Waste lubricating oil regeneration processing device

A processing device and a technology for waste lubricating oil, applied in the direction of lubricating composition and the like, can solve the problems of delaying the output of finished products, increasing the time of regeneration of waste lubricating oil, inability to carry out heating of waste lubricating oil, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

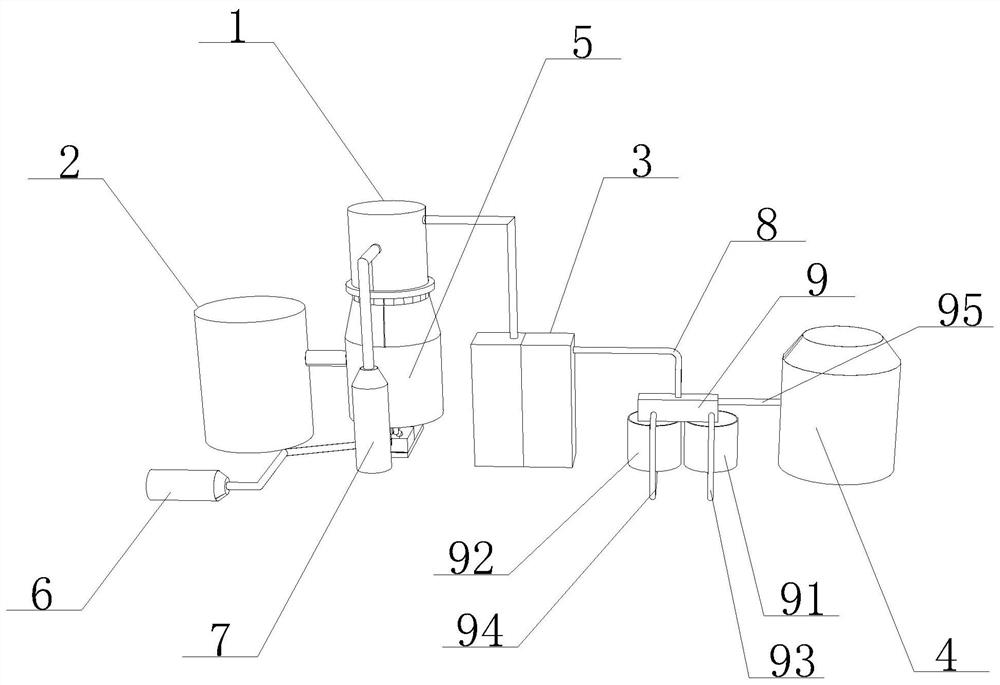

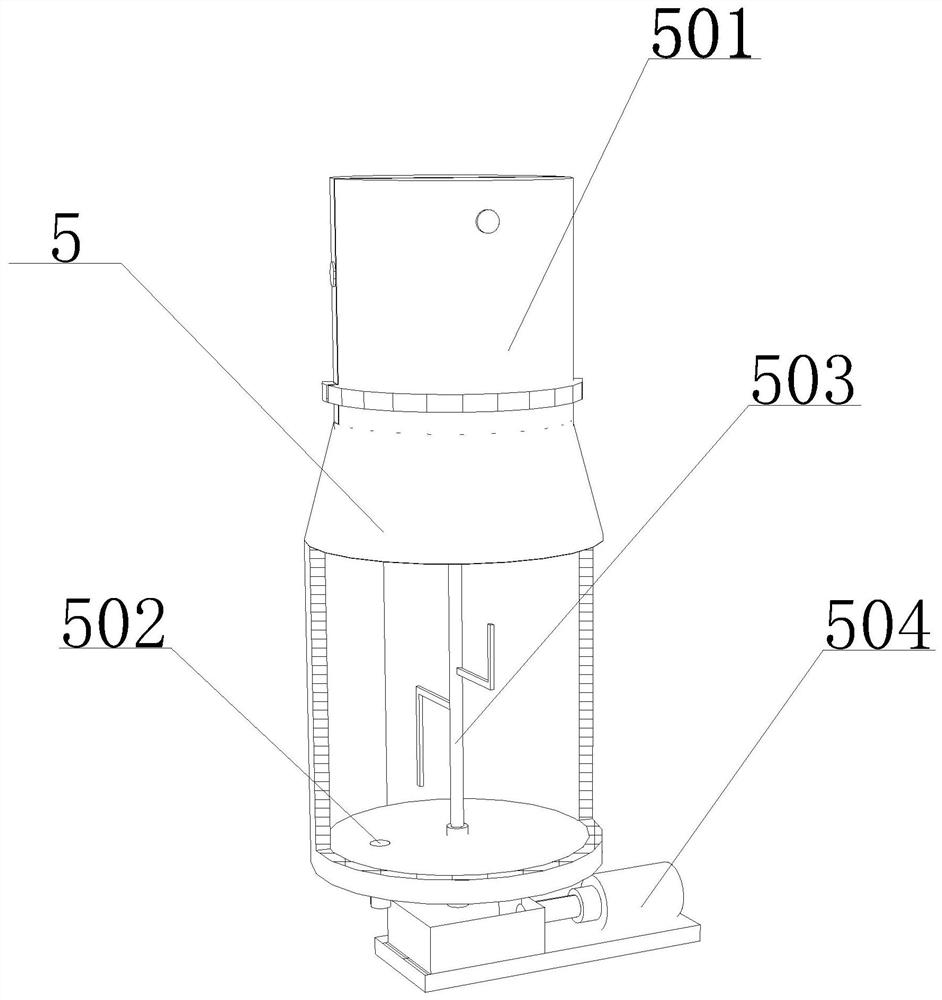

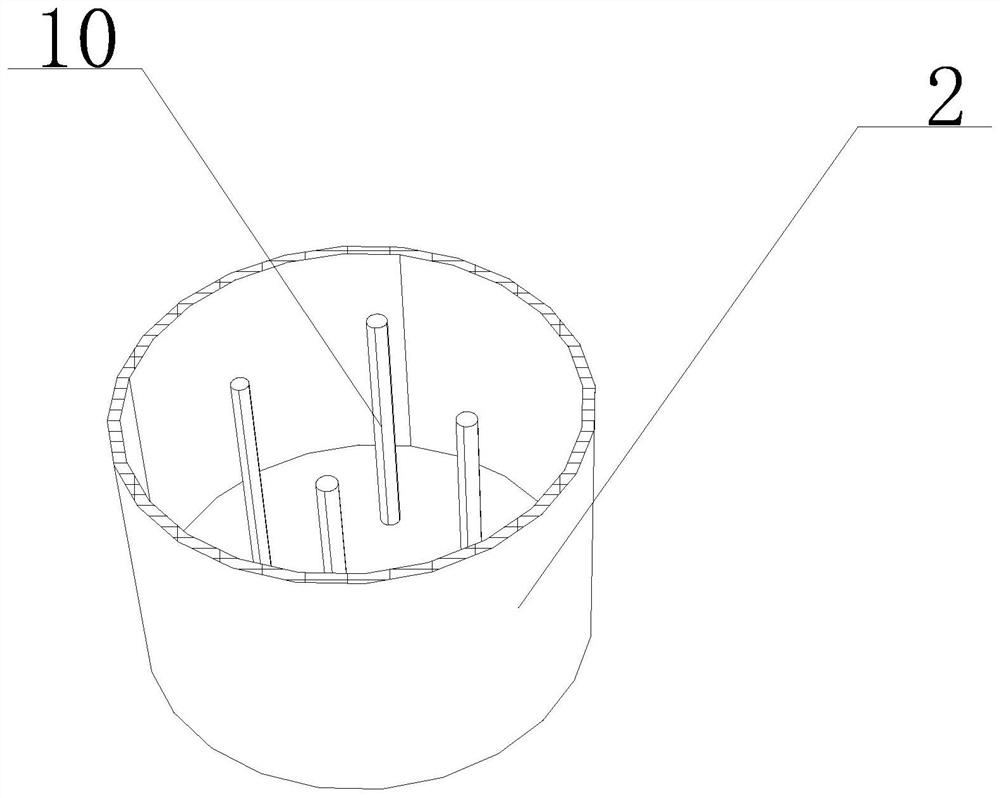

[0041] like Figure 1-6 As shown, the present invention provides a waste oil reproducing apparatus including the main body device 1, the distillation device 5, the acid-base treatment device 3 and the filter shunt device 9, the main body device 1 is provided with settling tank 2, settling tank 2 It is to settle the waste oil to settle down, and some of the impurities are removed, and the internal temperature of the settling tank 2 is provided with a temperature warming device 10, and the setting of the temperature warping device 10 is to provide constant temperature and sufficient. Heating, reducing the settling time, the main body device 1 is provided with a distillation device 5, and the arrangement of the distillation device 5 is to perform distillation treatment of the exhaust oil, and the top of the distillation device 5 is provided with a treatment tank 501, and the inner wall of the distillation device 5 is provided. The stirring transfer 503, the setting of the stirring tra...

Embodiment 2

[0044] like Figure 1-6 As shown in the basis of the first embodiment, the present invention provides a technical solution: preferably, the end of the first intake pipe 93 is provided with a first filter 91, and the setting of the first filter 91 is a primary filtration. The device, the end of the second intake pipe 94 is provided with a second filter 92, and the setting of the second filter 92 is provided with auxiliary spare filter, and the inner wall of the first filter 91 is fixedly connected to the filter cartridge 97, the filter element The upper surface of the passage pipe 97 is a closed setting, and the unfiltered lubricating oil is fixed by the outer surface of the filter cartridge 97, and the filtration combination device 96 is filtered to the lubricant by filtering the core through the outer surface of the filter core pipe 97, the filter element 97. Treatment, the outer surface side of the filtered combination device 96 is fixed to the connection with the built-in pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com