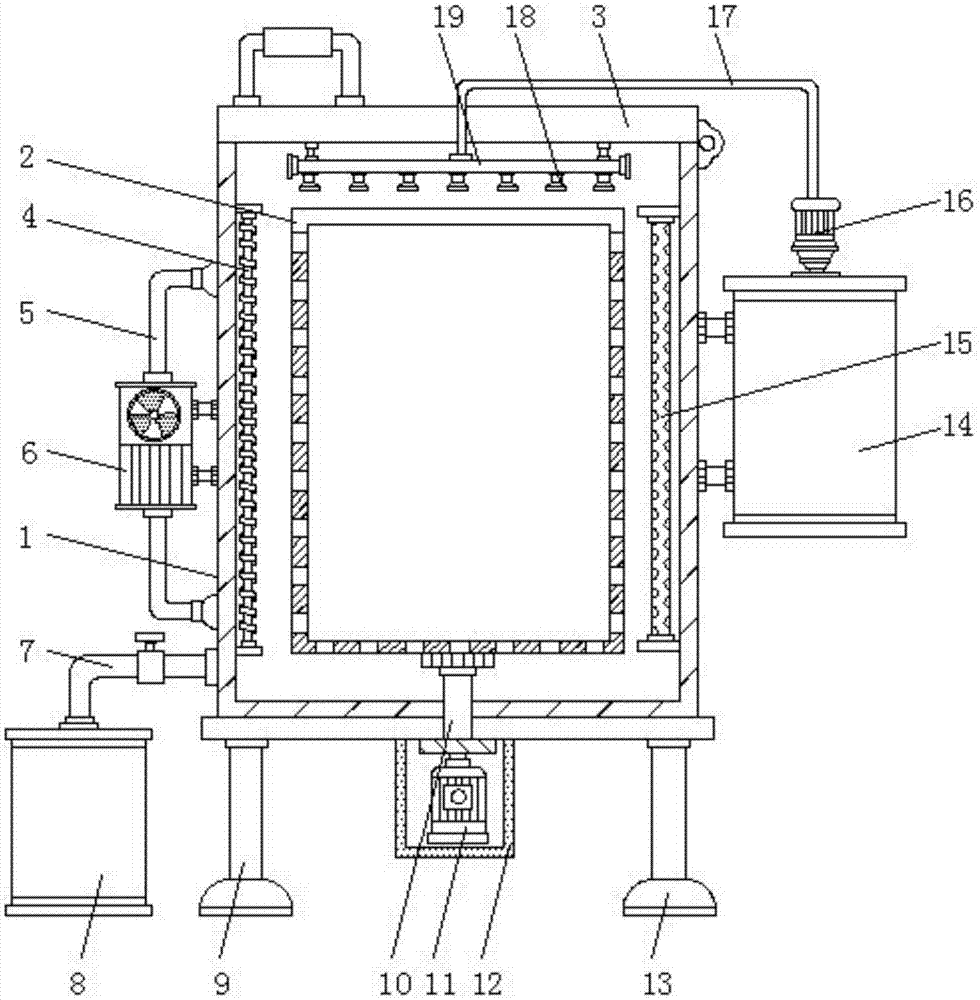

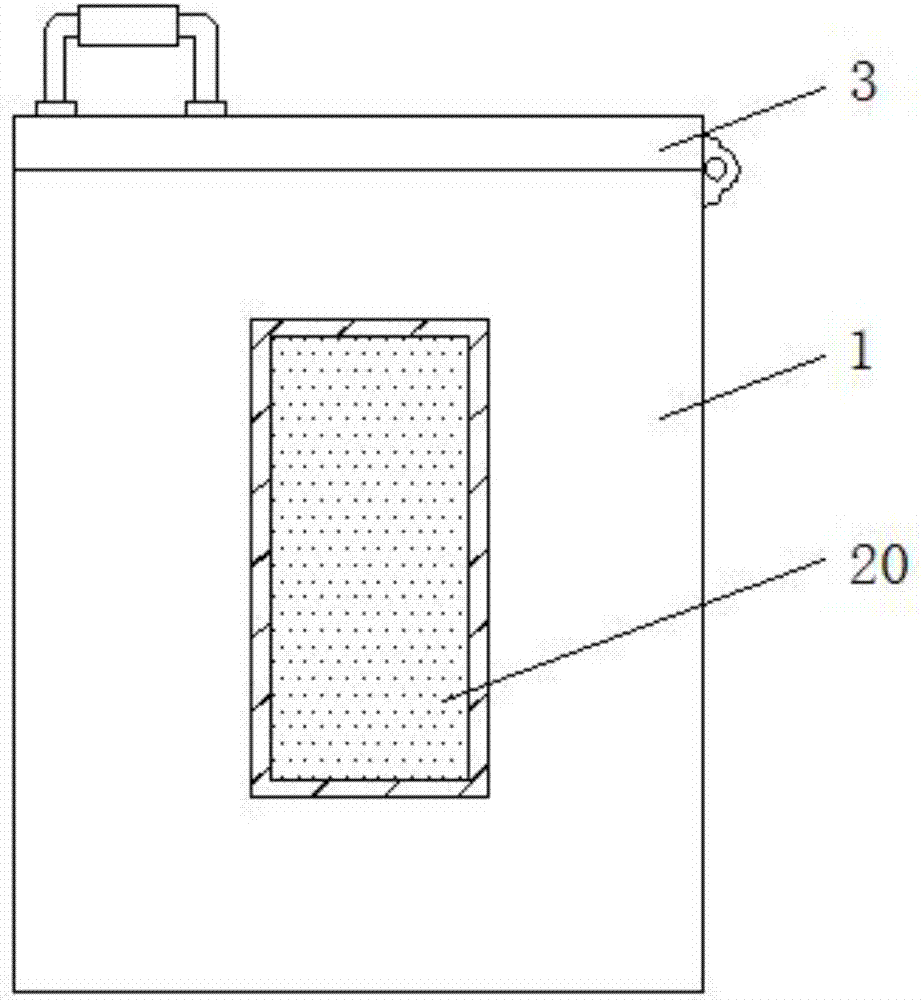

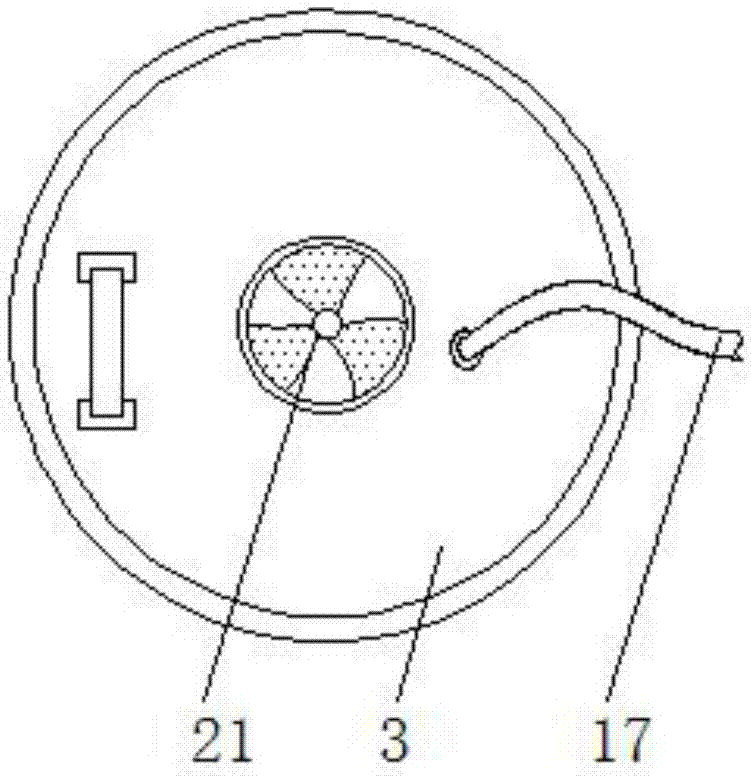

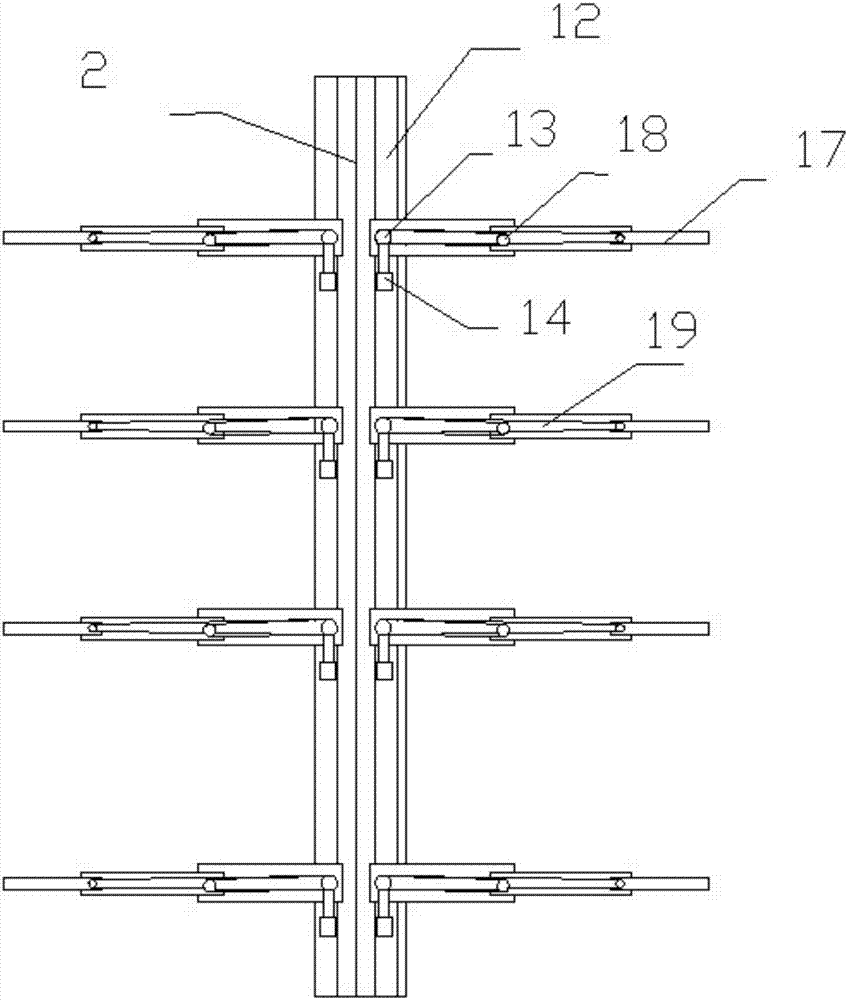

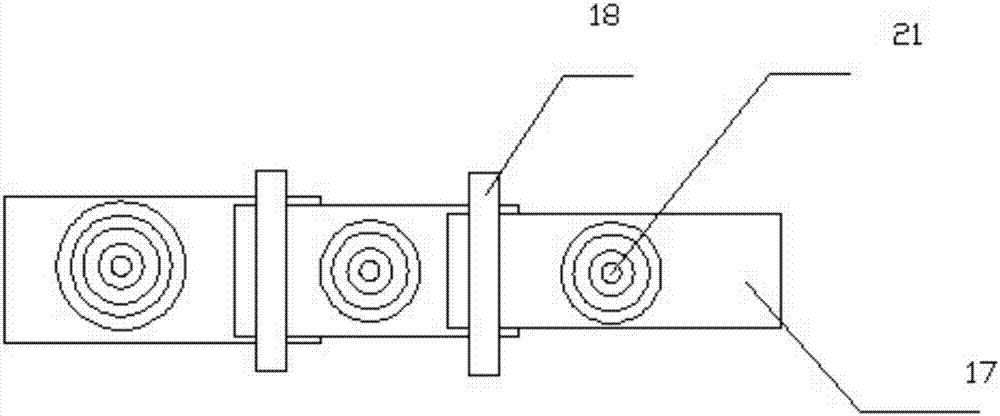

Tea cleaning and drying device

InactiveCN107965989ARealize the function of cleaning and removing impuritiesSpeed up the flowPre-extraction tea treatmentDrying gas arrangementsWater resourcesAgricultural engineering

The invention discloses a tea cleaning and drying device which comprises a drying box, a rotating tube and a seal cover. The bottom of the drying box is provided with a rotating motor, the rotating motor is connected with the rotating tube through a rotating shaft, two inner walls, close to the rotating tube, of the drying box are provided with a heating pipe and an ultraviolet ray lamp pipe correspondingly, the outer wall, close to the heating pipe, of the drying box is provided with an air blower, the bottom of one side of the drying box is connected with a waste water treatment box througha pollution discharge pipe, the top of the seal cover is provided with an air exhaust fan, and the bottom of the seal cover is provided with a water spray pipe. By means of the tea cleaning and dryingdevice, before agricultural and sideline products are dried, cleaning and impurity removing functions performed on the agricultural and sideline products can be realized, and the quality of dried products is improved; by means of the arrangement of the waste water treatment box, the waste water after cleaning can be filtered and purified, and the recycling of water resources is facilitated; and the tea cleaning and drying device is simple in structure, the efficiency of drying performed on the agricultural and sideline products is high, and the drying is performed more thoroughly.

