Patents

Literature

37results about How to "Fully distilled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

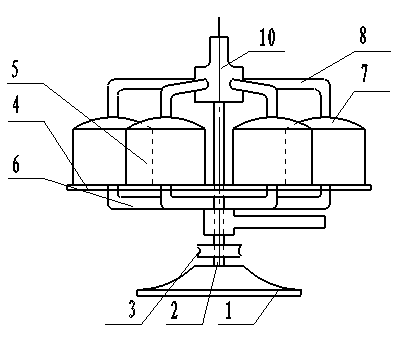

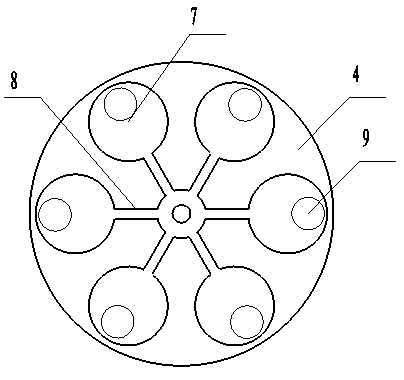

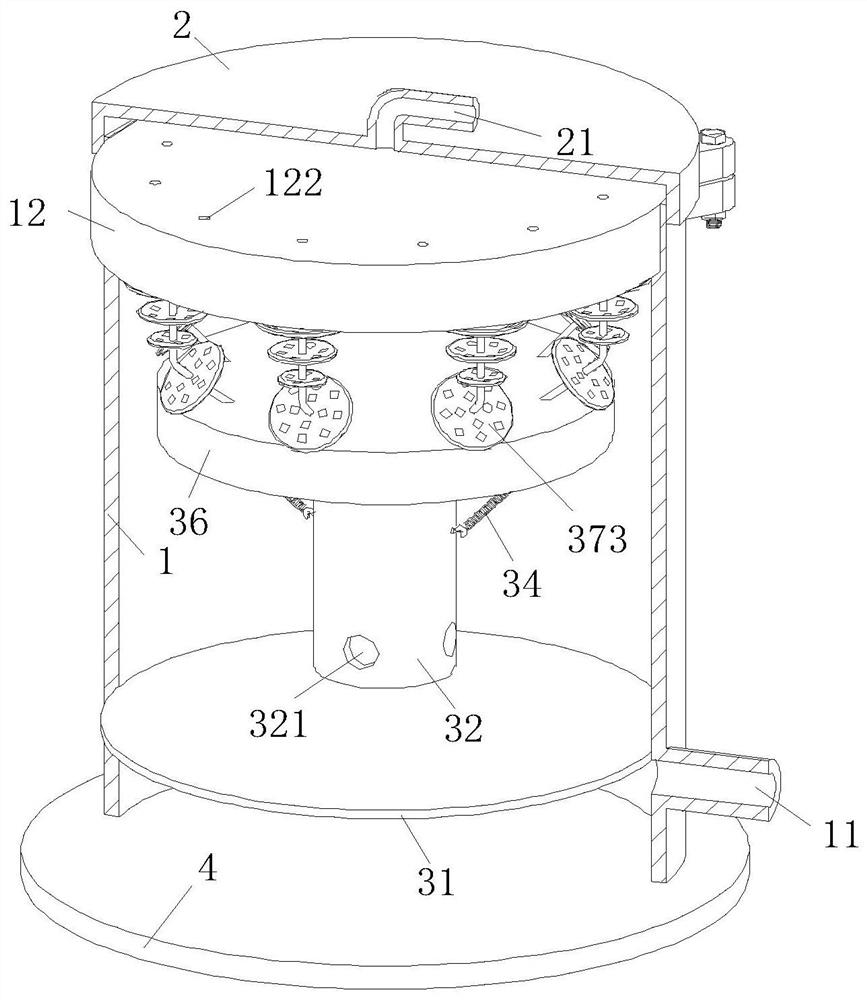

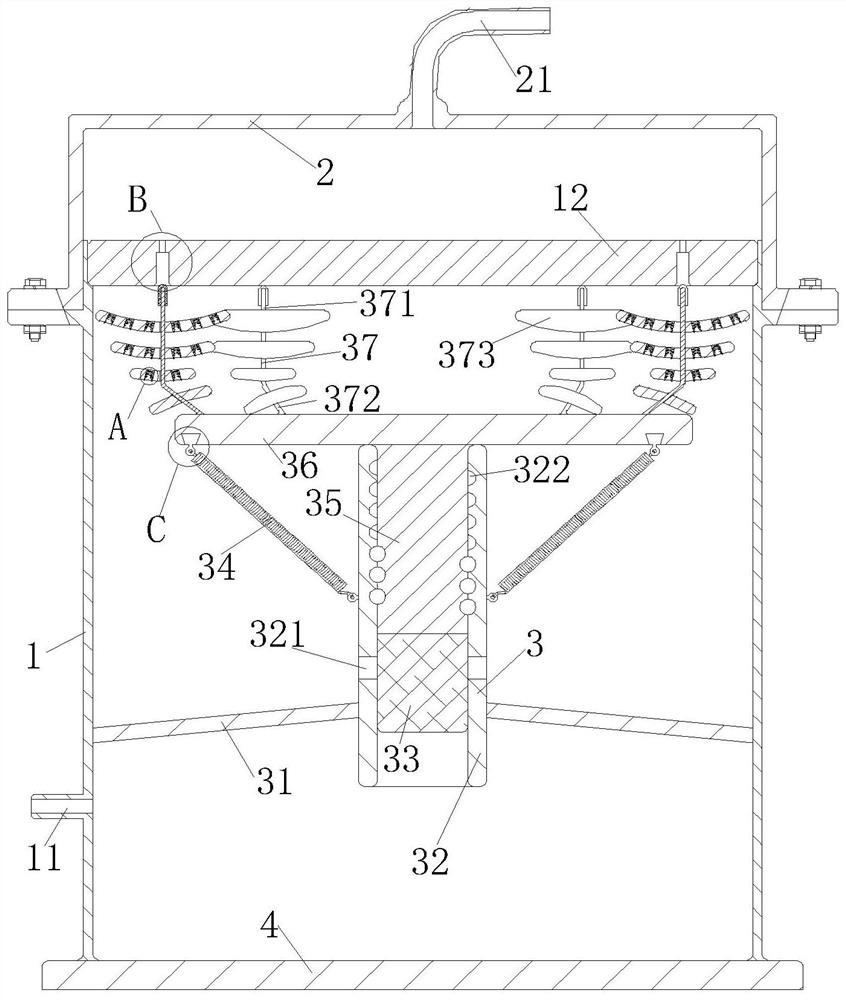

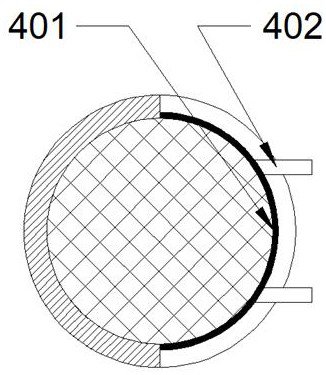

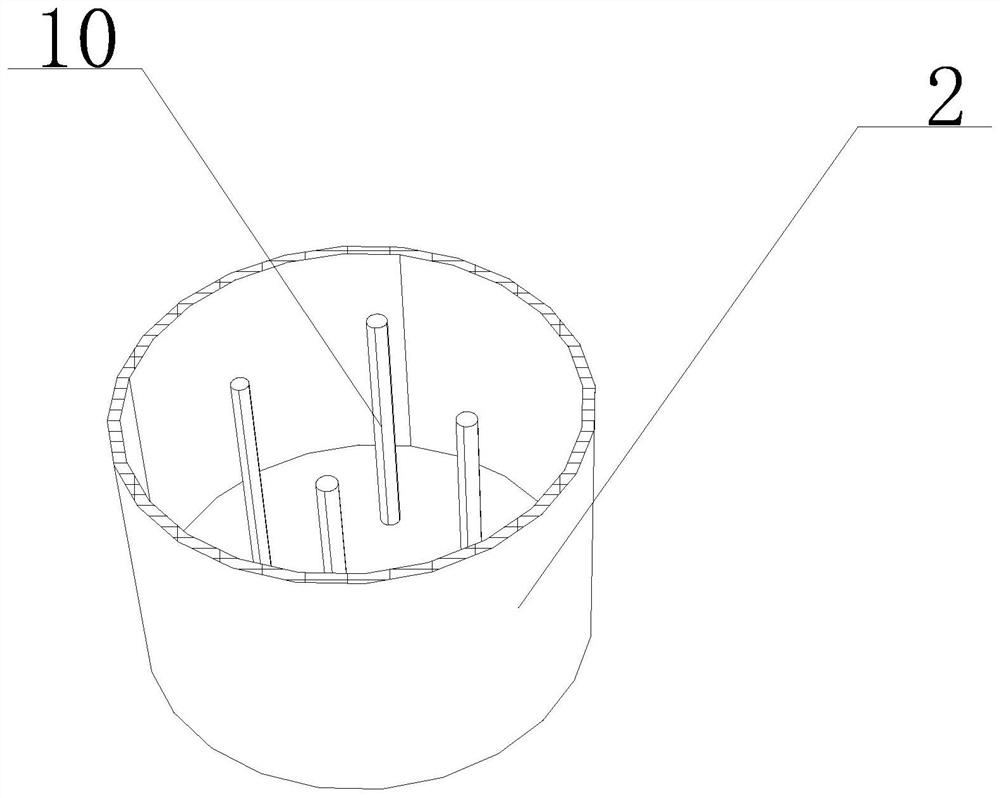

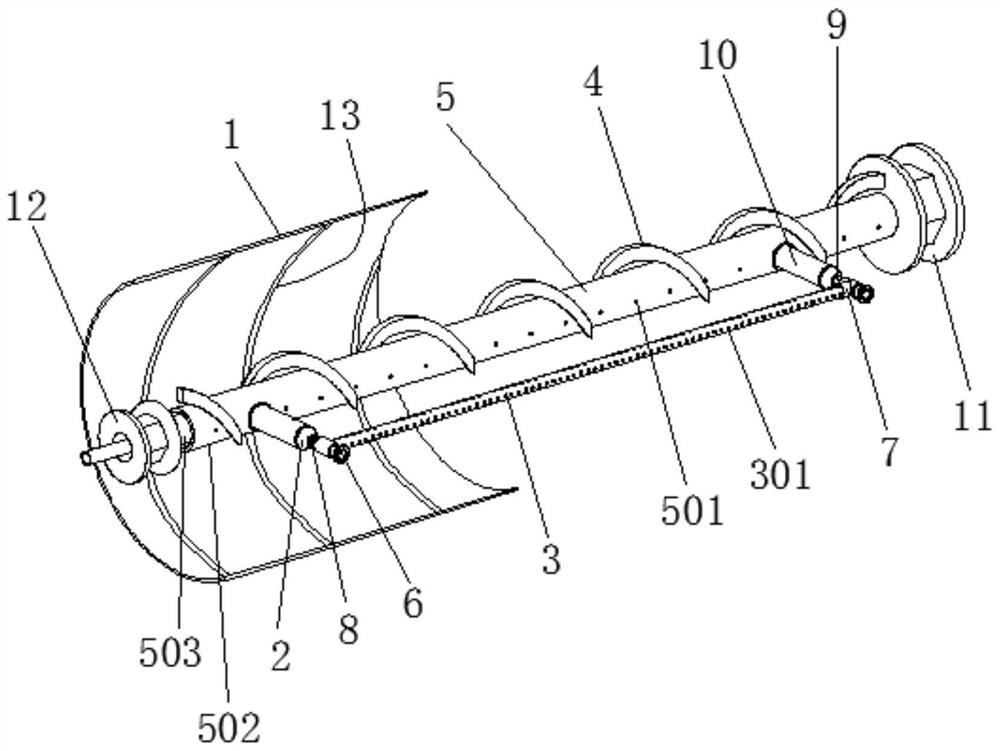

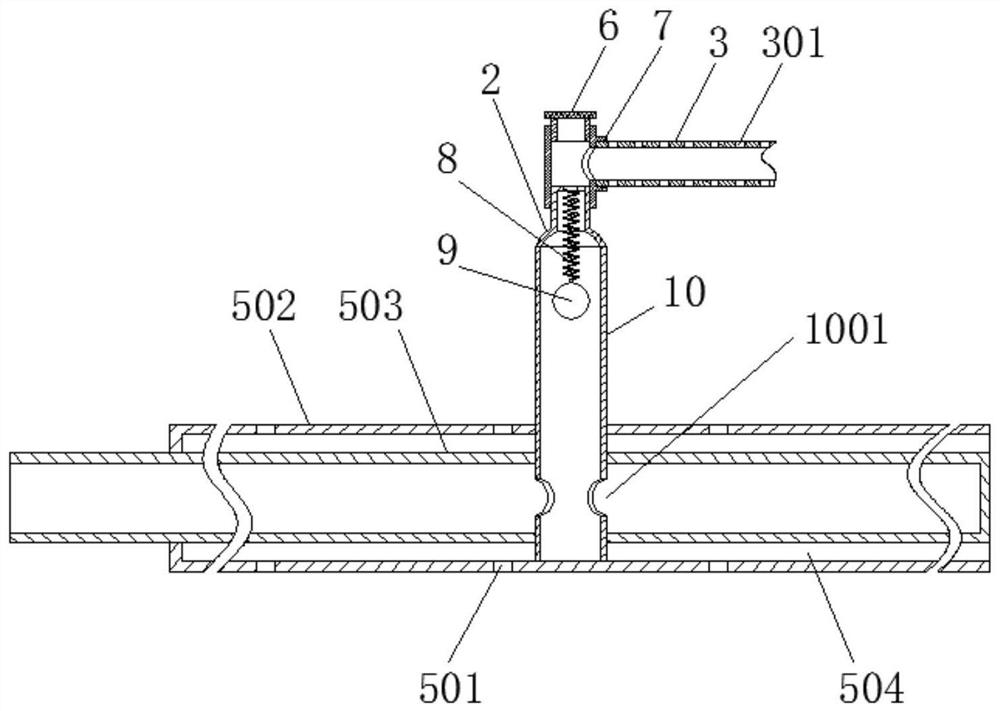

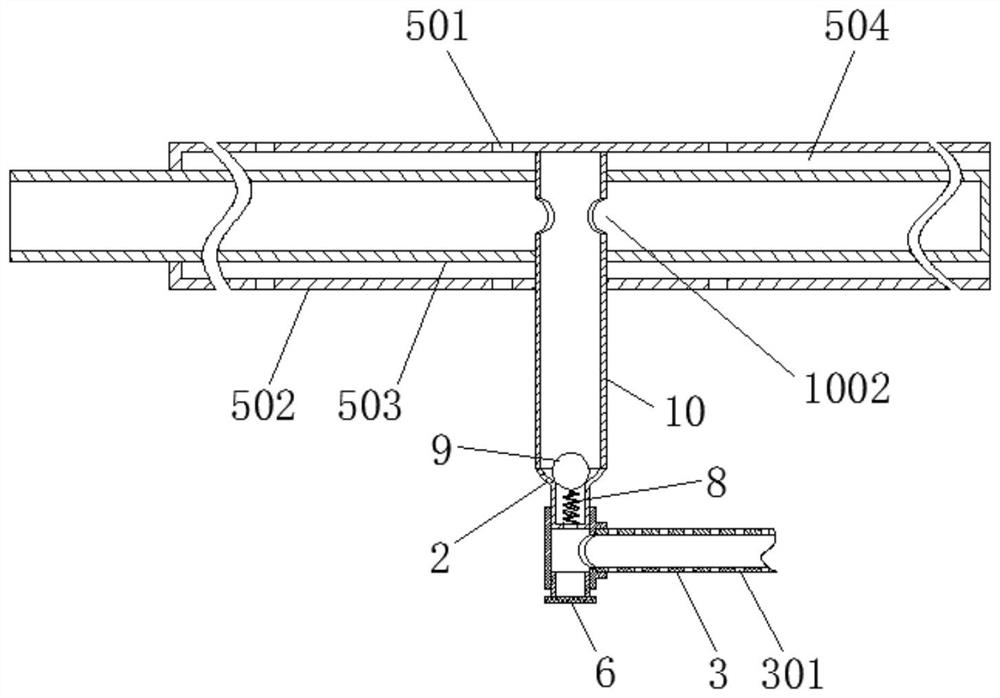

Alcohol distilling device

InactiveCN103657124AReduce volumeFully distilledAlcoholic beverage preparationDistillation separationDrive wheelAqueous alcohol

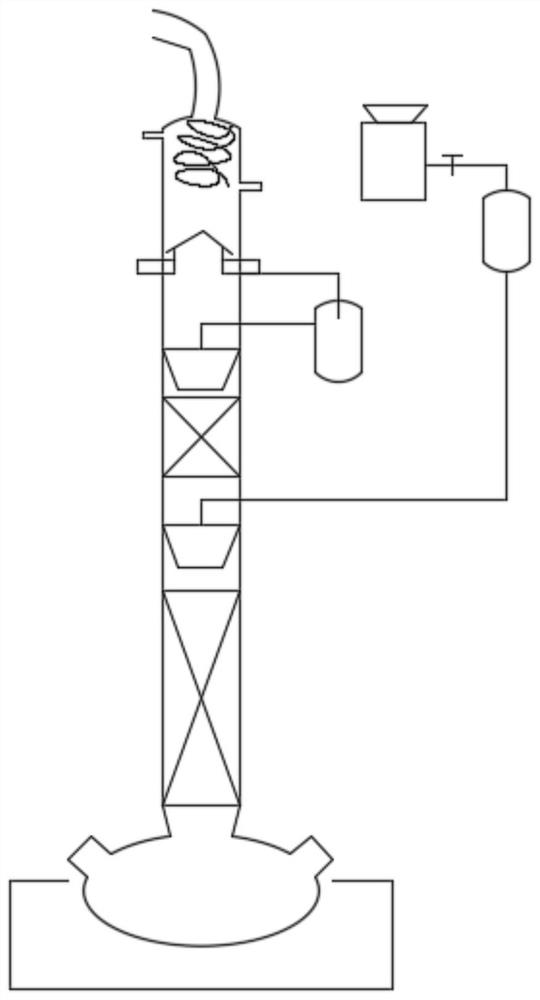

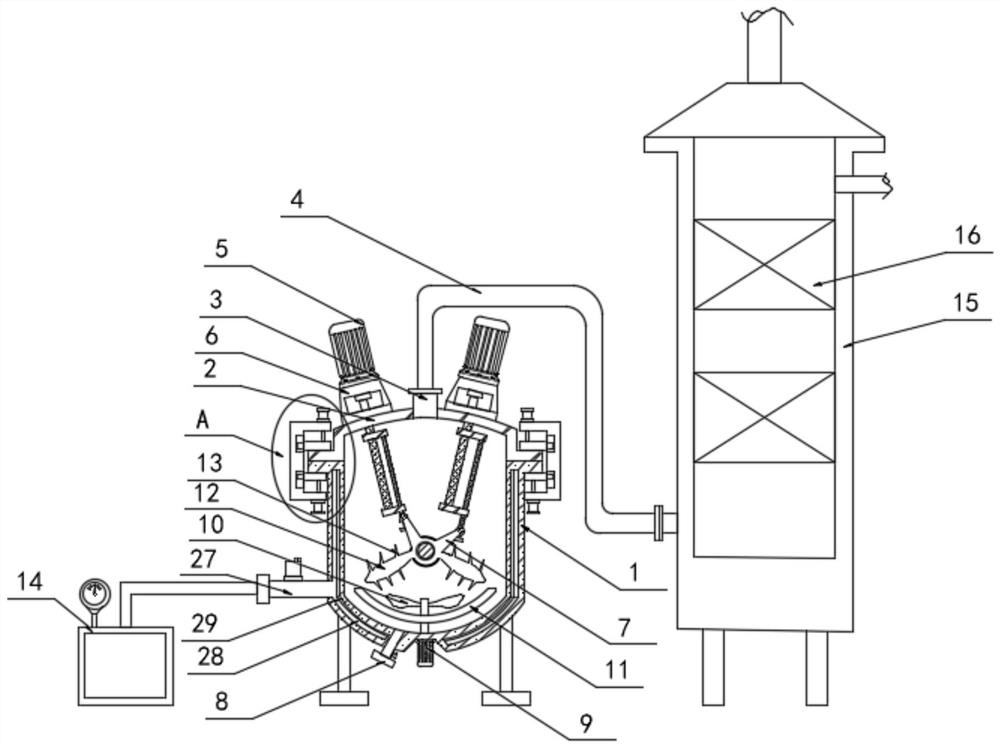

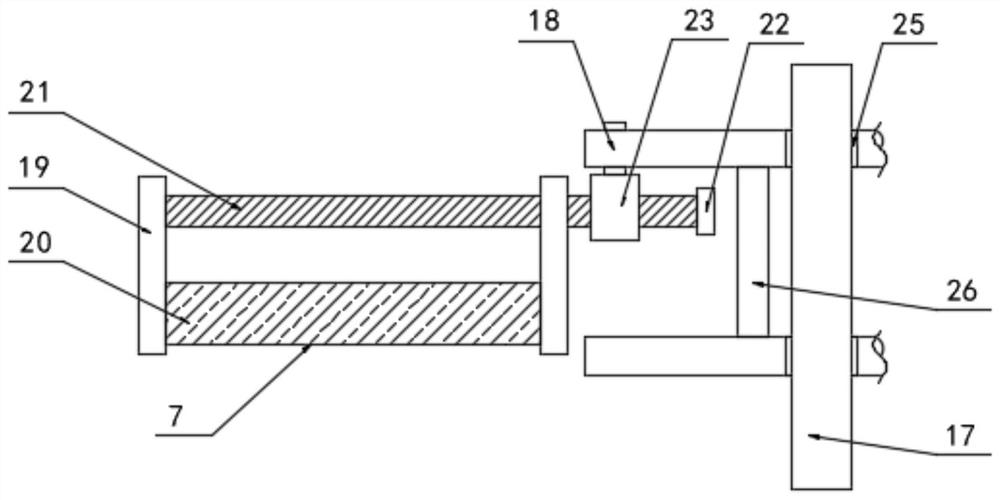

The invention relates to an alcohol distilling device. The alcohol distilling device comprises a fixed disc, a transmission shaft and a driving wheel, wherein one end of the transmission shaft is movably mounted on the fixed disc, and the driving wheel is mounted on the transmission shaft and is controlled by the driving device; a positioning disc is fixed on the transmission shaft; at least two steaming pots are mounted on the positioning disc, a high-temperature steam delivery pipe communicated with a high-temperature steam source is connected to the lower part of each steaming pot, movable steaming pot covers above the steaming pots are respectively connected with alcohol steam delivery pipes, and the tail end of each alcohol steam delivery pipe is communicated with an alcohol steam outlet. According to the alcohol distilling device, multiple steaming pots are used for replacing the single steaming pot for distilling, so that the volume of fermentation materials in the single steaming pot is reduced, the distilling is thorough, the distilling time is shortened, and the distilling efficiency is increased.

