High-purity dimethyl ester batch rectification device

A dimethyl ester, high-purity technology, applied in the field of distillation and separation, can solve the problems of uneven mixing of dimethyl ester raw materials, increase of follow-up process time, unsatisfactory rectification effect, etc., to increase sealing, avoid gas leakage, The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

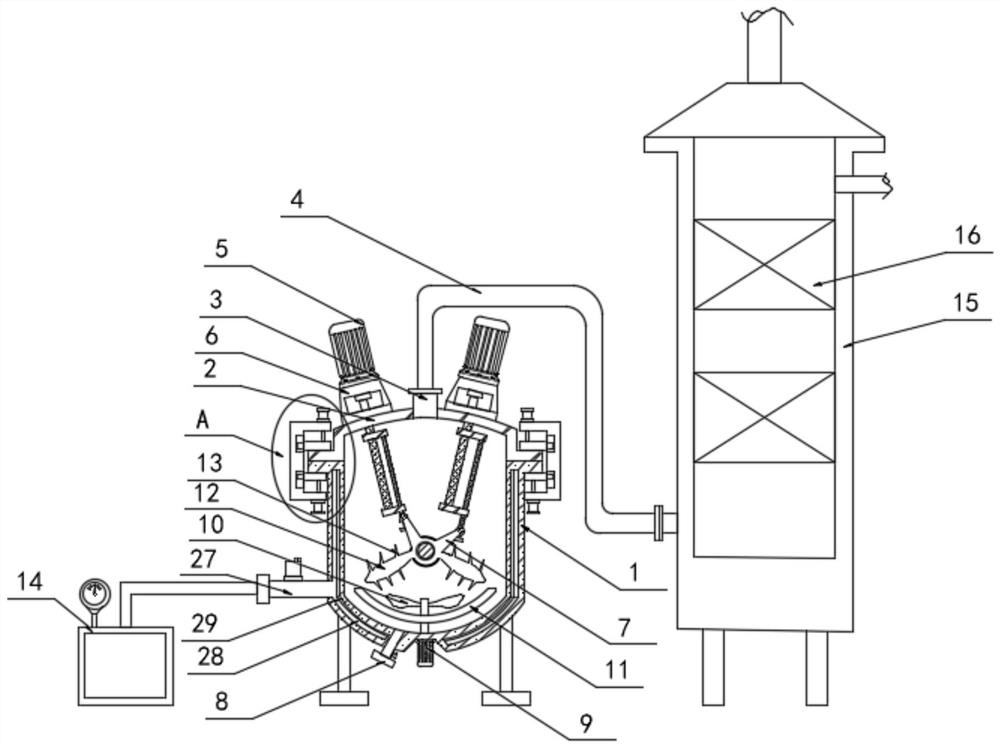

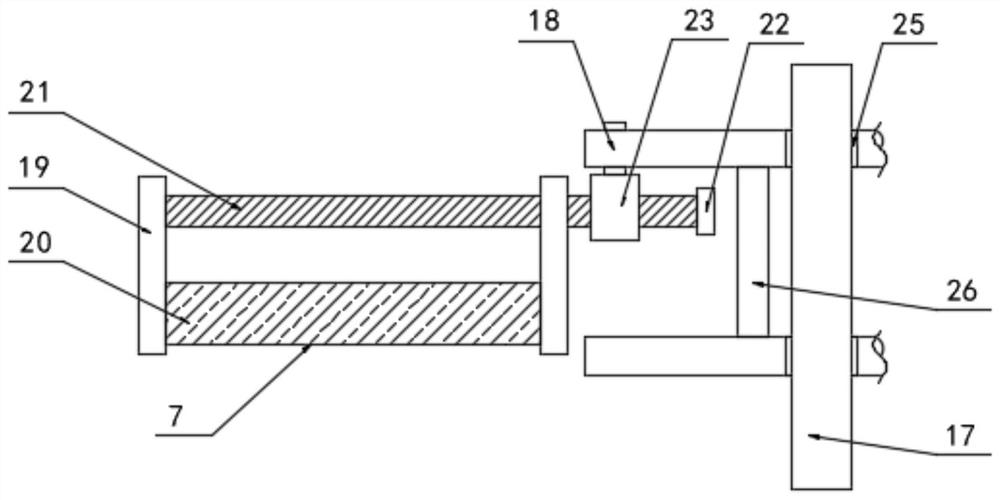

[0028] see Figure 2-Figure 6 As shown, in the embodiment of the present invention, a high-purity dimethyl ester batch rectification device includes a rectification kettle 1, a reaction cover 2 is connected to the top of the rectification kettle 1, and the inner wall of the rectification kettle 1 is fixedly arranged Fixed rod 17 is arranged, and the outer cover of fixed rod 17 is provided with reciprocating swing mechanism 7; The shaft is rotatably connected with a sliding seat 23 , the surface of the sliding seat 23 is penetrated with a limit slide bar 21 , and the limit slide bar 21 is slidably connected with the slide seat 23 .