Owner:WUZHOU YAZHENG AGRI TECH CO LTD

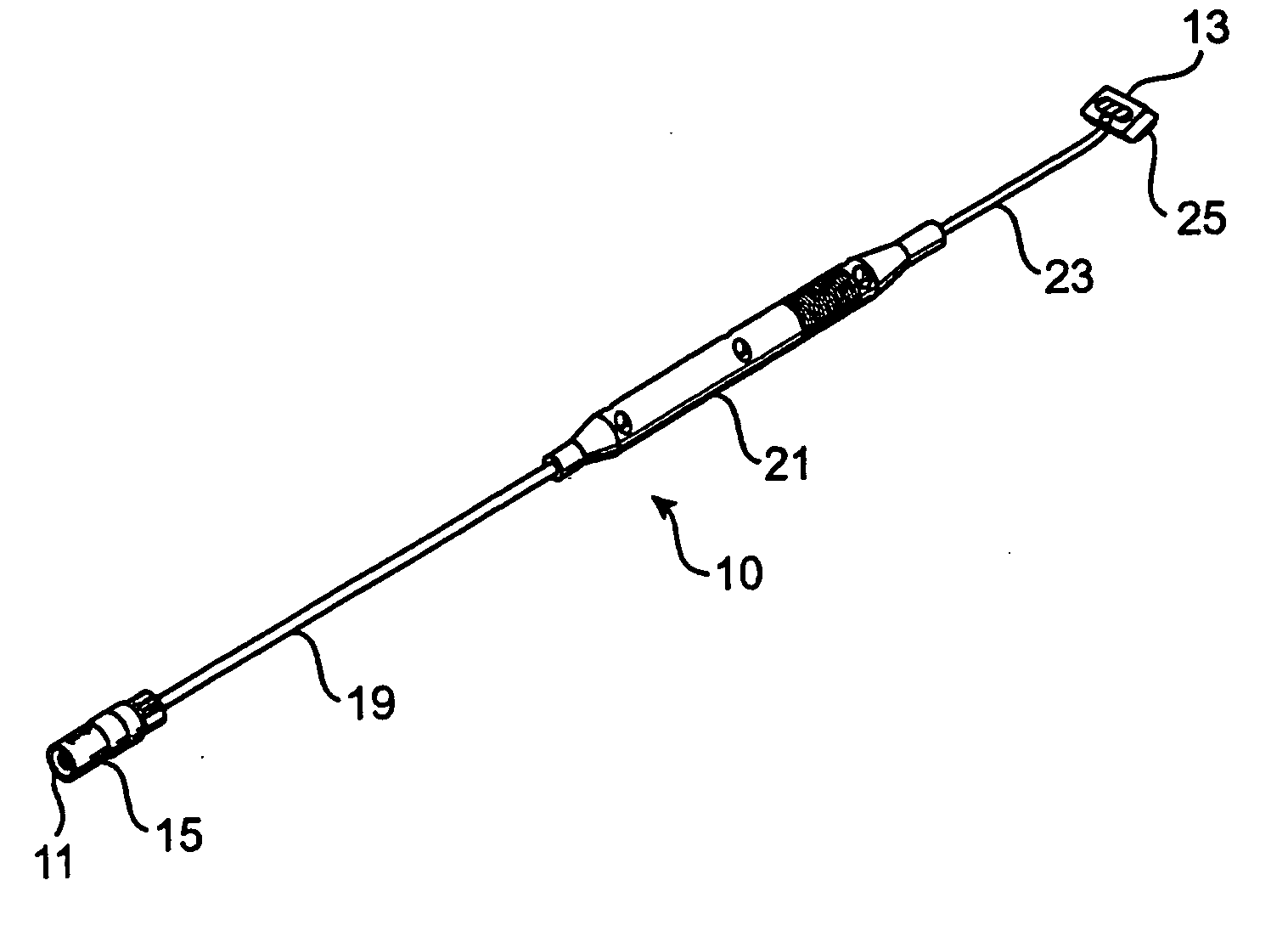

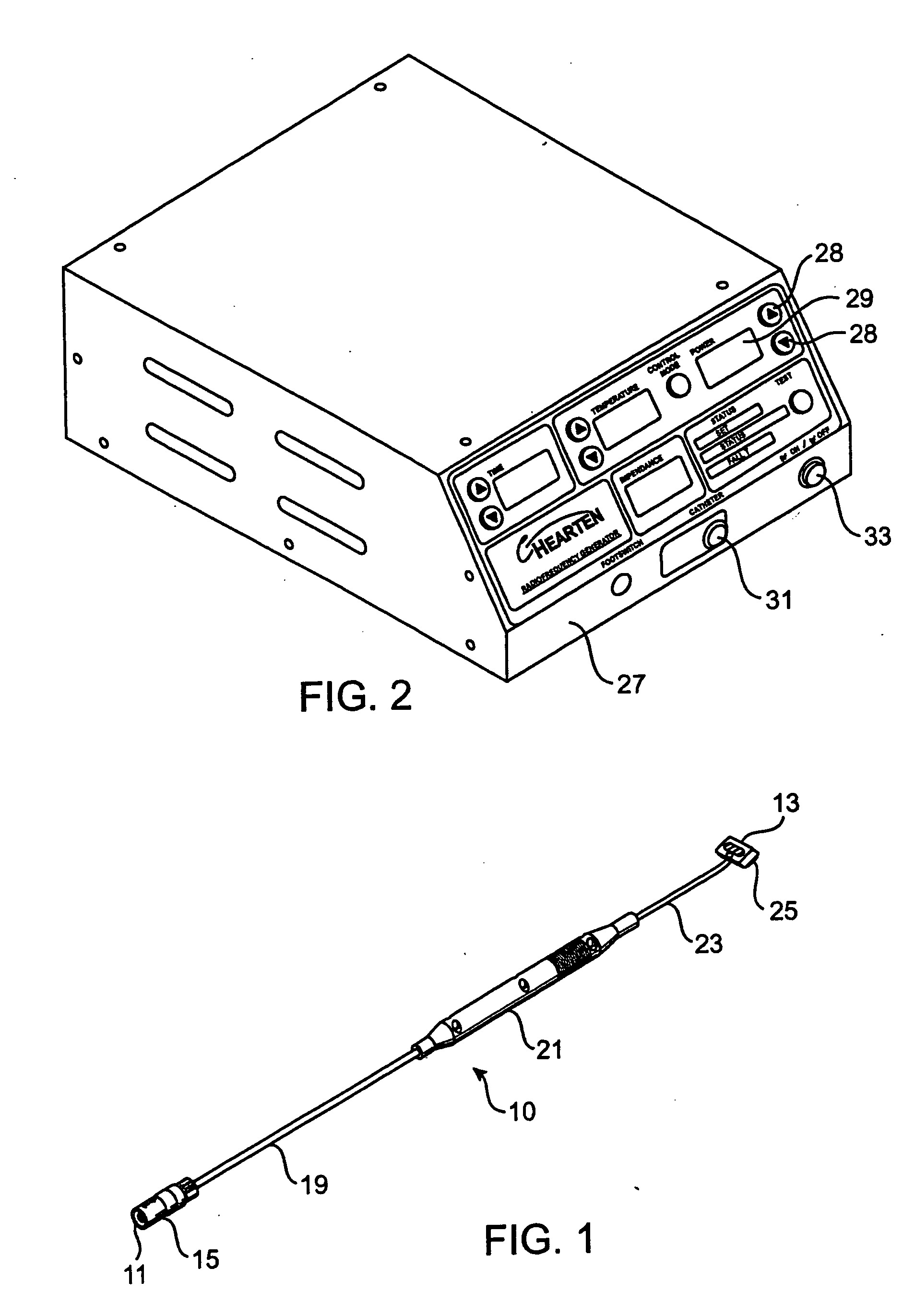

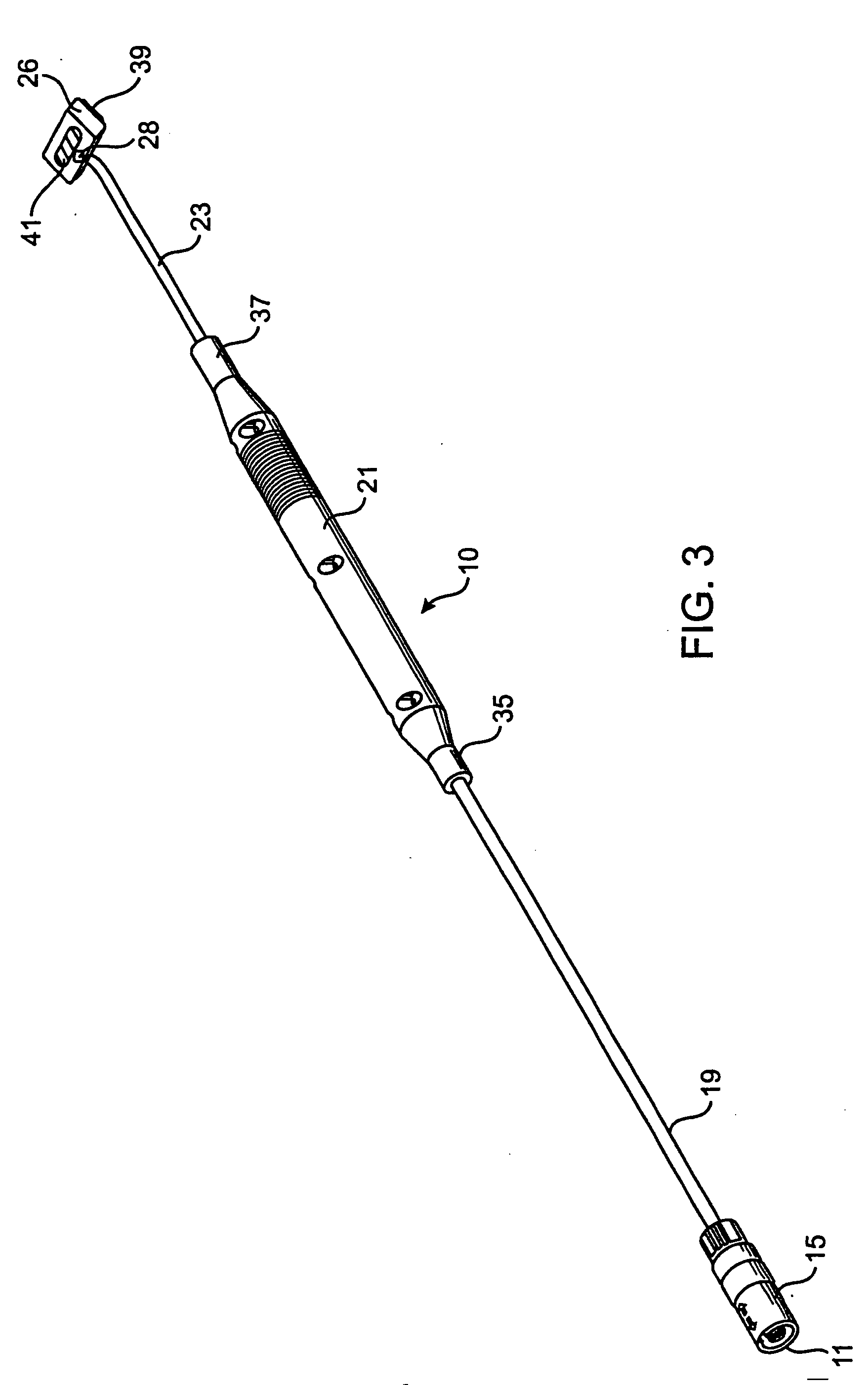

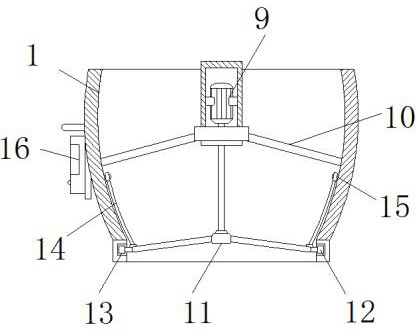

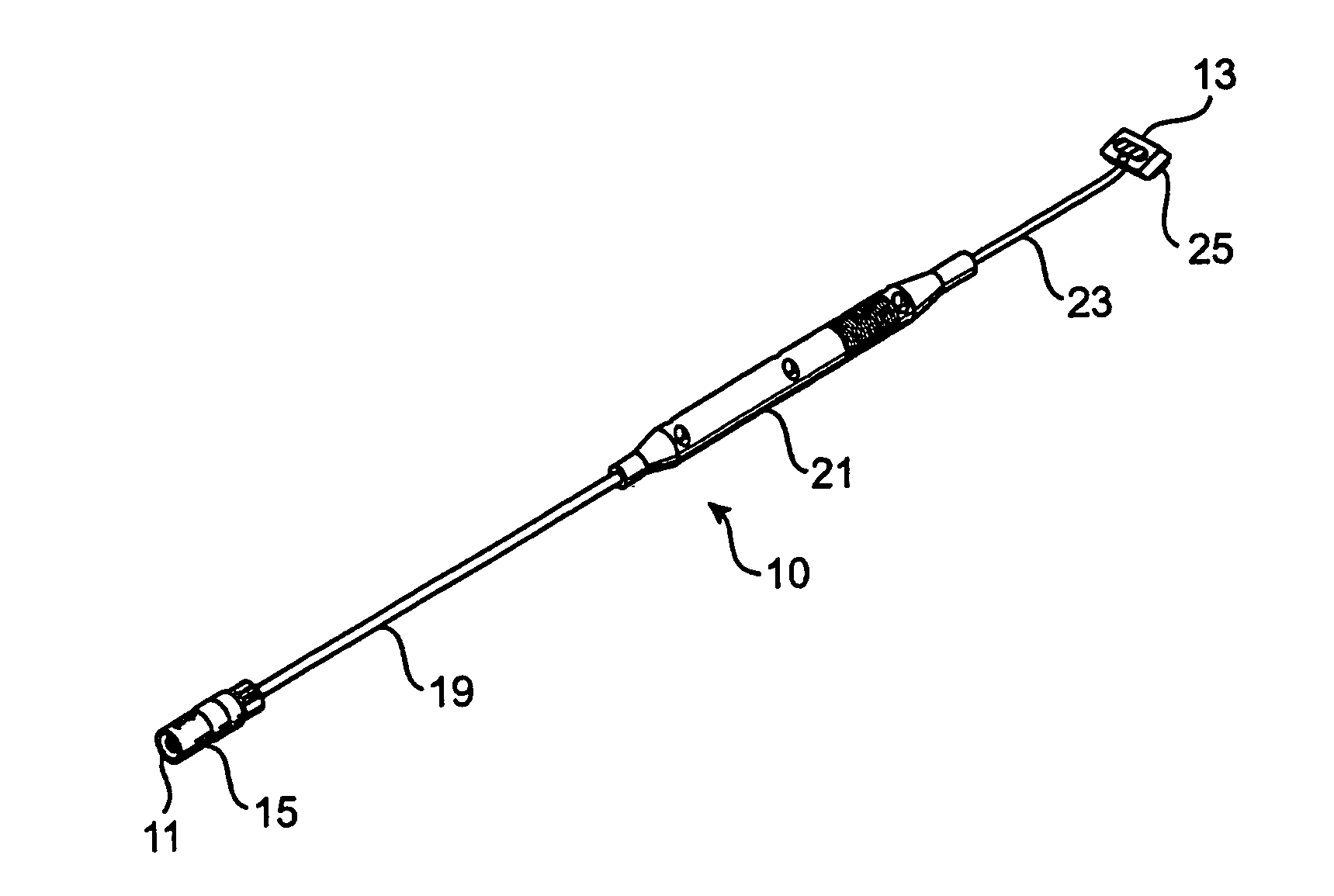

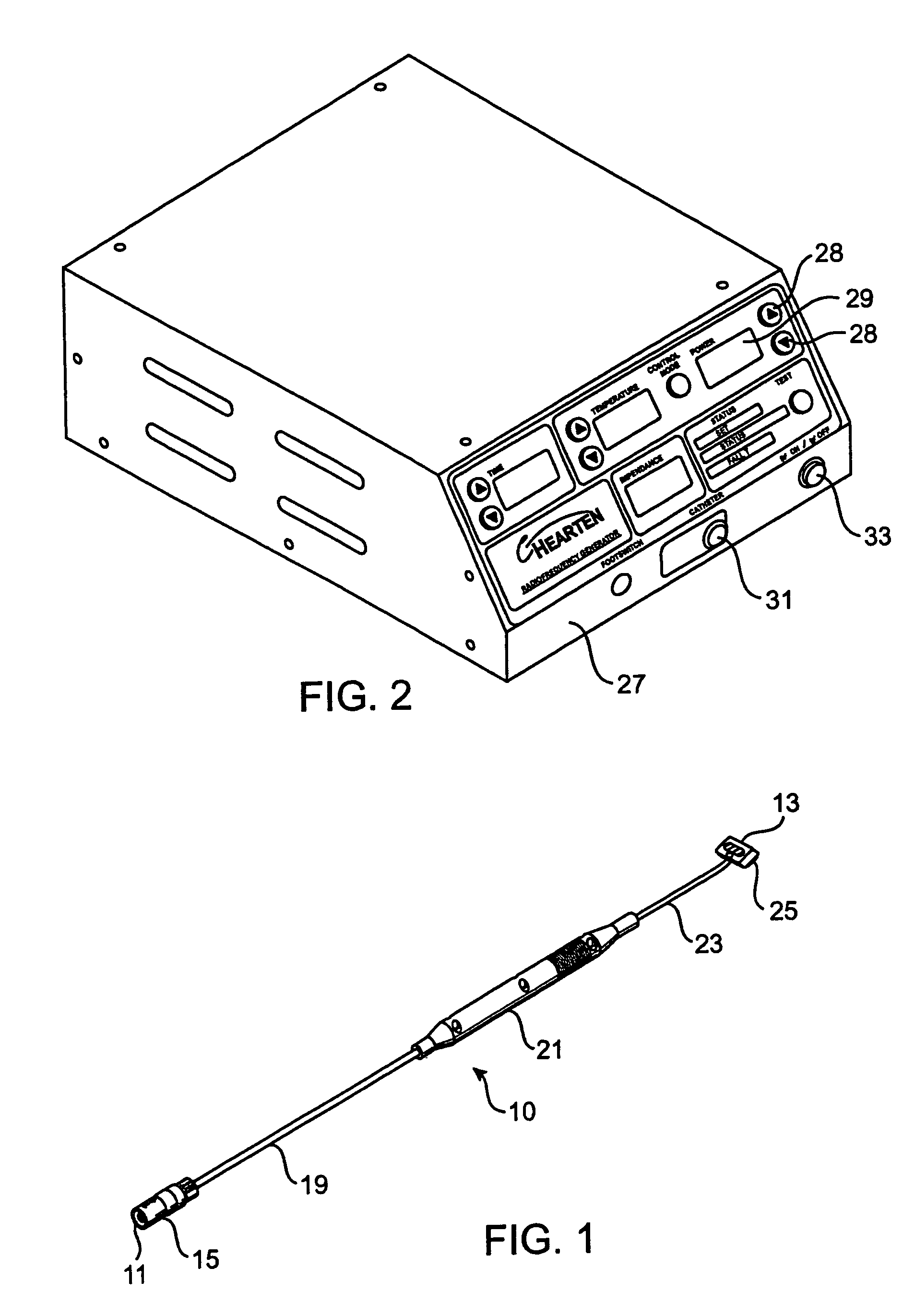

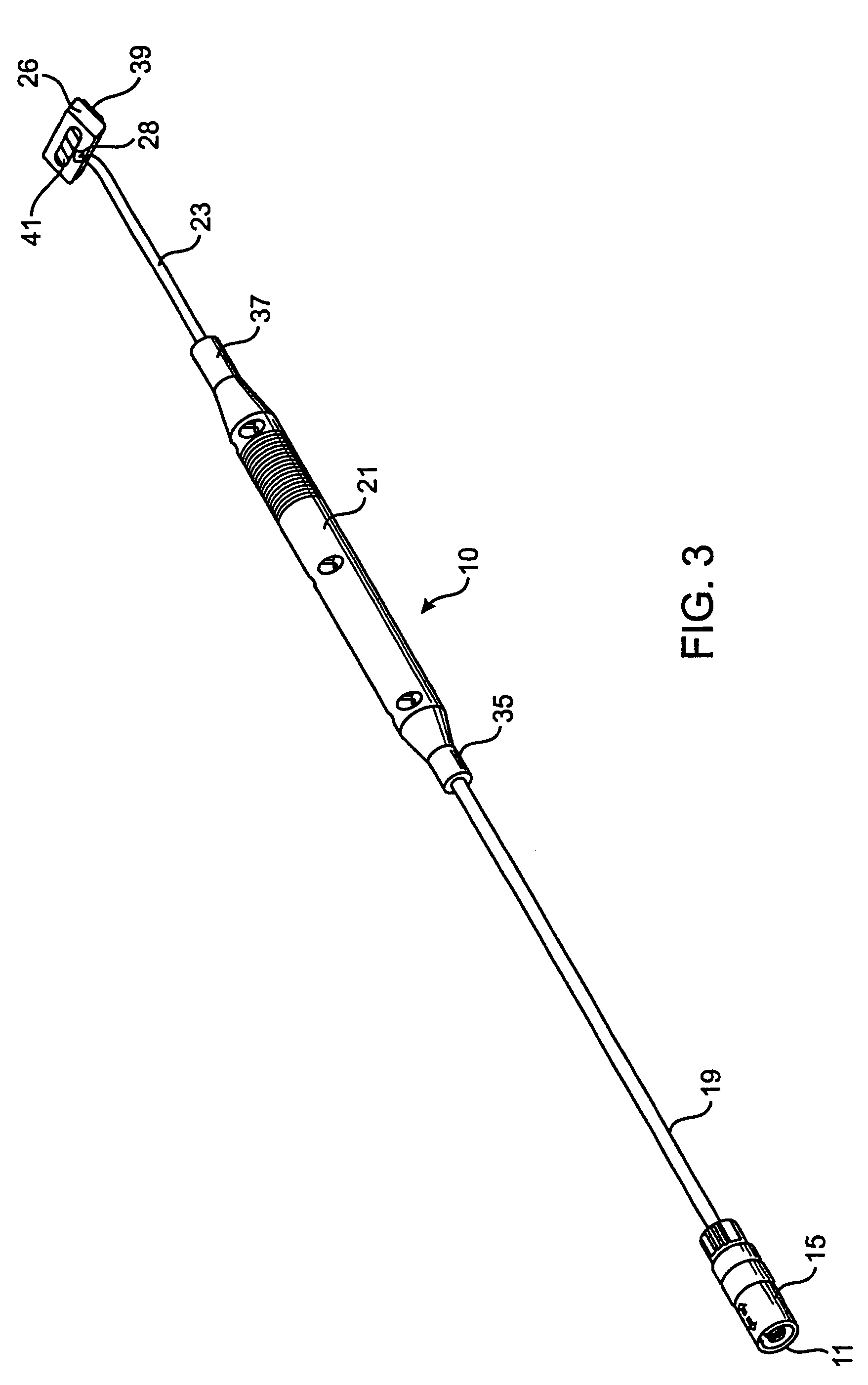

Device for shaping infarcted heart tissue and method of using the device

InactiveUS20060025838A1Prevent dilationImprove timingSurgical instrument detailsTherapeutic coolingInfarcted heartBiomedical engineering

A device and method for treating an infarct scar on a heart comprising an electric cable with proximal and distal ends; a handle with proximal and distal ends with the proximal end connected to the distal end of the cable; a stem with proximal and distal ends with the proximal end of the stem connected to the distal end of the handle; a heating element with a first surface for contacting infarct scar tissue connected to the distal end of the stem wherein the heating element comprises at least two electrodes and at least one temperature sensor positioned on the first surface for sensing a temperature of infarct scar tissue adjacent to the sensor; an energy source connected to the electrodes via the electric cable; and a regulator connected to the energy source and the temperature sensor of the infarct scar tissue, for controlling the temperature of the infarct scar tissue from about 60 degrees C. to about 99 degrees C. Once the heart has been treated, a restraint is disclosed that allows for the shrinkage to be maintained over time.

Owner:LAUFER MICHAEL D +4

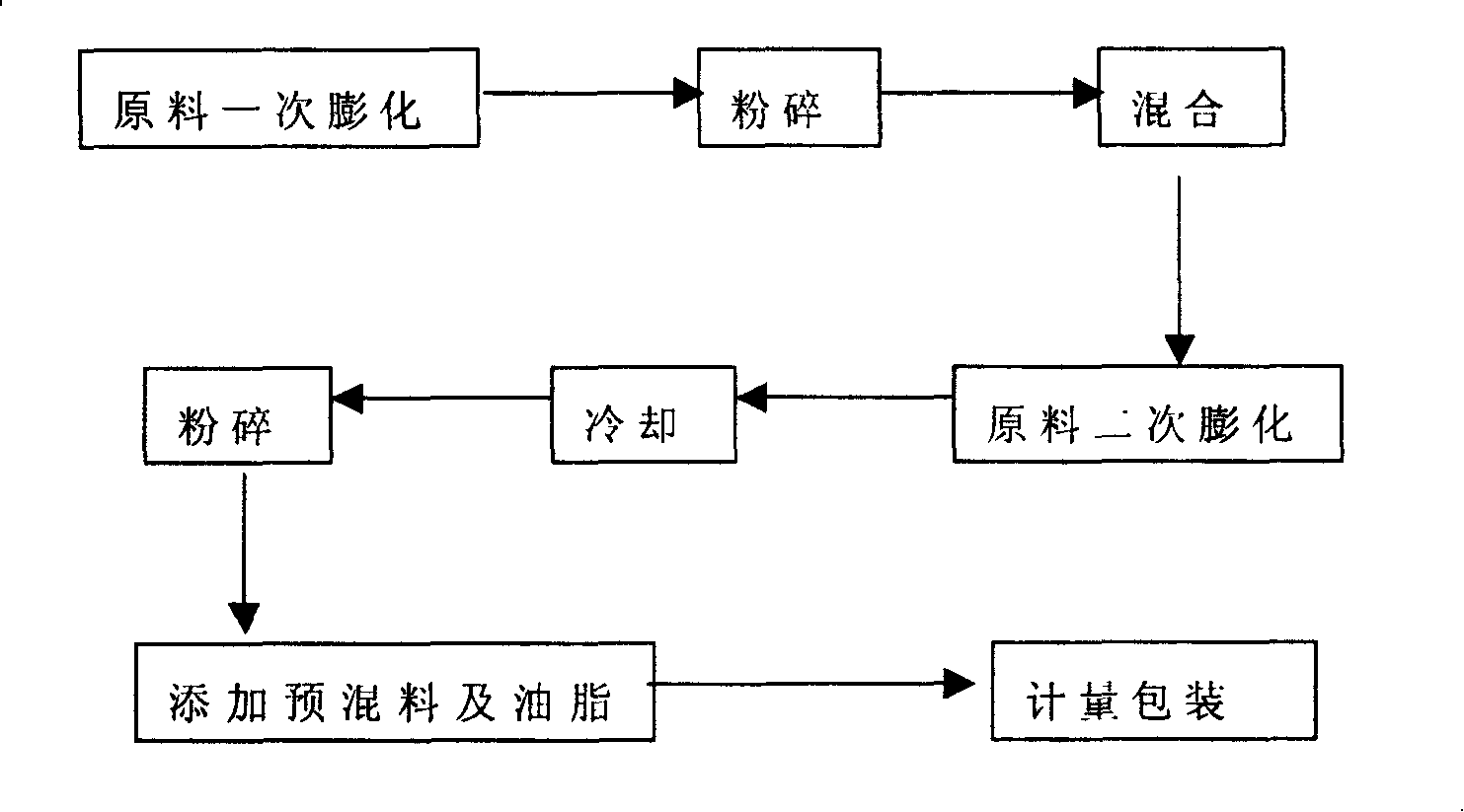

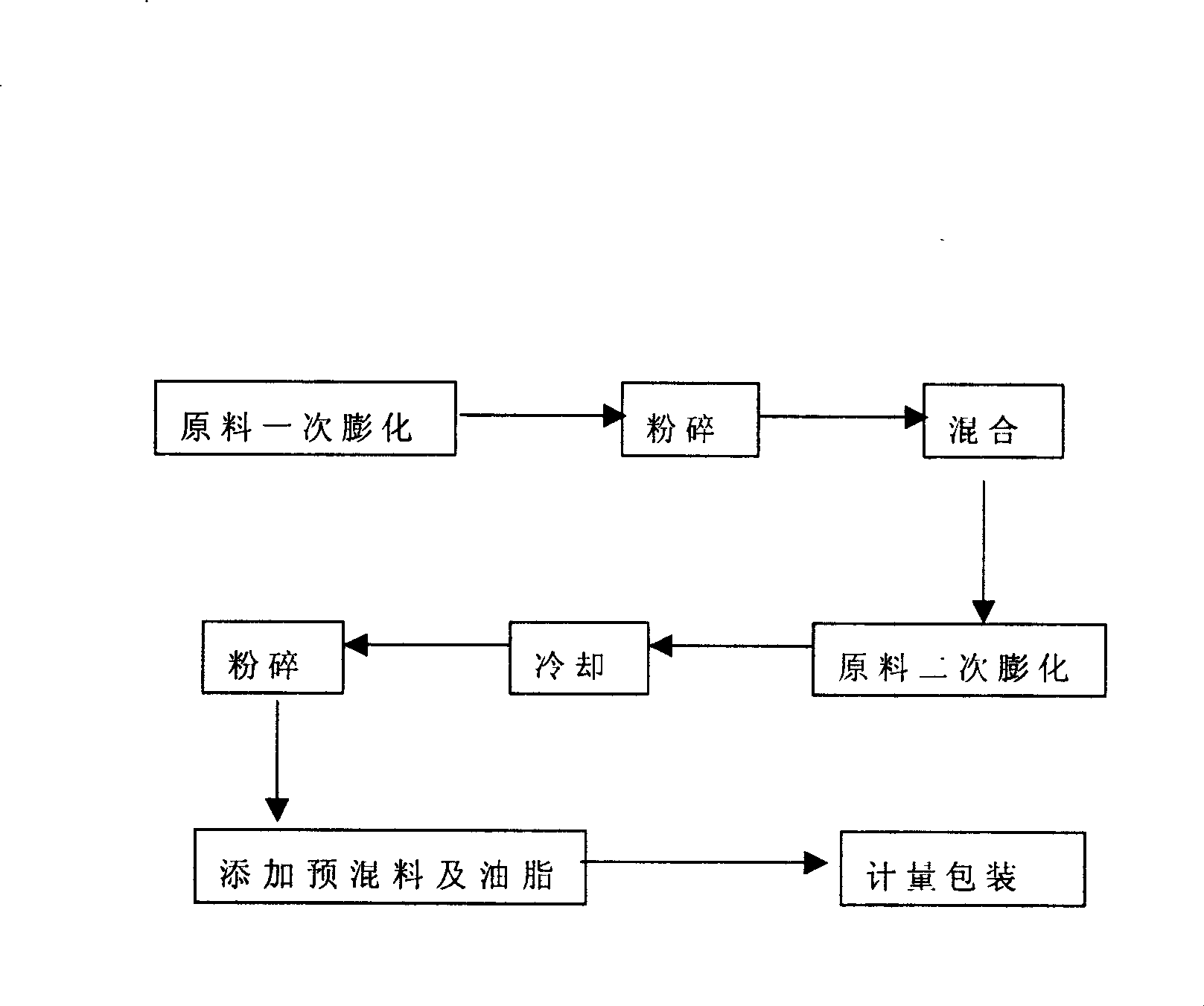

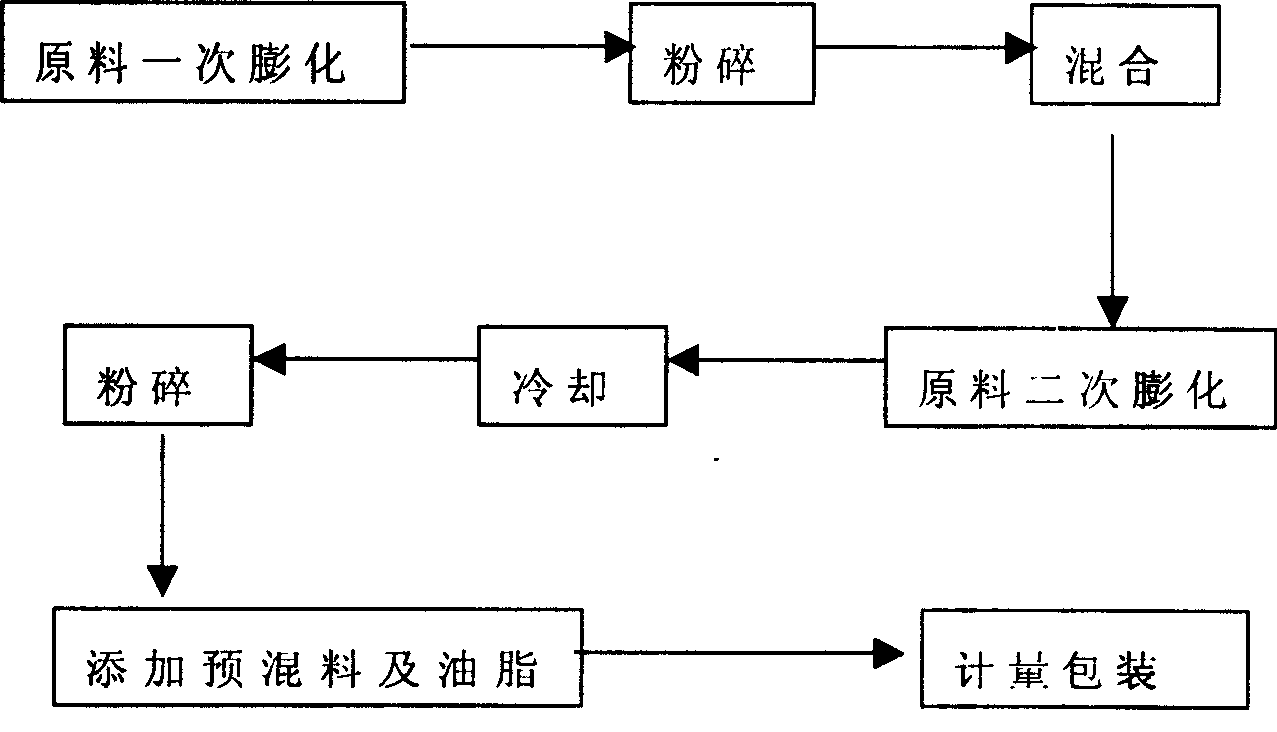

Feed fabricating method for special animal such as fox, ermine and raccoon dog

ActiveCN101223939AAvoid destructionFor the purpose of sterilizationFeeding-stuffAnimal feeding stuffMinkNyctereutes procyonoides

The invention relates to a manufacturing method for animal feed, in particular to a manufacturing method for a special animal feed exclusively used in fox, mink and raccoon dog. The method has the advantages that: raw materials of corn and soybean meal required in the formula are bulked by a dry method or wet method and ground; the ground material is mixed with meat and bone meal and imported fishmeal, and then bulked again (by the dry method or wet method); the second bulking is completely different from other bulking methods for an annular space discharging mode is adopted in the discharging in front of a bulking machine in the second bulking and the bulking temperature is 100-130 DEG C, which not only realizes the aim of sterilization and curing, but also avoids breaking the nutritional factors of the materials due to over-high temperature; the product produced by the process has high bulking degree, good water binding capacity, good palatability and thorough sterilization. The premix materials are added and mixed twice to avoid reducing the effect caused by heating.