Owner:山西鼎圣精工机械制造股份有限公司

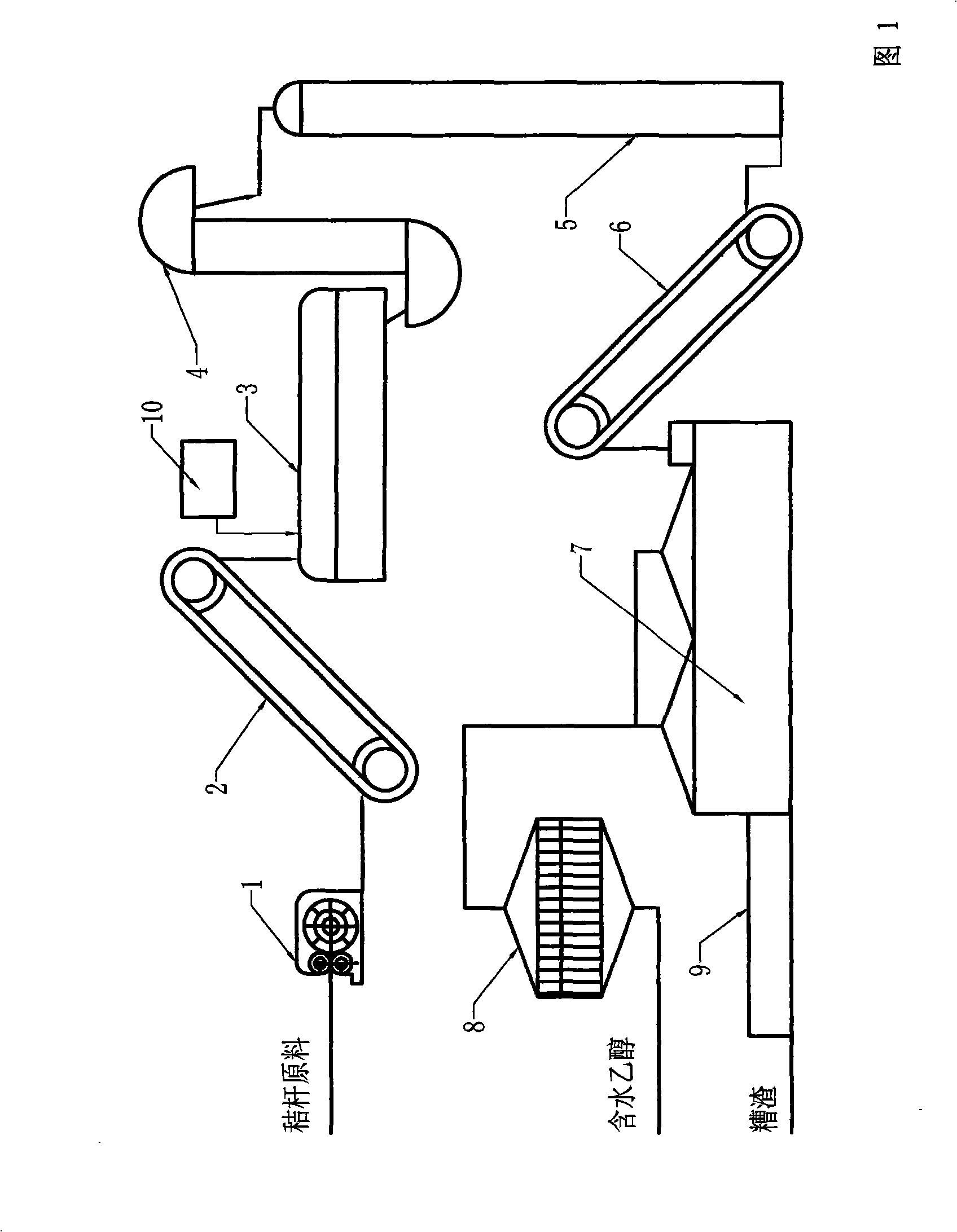

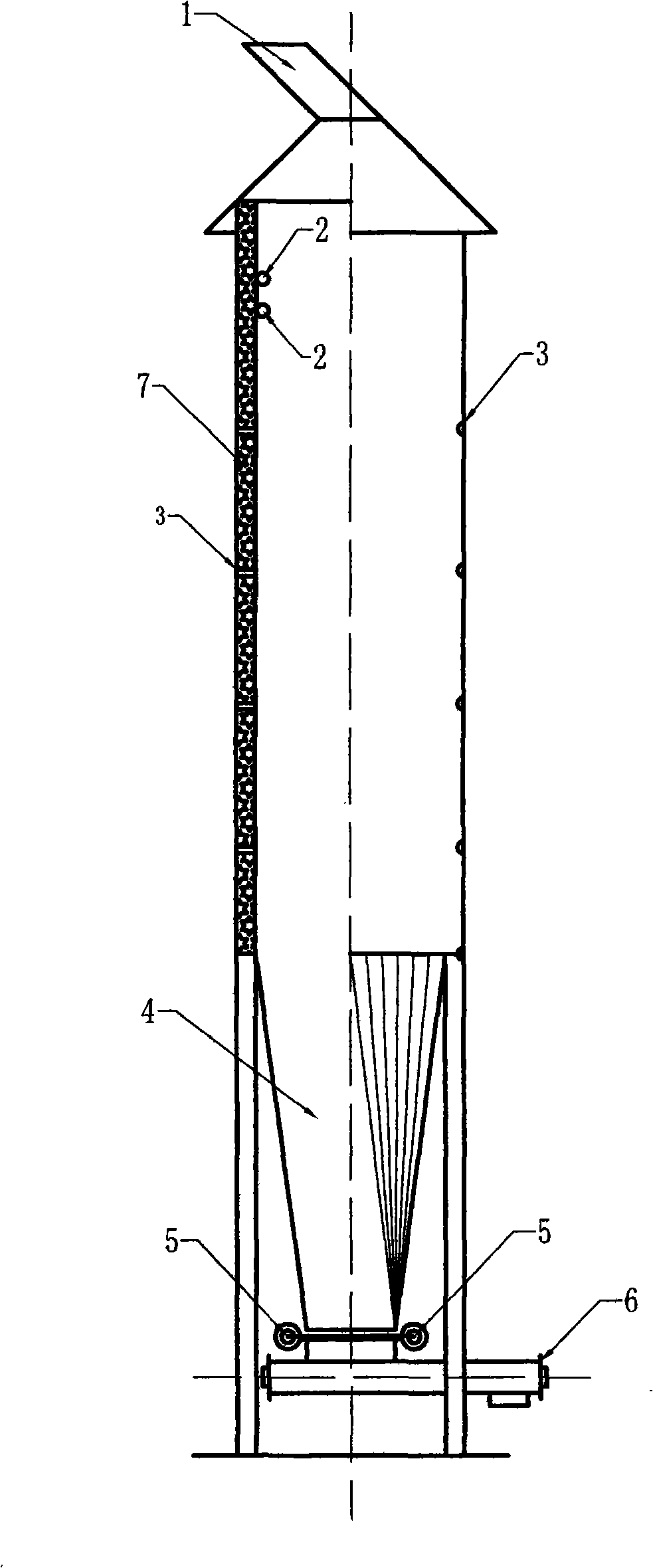

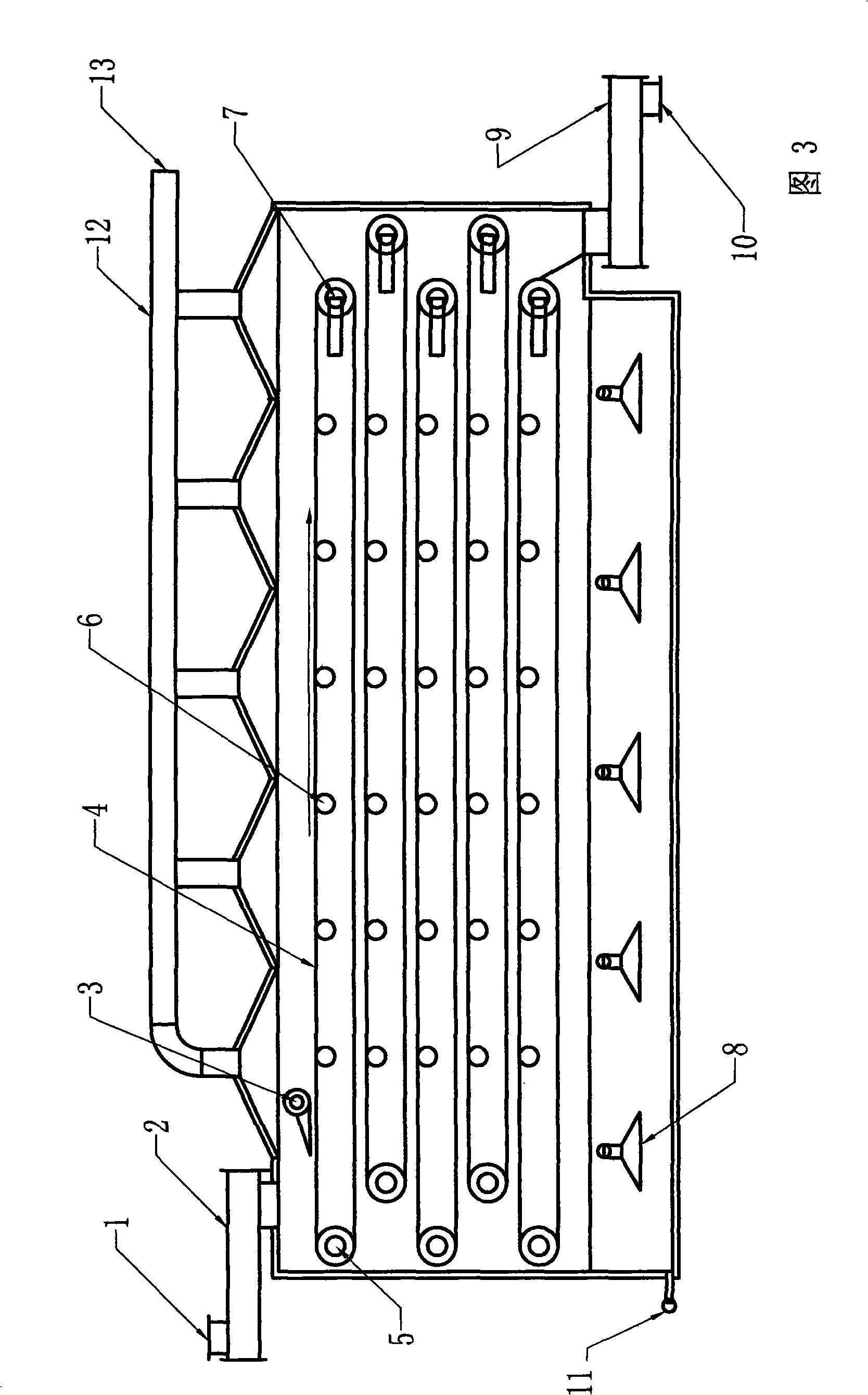

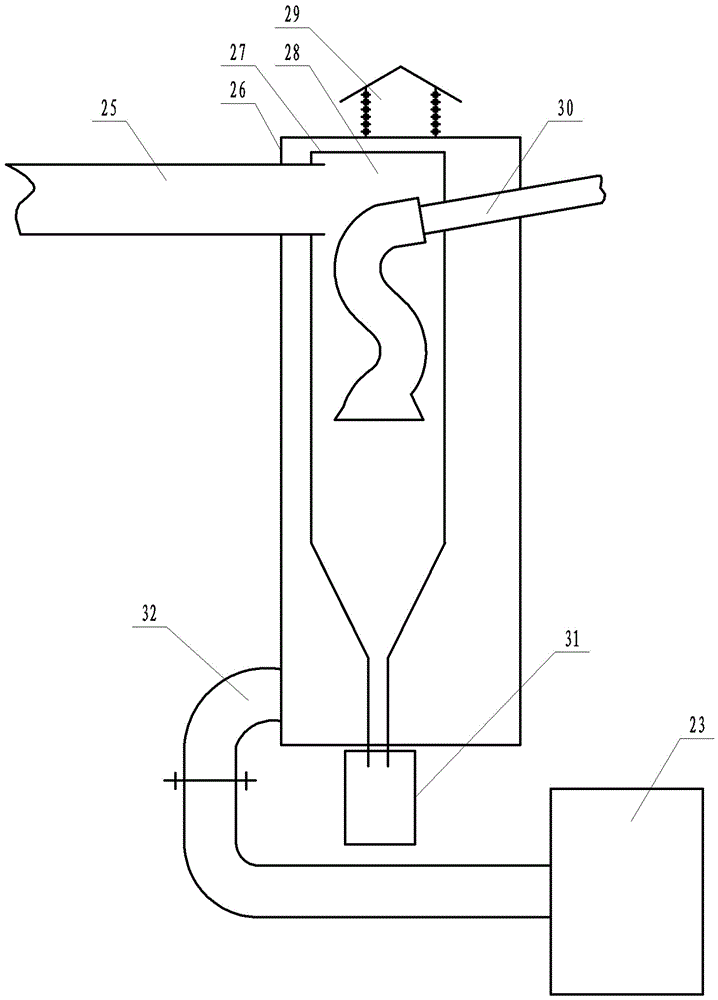

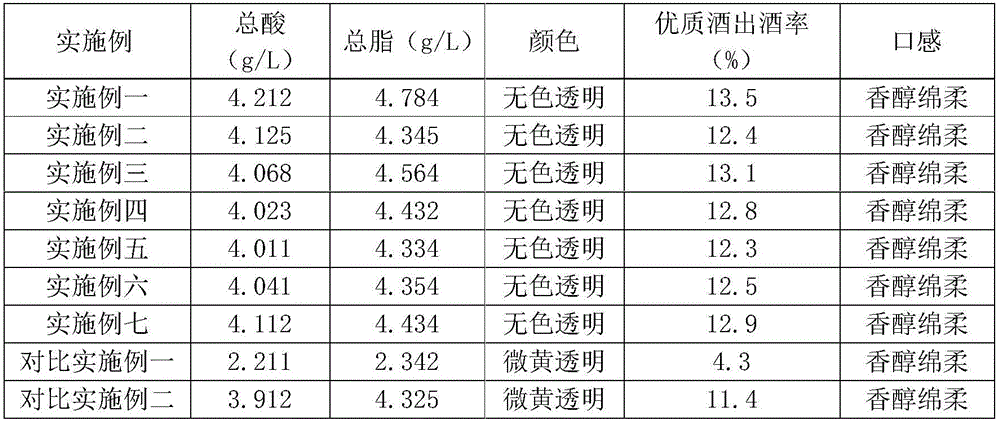

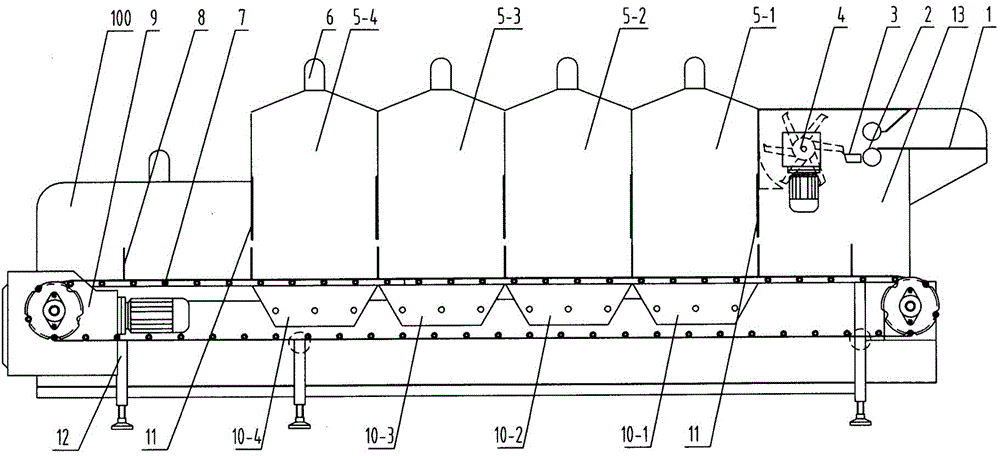

Production process for continuously distilling ethanol by continuous fermentation of sweet sorghum stalks

InactiveCN101333544AAdjustable tightnessWell mixedBioreactor/fermenter combinationsBiological substance pretreatmentsProduction lineContinuous fermentation

Disclosed is a continuous fermentation and continuous distillation production process for producing ethanol by fermenting straws and stalks such as sugarcanes, sweet sorghum stalks, cornstalks and straws by dry method as well as a product line. The process mainly adopts facilities of a continuous fermentation tower and a continuous distillation tunnel. The process and the product line overcome the defects of intermittent production, incomplete material steaming, low product yield, complex charging and discharging operations and disordered field of the traditional process. The process and the product line have the advantages of continuous production, high degree of automation, even mixing of materials, proper fermentation, complete distillation and high product yield. The process is a novel process with innovation significance.

