Method for removing Si from waste liquid of Si-containing hydrofluoric acid, method for recovering hydrofluoric acid from mixed acid waste liquid of Si-containing hydrofluoric acid, and recovery device

A hydrofluoric acid system, hydrofluoric acid technology, applied in chemical instruments and methods, fluorine/hydrogen fluoride, water/sludge/sewage treatment, etc., can solve problems such as inability to reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

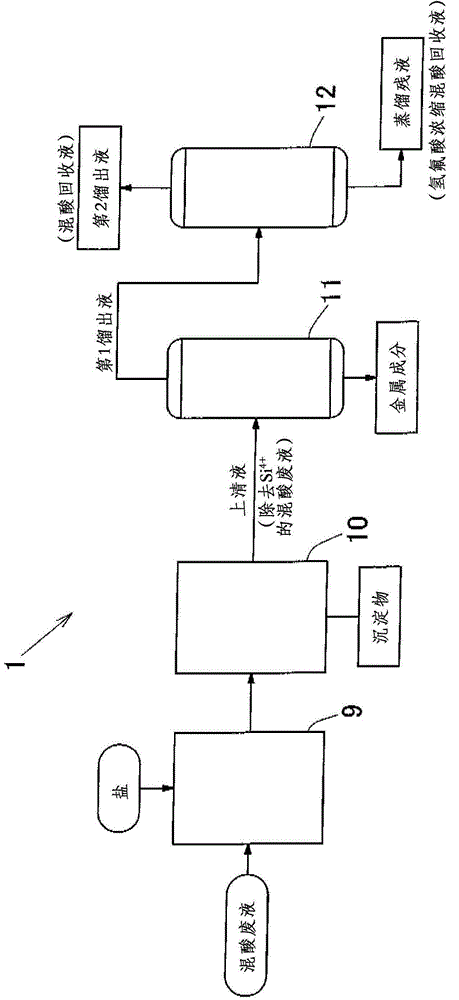

[0172] For mixed acid waste liquid (containing hydrofluoric acid, hydrochloric acid and Si 4+ mixed acid waste liquid), using figure 1 The recovery device 1 of the shown structure implements Si as follows: 4+ Removal process, 1st distillation process, 2nd distillation process.

[0173] (Si 4+ removal process)

[0174] 300 g of the mixed acid waste liquid (the components and the content of each component are shown in Table 1) and 25 g of sodium chloride were put into the mixing tank 9, and then stirred and mixed for 24 hours using a stirring blade to obtain a mixed liquid.

[0175] Next, the mixed solution is put into a centrifuge (solid-liquid separator) 10 for centrifugation, and the mixed solution is separated into precipitates (containing Si 4+ ) and supernatant (remove Si 4+ mixed acid waste; no sediment). The obtained precipitate was 66 g, and the obtained supernatant was 258 g.

[0176] In addition, it was confirmed from the analysis results obtained by XRD (X-ray...

Embodiment 2

[0182] For mixed acid waste liquid (containing hydrofluoric acid, hydrochloric acid and Si 4+ mixed acid waste liquid), using figure 1 The recovery device 1 of the shown structure implements Si as follows: 4+ Removal process, 1st distillation process, 2nd distillation process.

[0183] (Si 4+ removal process)

[0184] In the mixing tank 9, 300 g of the mixed acid waste liquid (the content of the components and the content of each component are shown in Table 2) and 25 g of potassium fluoride were put into the mixing tank 9, and then stirred and mixed with a stirring blade for 24 hours to obtain a mixed solution.

[0185] Next, the mixed solution is put into a centrifuge (solid-liquid separator) 10 for centrifugation, and the mixed solution is separated into precipitates (containing Si 4+ ) and supernatant (remove Si 4+ mixed acid waste; no sediment). The obtained precipitate was 103 g, and the obtained supernatant was 222 g.

[0186] In addition, it was confirmed from t...

Embodiment 3

[0192]For mixed acid waste liquid (containing hydrofluoric acid, hydrochloric acid and Si 4+ mixed acid waste liquid), using figure 1 The recovery device 1 of the shown structure implements Si as follows: 4+ Removal process, 1st distillation process, 2nd distillation process.

[0193] (Si 4+ removal process)

[0194] 300 g of the mixed acid waste liquid (the contained components and the content of each component are shown in Table 3) and 18 g of sodium fluoride were put into the mixing tank 9, and then stirred and mixed for 24 hours using a stirring blade to obtain a mixed liquid.

[0195] Next, the mixed solution is put into a centrifuge (solid-liquid separator) 10 for centrifugation, and the mixed solution is separated into precipitates (containing Si 4+ ) and supernatant (remove Si 4+ mixed acid waste; no sediment). The obtained precipitate was 69 g, and the obtained supernatant was 248 g.

[0196] In addition, it was confirmed from the analysis results obtained by X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com