Owner:大连一鑫畜牧科技股份有限公司

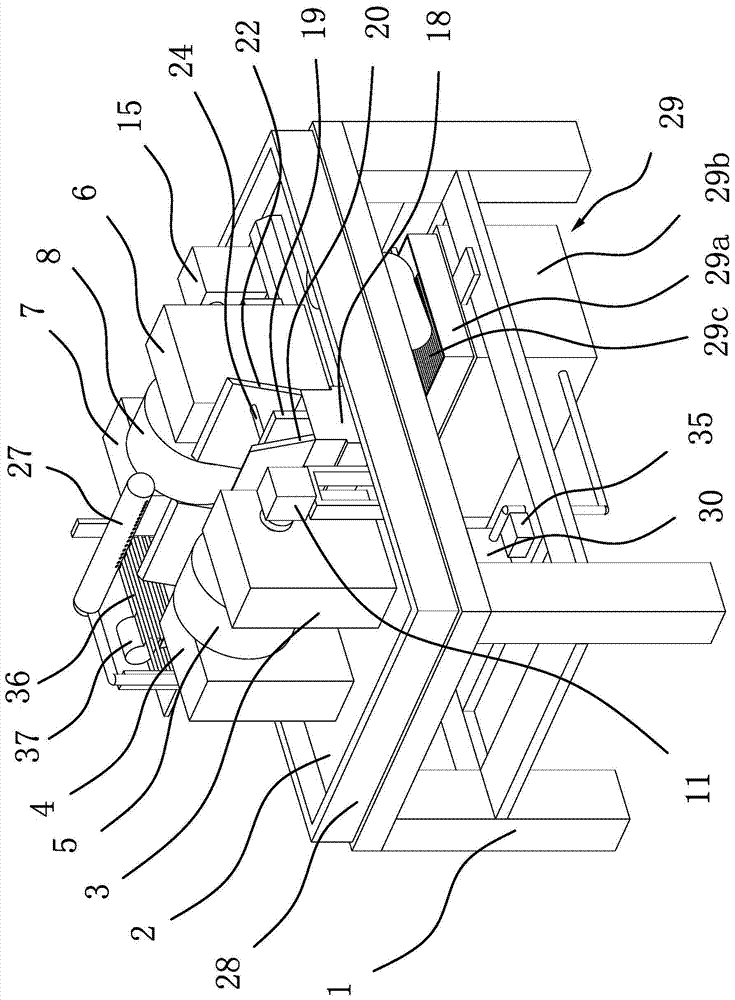

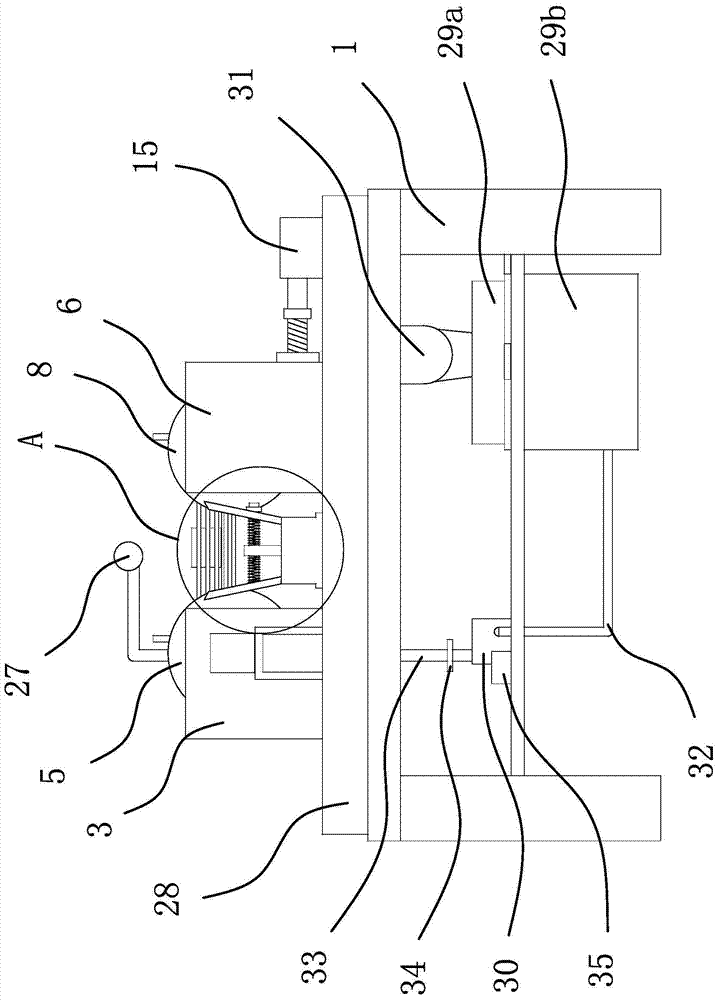

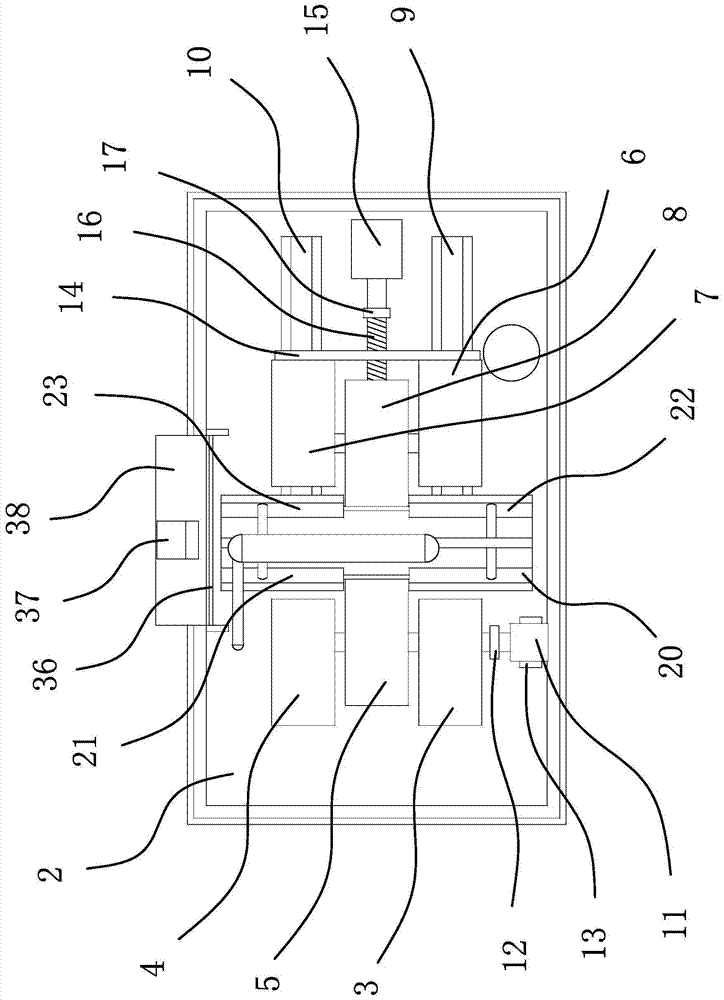

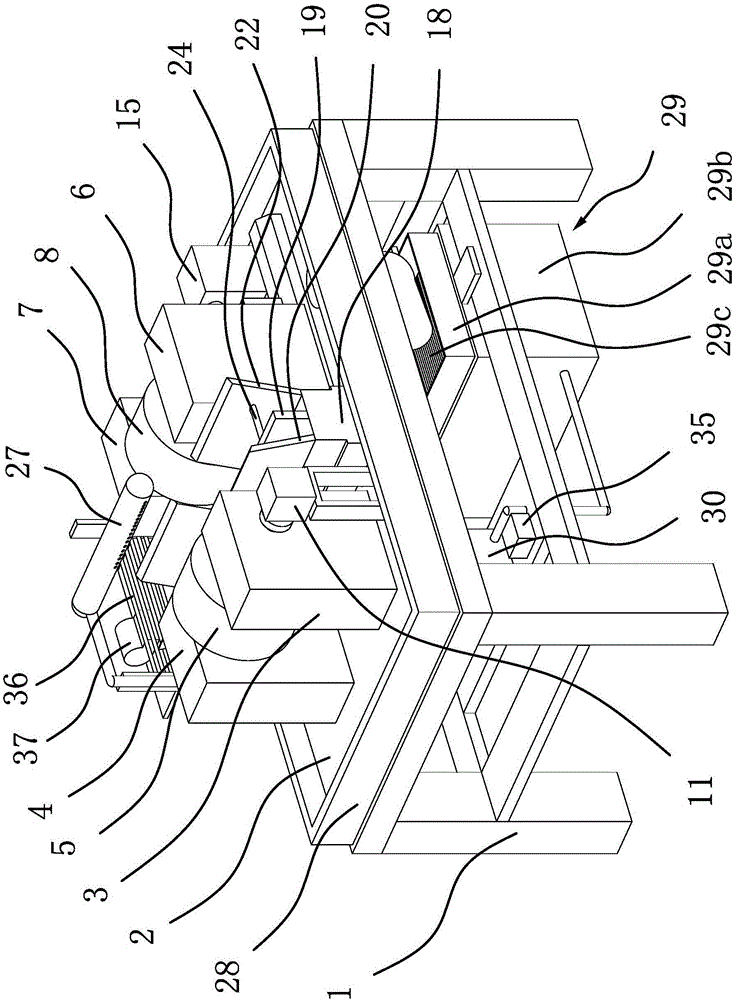

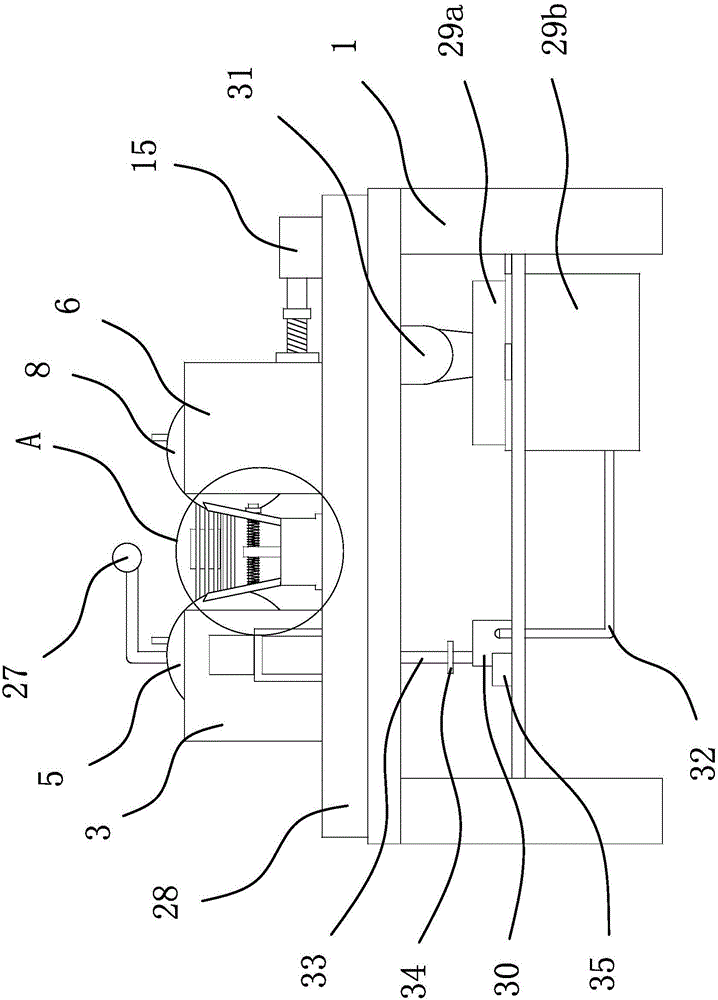

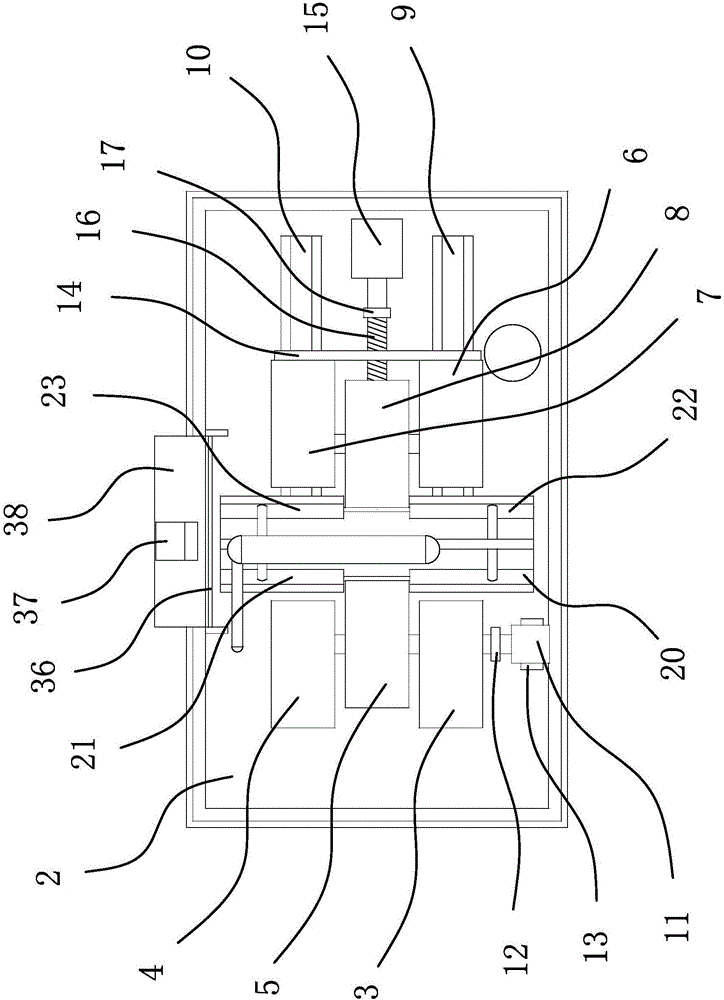

Outer peripheral face polishing machine for bearing outer ring

ActiveCN103753359AImprove grinding performanceAchieve grindingGrinding carriagesRevolution surface grinding machinesPeripheralEngineering

The invention provides an outer peripheral face polishing machine for a bearing outer ring and belongs to the technical field of machinery. The problem in the prior art that a special device for polishing the outer peripheral face of the bearing outer ring is unavailable is solved. The machine comprises a machine frame, a work table board is fixed on the machine frame, a first bearing seat and a second bearing seat which correspond to each other are fixed on the work table board, a grinding wheel is arranged between the first bearing seat and the second bearing seat through a first rotary shaft, and the first rotary shaft is connected with a power mechanism. A third bearing seat and a fourth bearing seat are arranged on the work table board, and a locating wheel is arranged between the third bearing seat and the fourth bearing seat through a second rotary shaft. A first guide track and a second guide track are fixed on the work table board, the third bearing seat and the fourth bearing seat are arranged on the first guide track and the second guide track in a sliding mode respectively, and the third bearing seat and the fourth bearing seat are connected with an adjusting mechanism. The machine can polish the outer peripheral face of the bearing outer ring and is high in efficiency.

Owner:HAINING QI SHENG BEARING

High-efficiency hot dip galvanizing production line

ActiveCN105861970AQuick removalEasy to salvageHot-dipping/immersion processesAcid washingEngineering

The invention discloses a high-efficiency hot dip galvanizing production line which comprises a lifting appliance, a zinc pot, an acid washing tank, a water washing tank, a cosolvent tank and a cooling tank. The high-efficiency hot dip galvanizing production line can quickly remove bubbles on the workpiece surface in the workpiece galvanizing process, can gather the zinc ash on the surface before the workpiece is taken out of the zinc pot so as to prevent the adhesive pollution, can enable the reflux motion of the acid liquor in the acid washing tank so as to increase the contact reaction rate between the acid liquor and acid-washed workpiece, can monitor the concentration of the acid liquor in real time, can enable the water washing of the workpiece to proceed more quickly and thoroughly, can enable the contact between the workpiece and cosolvent more uniformly and quickly, can eliminate the influence of the impurities and stains attached to the workpiece surface on the cosolvent treatment so as to effectively ensure the feed quality of the subsequent procedure, and can enable the water cooling heat transfer of the acid washing wastewater for the hot dip galvanizing cooling tank so as to save the water resources and enhance the wastewater utilization efficiency, thereby saving the production cost.

Owner:浙江慧钢技术发展股份有限公司

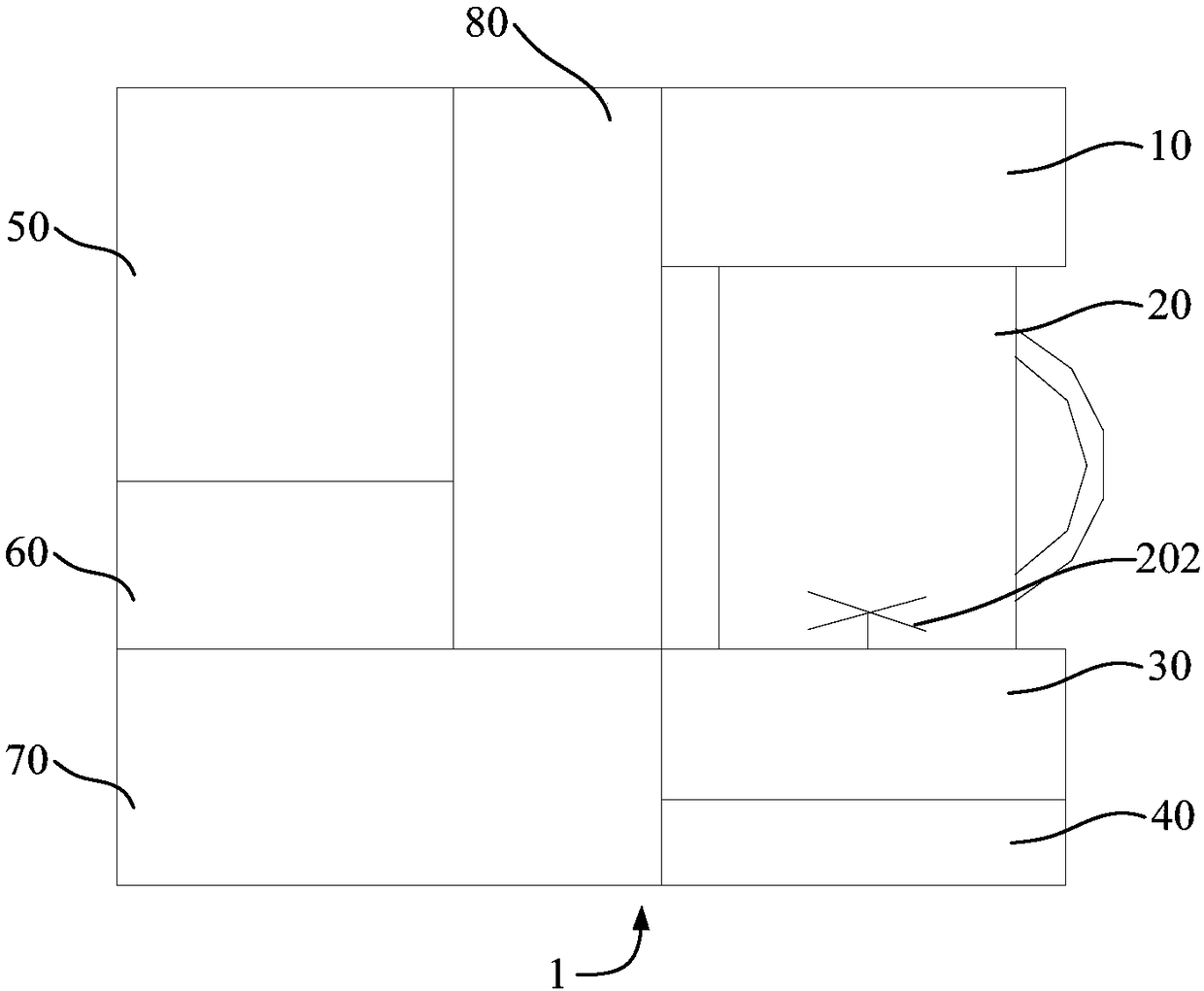

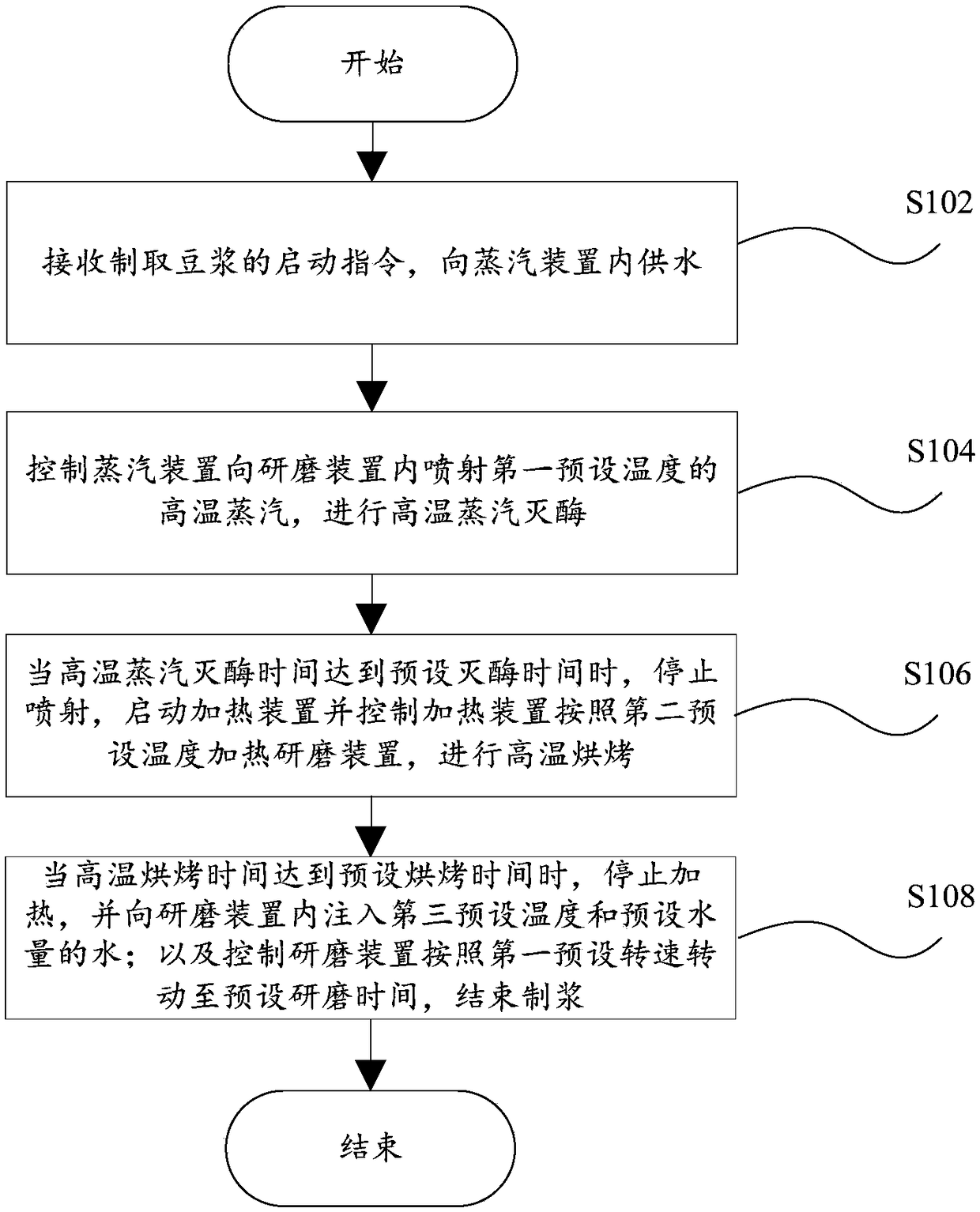

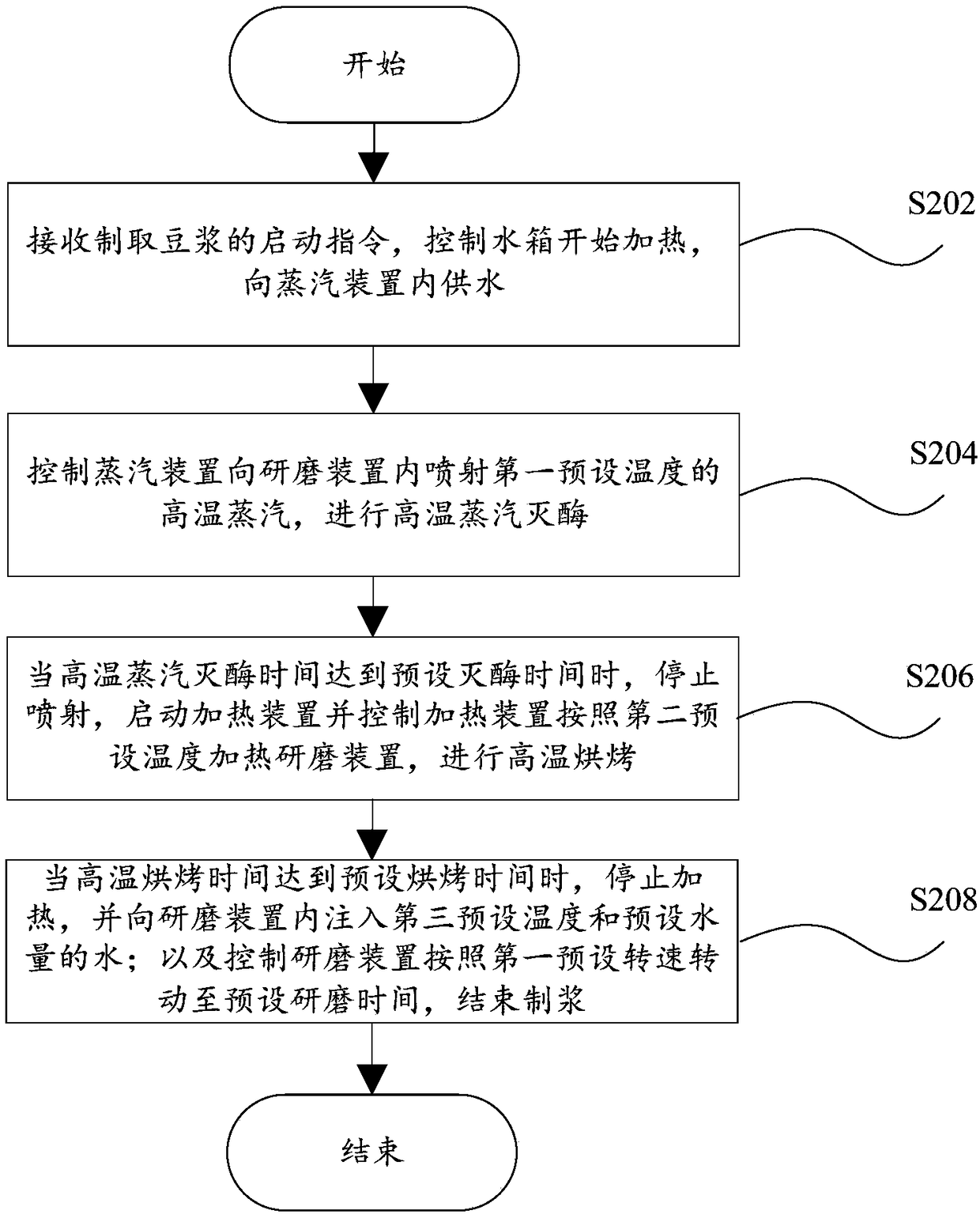

Cooking utensil, method for preparing soybean milk and computer device

The invention provides a cooking utensil, a method for preparing soybean milk, a computer device and a computer readable storage medium. The cooking utensil comprises a shell, a steam device, a grinding device and a heating device, wherein the steam device is arranged in the shell and provided with a steam outlet, and the steam device is used for converting water into high-temperature steam; the grinding device is detachably arranged on the shell and located below the steam outlet; the heating device is arranged on a base of the shell, and the grinding device is located between the heating device and the steam device; the heating device is used for heating the grinding device. The steam device can convert water into high-temperature steam, and the converted high-temperature steam enters the grinding device through the steam outlet, so that inactivation of anti-nutritional factors of trypsin and the like in to-be-cooked food is achieved by utilizing the high-temperature steam, the cooking time is shortened, and the taste of the food is enriched; furthermore, the grinding device is used for enzyme deactivation treatment of the food through combination of high-temperature baking and high-temperature steam enzyme deactivation, and enzyme deactivation is more thorough.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

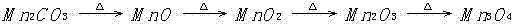

Method for preparing trimanganese tetroxide

InactiveCN102849800AFast heatingShorten the heating cycleManganese oxides/hydroxidesManganese(II) carbonateManganous-manganic oxide

The invention discloses a method for preparing trimanganese tetroxide. Manganese carbonate is used as a raw material, added with a carbon source, placed in sealed microwave equipment, then heated to 650-750 DEG C with a heating rate of 8-20 DEG C / min, and sintered for 0.5-2 h; and the product is ground by a wet grinding after tapping, so as to obtain trimanganese tetroxide. According to the present invention, rapid and comprehensive heating of the microwave equipment and ''non-thermal effect'' enable carbon dioxide generated from decomposition of manganese carbonate to timely react with manganese oxide at a low temperature, so as to produce trimanganese tetroxide; and the method has the advantages of simple process, easy control process, low energy consumption, complete reaction process and stable specific surface area.