Owner:陈奇伟

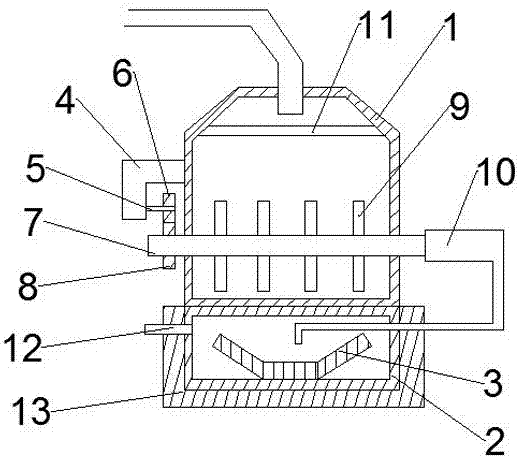

Distillation device for Baijiu

InactiveCN107418857AEvenly distributedFully distilledAlcoholic beverage preparationDistillationEngineering

The invention discloses a distillation device for Baijiu. The distillation device is characterized in that a steam disperser is fixed at the center of the bottom of a steam tank, a motor is arranged on the outer wall of a steamer, a rotary shaft is connected to the motor, a first gear is fixedly connected to one end of the rotary shaft, a first steam inlet pipe is horizontally rotatably connected into the steamer, two ends of the first steam inlet pipe penetrates the lateral walls of the steamer and extend out of the steamer, the first steam pipe is provided with a plurality of stainless-steel stirring shafts, the stirring shafts are in clearance fit with the bottom of the steamer, one end of the steam inlet pipe is fixedly connected with a second gear in a sleeved manner, the first gear meshes with the second gear, the other end of the first steam inlet pipe is communicated with a second steam inlet pipe, the first steam inlet pipe is rotatably connected with the second steam inlet pipe, one end of the second steam inlet pipe is located in the steam tank and located above the steam disperser, and the steam tank is provided with a steam outlet pipe. When the distillation device is used for brewing the Baijiu, raw materials in the steamer can be thoroughly distilled, and distillation efficiency is increased at the same time.

Owner:ZUNYI JINHONG METAL EQUIP

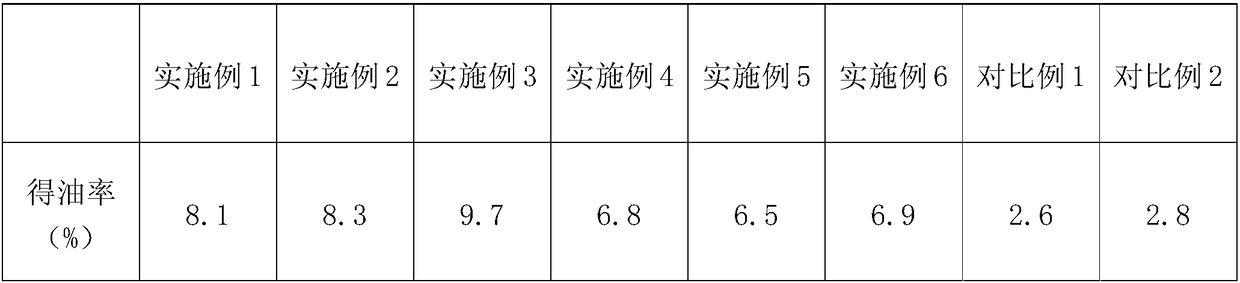

Preparation method of cedarwood essential oil and product thereof

The invention discloses a preparation method of cedarwood essential oil. The method comprises the following steps: (1), grinding cedarwood raw materials into powder; adding surfactant into the powder;then performing stirring and dropping into a distilled tower, and then introducing water vapor into the distilled tower and carrying out distillation treatment to obtain mixed steam; (2), feeding themixed steam obtained in the step (1) into a cooling tower and carrying out cooling treatment to obtain oil-water mixed liquid; (3) performing refined distillation treatment on the oil-water mixed liquid obtained in the step (2) and collecting the cedarwood essential oil subjected to refined distillation. On the other hand, the invention also provides the cedarwood essential oil prepared by usingthe method. The preparation method of the cedarwood essential oil disclosed by the invention has the advantages that an operation is simple, the cost is low, the oil yield of the cedarwood raw material is high, and the preparation method of the cedarwood essential oil is suitable for large-scale industrial production.

Owner:FUJIAN XINLYULIN PROD DEV

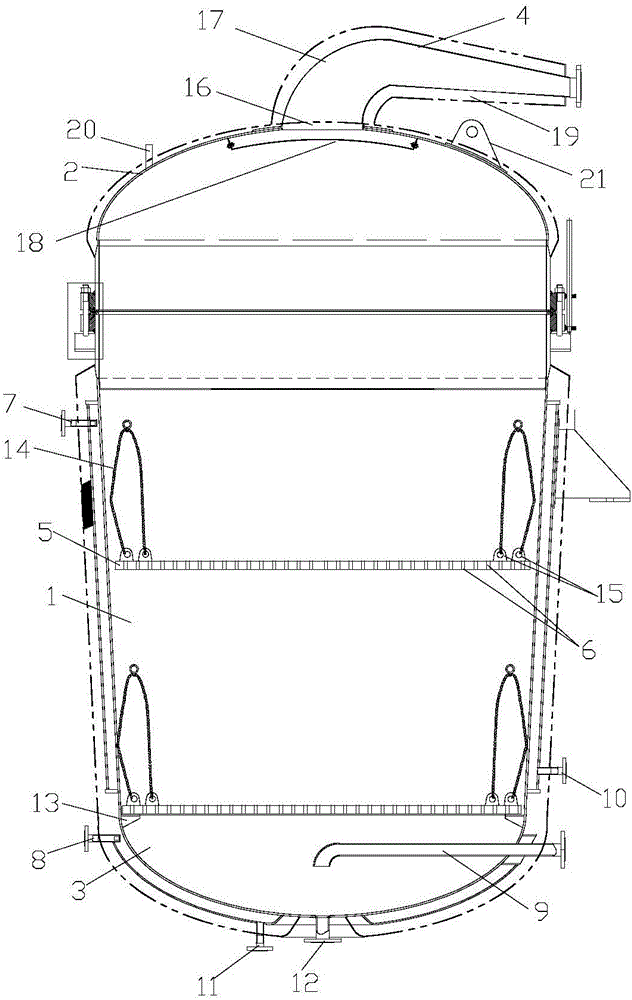

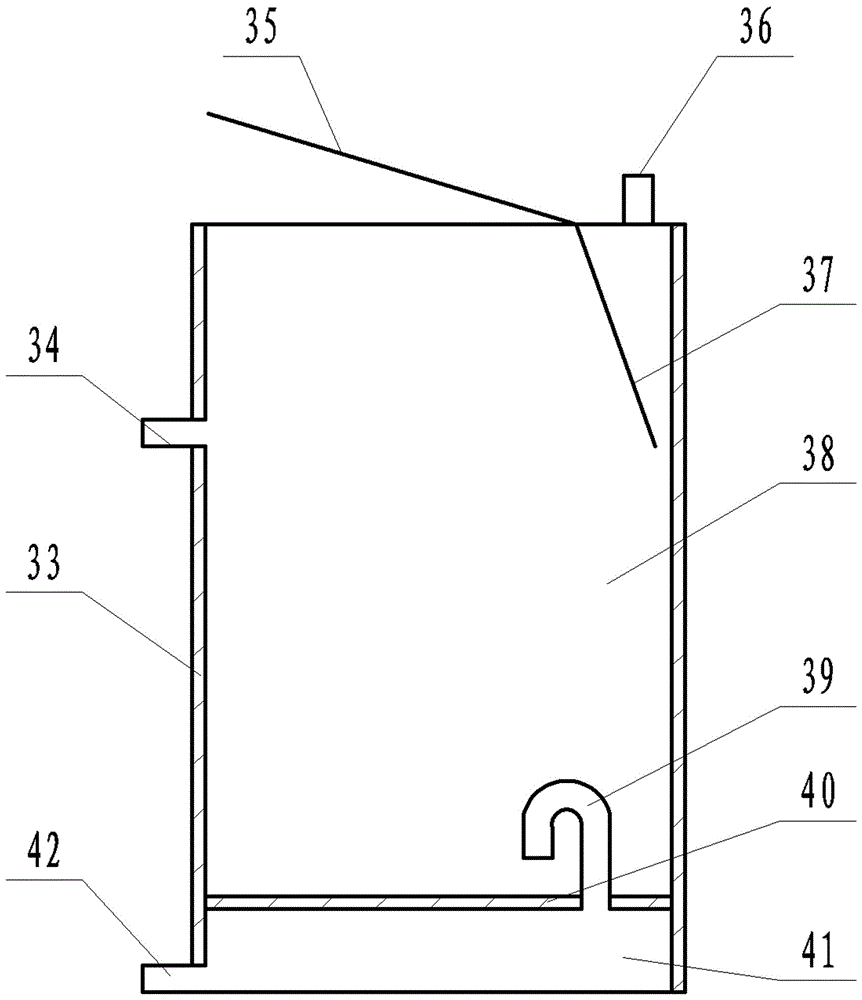

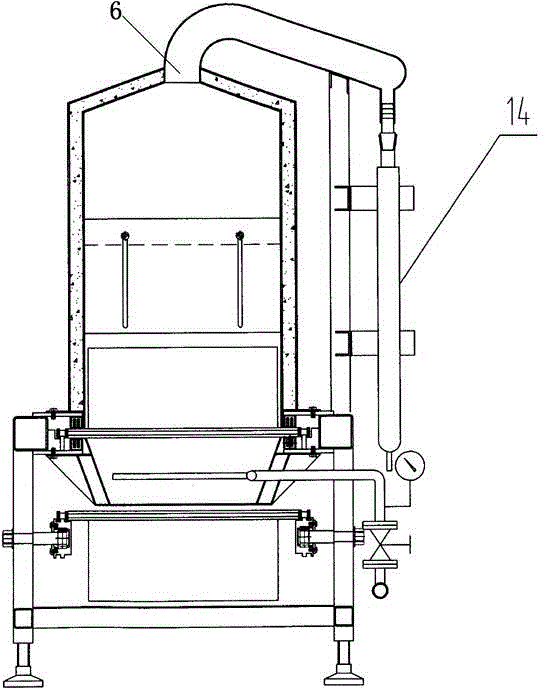

Multifunctional volatile oil distilling and extracting tank

The invention discloses a multifunctional volatile oil distilling and extracting tank, and belongs to the field of traditional Chinese medicine extracting equipment. The multifunctional volatile oil distilling and extracting tank comprises a tank body, a tank cap, a tank bottom and a steam supply system, and the tank cap is connected with an oil outlet pipe. The multifunctional volatile oil distilling and extracting tank is characterized in that the tank body is in the shape of a big-end-up cone, the tank body and the tank bottom adopt interlayers, steam is pumped into the interlayers, multiple layers of detachable separation plates are arranged in the tank body, and through holes are formed in the separation plates. The multifunctional volatile oil distilling and extracting tank can be used for extracting general medicinal oil and essential oil according to the routine and normal pressure, extracting high-boiling-point medicinal oil and essential oil containing aldehydes and alcohols at high temperature and high pressure, extracting medicinal oil and essential oil which are prone to volatilizing andloseand contain more alkenes in a vacuum decompression mode and extracting extracts, one tank has multiple purposes, distilling can be completed for one time, the equipment cost is saved, and the yield of the materials, especially volatile oil, is improved.

Owner:湖南时代阳光药业股份有限公司

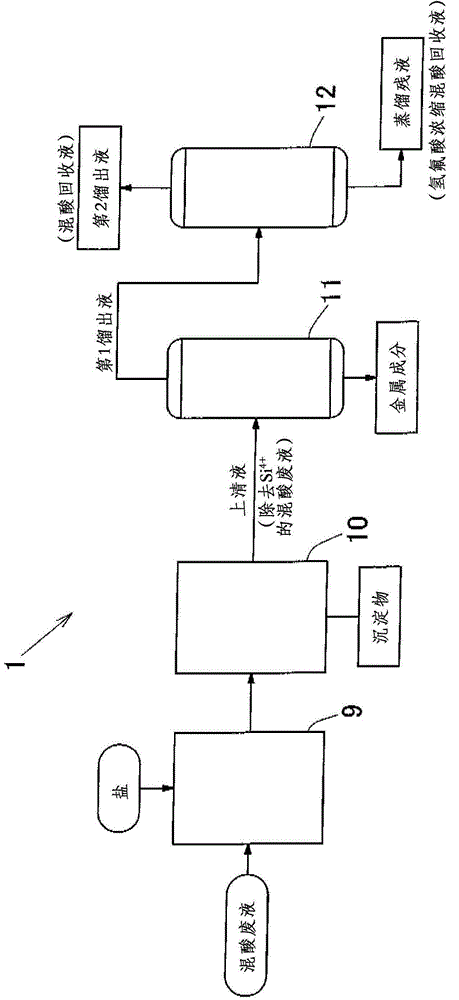

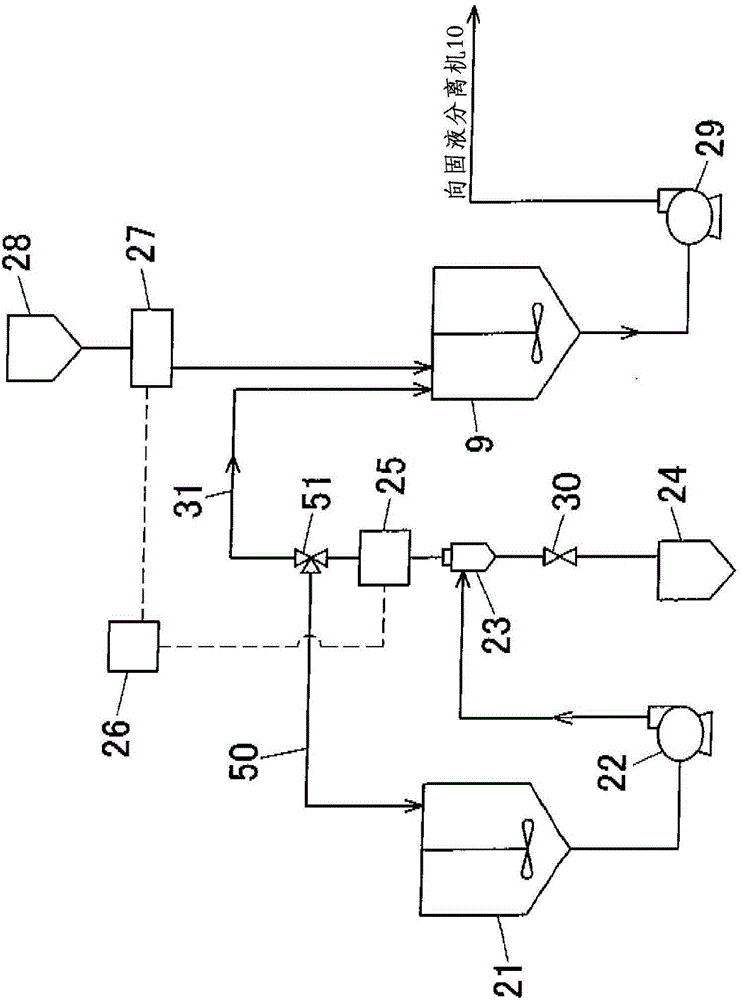

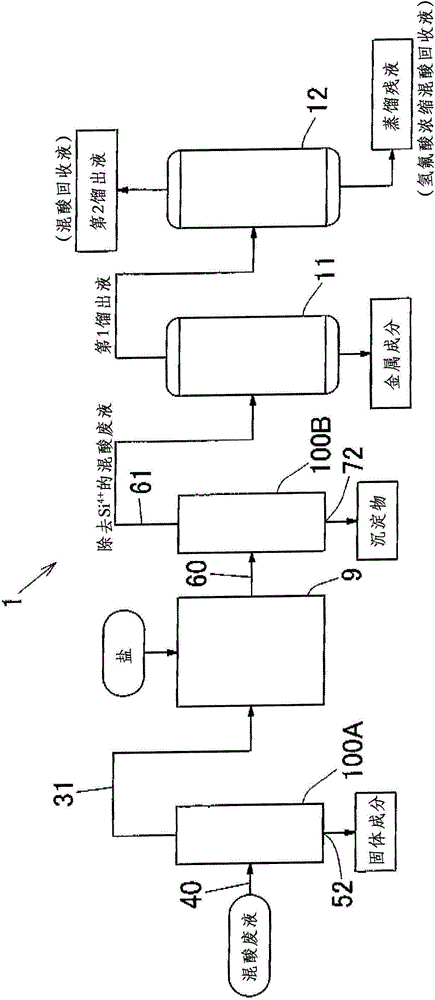

Method for removing Si from waste liquid of Si-containing hydrofluoric acid, method for recovering hydrofluoric acid from mixed acid waste liquid of Si-containing hydrofluoric acid, and recovery device

InactiveCN103818992AFully removeHigh precision processingWater/sewage treatmentChemical/physical/physico-chemical stationary reactorsHydrofluoric acidChloride

According to the present invention, a removing method comprises a following process of removing, after a salt is added to a waste liquid of Si-containing hydrofluoric acid, a precipitate generated due to the added salt. In such a way, a process for removing Si in the waste liquid is obtained. The salt is preferably selected from one or two or more salts from a fluoride metal salt and a chloride metal salt. The Si contained in waste liquid of the Si-containing hydrofluoric acid can be effectively reduced or removed by using the removing method.