[0029] When in use, one end of the transmission arm 18 is movably connected with the sliding seat 23, and the sliding seat 23 slides on the upper limit of the limit sliding rod 21, and then drives the movement of the transmission arm 18, so that the swinging member 24 reciprocates and accelerates rectification. The dimethyl ester raw material in k...

Embodiment 2

[0040] see figure 2 As shown, the inner cavity of the rectification kettle 1 is provided with a heating chamber 28, and the inside of the heating chamber 28 is provided with a heating plate 29, and the bottom side of the rectification kettle 1 is provided with a waste heat outlet 27 communicating with the heating chamber 28, and the waste heat outlet 27 One end is connected with a waste heat collection box 14 for waste heat recovery and utilization.

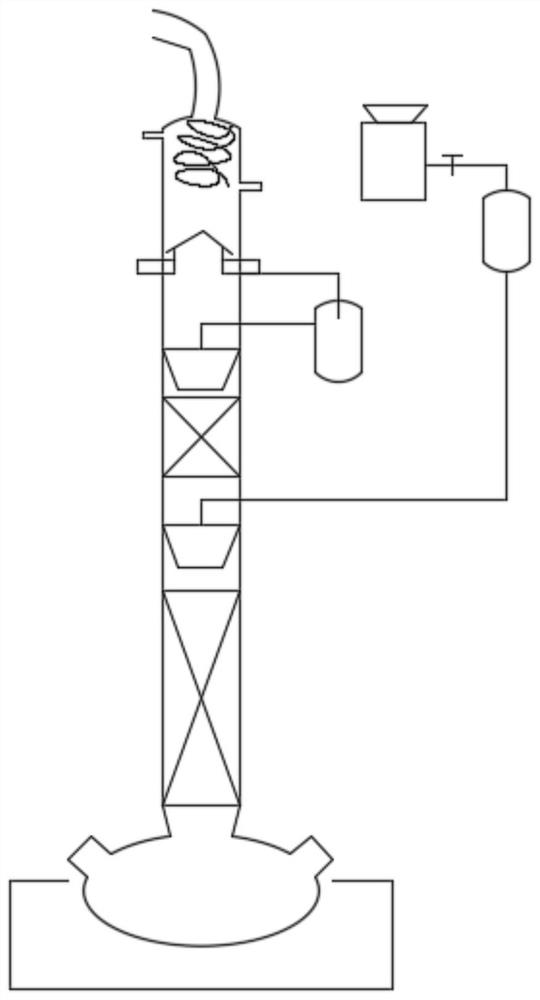

[0041] see figure 2 As shown, the top of the gas outlet 3 is connected with a conveying pipeline 4, and one end of the conveying pipeline 4 is connected with a rectifying tower 15, and the inside of the rectifying tower 15 is provided with a packing layer 16, and the top of the rectifying tower 15 is connected with a condensation tower through a pipeline. device.

[0042] During use, the rectification kettle 1 is heated and rectified by the heating plate 29, and the gas generated by the rectification enters the rectification ...

Embodiment 3

[0044] see Figure 2-Figure 6 As shown, the connection between the rectifying kettle 1 and the reaction cover 2 is covered with an annular sleeve plate 30, and the top and bottom ends of the annular sleeve plate 30 are equipped with a miniature cylinder 31, and the inner wall of the annular sleeve plate 30 is slidingly connected with the upper miniature cylinder. The upper clamping plate 32 affixed to the end of the piston rod of the cylinder 31 is fitted with a lower clamping plate 33 affixed to the end of the piston rod of the miniature cylinder 31 below.

[0045] When in use, the annular cover plate 30 can be directly placed on the junction of the rectification kettle 1 and the reaction cover 2, and the upper and lower clamping plates 32 and the lower clamping plate 33 are respectively pushed by the upper and lower miniature cylinders 31 to move, and the upper clamping plate 32 and the lower clamping plate The clamping plate 33 is attached to the top of the reaction cover 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com