Owner:湖南隆泰环保能源科技有限公司

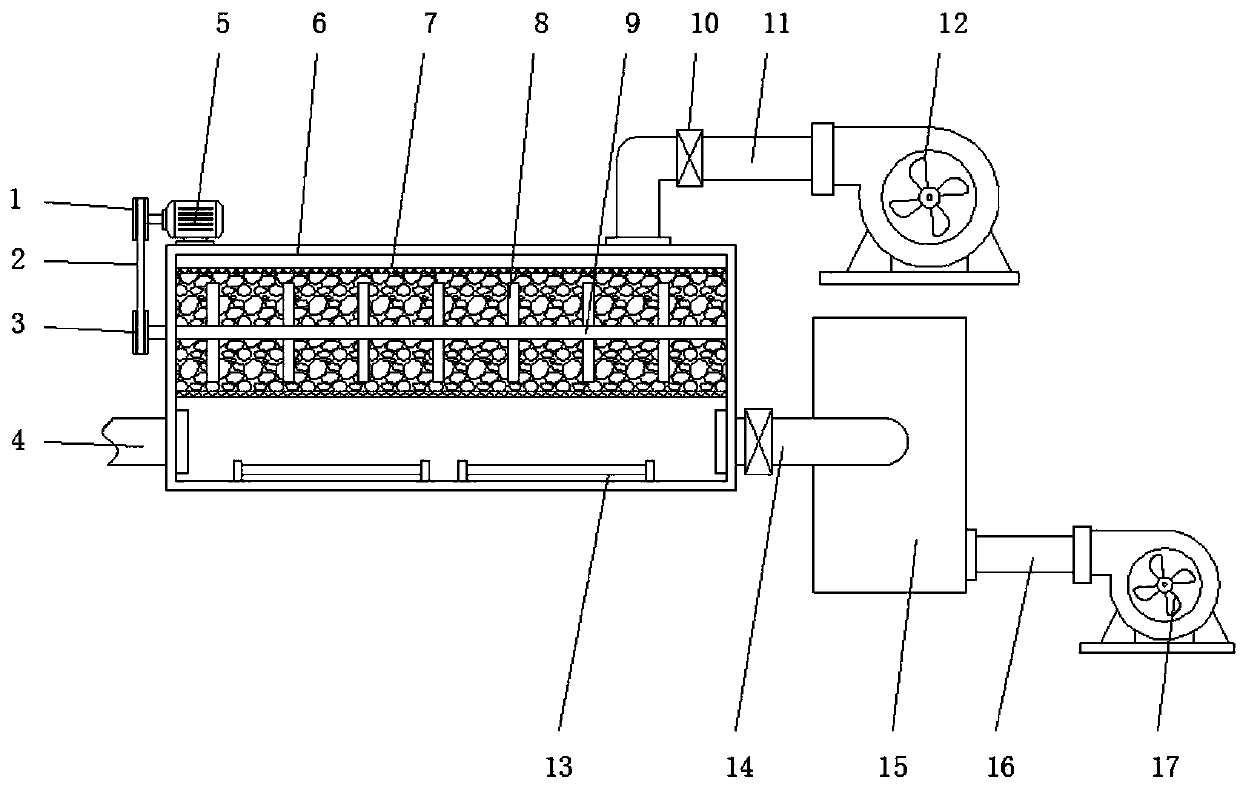

Activated carbon adsorption and desorption regeneration device for organic waste gas treatment

InactiveCN111228959AIncrease temperatureIncrease profitGas treatmentDispersed particle separationActivated carbonCombustion chamber

The invention discloses an activated carbon adsorption and desorption regeneration device for organic waste gas treatment. The activated carbon adsorption and desorption regeneration device comprisesa waste gas treatment box. An infrared heating device works, so that the temperature of activated carbon in the waste gas treatment box is increased, adsorbed components on the activated carbon are desorbed and volatilized, and the desorbed and volatilized components are fed into a catalytic combustion device to be combusted and decomposed into hot air such as CO2 and H2O steam by starting a desorption fan; one part of the hot air returns to an activated carbon adsorption box to continue to heat the activated carbon, the other part of the hot air is emptied through the desorption fan, the activated carbon can be regenerated by circulating in the hot air multiple times, and the utilization rate of the activated carbon is increased; the path of a gas passing through a combustion chamber is increased through a partition plate, and the flow speed of the gas in the combustion chamber can be reduced, so that the time of the gas in the combustion chamber is prolonged, and the gas is combustedmore sufficiently and thoroughly.

Owner:湖北中涂科技有限公司

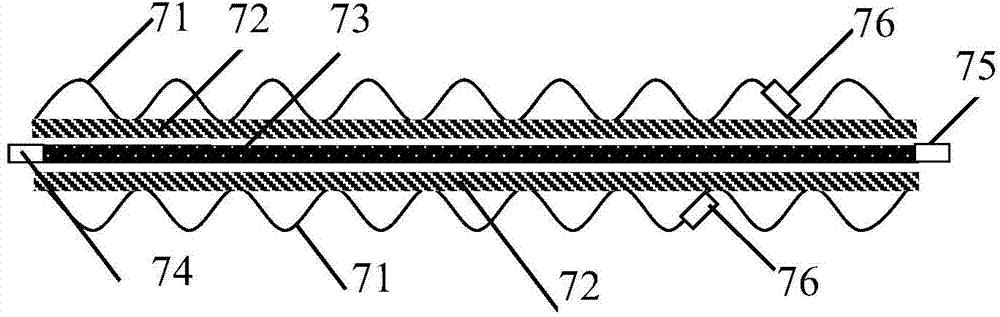

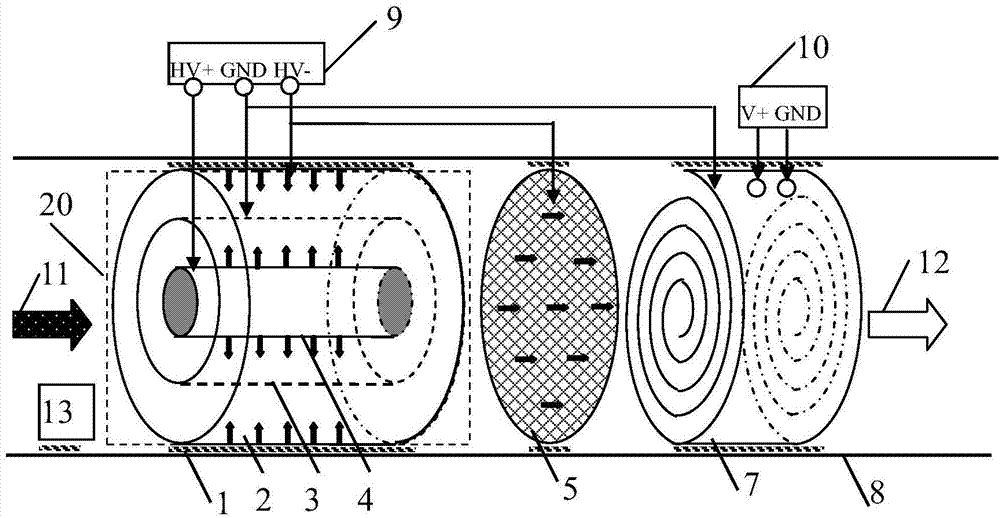

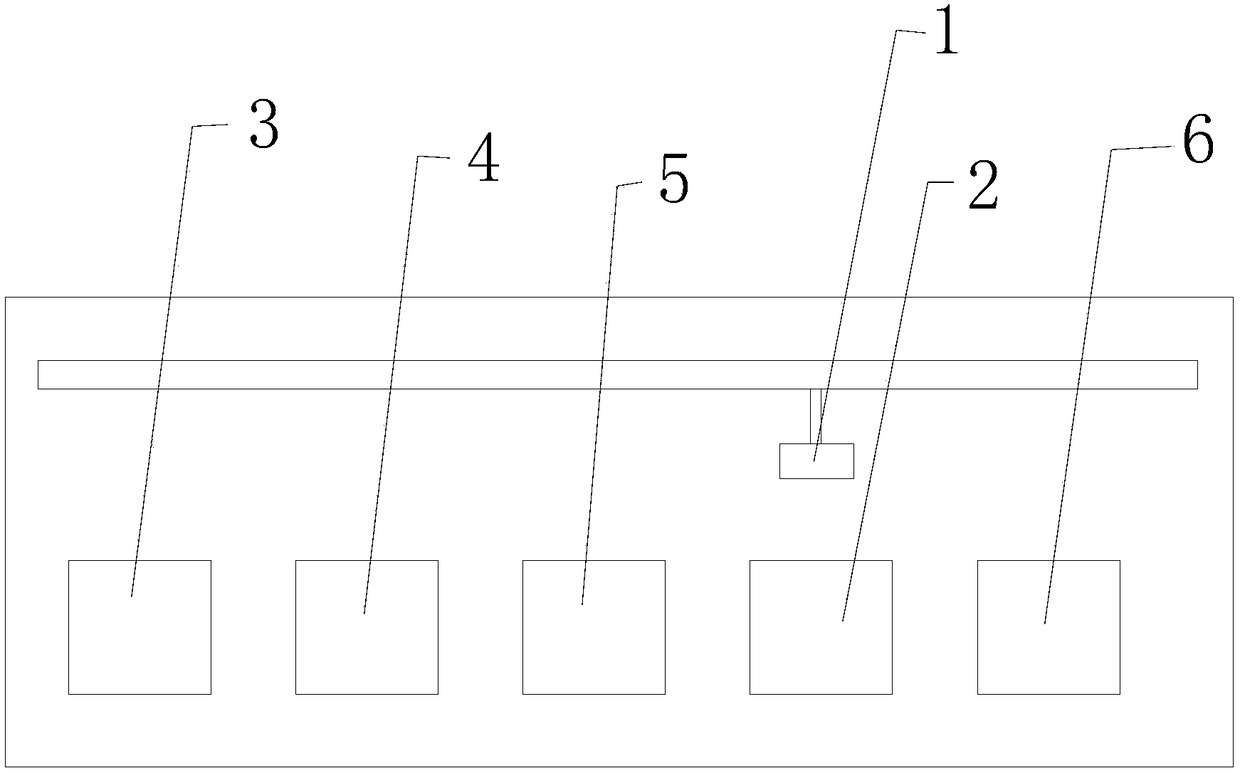

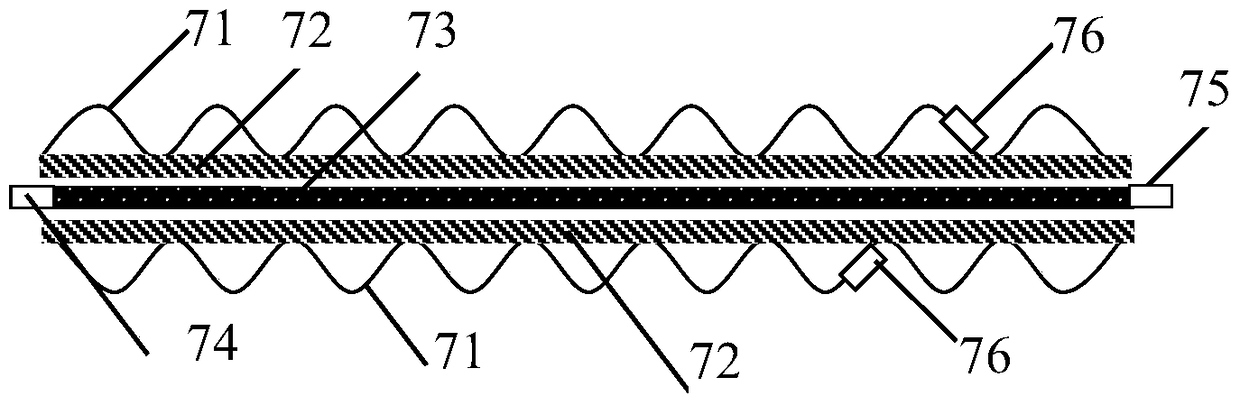

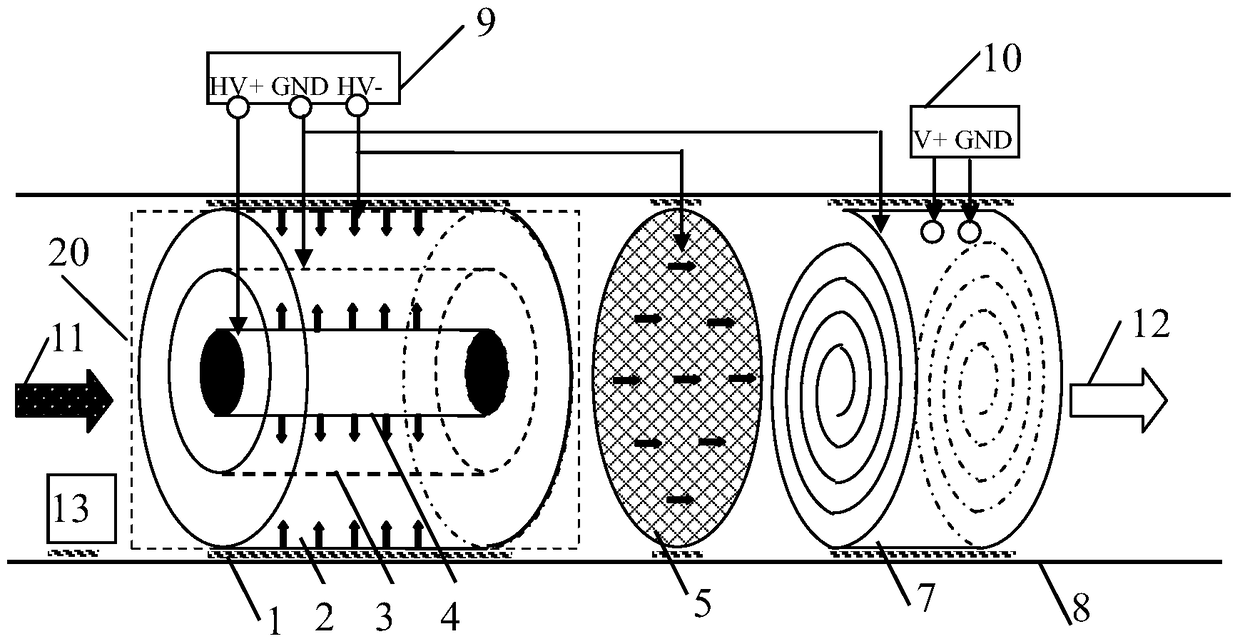

Automobile tail gas particulate matter trap and filter element

ActiveCN104763493ASmall exhaust pressure lossImprove capture capacityExhaust apparatusSilencing apparatusParticulatesInsulation layer

The invention discloses an automobile tail gas particulate matter trap and a filter element. A particulate matter coagulation unit (20), a charging unit (5) and the filter element (7) are arranged in a shell (8) in sequence in a direction from air inlet to air outlet, and the filter element (7) is wound into a cylindrical shape through a metal fiber plate (70). The metal fiber plate (70) comprises two metal fiber filtration and adsorption outer surface layers (71) and an electric heating film layer (73) clamped between the two metal fiber filtration and adsorption outer surface layers; heat conduction insulation layers (72) are arranged between the metal fiber filtration and adsorption outer surface layers (71) and the electric heating film layer (73); and the cross sections of the metal fiber filtration and adsorption outer surface layers (71) are corrugated, and the metal fiber filtration and adsorption outer surface layers (71) guide tail gas in the longitudinal direction. The automobile tail gas particulate matter trap is integrated with multiple functions of electrostatic adsorption and dust removal, filter element diffusion, intercepting, collision mechanism dust removing and the like, and the particulate matter trap effect is improved; the exhaust pressure loss of an engine is small, and the particulate matter trap effect is good; and the filter element is convenient to regenerate and reliable, and has the advantages of being low in use and maintenance cost and is suitable for popularization.