Owner:OG KK +1

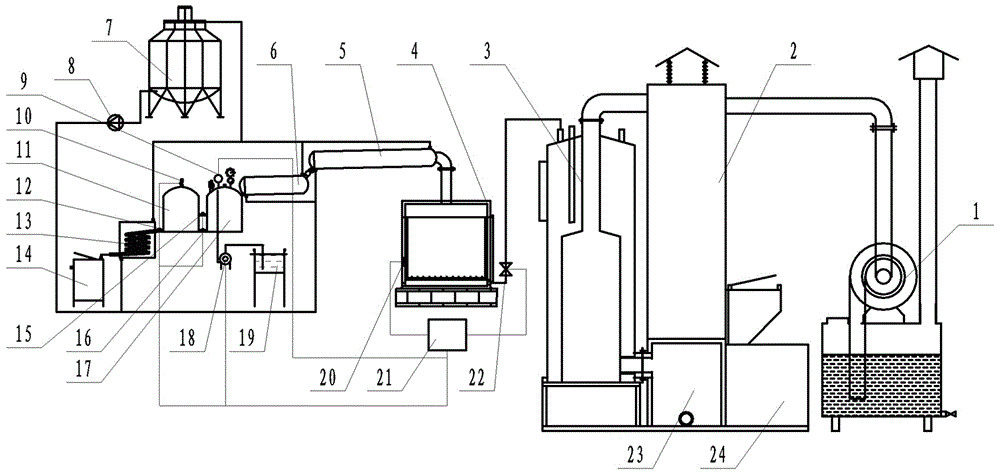

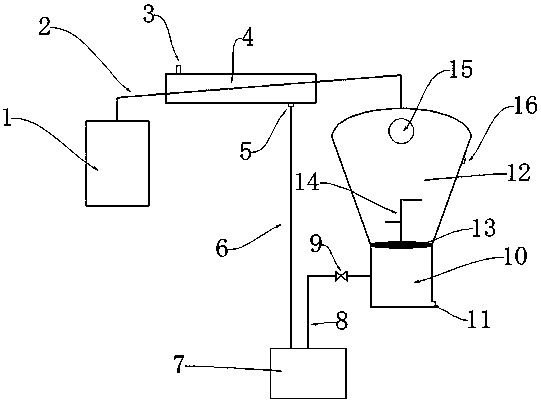

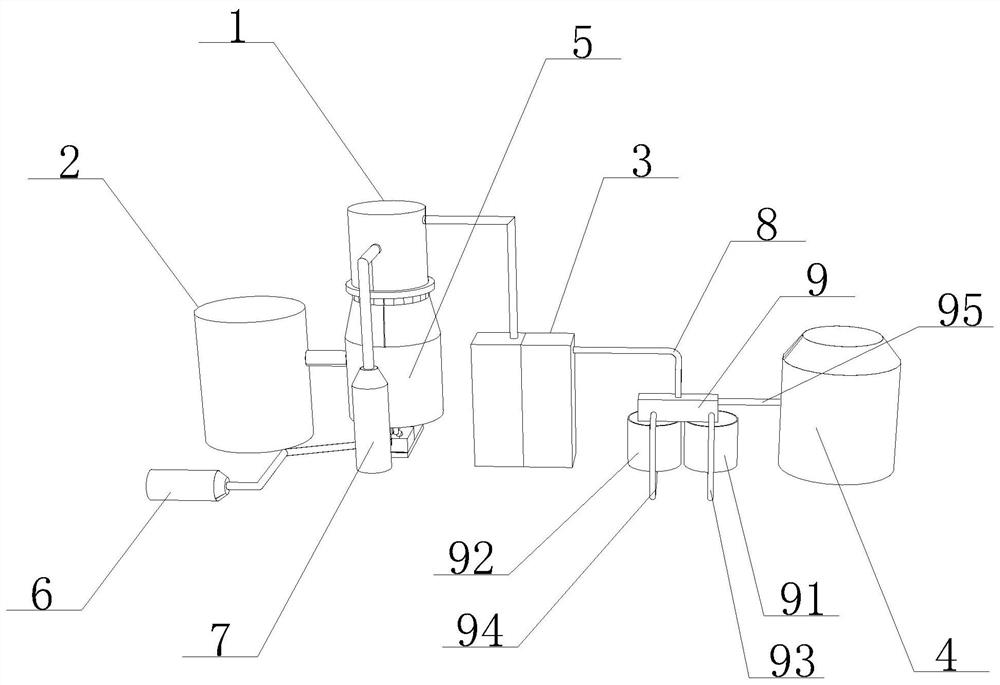

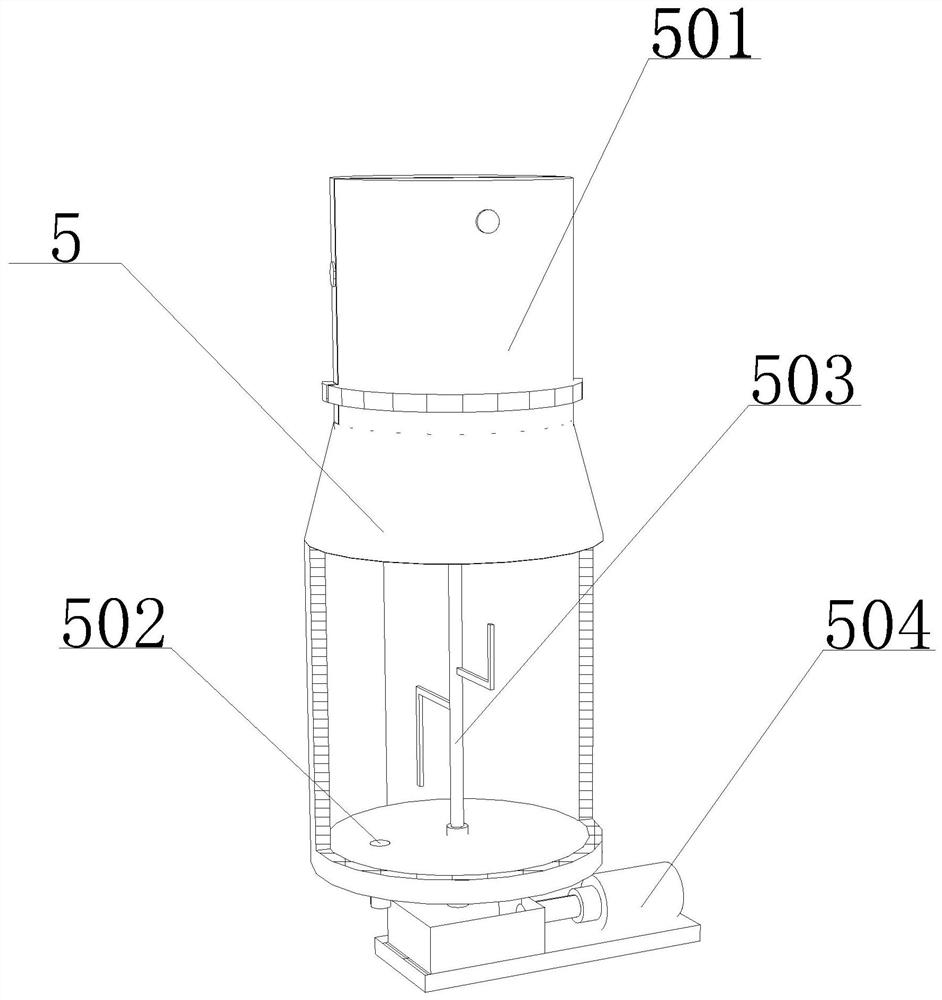

Distilling production method for sandalwood essential oil and equipment

InactiveCN105733814AAvoid enteringPrevent flashbackEssential-oils/perfumesEngineeringProcess engineering

The invention discloses a distilling production method for sandalwood essential oil.The method comprises the specific steps that 1, a sandalwood plant raw material is smashed into fragments with the thickness of 1 millimeter to 6 millimeters, and the fragments are placed in a distilling cabinet; 2, steam generated by a steam boiler is led into the distilling cabinet, and the sandalwood fragments are distilled; 3, tail gas of the steam boiler is processed through a first-level dust remover and a second-level dust remover before being discharged out of a chimney; 4, the steam discharged from the distilling cabinet passes through a first-level condenser and a second-level condenser before entering a receiving tank and an excessive receiving tank, and distillate is obtained; 5, the pressure in the receiving tank is kept between 0.01 Mpa and 0.3 Mpa; 6, the distillate in the excessive receiving tank passes through a third-level condenser before being discharged into a fractionation barrel; 7, the distillate is discharged out of an essential oil outlet of the fractionation barrel, and then the sandalwood essential oil is obtained.The method is simple, the oil is discharged quickly, time is short, the obtained sandalwood essential oil is high in quality, and adopted equipment is easy to operate.

Owner:GUANGXI GUIGANG HONGLI BIOENERGY TECH CO LTD

Process for rectifying trichlorosilane

InactiveCN102070147AGood removal effectEnhanced carbon removal capacityHalogenated silanesPhysical chemistrySilicon tetrachloride

The invention relates to a process for rectifying trichlorosilane. In the process, trichlorosilane feed liquor passes through two sieve plate rectifying towers and two filler rectifying towers in turn to be rectified so as to obtain a high-purity trichlorosilane product, and a silicon tetrachloride product also can be obtained during rectification. Due to the design of the sequence of the sieve plate rectifying towers and the filler rectifying towers and the setting of a reflux ratio parameter, capability of removing trace impurities which cannot be removed by the conventional process flow can be improved, capability of removing boron and carbon is obviously improved, the separation effect is better, and the requirements of polycrystalline silicon manufacturers are met.

Owner:乐山永祥硅业有限公司

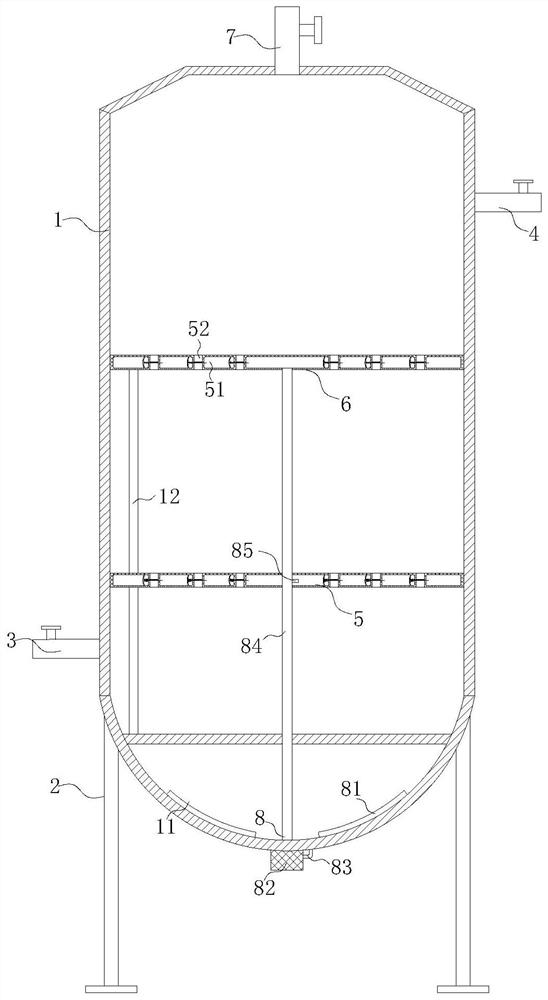

Rectifying tower for light component removal

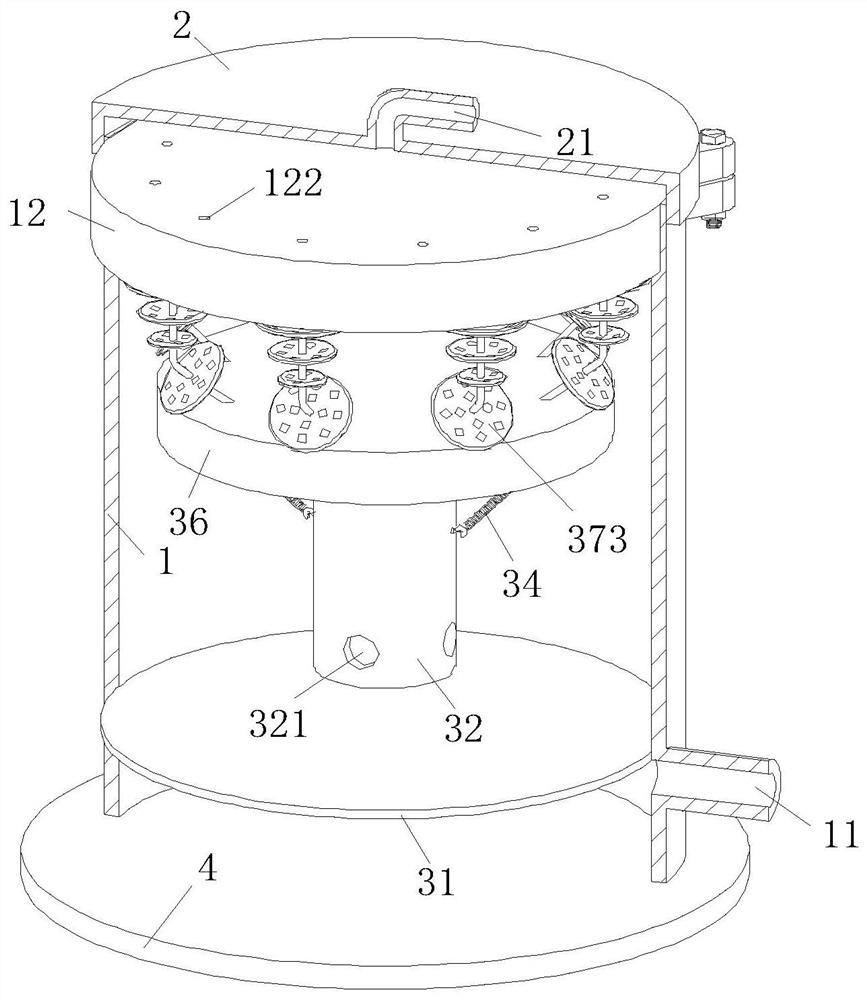

ActiveCN111921216AA large amountQuality improvementCombination devicesFractional distillationHollow cylinderMaterials science

The invention belongs to the field of chemical equipment, and particularly relates to a rectifying tower for light component removal. The rectifying tower comprises a tower body, a tower cover, a working unit and a heater, wherein the tower body is of a hollow cylinder structure, the heater is installed at the bottom of the tower body, the working unit is installed in the tower body, and the towercover is fixedly connected with the top of the tower body in a bolt connection mode; and the working unit comprises a fixing plate, a first pipe, sponge, a spring, a shaft rod and a top plate. When the rectifying tower works, the sponge can absorb mixed liquid and foam in mixed gas; the shaft rod rotates to drive the mixed gas, so mixed liquid and foam in the mixed gas are removed; and the spongeand the rotating shaft rod can delay flowing of the mixed gas, so the mixed gas is rectified more sufficiently, the contained foam is removed more thoroughly, and finally, a rectification product with better quality is obtained.

Owner:山东禧龙石油装备有限公司

Dehydroepiandrosterone acetate preparation method

A dehydroepiandrosterone acetate preparation method relates to the technical field of preparation of a steroid hormone drug medical intermediate. Dehydropregnenolone acetate is used as a raw material, a toluene and ethanol mixed solvent is used as a reaction solvent, then dehydropregnenolone acetate oxime is obtained by oximation reaction, cooling crystallization, centrifugation, water washing and drying; a dehydroepiandrosterone acetate crude product is obtained by rearrangement hydrolysis reaction, water washing rushed distillation, centrifugation and drying; and a dehydroepiandrosterone acetate fine product is obtained by decolouring refining, filtration, concentration and crystallization and drying of the crude product. According to the method, the solubility of the dehydropregnenolone acetate and oxime is greatly improved, the reaction is more complete, and methyl in the toluene can be transformed into carboxyl group in the human body, so that the toluene can be transformed into benzoic acid to be excreted the body, and the dehydroepiandrosterone acetate is non-toxic.

Owner:JIANGXI CHENYANG PHARMA CO LTD

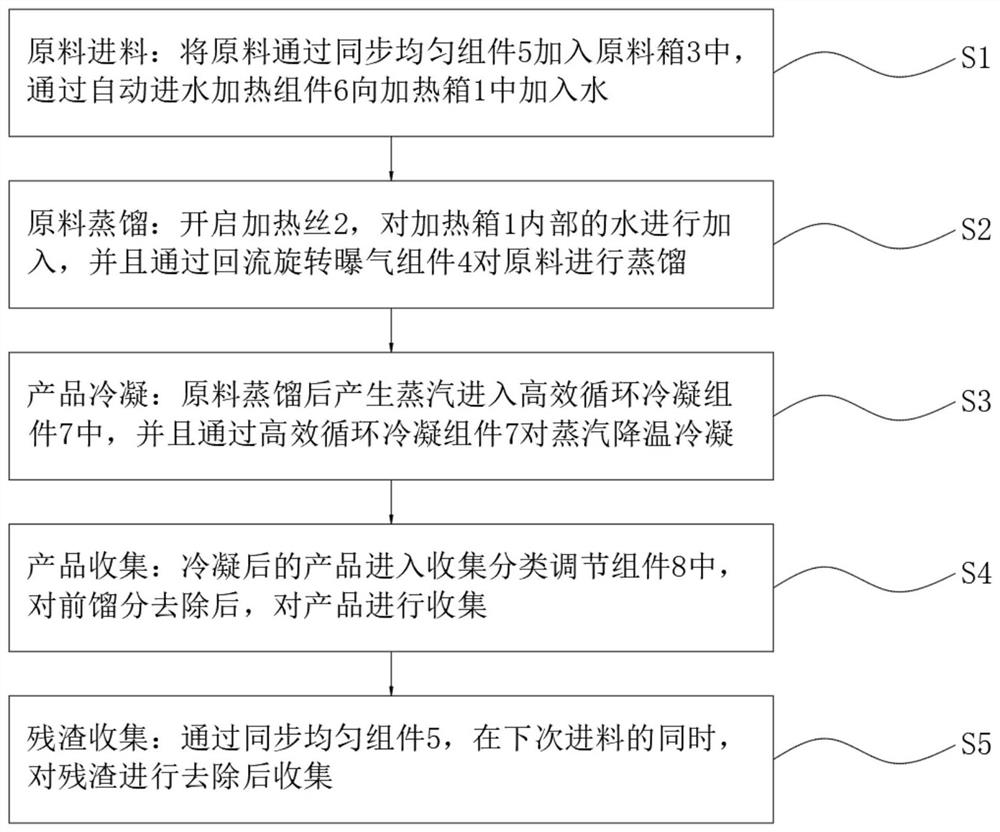

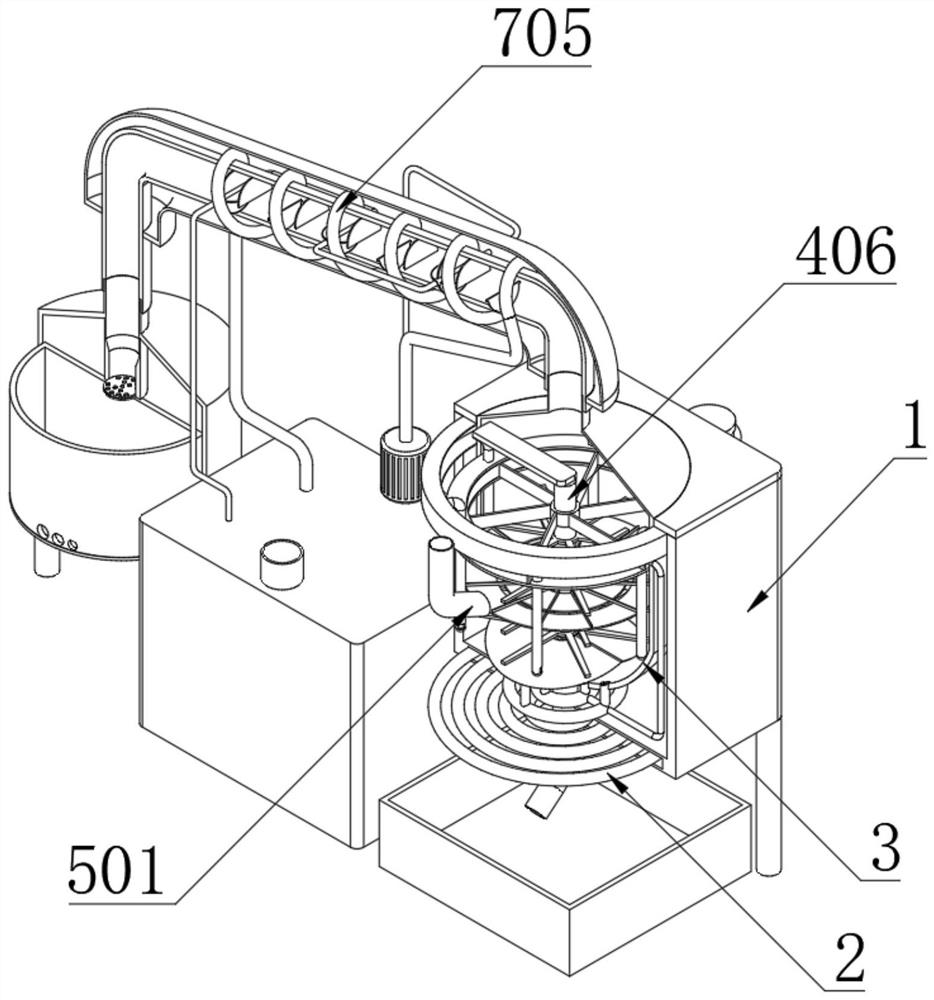

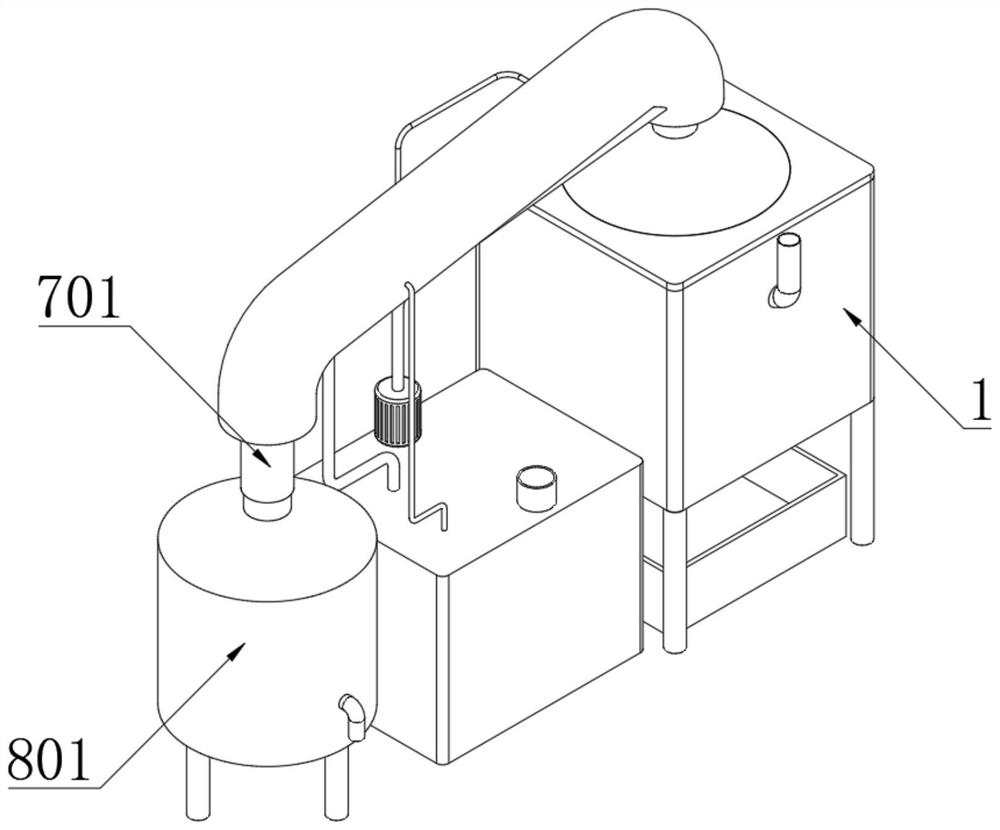

Preparation method of whitening and moisturizing essence for dry skin

ActiveCN112043610AScientific and reasonable structureEasy to useCosmetic preparationsTransportation and packagingProcess engineeringEnvironmental engineering

The invention discloses a preparation method of whitening and moisturizing essence for dry skin. The method is characterized in that a gas collecting ring sleeve is welded to the position, at the topend of the outer side of a raw material box, of the top end of the interior of a heating box, gas inlet holes are formed in one end of the bottom face of the gas collecting ring sleeve, gas inlet pipes are evenly welded to the top end of the interior of the raw material box, one ends of the gas inlet pipes are located in the gas inlet holes, gas blowing holes are formed in one sides of top ends ofthe gas inlet pipes, and gas outlet holes are formed in one sides of bottom ends of the gas inlet pipes. Compared with the prior art, through the use of the gas outlet holes, driving paddles, rotating columns and stirring blades, a double-layer two-way stirring effect can be achieved, the purpose of uniformly dispersing raw materials is achieved, the time required by distillation is effectively shortened, and the distillation efficiency is improved; through windproof plates and limiting plates, the temperature of gas outlets of the raw material box can be kept, and the situation that steam iscondensed in advance is effectively avoided; and driving of electric appliance elements is not needed, noise brought by the electric appliance elements is lowered, and the environmental pollution isreduced.

