Process for producing aromatic type baijiu

A sauce-flavored liquor and production process technology, which is applied in the field of liquor production, can solve problems such as difficult ripening of sorghum, uneven fermentation, and difficult volatilization of alcohol, and achieve the effects of complete distillation, uniform heating, and improved taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

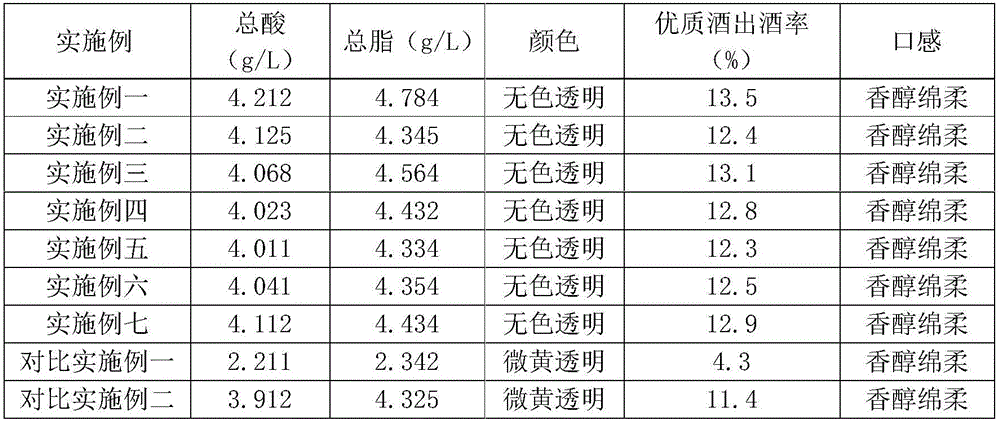

Examples

Embodiment 1

[0026] Embodiment one: comprise the following steps:

[0027] (1), crushing: take the sorghum with full particles, use a pulverizer to pulverize, pass through a 120-mesh sieve after pulverization, and collect sorghum particles and sorghum powder;

[0028] (2), soaking and adding koji: Take 100 parts of sorghum powder according to the number of parts by mass, add 120 parts of clear water to soak for 60 hours, add 12 parts of glutinous rice starch and 4 parts of high-temperature koji after soaking, mix and stir evenly, and put Cultivate under the environment for 40h;

[0029] (3), rubbing balls: Knead the sorghum powder fermented in step (2) into sorghum balls with a diameter of 90mm, rub steel balls into the middle of the sorghum balls, the steel balls have a diameter of 30mm, and put them in the prepared sorghum balls 6 holes with a diameter of 6mm on the top;

[0030] (4), steamed grain: Prepare a retort grate with a diameter of 1000mm, sprinkle 1.5kg of rice husks on the b...

Embodiment 2 Embodiment 7

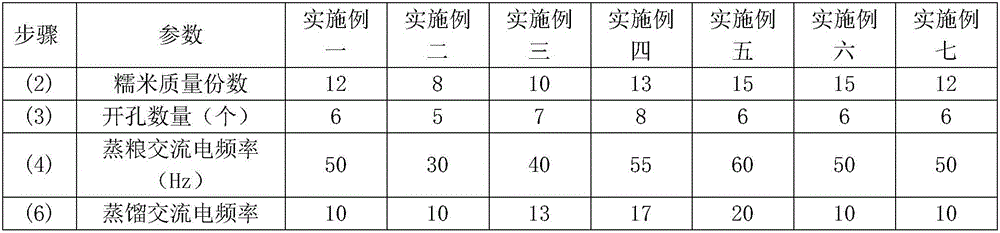

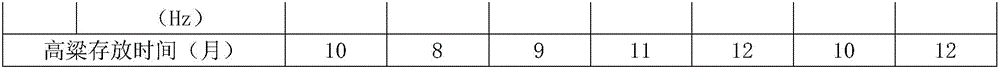

[0035] On the basis of Example 1, the difference is that corresponding parameters are adjusted according to the proportions of Example 2 to Example 7 in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com