Owner:REED XINXIANG ROAD INC

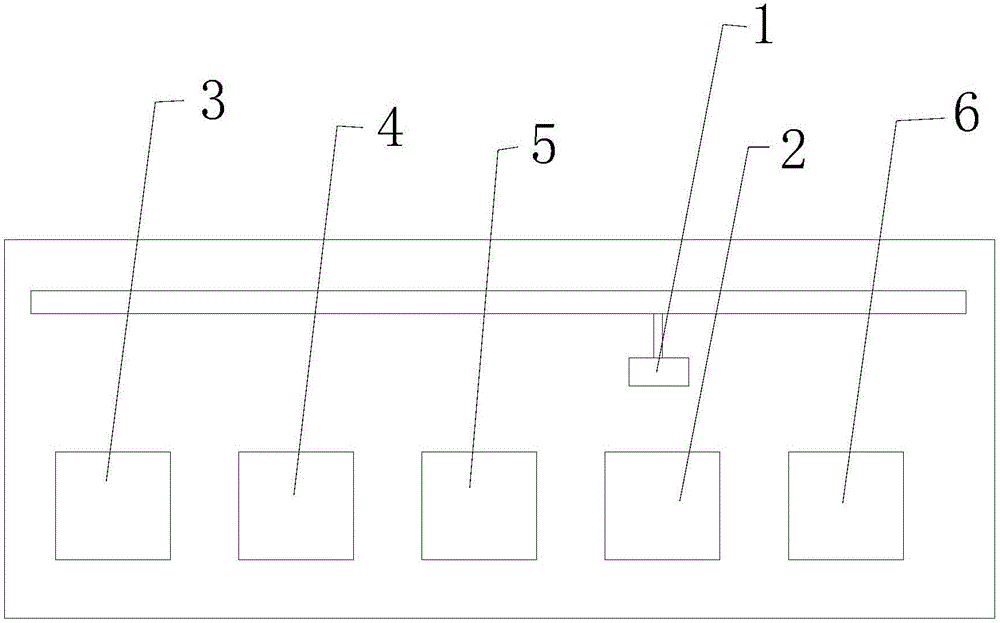

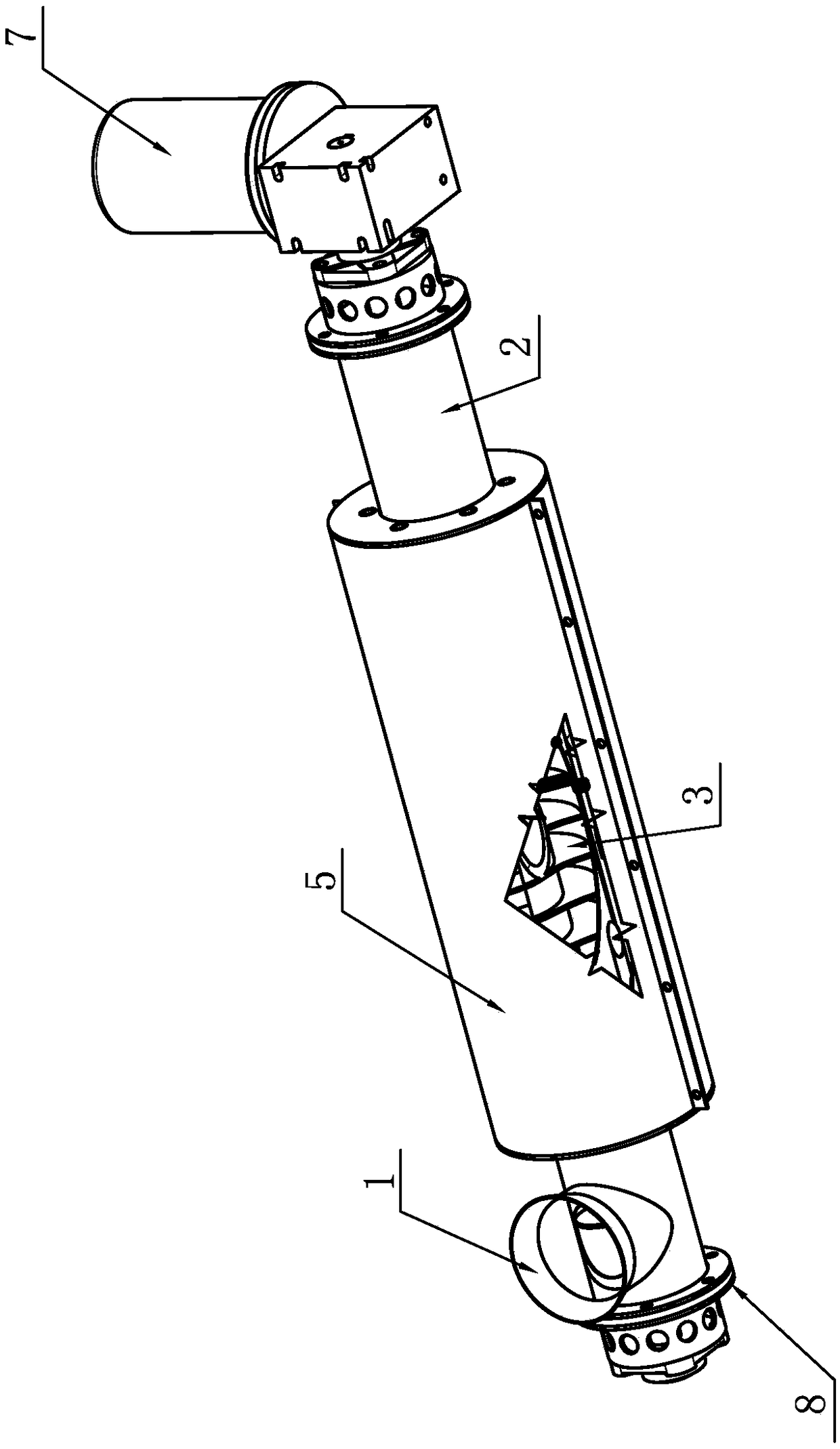

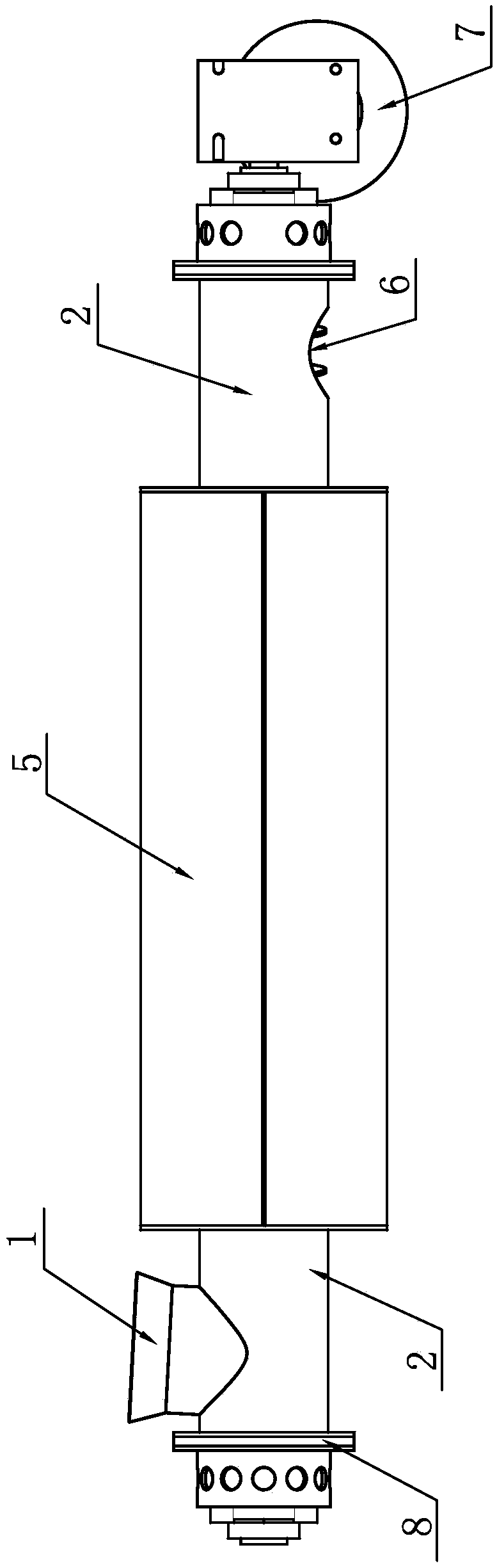

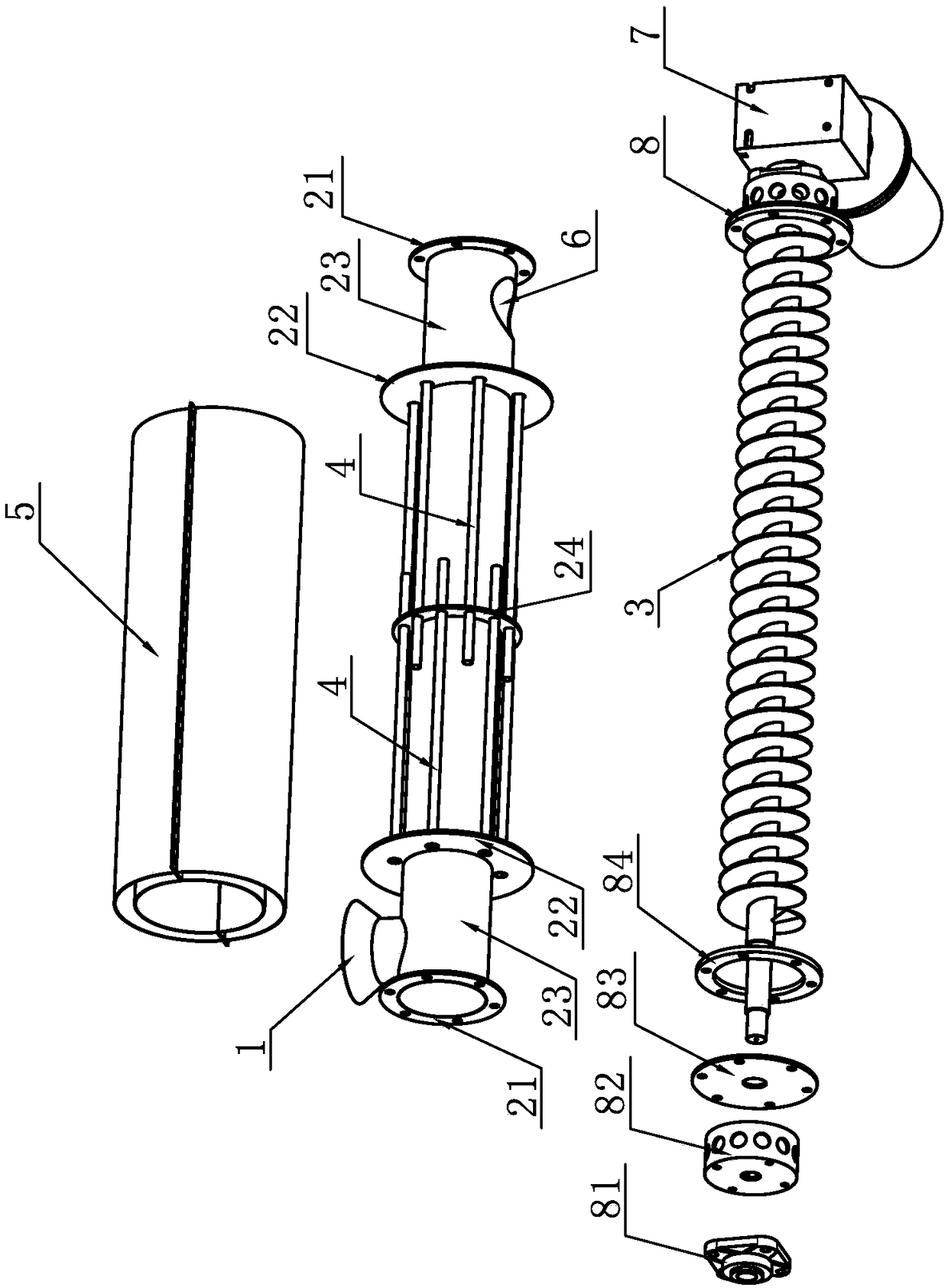

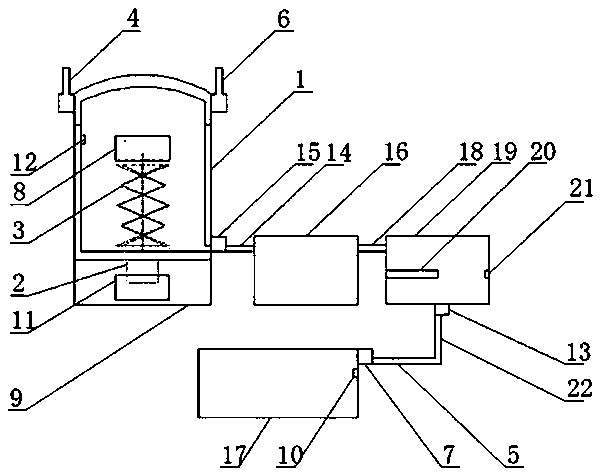

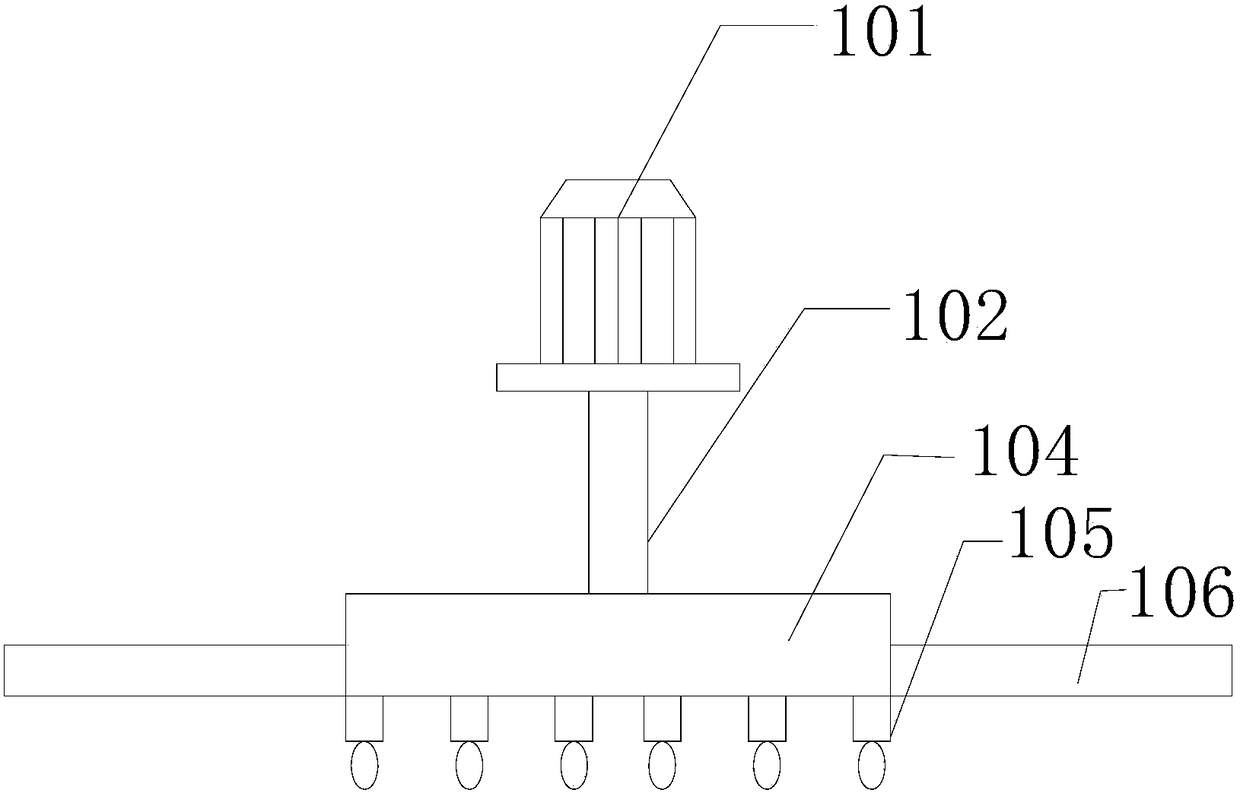

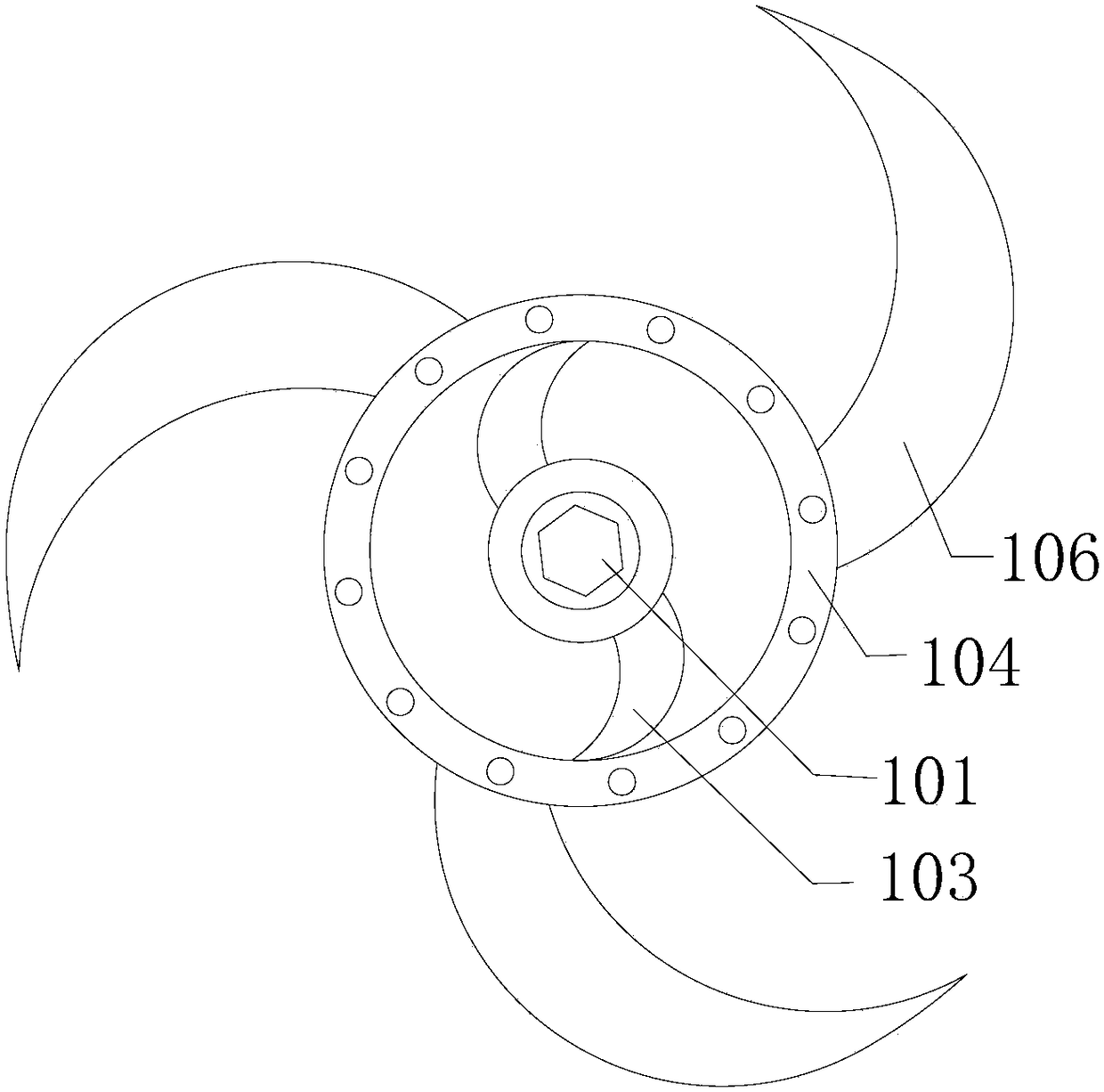

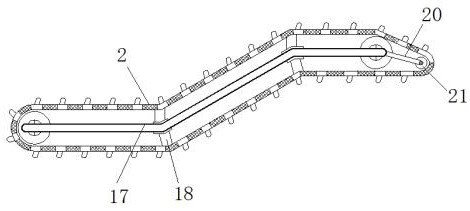

Transfer type heat sterilization drying pipeline part

PendingCN109210916AImprove dehydration efficiencyHeating evenlyDrying solid materialsGarbage dryingProcess engineeringFlange

The invention discloses a transfer type heat sterilization drying pipeline part. The transfer type heat sterilization drying pipeline part comprises a feeding pipe, a conveying pipe, heating parts, aheat insulation and heat preservation pipe and a drying discharging opening, wherein the heating parts are arranged between the heat insulation and heat preservation pipe and the conveying pipe. End face connecting flanges, heat preservation cylinder connecting flanges, a pipe body and a supporting ring are arranged on the conveying pipe, the heat preservation cylinder connecting flanges are arranged on a heating section of the pipe body, the supporting ring is arranged between the two heat preservation cylinder connecting flanges, the heating parts are installed on the heat preservation cylinder connecting flanges and the supporting ring, and the heat insulation and heat preservation pipe is installed between the two heat preservation cylinder connecting flanges. The transfer type heat sterilization drying pipeline part is a temperature field for heating, heat preservation, dehydration, drying and sterilization in a drying sterilization treatment device. A spiral auger is used for transporting materials to enable the materials to subjected to heating glue stir-frying under continuous stirring conditions, the dehydration efficiency is high, heating is uniform, sterilization is thorough, and no scorching and no caking are achieved. The transfer type heat sterilization drying pipeline part is matched with a belt type material transport mechanism for use to heat, dehydrate, dry and sterilize the materials.

Owner:江苏恒通环保科技有限公司

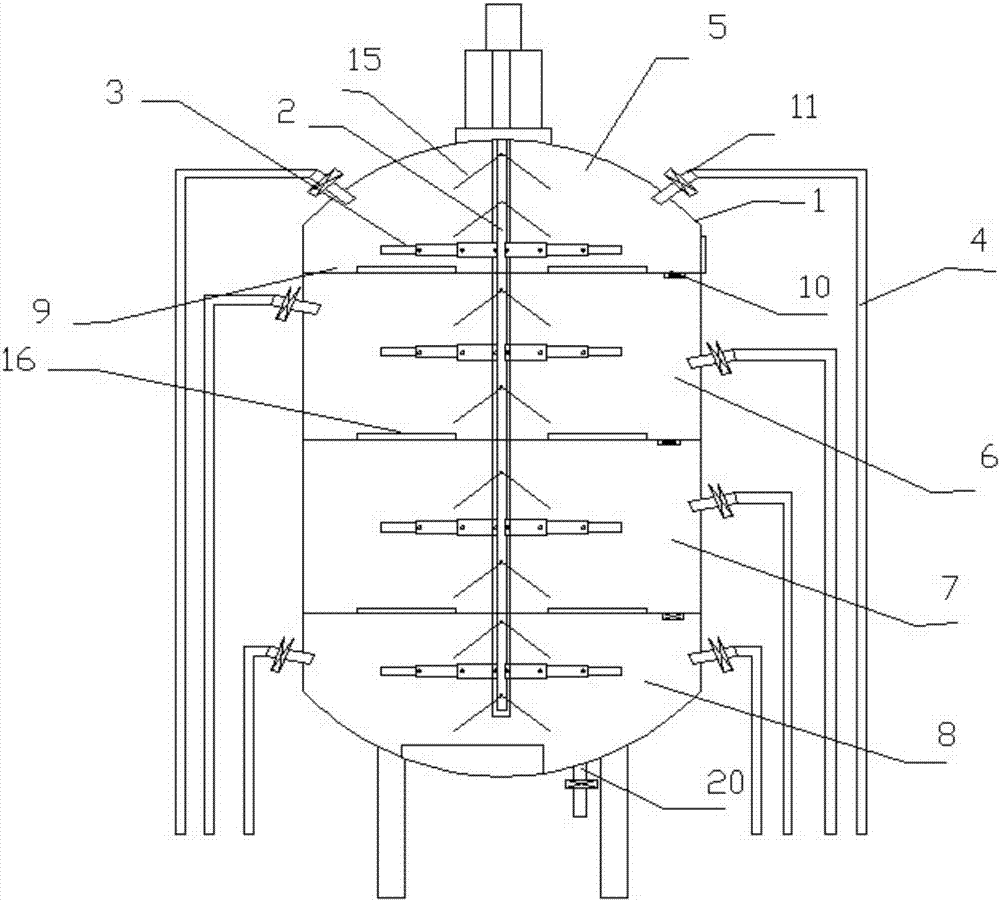

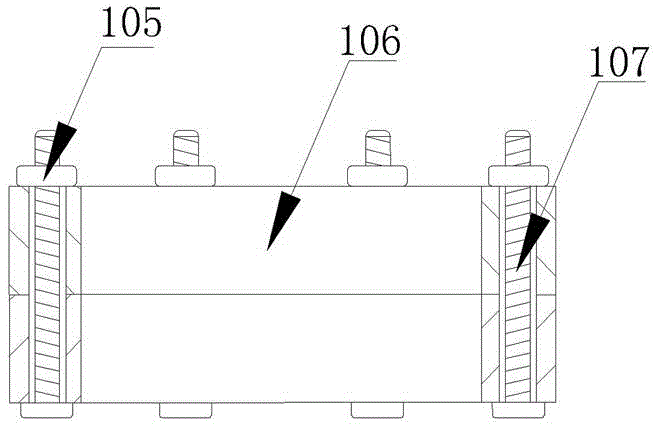

Reaction kettle for producing liquid barium-zinc heat stabilizer

PendingCN107213860AIncrease productivityImprove feeding efficiencyChemical/physical/physico-chemical stationary reactorsEnergy based chemical/physical/physico-chemical processesElectrical resistance and conductanceHeat resistance

The invention discloses a reaction kettle for producing liquid barium-zinc heat stabilizer, which comprises a shell, an agitator, and a heater, the agitator comprises an agitating shaft and blades, the blades are fixed on the agitating shaft, the agitating shaft extends into the shell, a feed inlet and a discharge outlet are arranged on the shell, the heater is embedded in the blades, the heater comprises heating resistance wires and wires, the heating resistance wires are coiled in the blades, the wires are connected to a power supply, the agitating shaft is provided with vertical slide ways, the blades are fastened in the vertical slide ways by means of sliding shafts, pneumatic cylinders are mounted on the agitating shaft, and the other ends of the pneumatic cylinders are connected to the sliding shafts of the blades. When the reaction kettle for producing liquid barium-zinc heat stabilizer disclosed by the invention is utilized to prepare liquid barium-zinc heat stabilizer, the agitator can move up and down, consequently, substances can be promoted to be uniformly heated, reaction is thorough, the heat preservation time is shortened, and the production efficiency is increased.