Owner:广州中尚生物科技有限公司

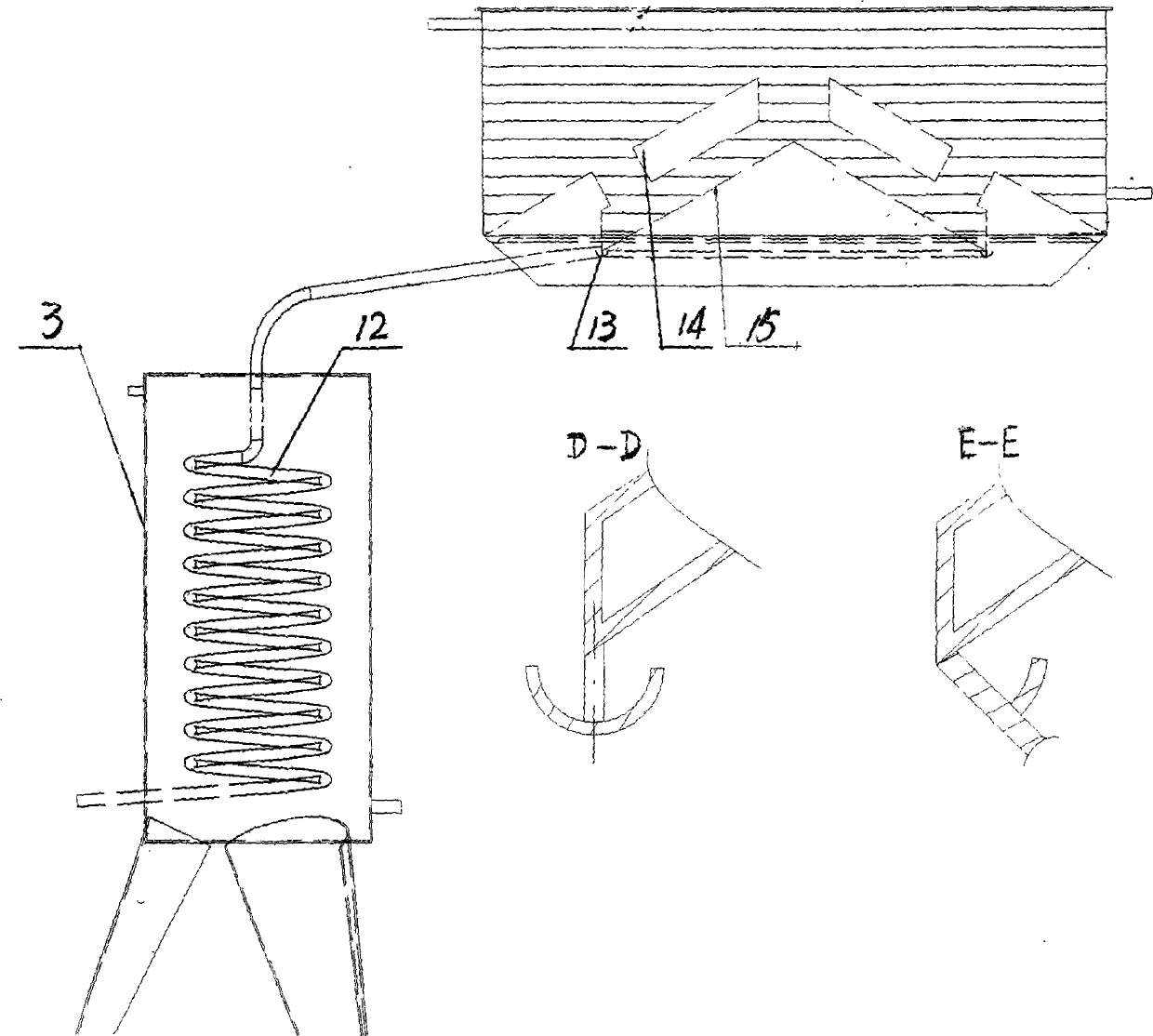

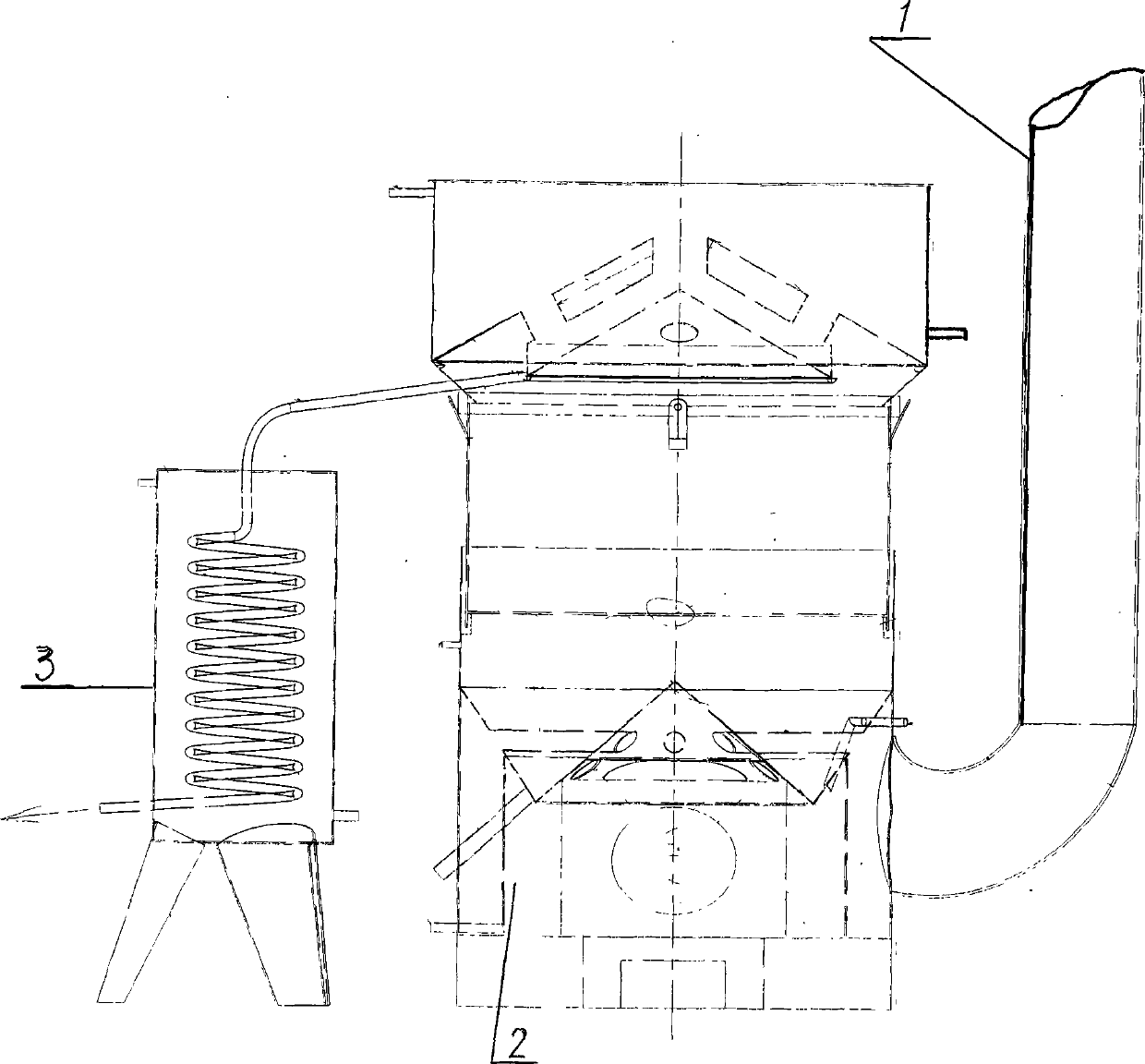

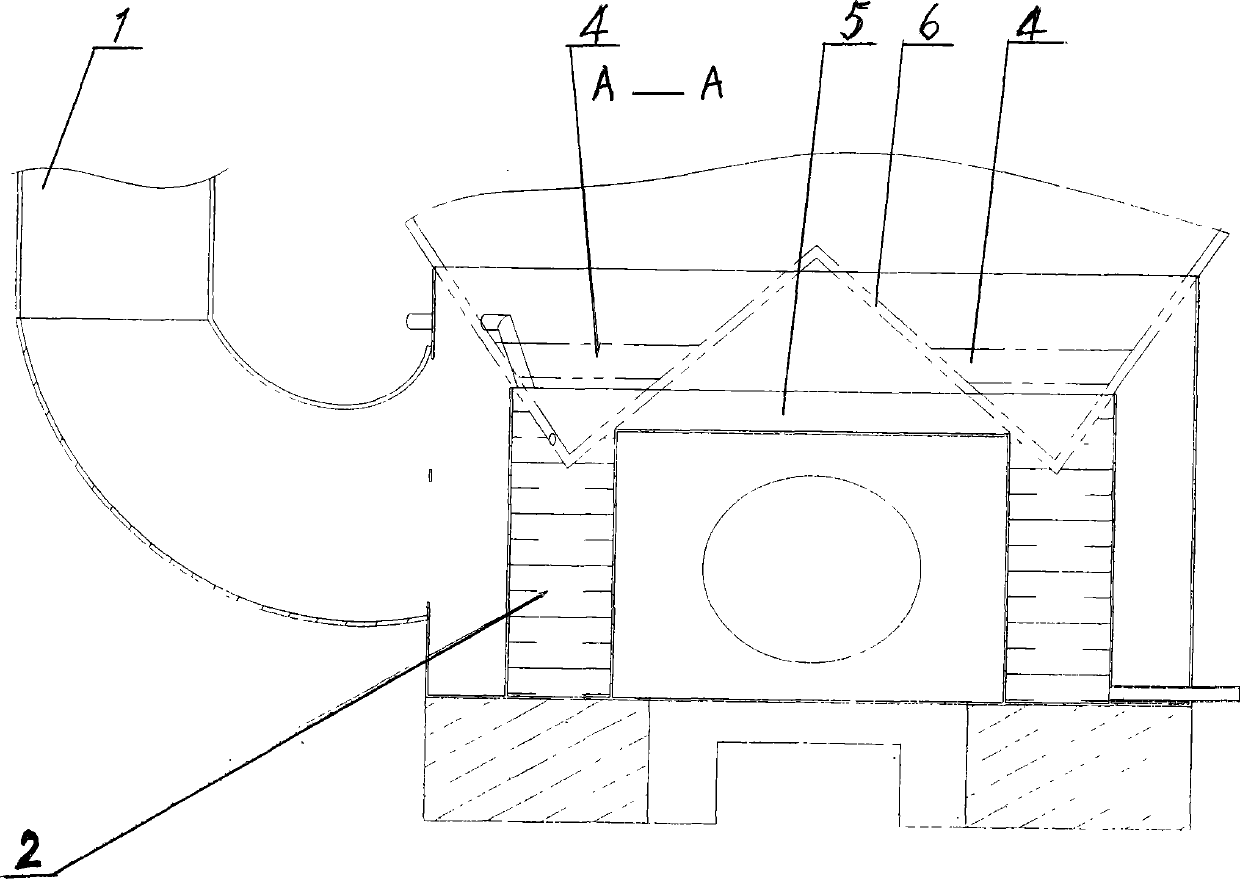

Lifting-dismounting type fire-heating ceiling pot winemaking device

InactiveCN104232452AShort labor intensityReduce labor intensityAlcoholic beverage preparationFlavorDistillation

The invention discloses a lifting-dismounting type fire-heating ceiling pot winemaking device which is used for solving the defects, namely great energy consumption, easiness for stream escaping, a small condensing area of the ceiling pot, insufficient cooling, much wine volatilization due to a high wine temperature, high cost, low yield, great labor strength and easiness for burning, in the background technology. The lifting-dismounting type fire-heating ceiling pot winemaking device is characterized in that five heating tubes, which are parallel to one another, at the upper end of a furnace hearth 7 are communicated with a W-shaped pot bottom; eight fire exhausting tubes 4 are arranged at the topmost end of the furnace hearth 7 above the five heating tubes 5 which are parallel to one another; cavities are internally formed in an upper ceiling pot body 15 and a lower ceiling pot body 14, and are filled with circulating cooling water; the two ends of each of five water tubes 11 are communicated with the upper ceiling pot body 15 and the lower ceiling pot body 14 respectively; a coiler secondary condenser is composed of a spiral coiled tube 12 and a condensing barrel 3. The lifting-dismounting type fire-heating ceiling pot winemaking device has the advantages of being energy-saving and environment-friendly, great in heating area, short in distillation time, great in cooling area, time-saving and labor-saving, complete in distillation, low in cost, high in yield, safe and reliable in pressure-free operation, less in possibility of pot burning, low in distillation temperature, low in wine temperature, high in flavor substance content of a finished product wine, good in quality and good in mouthfeel. The lifting-dismounting type fire-heating ceiling pot winemaking device is used for making wine.

Owner:周取闻

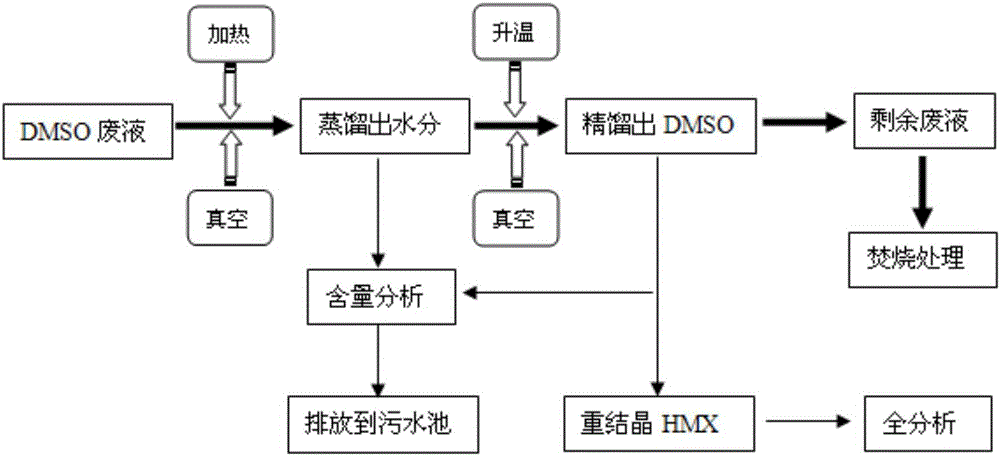

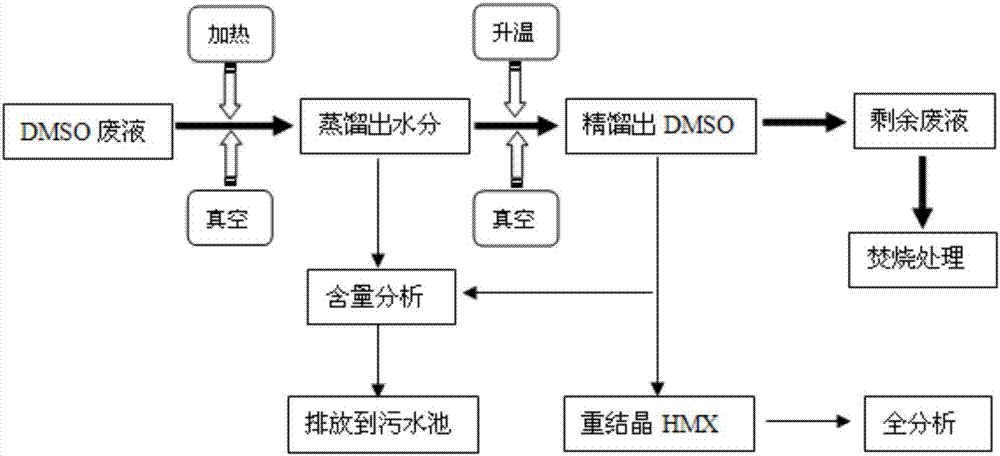

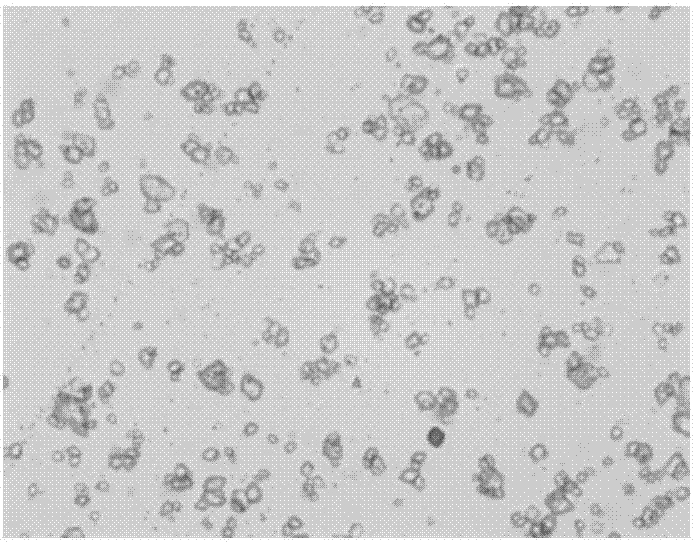

Method for recycling dimethyl sulfoxide from explosive-containing dimethyl sulfoxide waste liquid

ActiveCN106008291AEfficient recyclingReduce energy consumptionOrganic chemistryOrganic compound preparationHigh energyDistillation

The invention discloses a method for recycling dimethyl sulfoxide (DMSO) from explosive-containing dimethyl sulfoxide waste liquid. The method comprises the following steps: adding the waste liquid into a distillation flask; refluxing in condensed water, in vacuum and in an oil bath, wherein the refluxing temperature is 50 DEG C to 52 DEG C at the beginning; improving a heating temperature and refluxing under the conditions that the temperature of the oil bath is 86 DEG C to 90 DEG C and the vacuum degree is 0.088MPa; after no refluxing liquid exists, adding the waste liquid without water into a rectification bottle; refluxing by a system under the conditions of condensed water, vacuum and oil bath, wherein the refluxing temperature is 95 DEG C to 97 DEG C; after refluxing for a period of time, stopping heating when the volume of a residual solution is reduced to be 1 / 3 to 1 / 5 of the volume of a stock solution; condensing and recycling to obtain liquid, namely the dimethyl sulfoxide. By adopting a method combining decompression and distillation and decompression and rectification, the disadvantage of high energy consumption of an existing method for recycling the dimethyl sulfoxide is avoided; distilled water is discharged when reaching the standards; the purity of the rectified DMSO reaches index requirements and can be used for recrystallizing explosive octogen.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

