Production process for continuously distilling ethanol by continuous fermentation of sweet sorghum stalks

A technology of sorghum stalks and straws, which is applied in the field of continuous fermentation and continuous distillation of ethanol from sweet sorghum stalks and other straws, which can solve the problems of large height-to-diameter ratio and achieve the effects of stable texture, high product yield and continuous production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

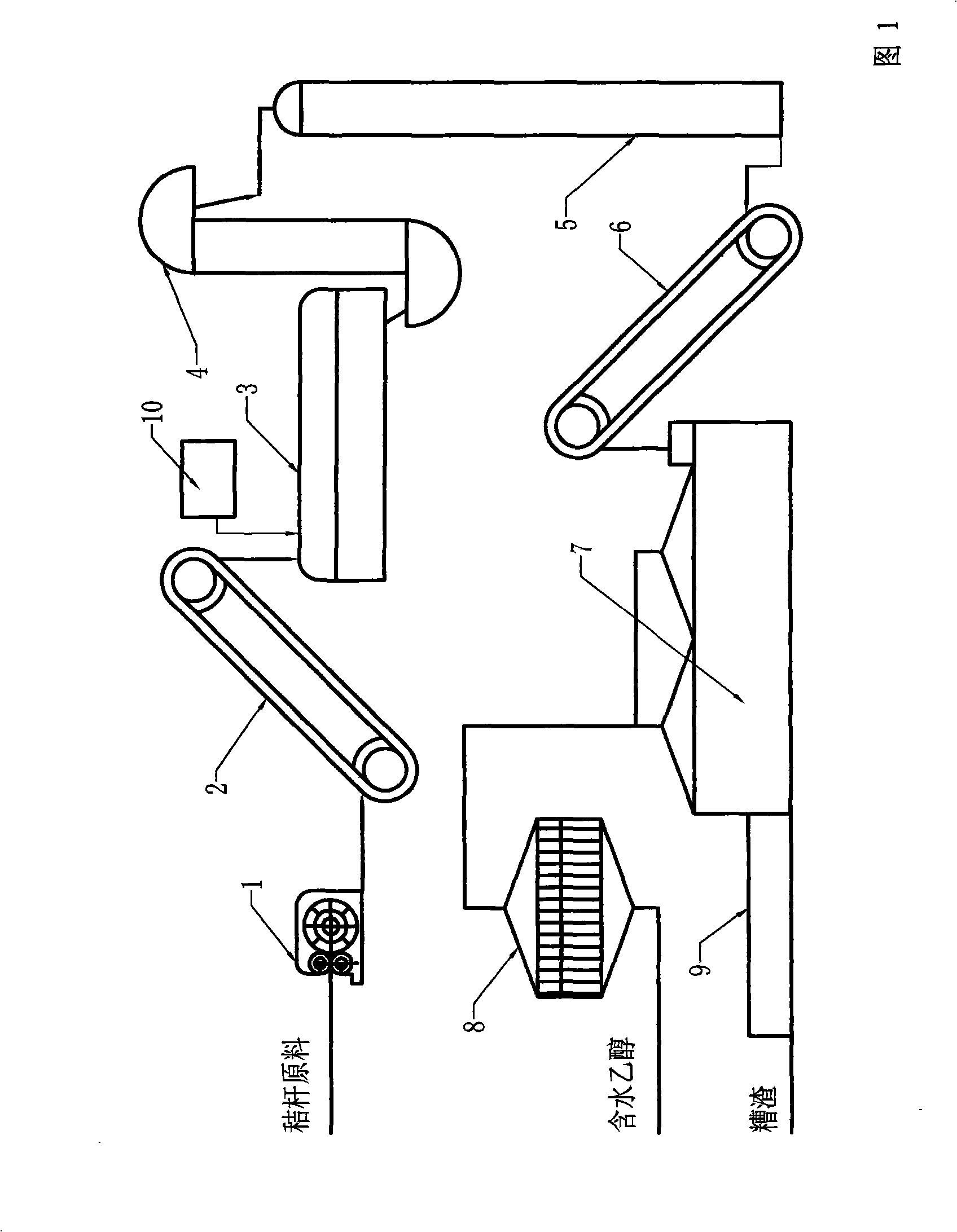

[0014] The production process is (see Figure 1): after straw raw materials such as sugarcane, sweet sorghum stalk, corn stalk, and wheat stalk are added to the guillotine cutter 1 with the function of guiding the material to the rollers, they are pushed into the rotating guillotine by the guiding rollers at a uniform speed. Parts are cut into pieces of a certain length to form straw scraps. After the stalk debris is lifted to a certain height by the lifting conveyor 2, it falls into the spiral continuous mixer 3 that can heat the material. Simultaneously according to the required ratio, the strains in the spawn tank 10 are also uniformly and continuously added to the spiral continuous mixer 3, mixed with straw scraps, and the materials are heated when needed, and the heating degree can be automatically control and regulation. After the mixed and heated straw fragments are lifted to a certain height by the bucket elevator 4, they fall into the continuous fermentation tower 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com