Owner:德清县东来化学有限公司

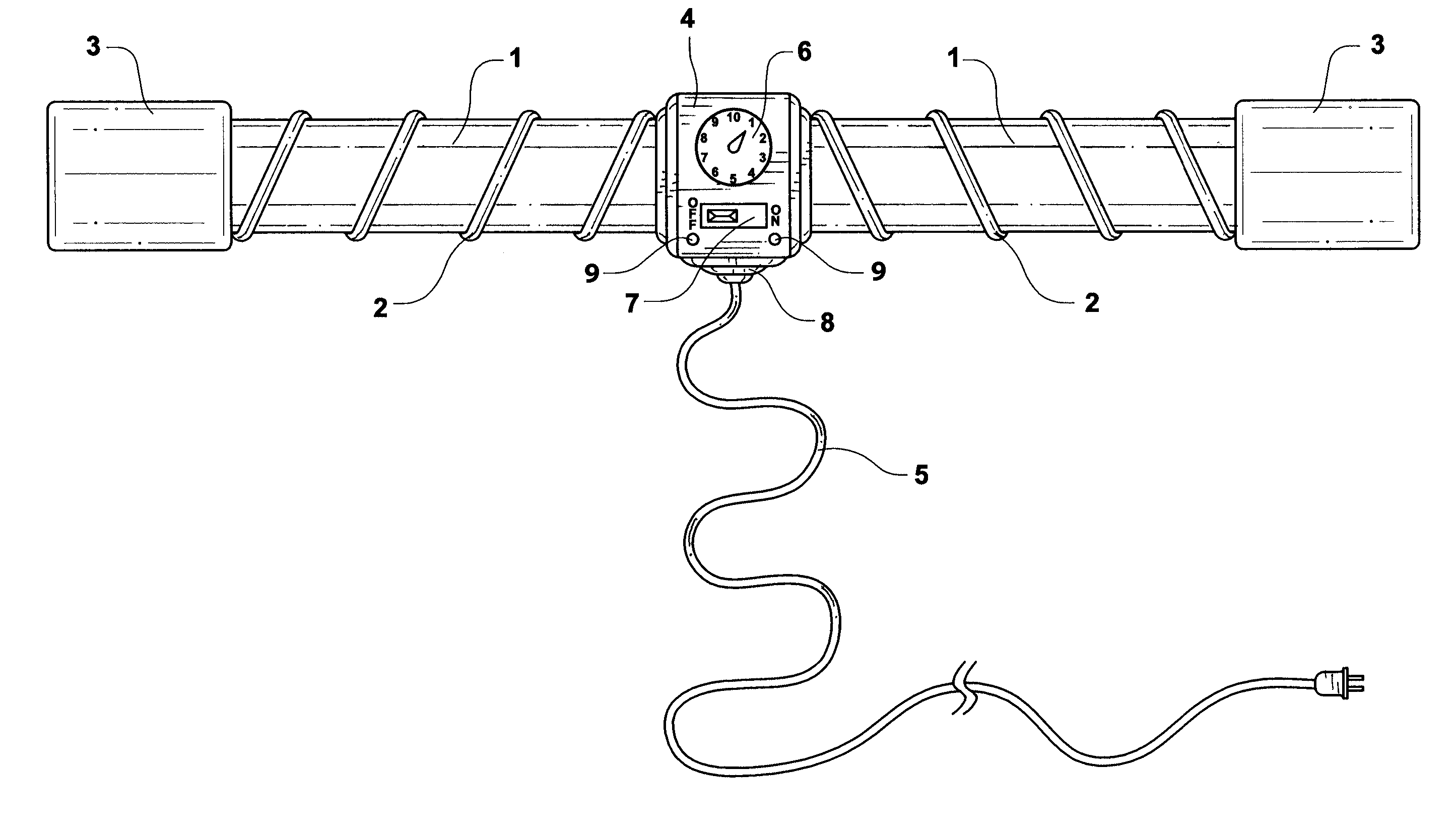

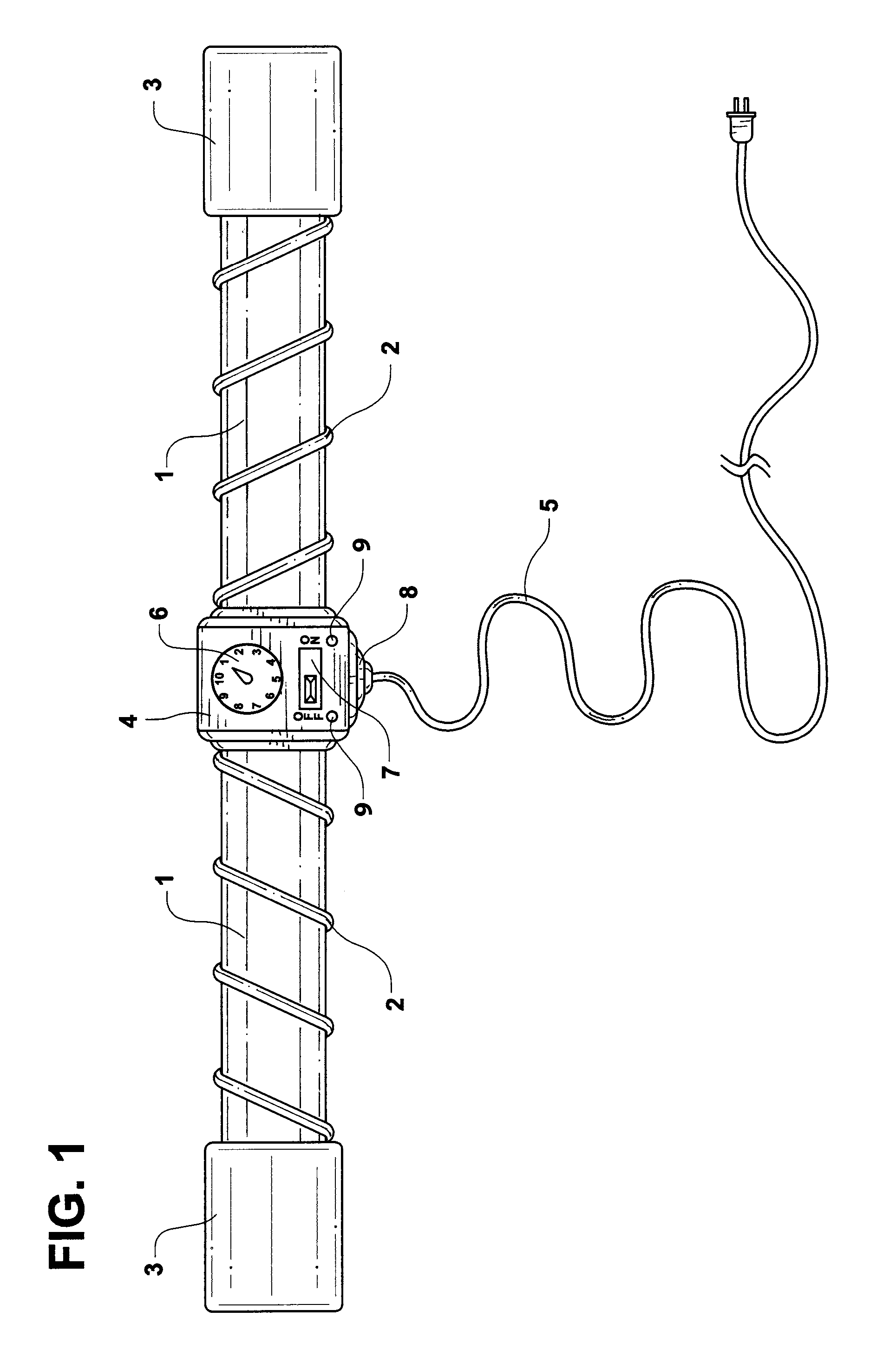

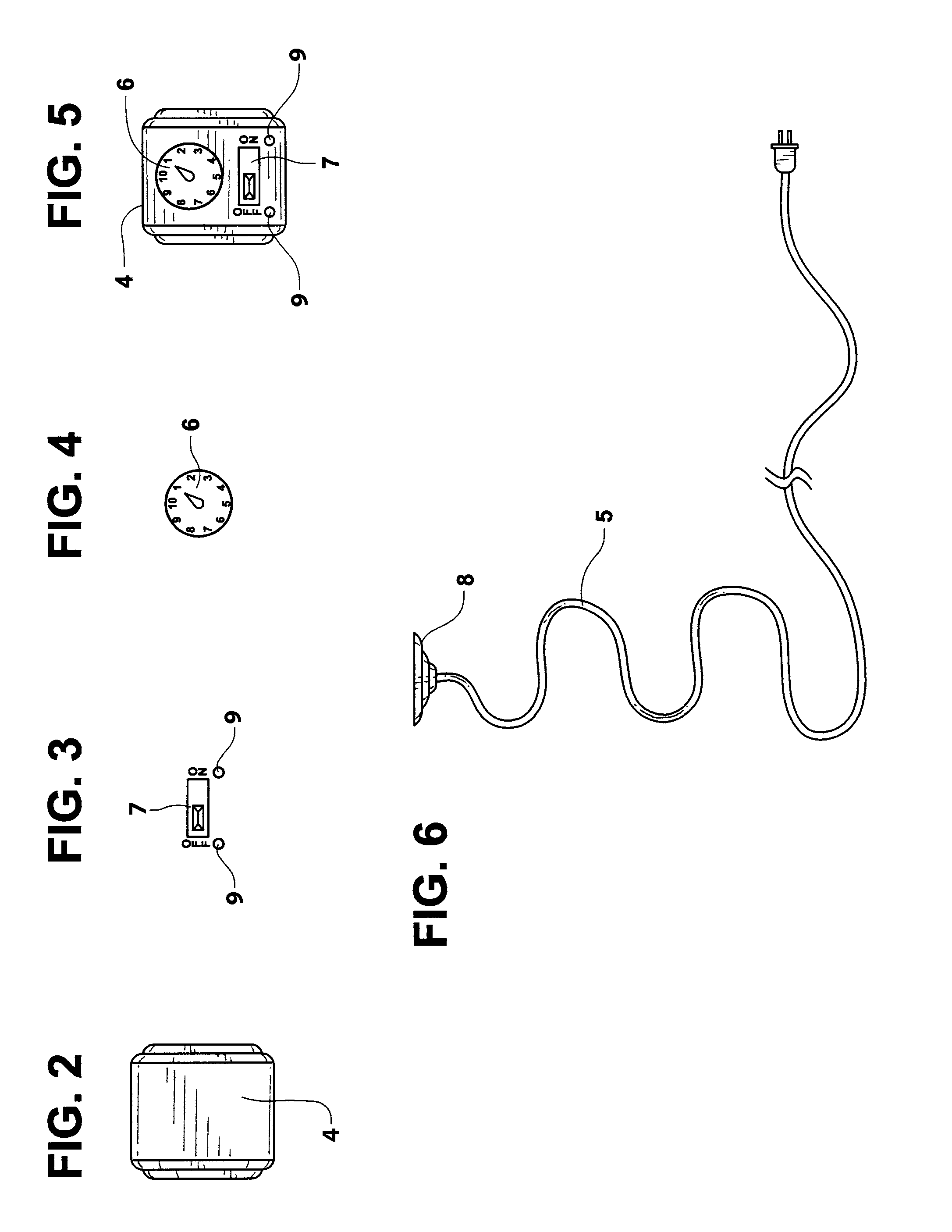

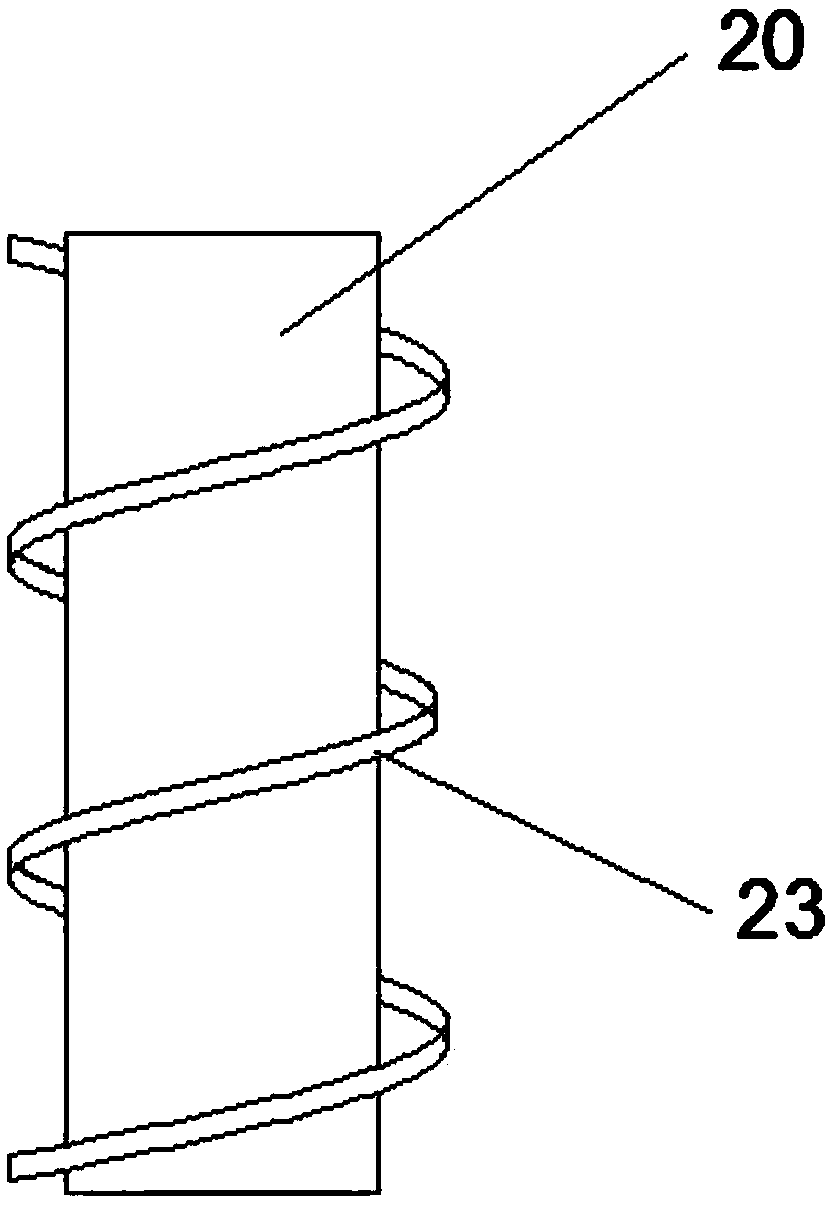

Heated hair curler for even curling of hair

InactiveUS20110259357A1Minimize timeMinimizing electricityCurling-ironsCurling-tongsConductive materialsElectric power

A device for curling hair comprised of an elongated cylindrical body member with heat-resistant handles on both ends and a housing unit located between the two ends. The cylindrical body is constructed of a conductive material. The cylindrical body further has on its surface a means for evenly spacing the hair to be heated, and is preferably comprised of a raised spiral groove made of a non-conductive medium. In a preferred embodiment, the device is operated with at least one hand on either of the heat-resistant handles and by the act of winding the hair around the cylindrical body. The device is heated using electrical power, which in the present embodiment is supplied by an electrical cord but may also be supplied by alternate power sources. The device facilitates even curling of the hair across the head, thereby reducing the time and energy involved in using a traditional hair curler.

Owner:LEVINE ROBIN +1

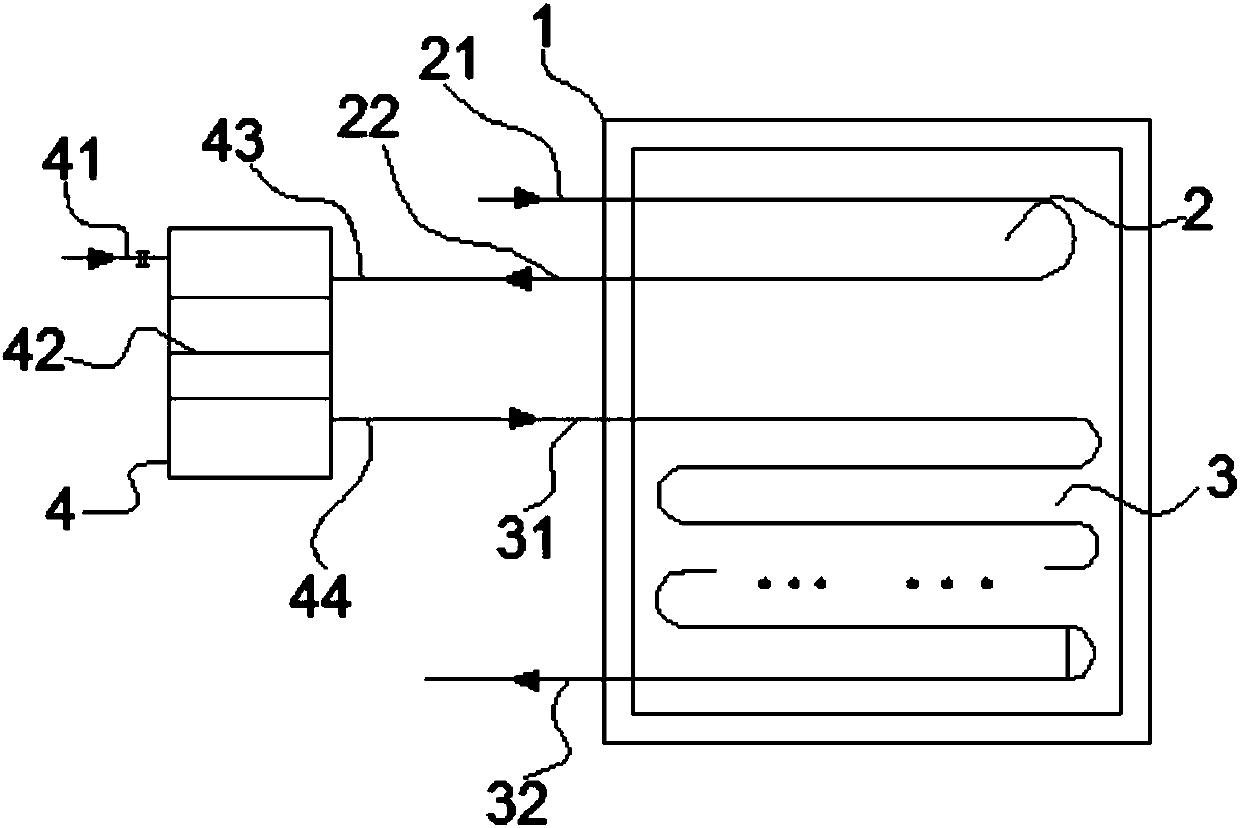

Raw material heating system and process for preparing carbon disulfide

The invention discloses a raw material heating system for preparing carbon disulfide, which is characterized by comprising a heating furnace body, a preheating pipeline, a heating pipeline and a raw material mixing device, wherein the preheating pipeline and the heating pipeline are arranged inside the furnace body, both ends of which penetrating out of the heating furnace body; an outlet of the preheating pipe and an inlet of the heating pipe communicate with the raw material mixing device respectively; and the raw material mixing device is further provided with a raw material inlet at the upper end. The system and process provided by the invention have the beneficial effects of sufficient mixing of raw materials, thorough heating of the raw materials, saving of the raw materials, improved reaction efficiency of the raw materials and increased yield of products.

Owner:重庆兴发金冠化工有限公司

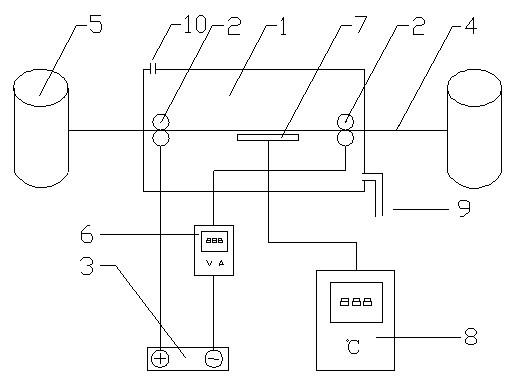

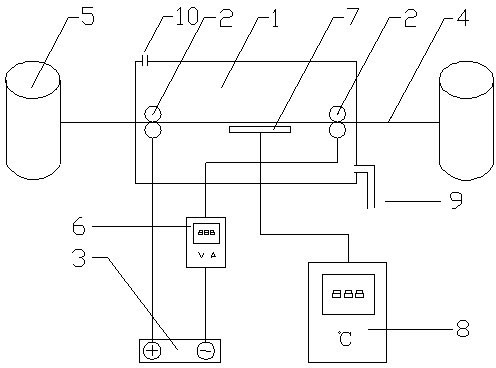

Colloid quick removing method for carbon fiber

InactiveCN102330326AAvoid surface damageSmall mechanical propertiesPhysical treatmentFiberCarbon fibers

The invention discloses a colloid quick removing method for a carbon fiber, comprising the following steps of: a, connecting two ends of the carbon fiber, which is needed to remove the colloid, to the anode and the cathode of a power supply; b, electrifying the carbon fiber to emit heat; c, measuring the surface temperature of the carbon fiber via a temperature sensor; d, controlling the current so as to control the surface temperature of the carbon fiber, thereby enabling the temperature to satisfy a condition of quickly melting and volatilizing the surface colloid without reducing the mechanical properties of the carbon fiber; e, controlling the colloid removing time, and rolling up the carbon fiber after removing the colloid. On one hand, the surface colloid is melted and volatilized by the heat emitted by the carbon fiber, which solves the defects of long temperature rise time, low colloid removing efficiency, energy wastage and the like of the conventional gaseous oxidation colloid removing mode in which a heat source is arranged at outside of the heated carbon fiber and the heat transfer is finished by convection, radiation and conduction, and is economic and environmentally friendly; on the other hand, the carbon fiber is heated under protective atmosphere, the heating temperature is high, the colloid is removed completely, simultaneously, damage on the surface of the carbon fiber is avoided, the mechanical properties of the carbon fiber are not changed greatly, and strength of the carbon fiber used as a composite material reinforcement is guaranteed.

Owner:CHINA ZHONGWANG

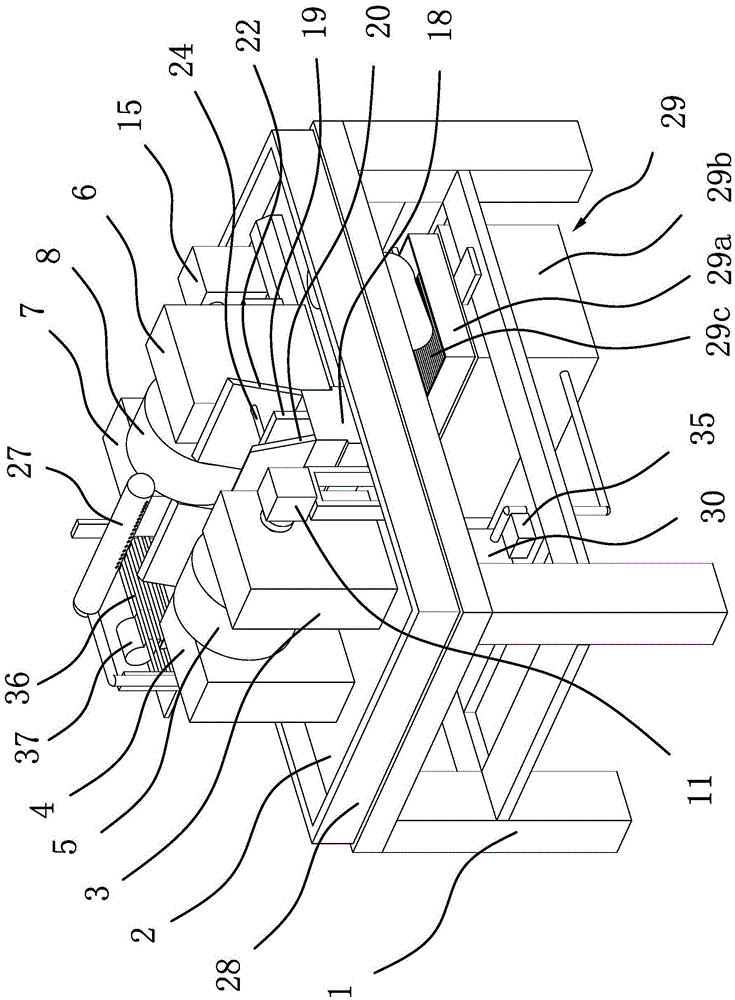

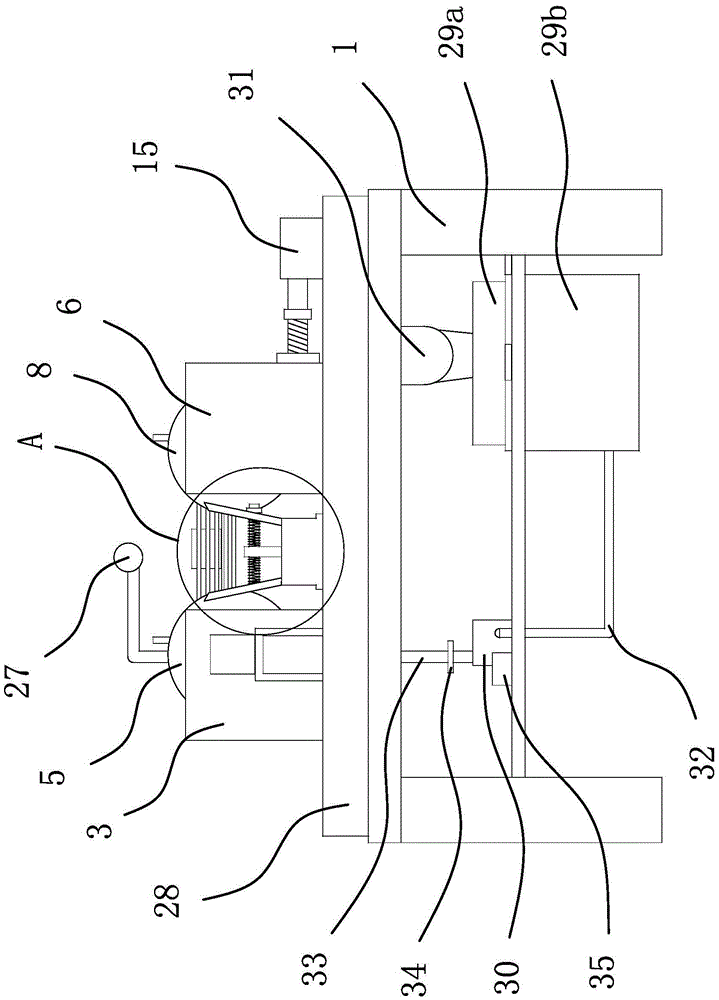

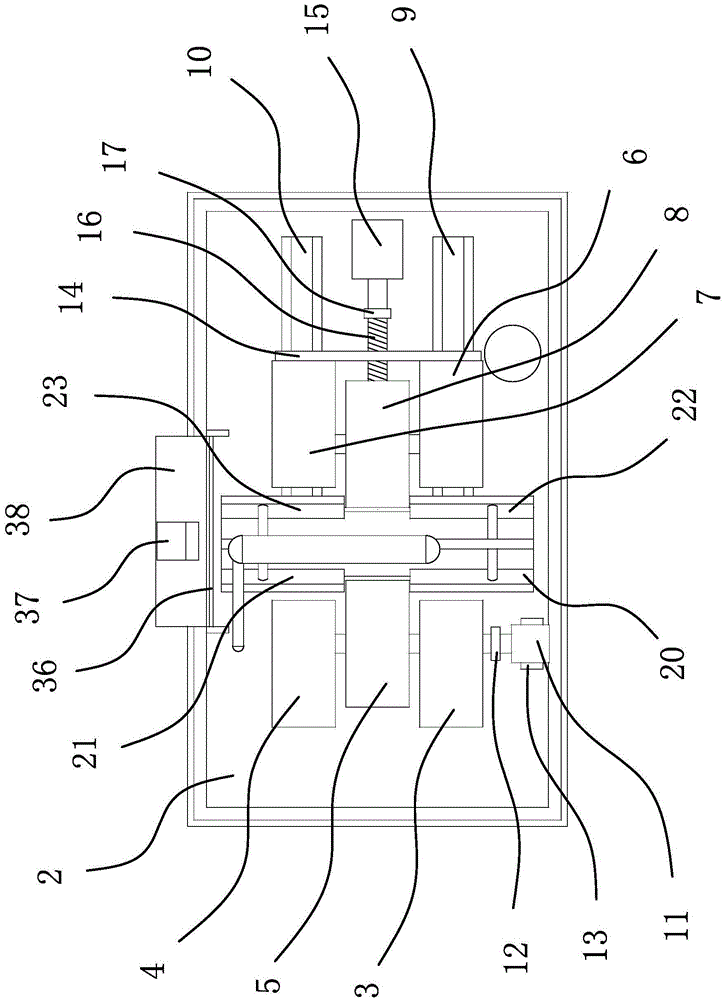

Grinding machine for outer peripheral surface of bearing outer ring

ActiveCN103753359BAchieve grindingWash thoroughlyGrinding carriagesRevolution surface grinding machinesSanderEngineering

The invention provides an outer peripheral face polishing machine for a bearing outer ring and belongs to the technical field of machinery. The problem in the prior art that a special device for polishing the outer peripheral face of the bearing outer ring is unavailable is solved. The machine comprises a machine frame, a work table board is fixed on the machine frame, a first bearing seat and a second bearing seat which correspond to each other are fixed on the work table board, a grinding wheel is arranged between the first bearing seat and the second bearing seat through a first rotary shaft, and the first rotary shaft is connected with a power mechanism. A third bearing seat and a fourth bearing seat are arranged on the work table board, and a locating wheel is arranged between the third bearing seat and the fourth bearing seat through a second rotary shaft. A first guide track and a second guide track are fixed on the work table board, the third bearing seat and the fourth bearing seat are arranged on the first guide track and the second guide track in a sliding mode respectively, and the third bearing seat and the fourth bearing seat are connected with an adjusting mechanism. The machine can polish the outer peripheral face of the bearing outer ring and is high in efficiency.

Owner:HAINING QI SHENG BEARING

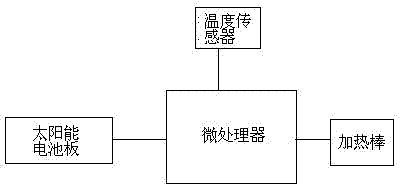

Heater

InactiveCN102905406ASave electricityHeat thoroughlyOhmic-resistance heating detailsThermodynamicsHeater Rod

The invention relates to a heater, belonging to the technical field of electronics. The heater comprises a solar cell panel, a heating rod, a temperature sensor and a microprocessor, wherein the output ends of the solar cell panel, the heating rod and the temperature sensor are respectively connected with the input end of the microprocessor. The heater disclosed by the invention has the advantages of electric energy saving, thorough heating, high heating efficiency and environmental friendliness.

Owner:SHENYANG CHUANGDA TECH TRADE MARKET

Bearing outer ring peripheral surface grinding machine of improved structure

ActiveCN105881122AAchieve grindingWash thoroughlyGrinding carriagesRevolution surface grinding machinesSurface grindingGrinding wheel

The invention provides a bearing outer ring peripheral surface grinding machine of an improved structure, and belongs to the technical field of machines. The bearing outer ring peripheral surface grinding machine solves the problems that in the prior art, equipment special for grinding the bearing outer ring peripheral surface lacks. The bearing outer ring peripheral surface grinding machine of the improved structure comprises a rack, a working table is fixed to the rack, a first bearing pedestal and a second bearing pedestal which correspond to each other are fixed to the working table, and a grinding wheel is arranged between the first bearing pedestal and the second bearing pedestal through a first rotating shaft; the first rotating shaft is connected with a power mechanism, and a third bearing pedestal and a fourth bearing pedestal are further arranged on the working table; a positioning wheel is arranged between the third bearing pedestal and the fourth bearing pedestal through a second rotating shaft; a first guide rail and a second guide rail are fixed to the working table, the third bearing pedestal is arranged on the first guide rail in a sliding manner, and the fourth bearing pedestal is arranged on the second guide rail in a sliding manner; and the third bearing pedestal and the fourth bearing pedestal are further connected with an adjusting mechanism. The bearing outer ring peripheral surface grinding machine can grind the bearing outer ring peripheral surface and is high in efficiency.