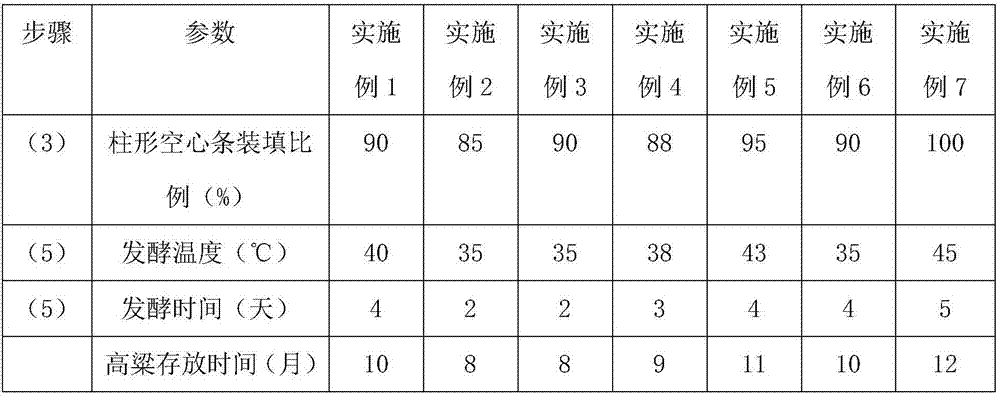

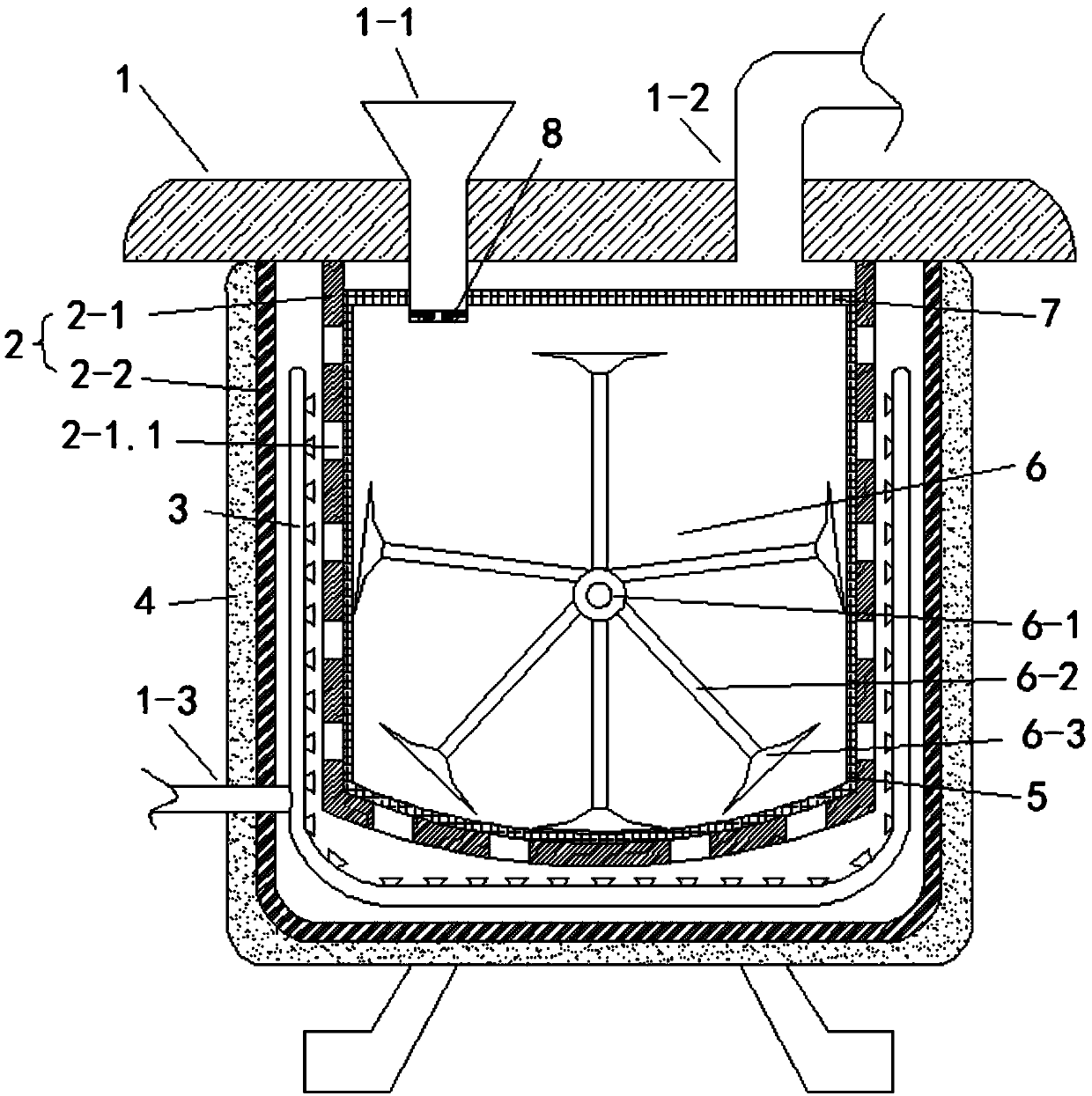

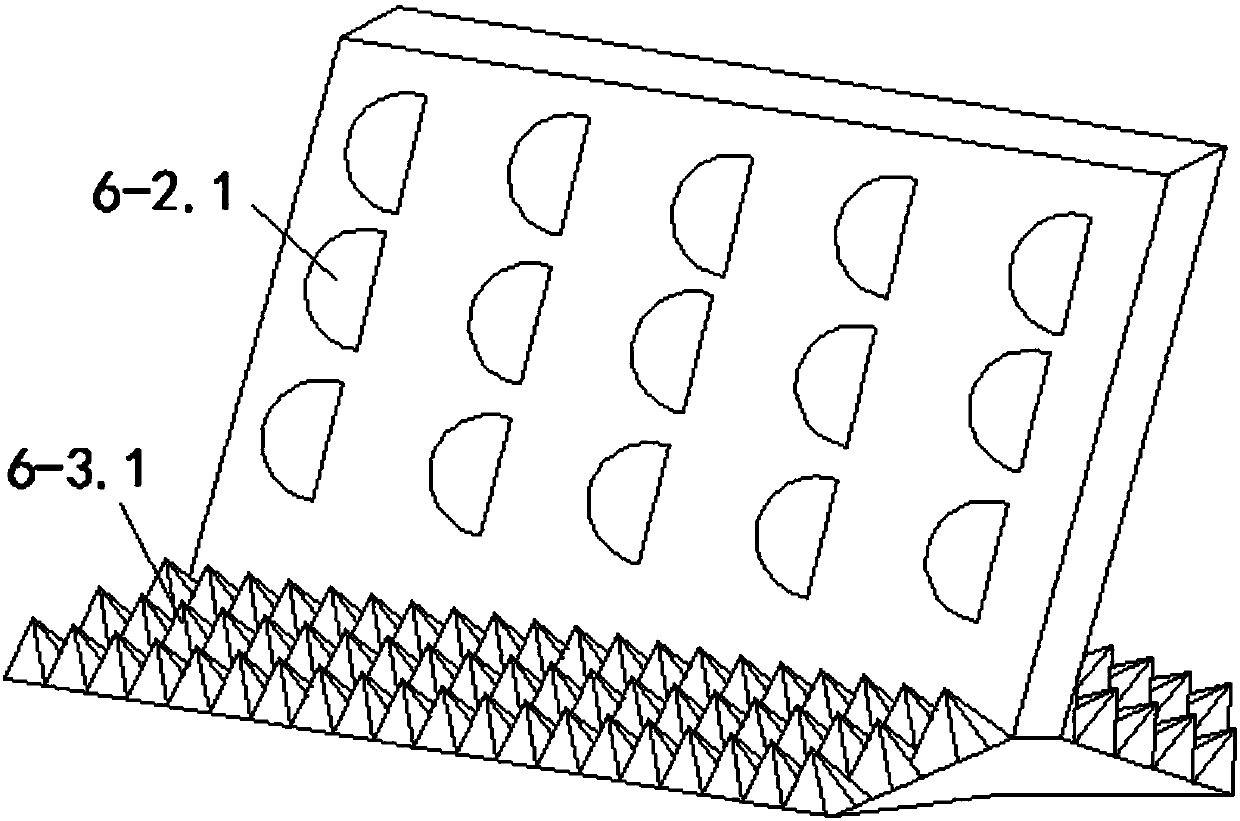

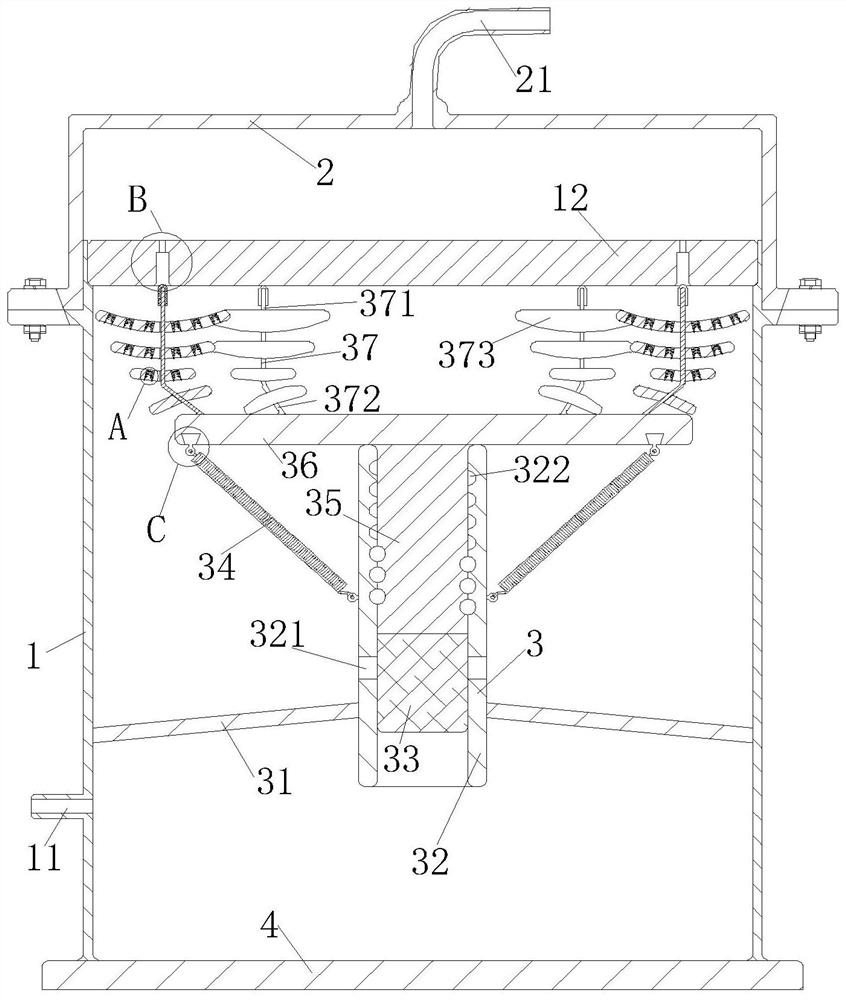

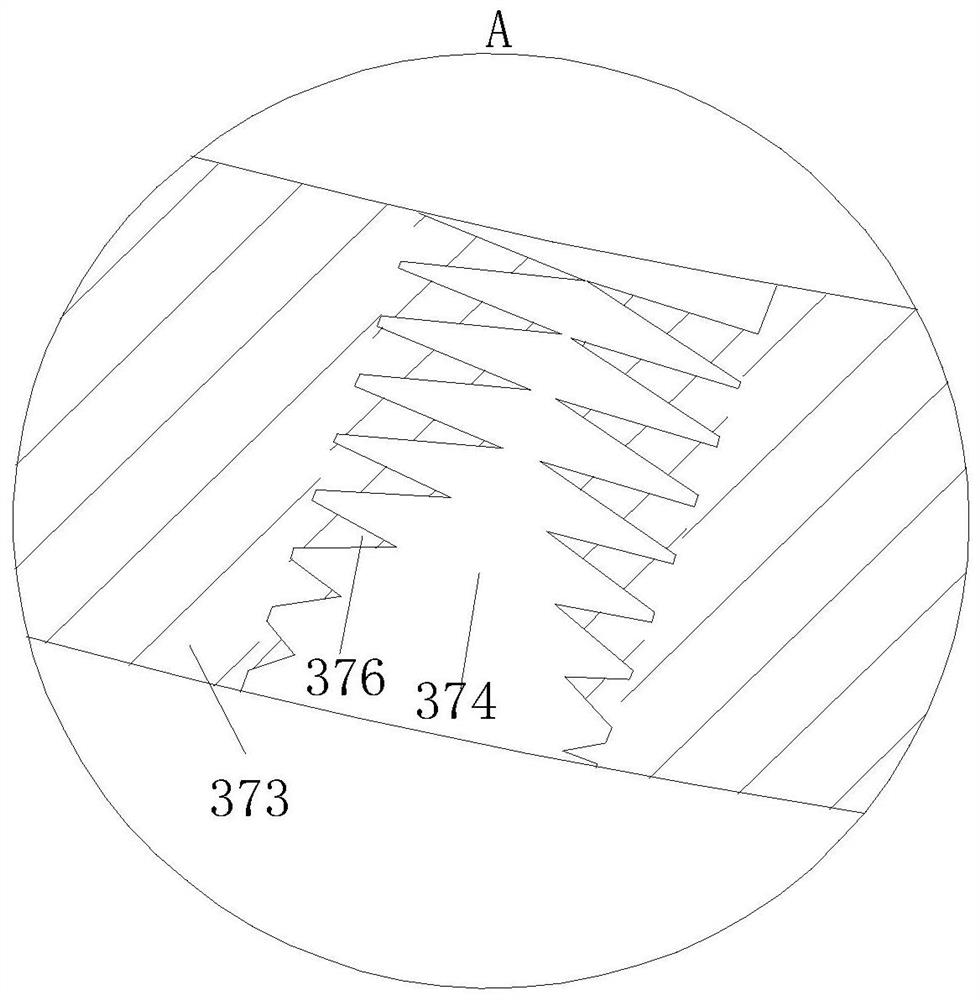

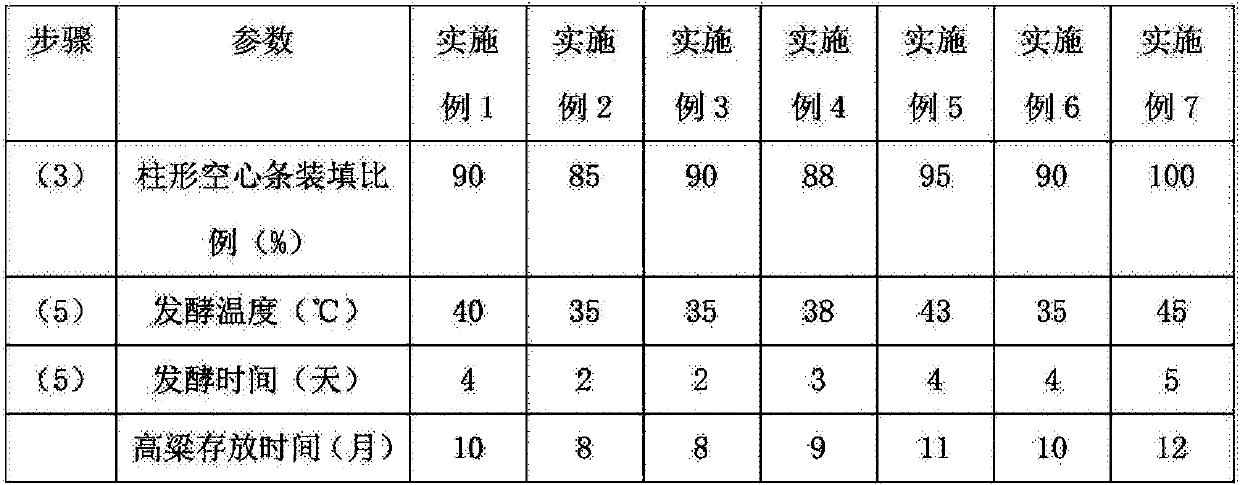

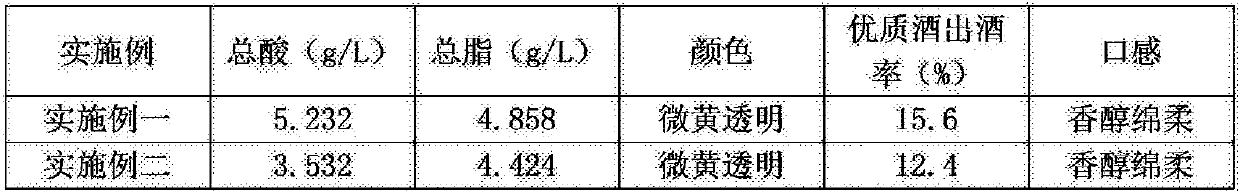

Baijiu fermenting method

The invention discloses a Baijiu fermenting method. The Baijiu fermenting method comprises the following steps: (1) crushing; (2) soaking and adding yeast; (3) filling powder; (4) steaming grains; (5) fermenting; (6) distilling; (7) storing and blending. Compared with the prior art, sorghum powder fills a cylindrical hollow bar with a through hole, a negative-pressure blade is impacted from bottom to top by utilizing high-pressure high-temperature vapor, the high-pressure gas can enable the negative-pressure blade to drive a turntable to continuously rotate in a retort grate, so that the sorghum powder also rolls in the cylindrical hollow bar, the sorghum powder is easier to cook, and the cooking time is shortened; and when in distillation, the turntable is arranged matching with a tillage watering plate, when in the heating process, the high-pressure carbon dioxide is introduced from the bottom, the high-pressure gas enables the turntable to rotate, the mixed liquid can form a circular flow, the alcohol is more completely and thoroughly distilled, and the produced Baijiu is mellow in taste, and the yield is higher.

Owner:贵州酣客君丰酒业有限公司

High-efficient tea tree essential oil distillation pot

InactiveCN107779263AEvenly heatedFully distilledEssential-oils/perfumesGas solvent extractionDistillationEngineering

The invention discloses a high-efficiency tea tree essential oil distillation tank, which relates to the technical field of essential oil production and processing equipment. The invention includes a distillation tank body and a tank cover matched with the distillation tank body. The tank cover is respectively provided with an exhaust port and an anti-clogging device. The feed hopper of the assembly is provided with a steam inlet on the distillation tank body. The distillation tank body includes an inner tank and an outer shell. U-shaped heating tube, the inner tank forms a distillation chamber, the distillation chamber is connected to the exhaust port, the inner tank is provided with a through hole connecting the heating cavity and the distillation chamber, and the distillation chamber is provided with a turning device for stirring the tea leaves. Stirring component, the invention stirs the tea tree leaves during the distillation process, so that the tea tree leaves are heated evenly, fully distilled, and the distillation efficiency is improved.

