Cleaning member, delivery member with cleaning function, and method of cleaning substrate processing apparatus

A substrate processing device and a technology for cleaning parts, which are applied in the directions of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inability to peel off adhesive substances, a lot of labor, and adhesive contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

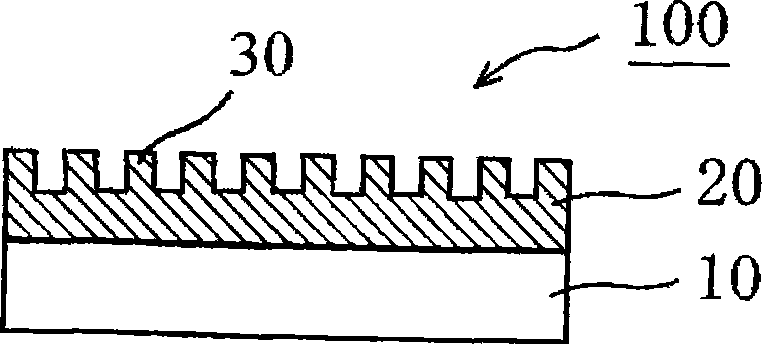

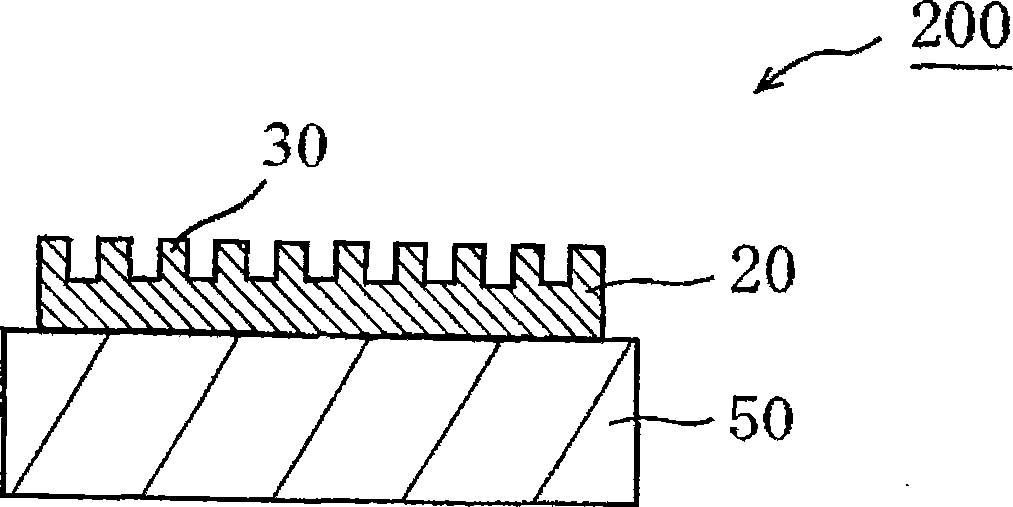

[0108] A polyimide film (manufactured by Kaneka, Apical NPI25-NPS) was cut so that the apparent surface area was 100 cm 2 , performing an oxygen plasma etching treatment (A) on one side of the film to obtain a cleaning layer having a plurality of protrusions with a columnar structure on the surface.

[0109] Oxygen plasma etching treatment (A), is the plasma etching treatment that utilizes oxygen to carry out, adopts following condition to implement: that is, the distance between the electrodes of plasma generator is 10cm, RF power supply, oxygen flow 300sccm, discharge power density is 0.78W / cm 2 , the processing time is 600 seconds, and the discharge energy is 468W·sec / cm 2 .

[0110] Regarding the obtained cleaning layer, the specific surface area of the cleaning layer, the density of the protrusions of the columnar structure on the surface of the cleaning layer, the aspect ratio of the protrusions of the columnar structure, the length of the protrusions of the protrusi...

Embodiment 2

[0112] A polyimide film (manufactured by Kaneka, Apical NPI25-NPS) was cut so that the apparent surface area was 100 cm 2 , performing an oxygen plasma etching treatment (B) on one side of the film to obtain a cleaning layer having a plurality of protrusions with a columnar structure on the surface.

[0113] The oxygen plasma etching treatment (B) is a plasma etching treatment using oxygen gas, and is carried out under the following conditions. That is, the distance between the electrodes of the plasma generator is 10cm, the RF power supply, the oxygen flow rate is 300sccm, and the discharge power density is 0.78W / cm 2 , the processing time is 300 seconds, and the discharge energy is 234W·sec / cm 2 .

[0114] Regarding the obtained cleaning layer, the specific surface area of the cleaning layer, the density of the protrusions of the columnar structure on the surface of the cleaning layer, the aspect ratio of the protrusions of the columnar structure, the length of the protr...

Embodiment 3

[0116] A polyimide film (manufactured by Kaneka, Apical NPI25-NPS) was cut so that the apparent surface area was 100 cm 2 , performing an oxygen plasma etching treatment (C) on one side of the film to obtain a cleaning layer having a plurality of protrusions with a columnar structure on the surface.

[0117]The oxygen plasma etching treatment (C) is a plasma etching treatment using oxygen gas, and is carried out under the following conditions. That is, the distance between the electrodes of the plasma generator is 10cm, the RF power supply, the oxygen flow rate is 20sccm, and the discharge power density is 0.07W / cm 2 , the processing time is 6600 seconds, and the discharge energy is 462W·sec / cm 2 .

[0118] Regarding the obtained cleaning layer, the specific surface area of the cleaning layer, the density of the protrusions of the columnar structure on the surface of the cleaning layer, the aspect ratio of the protrusions of the columnar structure, the length of the protru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com