Owner:HAINING QI SHENG BEARING

Car decorating part injection molding machine

The invention discloses a car decorating part injection molding machine which comprises a main frame body. A propelling box is arranged in the middle of the lower portion in the main frame body. A pushing rod is arranged in the propelling box in a sleeved manner. The right end of the pushing rod is located in the propelling box and provided with a baffle. A screw rod is arranged in the pushing rodin a sleeved manner. A first rack is arranged on the left side of the lower portion in the main frame body. A first motor is arranged at the upper end of the first rack. The first motor and the screwrod are fixedly connected. A flat pipe is arranged on the right side of the propelling box. When the device works, heating is carried out in the heating box, raw materials heated preliminarily are fed into the heating box again through an oblique pipe, heating is carried out many times, thus the raw materials can be heated fully, the heating efficiency is improved, and the situation that in the later machining and forming process, the raw materials deform insufficiently is avoided. The screw rod rotates to enable the pushing rod to move rightwards, the baffle enables heated plastic to enter aforming box through the flat pipe, then the heated plastic passes through the cooling device, by means of transmission of the screw rod, the propelling speed is increased greatly, and the situation that the heated raw materials are cooled sharply is avoided.

Owner:QUANJIAO XIANGRUI PLASTIC

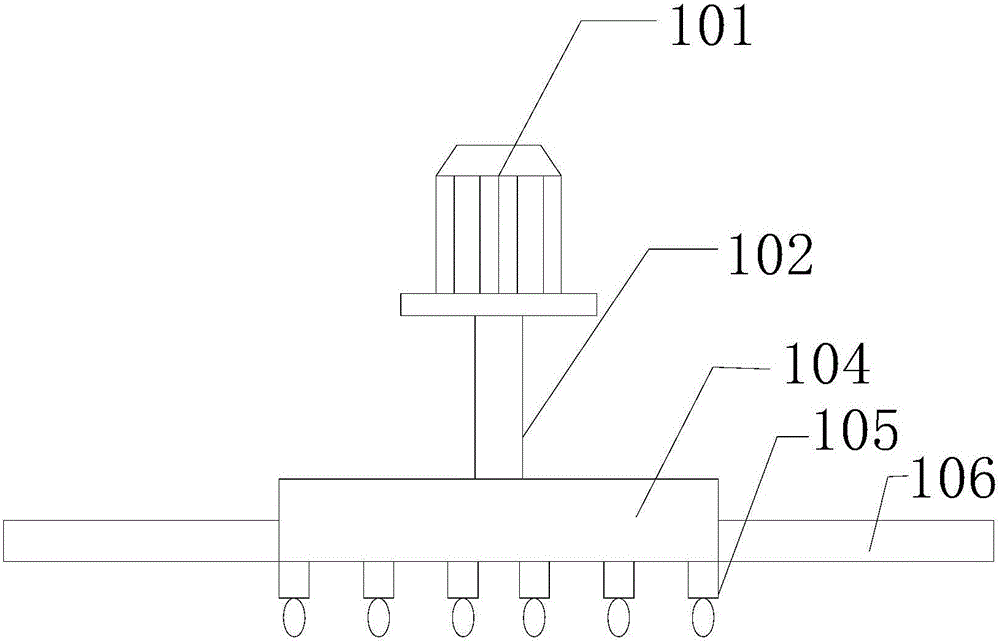

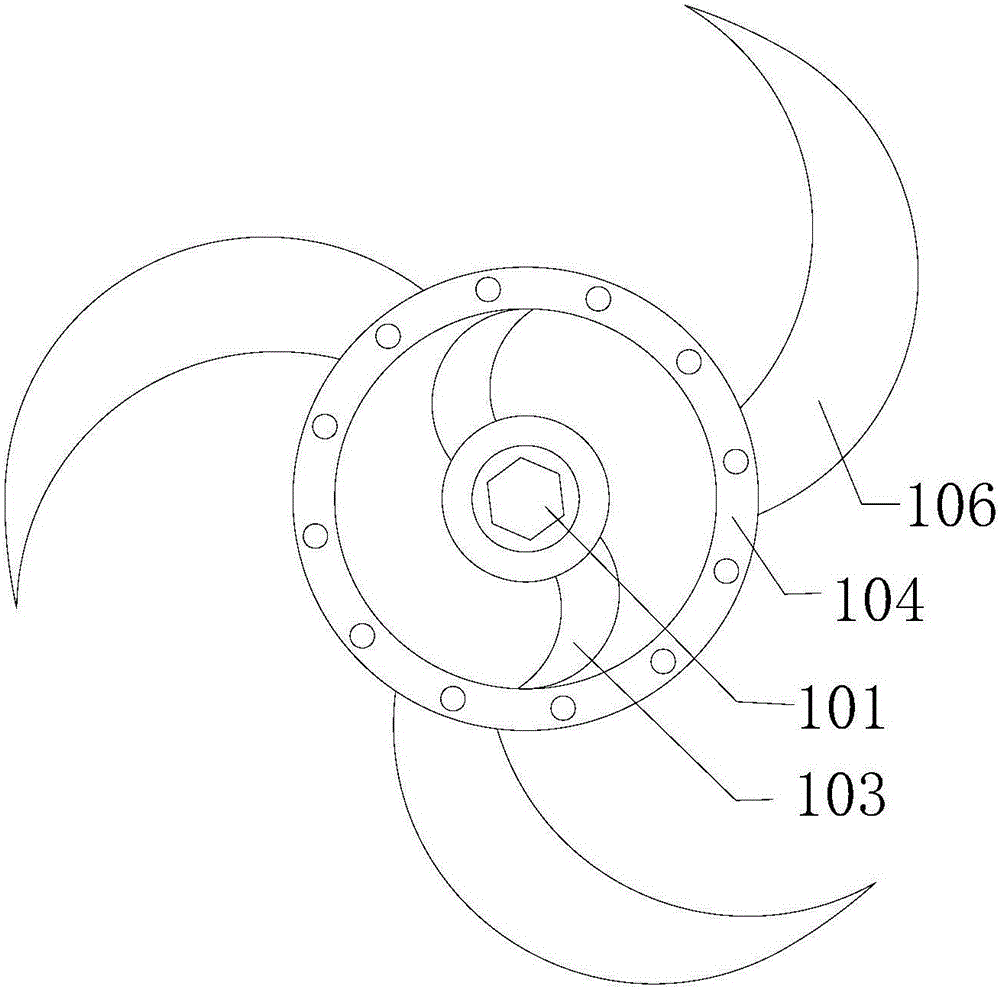

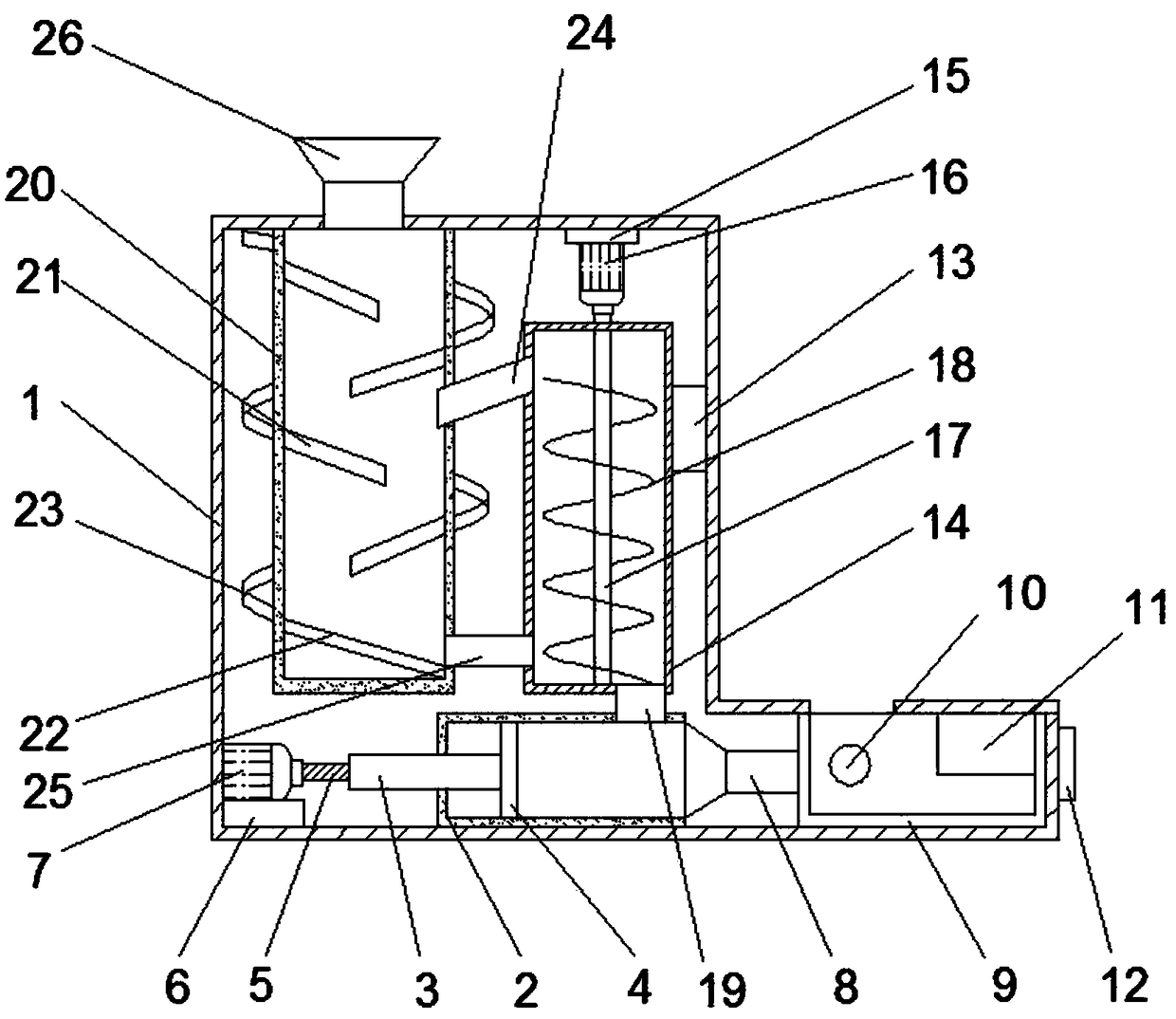

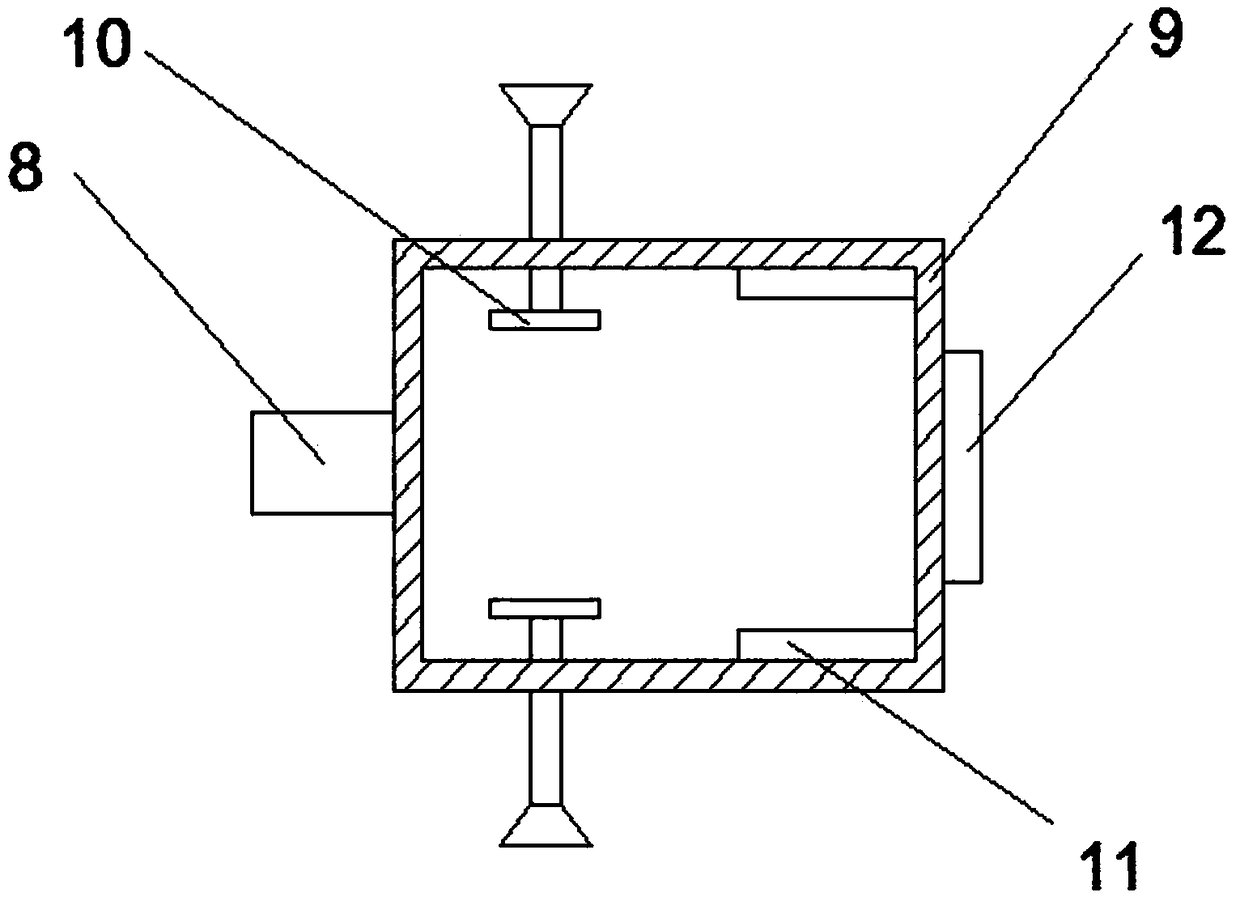

Automated traditional Chinese medicine extraction device

InactiveCN105498277AQuality improvementStir thoroughlySolid solvent extractionBiochemical engineeringDisplay device

The invention discloses an automated traditional Chinese medicine extraction device. The automated traditional Chinese medicine extraction device comprises a cooking device, wherein a driving device is arranged at the bottom of the internal cavity of the cooking device and is in driving connection with a stirring device, a charging pipeline is arranged at the upper end of one side of the cooking device, an exhaust pipeline is arranged at the upper end of the other side of the cooking device, a temperature display device is arranged on the surface of the upper end of the cooking device, a supporting platform is arranged below the cooking device, a control panel is arranged on the supporting platform, a temperature sensor is arranged on the internal wall of the cooking device, a discharging pipeline is arranged at the lower end of one side of the cooking device, a first electromagnetic valve is mounted at a charging end of the discharging pipeline, and a discharging end of the discharging pipeline is connected with a charging end of a settling chamber. According to the automated traditional Chinese medicine extraction device, the heating is more uniform while the stirring is more thorough, and various kinds of sensors are matched with a controller and the control panel, so that automated operation is achieved, and the quality of manufactured medicines is improved.

Owner:GUANGDONG KONBOM SCI & TECH IND CO LTD

A high-efficiency hot-dip galvanizing production line

ActiveCN105861970BQuick removalEasy to salvageHot-dipping/immersion processesAcid washingEngineering

The invention discloses a high-efficiency hot dip galvanizing production line which comprises a lifting appliance, a zinc pot, an acid washing tank, a water washing tank, a cosolvent tank and a cooling tank. The high-efficiency hot dip galvanizing production line can quickly remove bubbles on the workpiece surface in the workpiece galvanizing process, can gather the zinc ash on the surface before the workpiece is taken out of the zinc pot so as to prevent the adhesive pollution, can enable the reflux motion of the acid liquor in the acid washing tank so as to increase the contact reaction rate between the acid liquor and acid-washed workpiece, can monitor the concentration of the acid liquor in real time, can enable the water washing of the workpiece to proceed more quickly and thoroughly, can enable the contact between the workpiece and cosolvent more uniformly and quickly, can eliminate the influence of the impurities and stains attached to the workpiece surface on the cosolvent treatment so as to effectively ensure the feed quality of the subsequent procedure, and can enable the water cooling heat transfer of the acid washing wastewater for the hot dip galvanizing cooling tank so as to save the water resources and enhance the wastewater utilization efficiency, thereby saving the production cost.