Owner:成都元始信息科技有限公司

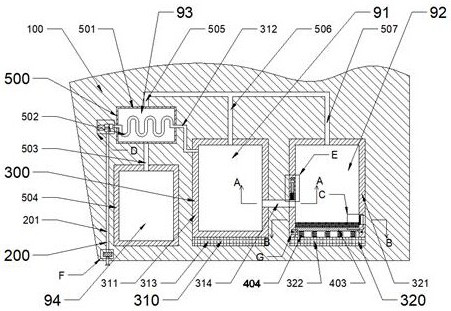

Marine seawater desalination equipment facilitating sea salt precipitation

InactiveCN112979035AFully distilledImprove desalination efficiencyWater treatment parameter controlAuxillariesSaline waterEnvironmental engineering

The invention relates to the technical field of ship equipment, in particular to marine seawater desalination equipment facilitating sea salt precipitation. The equipment comprises a ship body, wherein a water pumping system used for pumping water is arranged at the bottom of the ship body; a distillation system used for distillation, a precipitation system facilitating sea salt precipitation and a condensation system used for condensation are arranged in the ship body; a condensation cavity and a collection cavity are formed in the condensation system; the water pumping system comprises a water pump device; the distillation system comprises a first distillation device and a second distillation device; the precipitation system comprises a blocking device; a first distillation cavity is formed in the first distillation device, and a second distillation cavity is formed in the second distillation device. The problems that a large amount of fresh water needs to be carried during sailing, a large amount of space is occupied, the cost for purchasing fresh water resources is high, and emission of strong brine generated by traditional seawater desalination causes great threats to marine organisms can be solved.

Owner:深圳市埃文森商贸有限公司

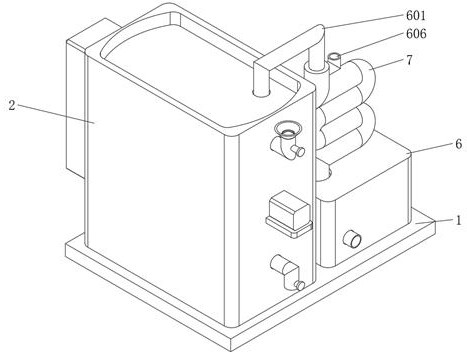

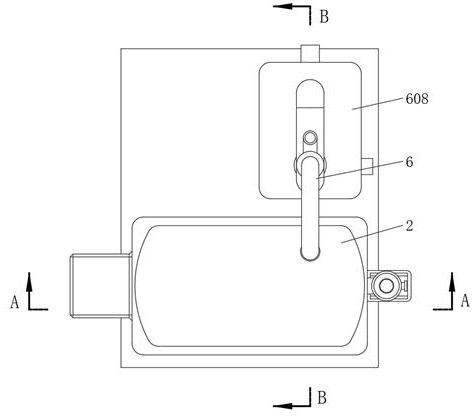

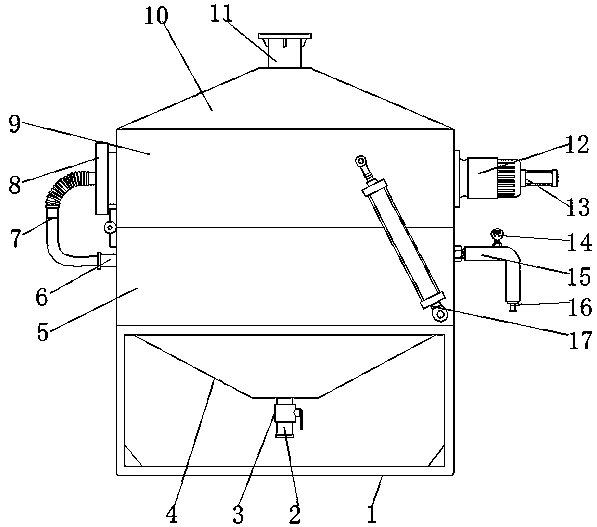

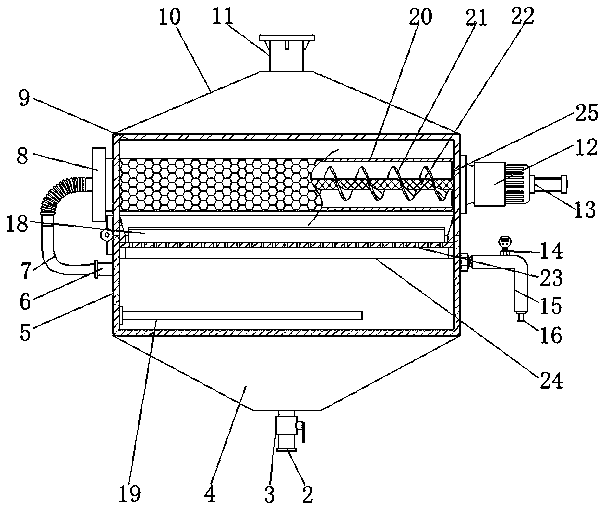

Wine brewing distillation equipment

The invention relates to the technical field of wine brewing equipment, and especially relates to wine brewing distillation equipment. The wine brewing distillation equipment comprises a wine containing barrel, a distillation apparatus and a steam generation apparatus, the distillation apparatus is divided into a distillation chamber and a discharge chamber communicated with the distillation chamber and positioned below the distillation chamber, a separator plate having air holes is arranged between the distillation chamber and the discharge chamber, a stirring member positioned at the distillation chamber is arranged at the separator plate, the steam generation apparatus is connected with the discharge chamber through a steam pipeline, the wine containing barrel is communicated with the top of the distillation chamber through a condenser pipeline, and an outer part of the condenser pipeline is coated with a condensed water cannula. The wine brewing distillation equipment has the advantages that the distillation rate is controlled, is in favor of increasing the wine quality, has good condensation effect, and can rapidly collect the distillation products, the condensed water realizes secondary utilization, and saves the energy.

Owner:安吉米亨酿酒酒坊(普通合伙)

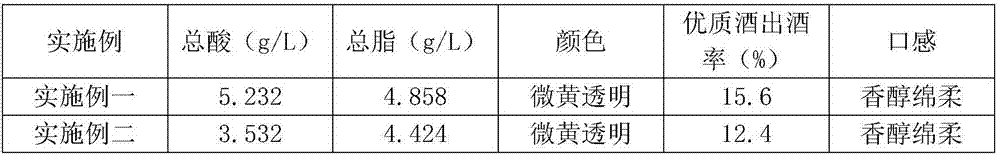

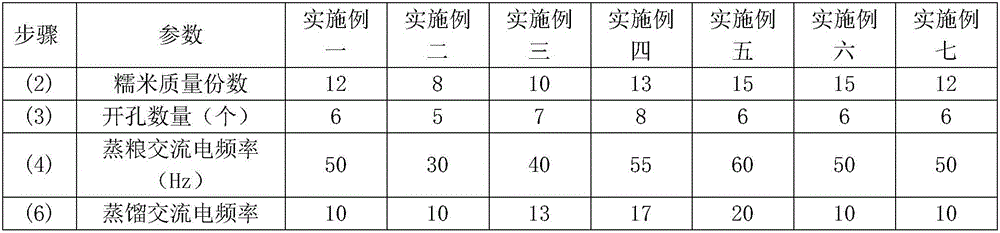

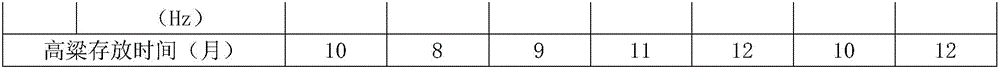

Process for producing aromatic type baijiu

The invention relates to the field of baijiu production, and discloses a process for producing aromatic type baijiu. The process includes smashing and screening sorghum; soaking sorghum powder in clear water; adding glutinous rice starch and high-temperature yeast into the sorghum powder; cultivating the sorghum powder, the glutinous rice starch and the high-temperature yeast and then rubbing the sorghum powder to obtain sorghum balls; filling the balls with steel balls by means of rubbing; steaming grain in steamer grates with electromagnetic coils on the walls; discharging the grain out of the steamer grates and then fermenting the grain; distilling the fermented grain and placing fermenting grains into distillation containers with electromagnetic coils on the walls when the grain is distilled, electrifying the electromagnetic coils with alternating currents with the frequencies of 10-20 Hz, continuously filling the distillation containers with carbon dioxide gas when the grain is distilled, distilling the grain to obtain strong liquor of baijiu; storing and blending the strong liquor of the baijiu to obtain the aromatic type baijiu. Compared with the prior art, the process has the advantage of high baijiu yield.

Owner:庄臣酿酒(福建)有限公司

Method for continuously distilling aromatic oil by subsectional temperature control

InactiveCN103215137BImprove daily processing capacityReduce labor intensityEssential-oils/perfumesFatty-oils/fats productionTemperature controlDistillation

Owner:YIBIN UNIV

A method for recovering dimethyl sulfoxide from waste liquid containing explosive dimethyl sulfoxide

ActiveCN106008291BEfficient recyclingReduce energy consumptionOrganic chemistryOrganic compound preparationDistillationHigh energy

The invention discloses a method for recycling dimethyl sulfoxide (DMSO) from explosive-containing dimethyl sulfoxide waste liquid. The method comprises the following steps: adding the waste liquid into a distillation flask; refluxing in condensed water, in vacuum and in an oil bath, wherein the refluxing temperature is 50 DEG C to 52 DEG C at the beginning; improving a heating temperature and refluxing under the conditions that the temperature of the oil bath is 86 DEG C to 90 DEG C and the vacuum degree is 0.088MPa; after no refluxing liquid exists, adding the waste liquid without water into a rectification bottle; refluxing by a system under the conditions of condensed water, vacuum and oil bath, wherein the refluxing temperature is 95 DEG C to 97 DEG C; after refluxing for a period of time, stopping heating when the volume of a residual solution is reduced to be 1 / 3 to 1 / 5 of the volume of a stock solution; condensing and recycling to obtain liquid, namely the dimethyl sulfoxide. By adopting a method combining decompression and distillation and decompression and rectification, the disadvantage of high energy consumption of an existing method for recycling the dimethyl sulfoxide is avoided; distilled water is discharged when reaching the standards; the purity of the rectified DMSO reaches index requirements and can be used for recrystallizing explosive octogen.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

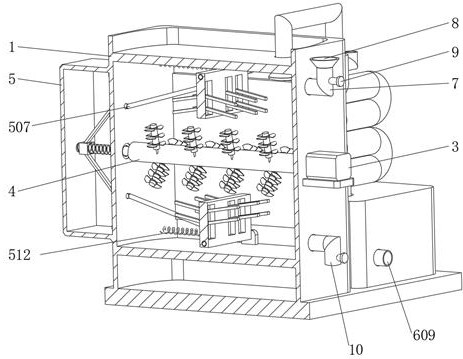

Distillation furnace device for drug intermediates

PendingCN113476876AEvenly heatedImprove the mixing effectRotary stirring mixersDistillation in boilers/stillsThermodynamicsPharmaceutical drug

The invention relates to the technical field of medicine production, in particular to a distillation furnace device for drug intermediates. The distillation furnace device comprises a bottom plate, wherein a distillation furnace main body is mounted on one side of the upper surface of the bottom plate, a driving motor is fixedly mounted on the surface of one end of the distillation furnace main body, a first stirring mechanism is arranged at the output end of the driving motor and located in the distillation furnace main body, a second stirring mechanism is arranged at the other end of the first stirring mechanism and located at the end, which is away from the driving motor, of the distillation furnace main body, and a cooling mechanism is arranged on the upper surface of the bottom plate and located on one side of the distillation furnace main body. By arranging the first stirring mechanism and the second stirring mechanism, internal materials can be longitudinally and transversely stirred at the same time, so that the mobility of the materials in the distillation furnace is higher, the materials are heated more uniformly, distillation is more sufficient, and the distillation efficiency is further improved.

Owner:南通辉正医药科技有限公司

A double-tower continuous feeding rectification system and control method

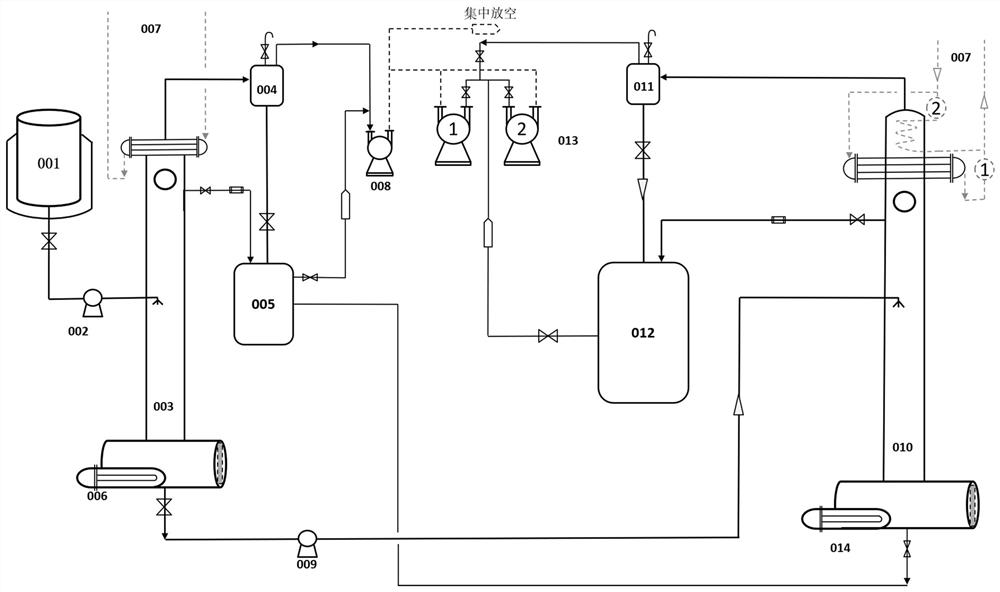

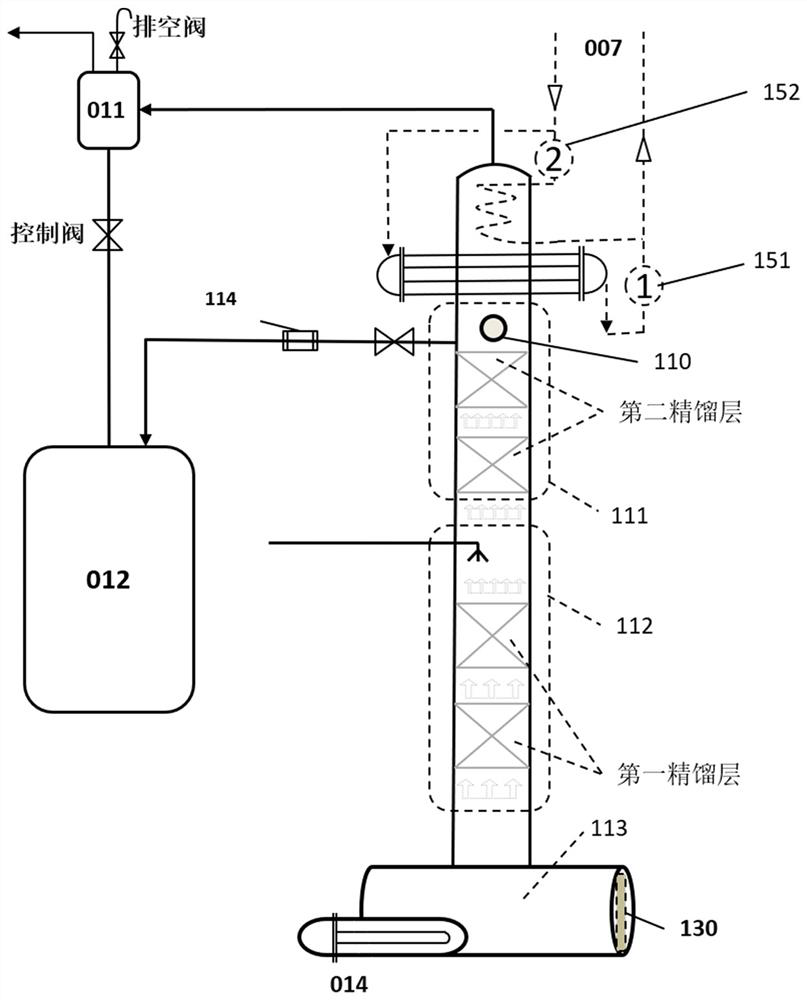

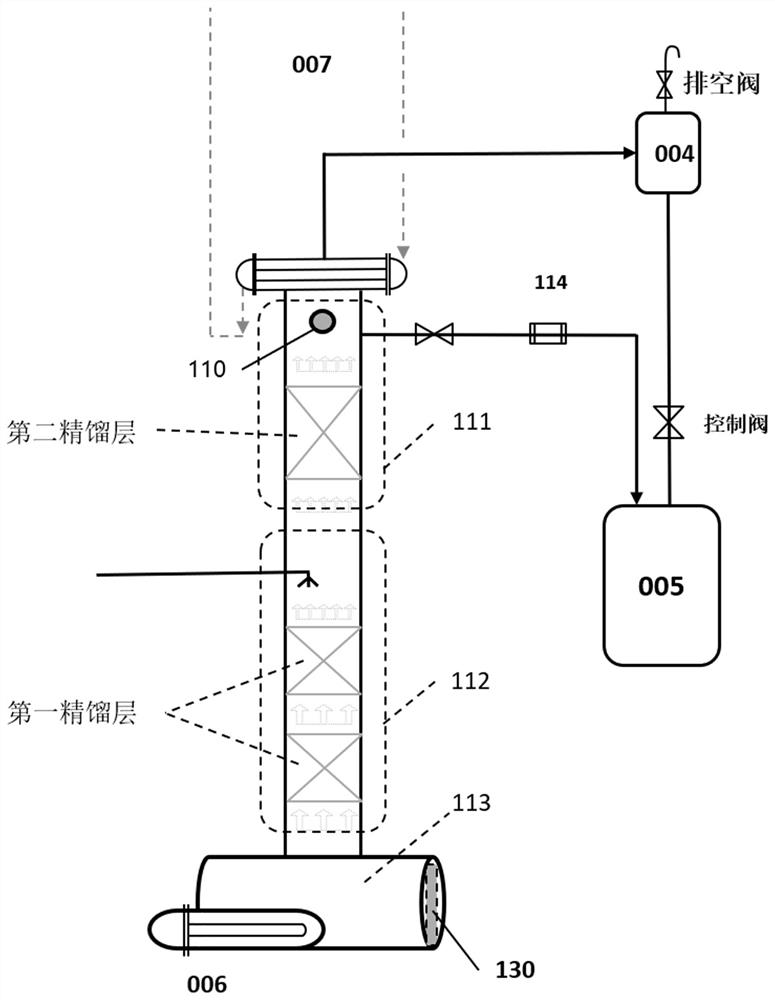

ActiveCN109745723BImprove separation and purification efficiencySmooth feedingOrganic chemistryDistillation regulation/controlTemperature controlProcess engineering

The present invention provides a control method and system for rectification with continuous feeding of double towers, including: feeding control, initial distillation process control, material delivery control and fine rectification process control; controlling the pressure P of 1# rectification tower 1 and pressure difference ΔP 1 , heat up until the top temperature reaches T 1 , open the control valve of the outlet outlet at the top of the tower, and wait for the rate of temperature increase at the top of the 1# rectification tower to be ΔT 1 , the initial distillation process is completed; the fine distillation process is: control the pressure difference ΔP at the top of the 2# rectification tower tower 2, Slowly increase the temperature of the tower kettle and control the heating rate ΔT 2 , control the temperature of the tower kettle at T 2 , when the top temperature reaches T 3 , to complete the fine distillation process control. The control method of the present invention adopts four continuous control steps, which ensures the continuous, safe and efficient feeding process, and improves the separation and purification efficiency of the rectification system. The invention also provides a double-tower continuous feeding rectification system, which has a reasonable raw material batching system, high rectification efficiency and high product purity.