Owner:浙江慧钢技术发展股份有限公司

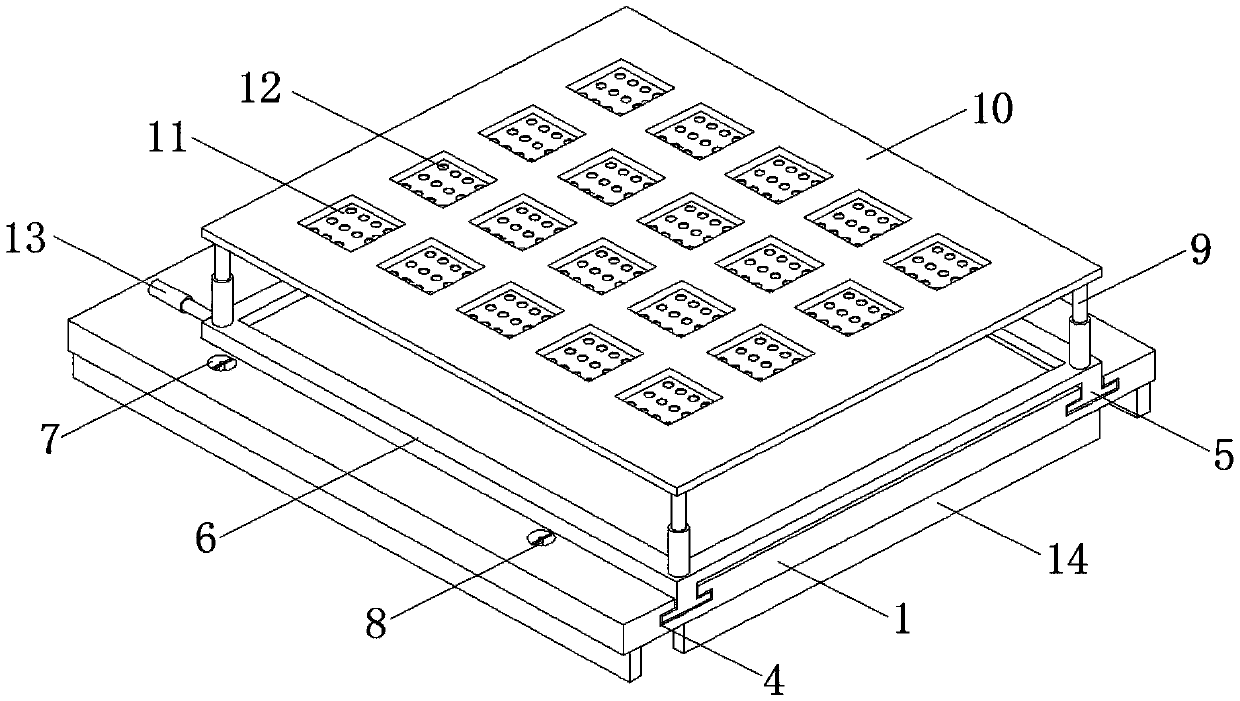

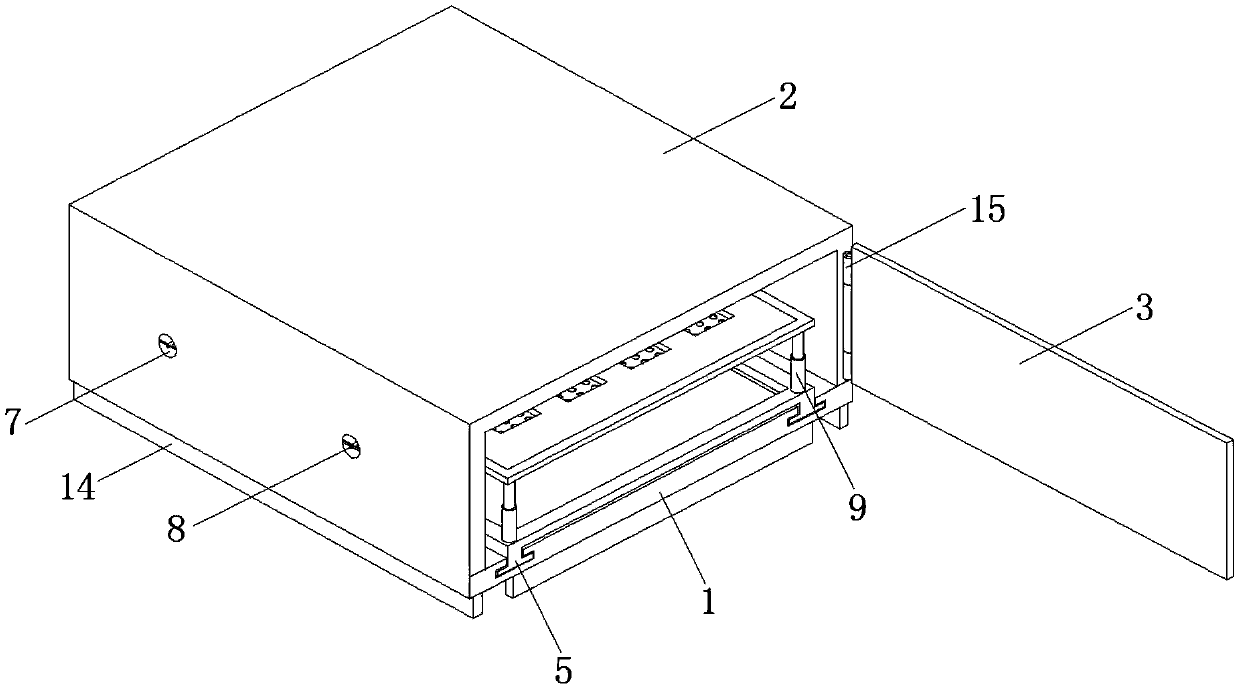

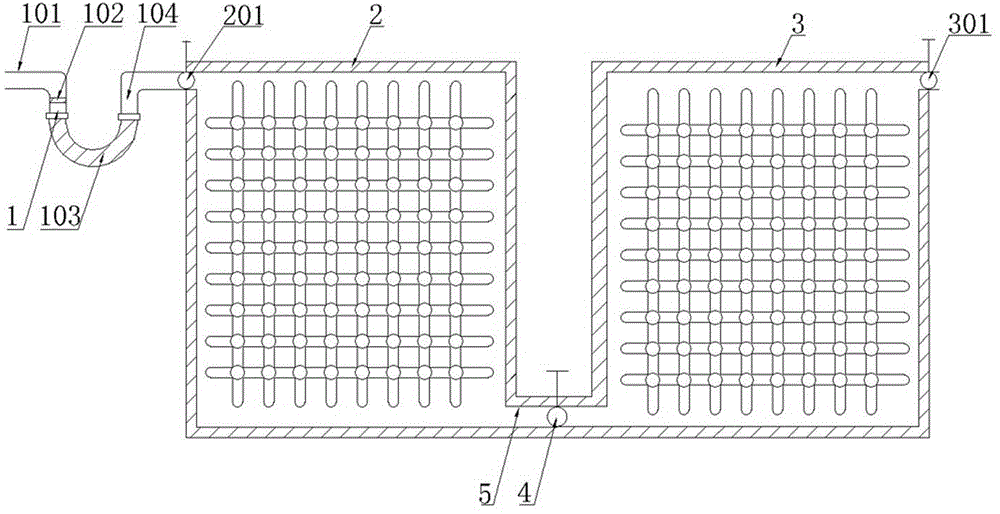

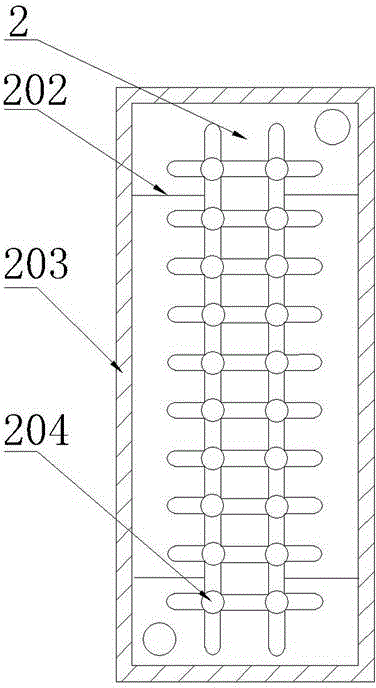

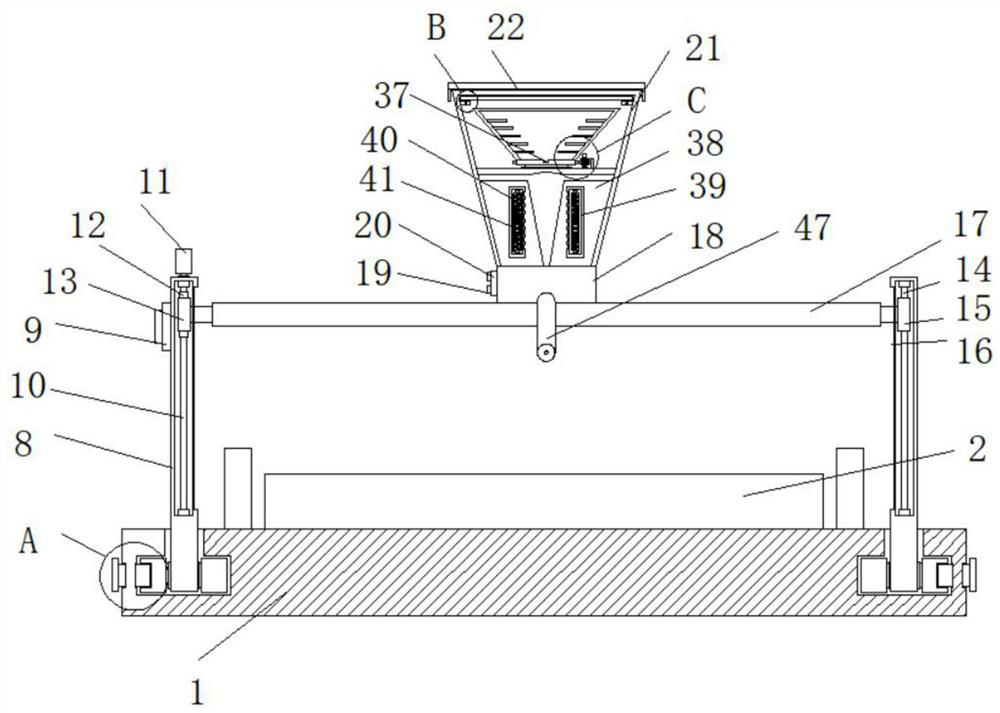

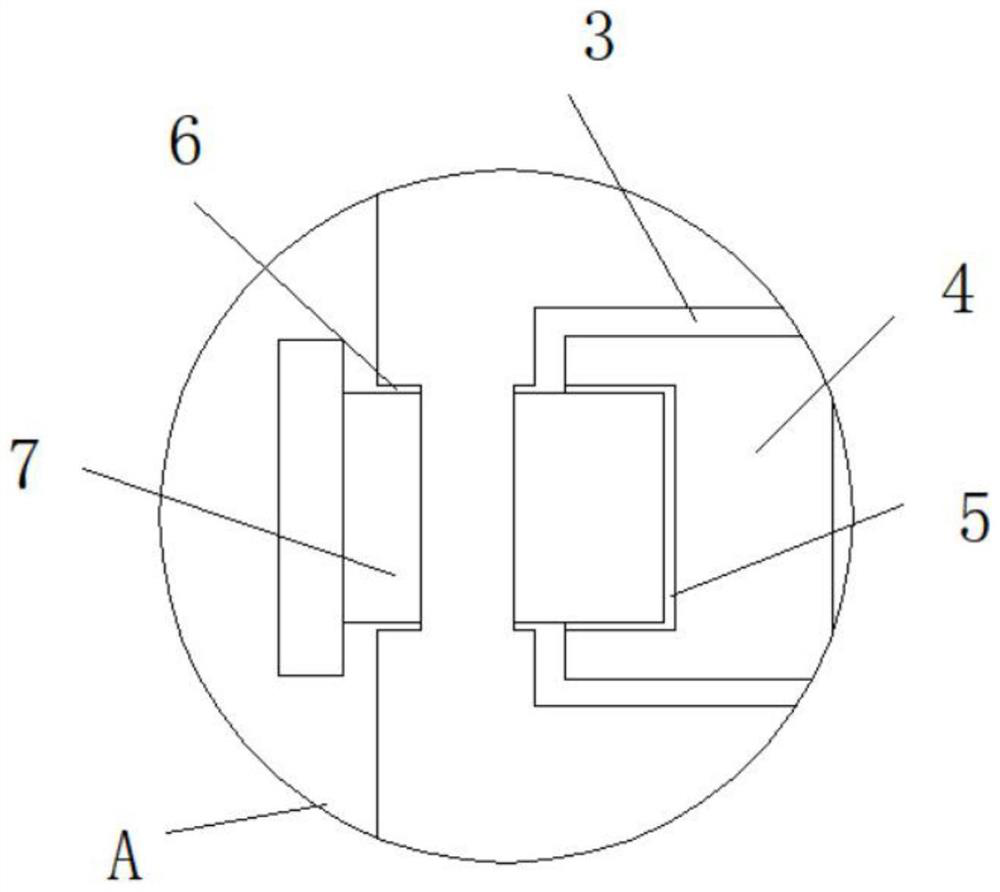

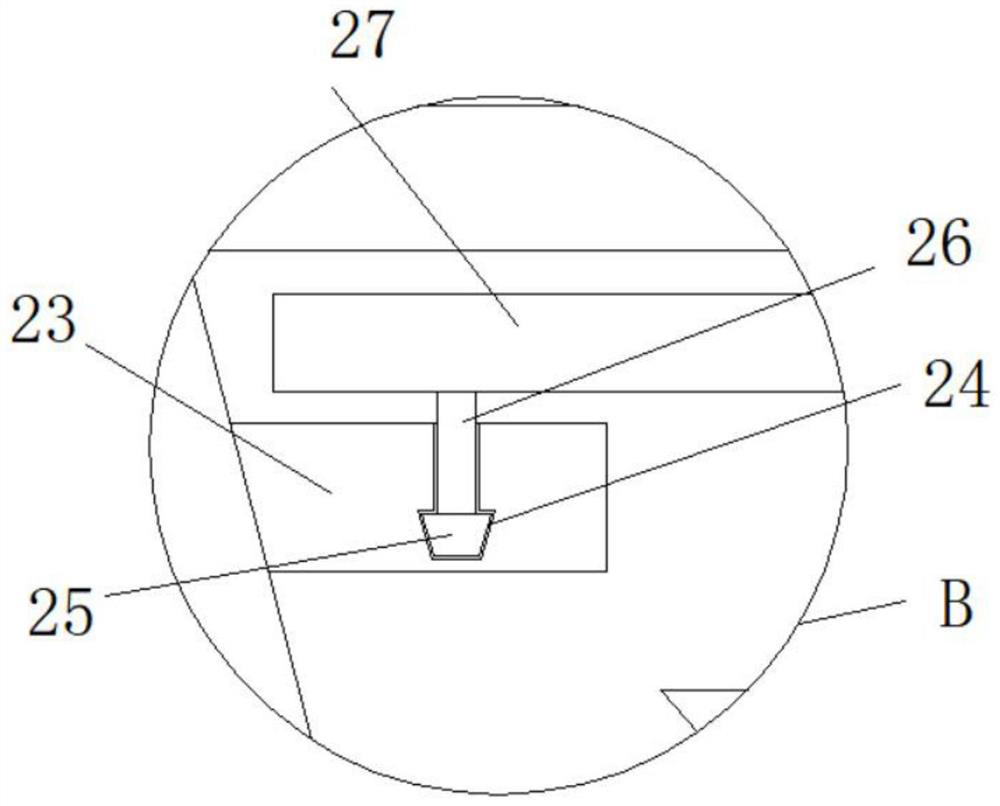

Solar cell piece drying device and processing process thereof

ActiveCN109585604ADry thoroughlyHeat thoroughlyFinal product manufactureDrying gas arrangementsElectrical resistance and conductanceArchitectural engineering

The invention discloses a solar cell piece drying device. The solar cell piece drying device comprises a bottom plate, a shield and a seal cover, three sides of the top wall of the bottom plate are welded and fixed to three sides of the bottom wall of the shield, the top wall of the bottom plate is provided with two sets of slots which are symmetrically distributed at the two sides of the top wallof the bottom plate, the top wall of the bottom plate is provided with a support frame, two sides of one side, far away from the opening of the inner cavity of the shield, of the support frame are respectively provided with flexible rods, the two ends of the flexible rods are respectively welded with the side wall of the inner cavity of the shield and the side wall of the support frame, two setsof sliding seats are welded at the bottom wall of the support frame, and the vertical section surfaces of the two sets of the sliding seats are T-shaped and are buckled and fixed with the two sets ofslots. According to the solar cell piece drying device and the processing process thereof, a first through hole, a first fan and a resistance wire are arranged at the bottom plate and the side wall ofthe shield to allow air at each position in the inner cavity of the shield to be heated so that the cell piece is dried more thoroughly.

Owner:江苏中宇光伏科技有限公司

Drying device for camellia chrysantha processing

InactiveCN108072250AHeating fastHeat thoroughlyDrying gas arrangementsDrying chambers/containersEngineeringPulley

The invention discloses a drying device for camellia chrysantha processing. The drying device comprises a baking oven, a discharge pipe, heating plates, stirring bars, a rotary shaft, an air pipe, a draught fan, a belt pulley and a feed pipe. The drying device for camellia chrysantha processing comprises the baking oven, the discharge pipe, the heating plates, the rotary shaft and the feed pipe. The discharge pipe is connected to one side of the bottom of the baking oven. The air pipe is connected to one side of the top of the baking oven. The top of the baking oven is provided with the rotaryshaft. The top of the rotary shaft is connected with the belt pulley. The feed pipe is connected to one side of the top of the baking oven. The heating plates are connected to the two sides of the interior of the baking oven correspondingly. The drying device for camellia chrysantha processing has the advantages that when needing to be dried, camellia chrysantha is poured into the baking oven, and the heating plates can heat the camellia chrysantha in the baking oven. The camellia chrysantha can be stirred and mixed through the rotary shaft and the stirring bars. Meanwhile, the draught fan blows external air into the baking oven through the air pipe to blow and mix the camellia chrysantha more completely. The camellia chrysantha is heated more uniformly. The baking effect and speed are better.

Owner:DONGXING XINYU IND

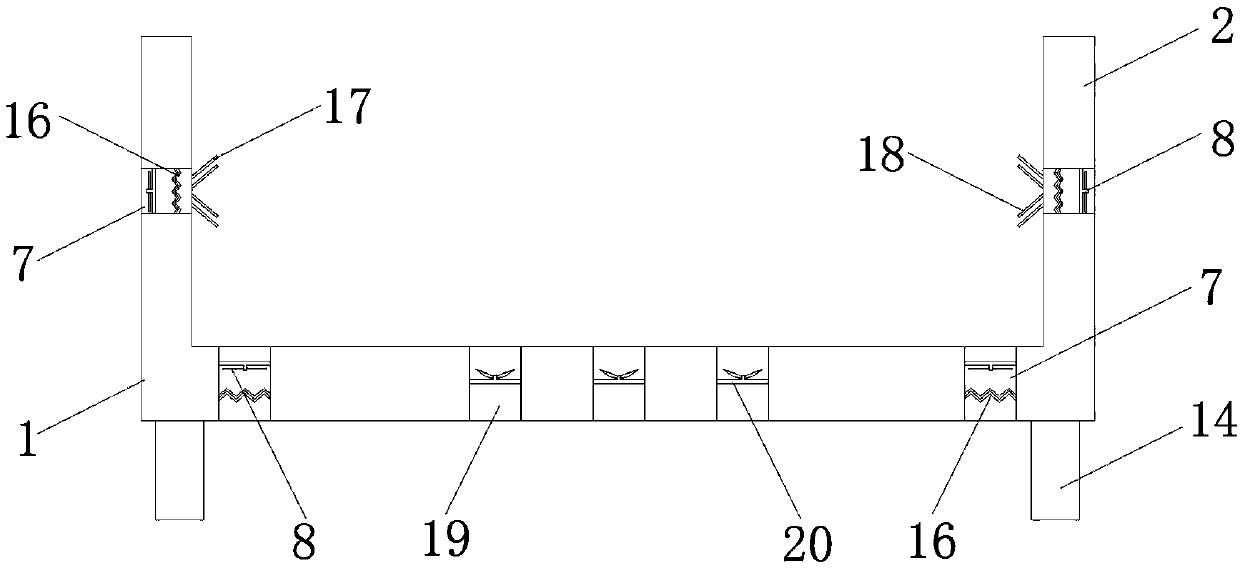

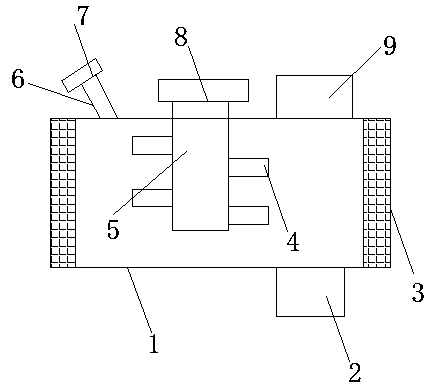

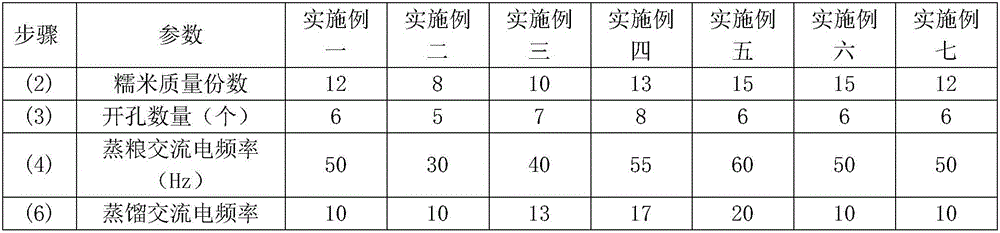

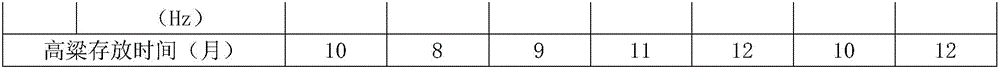

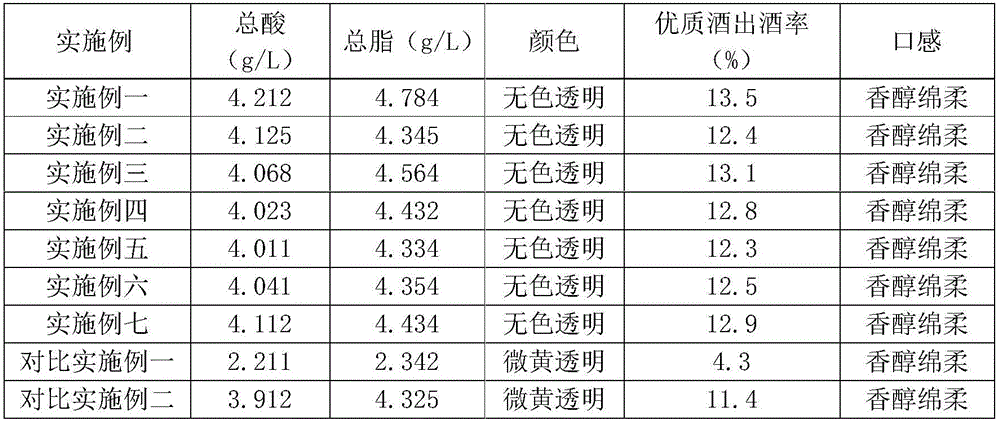

Process for producing aromatic type baijiu

The invention relates to the field of baijiu production, and discloses a process for producing aromatic type baijiu. The process includes smashing and screening sorghum; soaking sorghum powder in clear water; adding glutinous rice starch and high-temperature yeast into the sorghum powder; cultivating the sorghum powder, the glutinous rice starch and the high-temperature yeast and then rubbing the sorghum powder to obtain sorghum balls; filling the balls with steel balls by means of rubbing; steaming grain in steamer grates with electromagnetic coils on the walls; discharging the grain out of the steamer grates and then fermenting the grain; distilling the fermented grain and placing fermenting grains into distillation containers with electromagnetic coils on the walls when the grain is distilled, electrifying the electromagnetic coils with alternating currents with the frequencies of 10-20 Hz, continuously filling the distillation containers with carbon dioxide gas when the grain is distilled, distilling the grain to obtain strong liquor of baijiu; storing and blending the strong liquor of the baijiu to obtain the aromatic type baijiu. Compared with the prior art, the process has the advantage of high baijiu yield.

Owner:庄臣酿酒(福建)有限公司

A kind of automobile exhaust particle catcher and filter element

ActiveCN104763493BSmall exhaust pressure lossImprove capture capacityExhaust apparatusSilencing apparatusParticulatesInsulation layer

The invention discloses an automobile tail gas particulate matter trap and a filter element. A particulate matter coagulation unit (20), a charging unit (5) and the filter element (7) are arranged in a shell (8) in sequence in a direction from air inlet to air outlet, and the filter element (7) is wound into a cylindrical shape through a metal fiber plate (70). The metal fiber plate (70) comprises two metal fiber filtration and adsorption outer surface layers (71) and an electric heating film layer (73) clamped between the two metal fiber filtration and adsorption outer surface layers; heat conduction insulation layers (72) are arranged between the metal fiber filtration and adsorption outer surface layers (71) and the electric heating film layer (73); and the cross sections of the metal fiber filtration and adsorption outer surface layers (71) are corrugated, and the metal fiber filtration and adsorption outer surface layers (71) guide tail gas in the longitudinal direction. The automobile tail gas particulate matter trap is integrated with multiple functions of electrostatic adsorption and dust removal, filter element diffusion, intercepting, collision mechanism dust removing and the like, and the particulate matter trap effect is improved; the exhaust pressure loss of an engine is small, and the particulate matter trap effect is good; and the filter element is convenient to regenerate and reliable, and has the advantages of being low in use and maintenance cost and is suitable for popularization.

Owner:REED XINXIANG ROAD INC

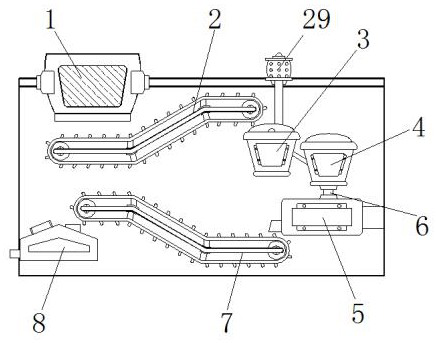

A desalination treatment device for sea sand used as construction sand

The invention discloses a desalination treatment device for sea sand used as construction sand, which comprises a feeding hopper, a first motor and a control switch. The bottom of the feeding hopper is provided with one end of a first conveying assembly, and the feeding hopper, The other end of the first conveying assembly is arranged above the heating device, the first motor is installed inside the feed hopper through the protective bracket, and one end of the anti-sticking rod is fixed at the connection between the sweeping rod and the slide block, and The other end of the anti-sticking rod is embedded with a first ball, the control switch is installed on the outer wall of the feed hopper, and the control switch is connected to the first motor, and a positioning rod is arranged in the middle of the first conveying assembly. The sea sand is used as a desalination treatment device for construction sand, which can carry out a large number of sea sand desalination operations at one time, which facilitates the work of sea sand desalination operations, and at the same time facilitates the transformation of chlorine elements in the sea sand when it is heated, making it dechlorinated It is more thorough and convenient for the purification of chlorine gas.

Owner:杨爱平

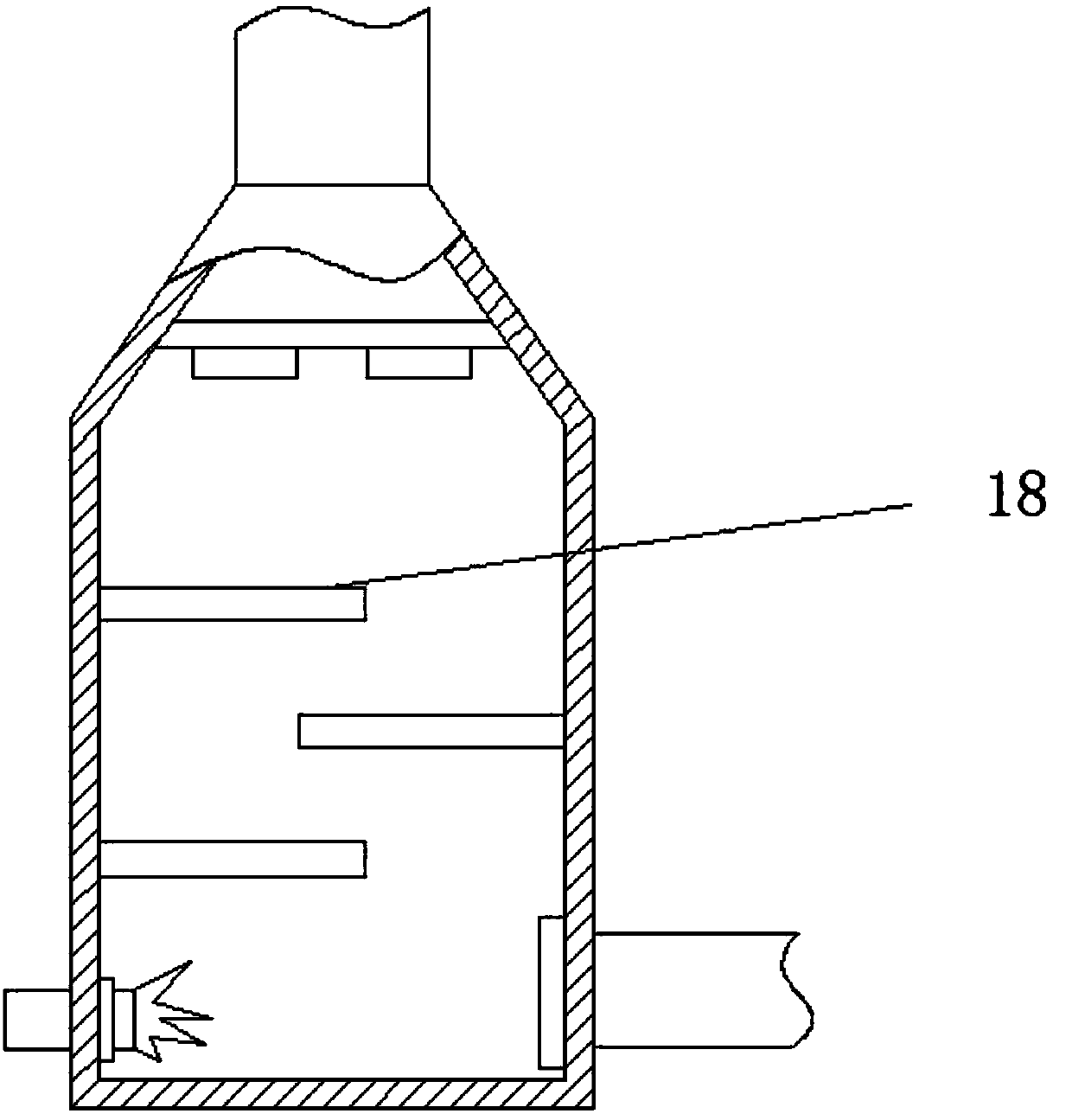

Waste hot wind circulating device

InactiveCN104930845AIncrease the time spent indoorsHeat thoroughlyHeating arrangementEngineeringHoneysuckle

The invention discloses a waste hot wind circulating device in the field of drug processing equipment. The device comprises a heating chamber. The heating chamber is internally provided with a heater. A thermal-insulating layer is connected with the external of the heating chamber. The device also comprises an integrated pipeline, a straight pipe, and a thermal-insulating chamber. The integrated pipeline is on the air inlet of the heating chamber. The straight pipe is between the heating chamber and the thermal-insulating chamber. The integrated pipeline comprises a blast pipe, a U-shaped pipe, and a discharge pipe. The blast pipe is on the air inlet end of the U-shaped pipe. The discharge pipe is on the air outlet end of the U-shaped pipe. The thermal-insulating chamber is internally provided with a warmer. The external of the thermal-insulating chamber is provided with a thermal-insulating layer. Through implementing the device, problems in the prior art that after hot wind dries honeysuckle flowers, generated waste hot wind cannot be recycled, which cause energy and environmental loss are solved, and a problem of storage after waste hot wind is recycled and heated is also solved.

Owner:遵义市郎笑笑食品有限责任公司

Medicine feeder for intensive care patient

InactiveCN112155894AImprove practicalityHeat thoroughlyRotating receptacle mixersTransportation and packagingIntensive careElectric machinery

The invention discloses a medicine feeder for an intensive care patient, and belongs to the field of intensive care equipment. The medicine feeder comprises a bed plate; a bed is fixedly mounted on the outer wall of the upper end of the center of the bed plate; sliding grooves are fixedly formed in the left and right sides of the bed plate; rotating wheels A are movably mounted in the sliding grooves; inserting grooves A are fixedly formed in the outer ends of the rotating wheels A; inserting grooves B are fixedly formed in the side walls of the outer ends of the sliding grooves; inserting rods are inserted into the inserting grooves A and the inserting grooves B; the upper sides of the centers of the rotating wheels A penetrate through the sliding grooves to be fixedly connected with fixing columns A; a motor A is fixedly mounted on the outer wall of the upper end of the left side of the corresponding fixing column A; and a screw is rotationally mounted at the lower end of the motor Ain a mode of penetrating through the corresponding fixing column A. By arranging a rotating structure, an embedded fixing structure, an embedded sliding structure and a heating device, the practicability of the medicine feeder is improved.

Owner:亓志玲

Device for shaping infarcted heart tissue and method of using the device

InactiveUS8285393B2Accurate temperature measurementAvoid elevationSurgical instrument detailsTherapeutic coolingScar tissueInfarcted heart

Owner:LAUFER MICHAEL D +4

Feed fabricating method for special animal such as fox, ermine and raccoon dog

ActiveCN101223939BAvoid destructionFor the purpose of sterilizationFeeding-stuffAnimal feeding stuffMinkNyctereutes procyonoides

The invention relates to a manufacturing method for animal feed, in particular to a manufacturing method for a special animal feed exclusively used in fox, mink and raccoon dog. The method has the advantages that: raw materials of corn and soybean meal required in the formula are bulked by a dry method or wet method and ground; the ground material is mixed with meat and bone meal and imported fishmeal, and then bulked again (by the dry method or wet method); the second bulking is completely different from other bulking methods for an annular space discharging mode is adopted in the discharging in front of a bulking machine in the second bulking and the bulking temperature is 100-130 DEG C, which not only realizes the aim of sterilization and curing, but also avoids breaking the nutritional factors of the materials due to over-high temperature; the product produced by the process has high bulking degree, good water binding capacity, good palatability and thorough sterilization. The premix materials are added and mixed twice to avoid reducing the effect caused by heating.

Owner:大连一鑫畜牧科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com