Owner:TIANE CHEM FIBER GROUP CORP BAODING +1

A light-removing distillation tower

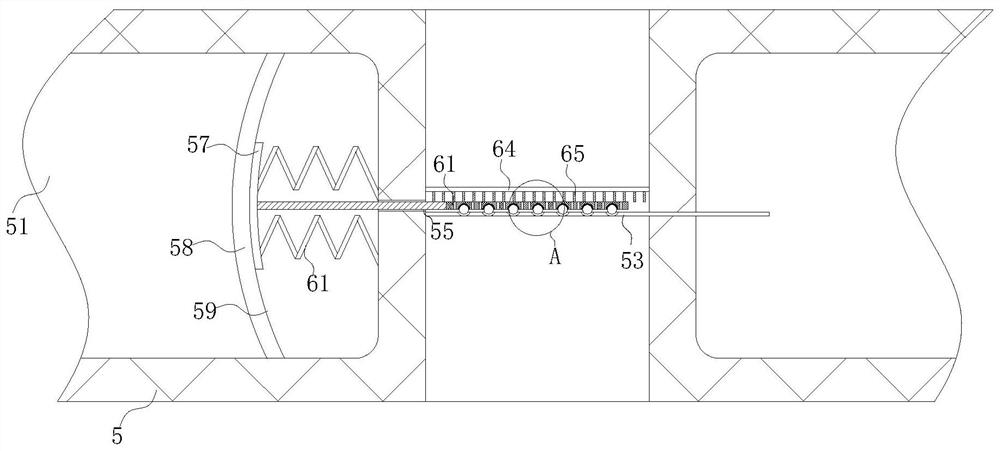

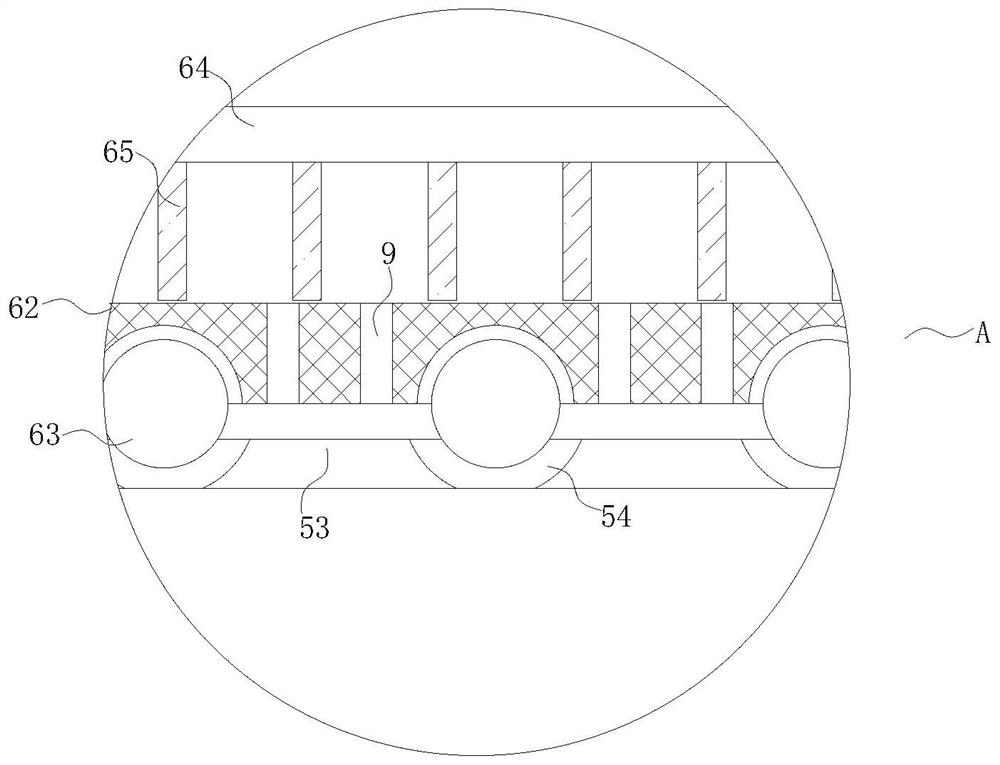

ActiveCN111921216BFully distilledClean up thoroughlyCombination devicesFractional distillationDistillationTower

The invention belongs to the field of chemical equipment, in particular to a lightening rectification tower, including a tower body, a tower cover, a working unit and a heater, the tower body is a hollow cylinder structure, and the heater is installed at the bottom of the tower body , the working unit is installed inside the tower body, and the tower cover is fixedly connected with the top of the tower body by means of bolt connection; the working unit includes a fixed plate, a No. 1 pipe, a sponge, a spring, a shaft rod and a top plate; when the present invention works , the sponge can absorb the mixed liquid and foam in the mixed gas, and the shaft drives the mixed gas by rotating, and removes the mixed liquid and foam in it, and both the sponge and the rotating shaft can delay the flow of the mixed gas, making the mixed gas fine The distillation is more complete and the contained foam is removed more thoroughly, and finally a better quality distillation product is obtained.

Owner:山东禧龙石油装备有限公司

Baijiu fermentation method

InactiveCN109837179AEasy to steamFully distilledAlcoholic beverage preparationDistillationFermentation

The invention discloses a Baijiu fermentation method comprising the following steps: 1 crushing; 2 soaking and raw starter addition; 3 powder filling; 4 grain steaming; 5 fermentation; 6 distillation;and 7 storage and blending.

Owner:刘大兴

High-purity dimethyl ester batch rectification device

ActiveCN114159817AWell mixedIncrease usageOrganic chemistryOrganic compound preparationElectric machineProcess engineering

The invention discloses a high-purity dimethyl ester batch rectification device, and particularly relates to the technical field of distillation separation, the high-purity dimethyl ester batch rectification device comprises a rectification kettle, the top end of the rectification kettle is connected with a reaction cover, the inner wall of the rectification kettle is fixedly provided with a fixed rod, and the fixed rod is sleeved with a reciprocating swing mechanism. The reciprocating swing mechanism is driven by the servo gear motor, so that the swing blades and the ratchet plates on the swing blades swing in a reciprocating manner, dimethyl ester raw materials in the rectifying kettle can be uniformly mixed, the dimethyl ester raw materials are enabled to be more fully and thoroughly rectified in cooperation with the use of the stirring blades and the stirring paddles, the utilization rate of the rectified raw materials is increased, and the production cost is reduced. The two micro air cylinders push the upper clamping plate and the lower clamping plate to move respectively, the first rubber mat and the second rubber mat are attached to the outer wall face of the reaction cover and the outer wall face of the rectifying still, the sealing performance of the reaction cover and the rectifying still is improved, the rectifying quality is improved, and redundant hot air generated by the heating plate is conveyed into the waste heat collecting box to be recycled.

Owner:安徽弋尚纺织科技有限公司

Waste lubricating oil regeneration processing device

PendingCN113214891AImprove efficiencyStable constant temperature heatingLubricant compositionProcess engineeringOil can

The invention discloses a waste lubricating oil regeneration processing device, and relates to the technical field of lubricating oil recovery equipment. The waste lubricating oil regeneration processing device comprises a main body device, a distillation device, an acid-alkali treatment device and a filtering and shunting device, the main body device is provided with a settling tank, a temperature increasing device is arranged in the settling tank, the main body device is provided with the distillation device, a treatment tank is arranged at the top of the distillation device, and a stirring device is arranged on the bottom surface of the inner wall of the distillation device. Through the settling tank and the temperature increasing device, the problem that the settling time is too long due to the fact that waste lubricating oil cannot be heated in traditional settling equipment is solved, and the problem that equipment cannot achieve full distilling due to the fact that the staying time of the waste lubricating oil in a high-temperature area is not reduced in traditional equipment is solved. Meanwhile, the filtering and shunting device is arranged, the problem that all traditional equipment needs to be stopped when filtering equipment is blocked is solved, sectional type filtering is carried out, and the problem that the filtering equipment needs to be stopped when being blocked is effectively solved.

Owner:吴文杰

Light component removal rectifying tower

PendingCN113769428AGuaranteed temperatureFully distilledDistillation regulation/controlFractional distillationOil canEngineering

The invention relates to the technical field of rectifying towers, in particular to a light component removal rectifying tower which comprises a tower body, a supporting frame, a gas phase inlet, a raw material inlet, a first filler plate, a second filler plate, a gas phase output pipe and a heating assembly, the supporting frame is fixedly connected to the outer surface of the lower end of the tower body, the position, close to the bottom end, of the outer surface of the left side of the tower body fixedly communicates with the gas phase inlet, the position, close to the upper end, of the outer surface of the right side of the tower body fixedly communicates with a raw material inlet, a first filler plate and a second filler plate are fixedly connected into the tower body, the outer surface of the upper end of the tower body is fixedly connected with a gas phase output pipe, and the heating assembly is arranged in the tower body. By arranging the heating assembly, conduction oil can circularly flow in a heating cavity I and a heating cavity II while the interior of the tower body is heated by utilizing the conduction oil, so that a liquid phase and a gas phase passing through the through holes are heated, the contact temperature of the liquid phase and the gas phase is ensured, the liquid phase and the gas phase are fully rectified, and the rectification efficiency is improved.

Owner:何金翠

Distillation device for producing chrysanthemum wine

InactiveCN109929716AEasy to pourEasy to adjust the tilt angleAlcoholic beverage preparationDistillationLiquid storage tank

The invention belongs to the technical field of distillation devices, and in particular relates to a distillation device for producing a chrysanthemum wine. The distillation device aims to solve the problem that the chrysanthemum is required to be distilled in the production process of the chrysanthemum wine, the existing distillation device cannot discharge slag conveniently, and the distillationeffect is general. The distillation device includes a liquid storage tank, a metal bucket is welded to the bottom end of the liquid storage tank, and the metal bucket is communicated with the liquidstorage tank. The bottom end of the metal bucket is screwed with a liquid discharge pipe, and the outer wall at the bottom end of the liquid storage tank is fixedly provided with a support frame through bolts. A steam box is hinged at the top end of the outer wall on one side of the liquid storage tank, a metal cover is welded to the top end of the steam box, and a discharge pipe is fixed to the top end of the metal cover by bolts. Metal mesh tubes equidistantly distributed are arranged on the inner wall of the steam box. According to the distillation device, the inclination angle of the steambox can be adjusted conveniently, so that materials in the metal mesh tubes can be poured conveniently, daily cleaning and maintenance are facilitated, the operation is simple, the contact area of steam and the materials can be increased, and the distillation effect is improved.

Owner:HUANGSHAN UNIV

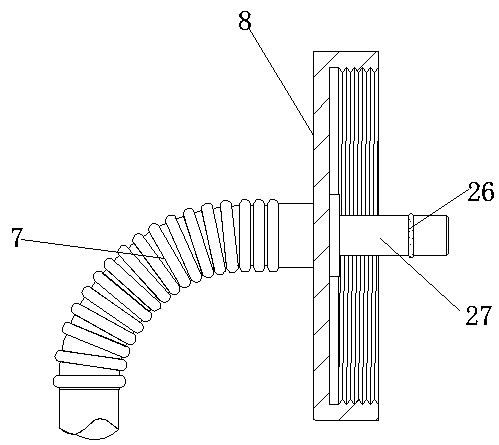

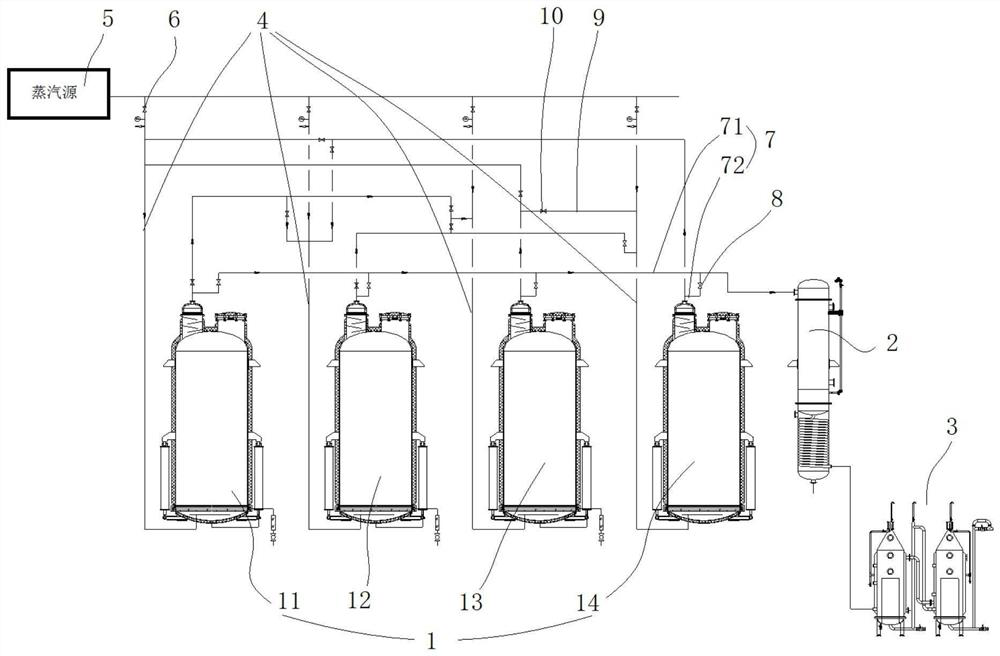

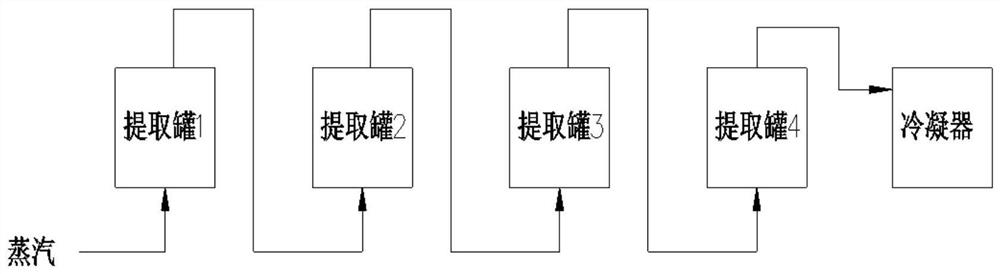

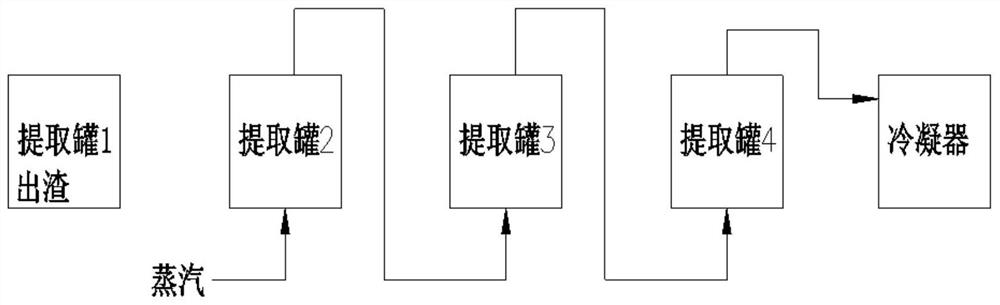

Countercurrent distillation essential oil extraction equipment and process

PendingCN111808682AReduce dosageTake advantage ofEssential-oils/perfumesProcess engineeringOil water

The invention discloses countercurrent distillation essential oil extraction equipment and a countercurrent distillation essential oil extraction process. The essential oil extraction equipment comprises extraction tanks, a condenser and an oil-water separator which are connected in sequence; the number of the extraction tanks is at least three; each extraction tank is connected with a steam source through a steam branch pipeline; a first control valve is arranged on each steam branch pipeline; the steam outlet of each extraction tank is connected with the steam inlet of the condenser througha conveying pipeline; a second control valve is arranged on each conveying pipeline; the steam outlet of each extraction tank is connected with the steam inlet of one adjacent extraction tank througha connecting pipeline; the steam inlet of each extraction tank is connected with the steam outlet of the other adjacent extraction tank through a connecting pipeline; and third control valves are respectively arranged on the connecting pipelines between the extraction tanks which are connected in series front and back. According to the countercurrent distillation essential oil extraction equipmentand the countercurrent distillation essential oil extraction process of the invention, the extraction tanks with the multiple stages of steam inlets and outlets connected in series, heat of directlyinjected steam can be fully utilized through the extraction tanks connected in series, and the steam consumption can be saved by 50% or above.

Owner:温州阳羽机械科技有限公司

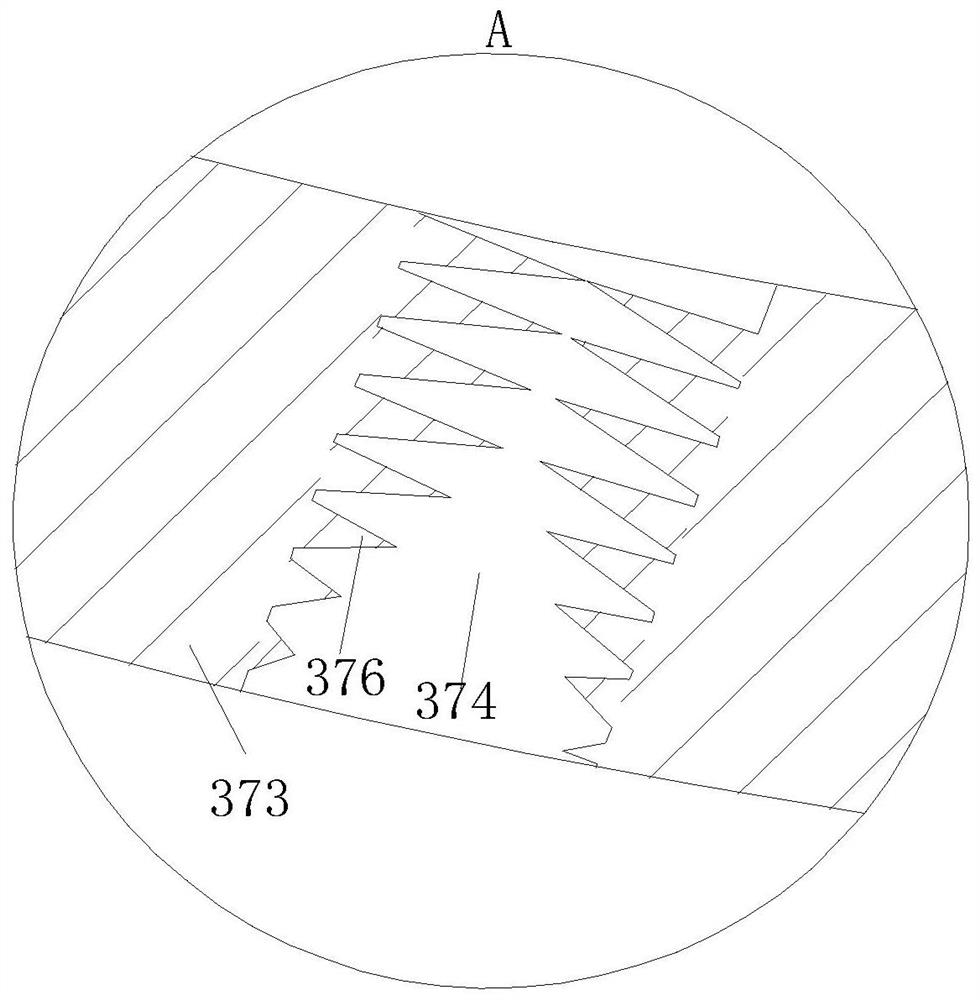

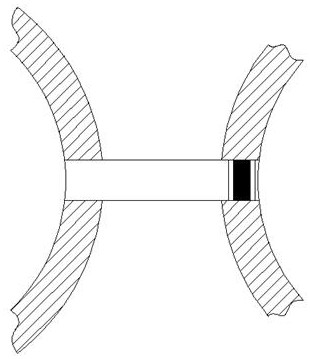

Inner barrel structure of wine-making distillation equipment

ActiveCN113337366ADelivery volume controllableEasy temperature controlBiofuelsAlcoholic beverage preparationVertical tubeProcess engineering

The invention discloses an inner barrel structure of wine-making distillation equipment, and belongs to the technical field of wine-making equipment. The inner barrel structure comprises a barrel body, a large rotary joint and a small rotary joint, wherein a wine taking tube assembly is arranged between the large rotary joint and the small rotary joint; the two ends of the wine taking tube assembly are separately connected and fixed with the large rotary joint and the small rotary joint, and can rotate along with the large rotary joint and the small rotary joint; the wine taking tube assembly comprises a steam conveying tube and a wine taking tube; a space is reserved between the wine taking tube and the steam conveying tube to form a steam channel; the two ends of the wine taking tube assembly are separately equipped with wine taking vertical tubes; and the wine taking tube is fixedly arranged in the steam conveying tube through the wine taking vertical tubes. According to the technical scheme adopted by the invention, the rotary steam conveying tube structure is adopted, so that the barrel body, the steam conveying tube, the wine taking vertical tubes and wine taking branch tubes rotate together; and the wine taking vertical tubes and the wine taking branch tubes are combined to realize active wine taking, so that a conventional passive wine taking mode is broken through.

Owner:贵州特征微生物研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com