High-efficient tea tree essential oil distillation pot

A technology of tea tree essential oil and distillation tank, which is applied in the directions of essential oil/spices, fat production, solid solvent extraction, etc. It can solve the problems of low distillation efficiency and insufficient distillation of tea tree leaves, etc., and achieve the effect of improving distillation efficiency and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

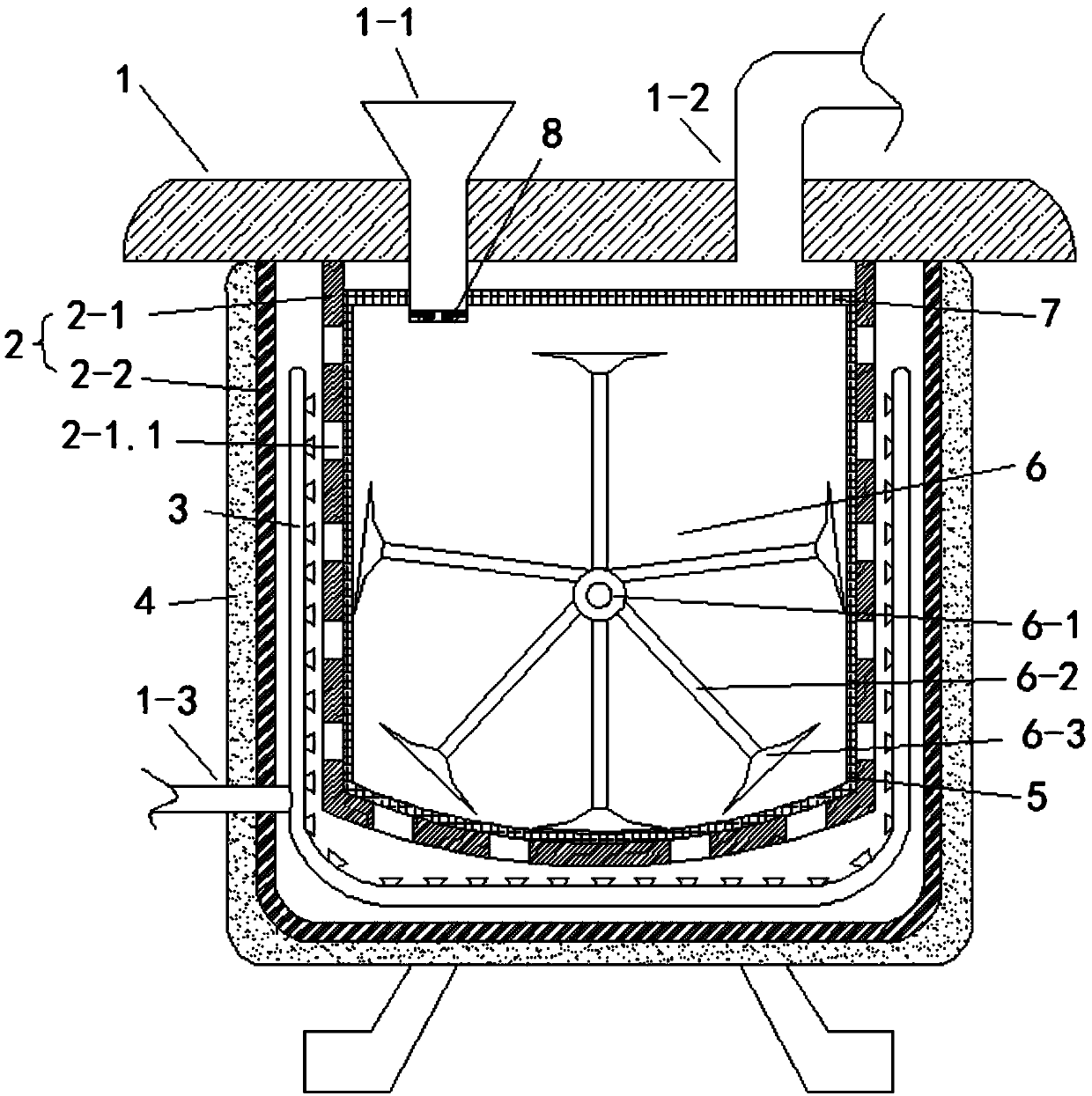

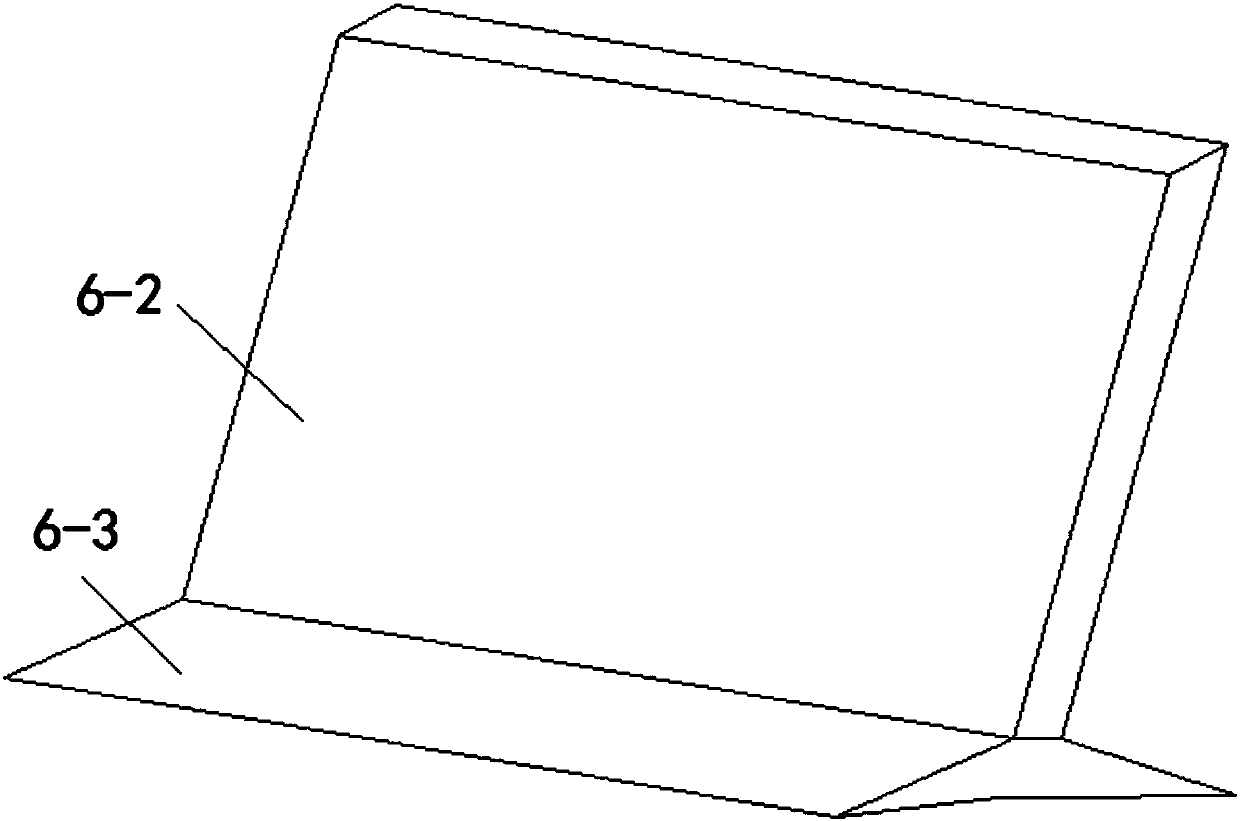

[0022] Such as figure 1 and figure 2 As shown, the present embodiment provides a high-efficiency tea tree essential oil distillation tank, comprising a distillation tank body 2 and a tank cover 1 matched with the distillation tank body 2, and the tank cover 1 is respectively provided with an exhaust port 1-2 and an anti-clogging tank. The feed hopper 1-1 of the component 8 is provided with a steam inlet 1-3 on the distillation tank body 2, and the distillation tank body 2 includes an inner tank 2-1 and an outer shell 2-2, and the outer wall of the inner tank 2-1 and the outer shell The inner wall of 2-2 constitutes a heating cavity, and the outer wall of the shell 2-2 is provided with a thermal insulation layer 4, and the thermal insulation layer 4 is filled with glass fibers, and the inner tank 2-1 is surrounded by the heating cavity. A U-shaped heating pipe 3 connected to the steam inlet 1-3 is provided, a distillation cavity is formed inside the inner tank 2-1, and the di...

Embodiment 2

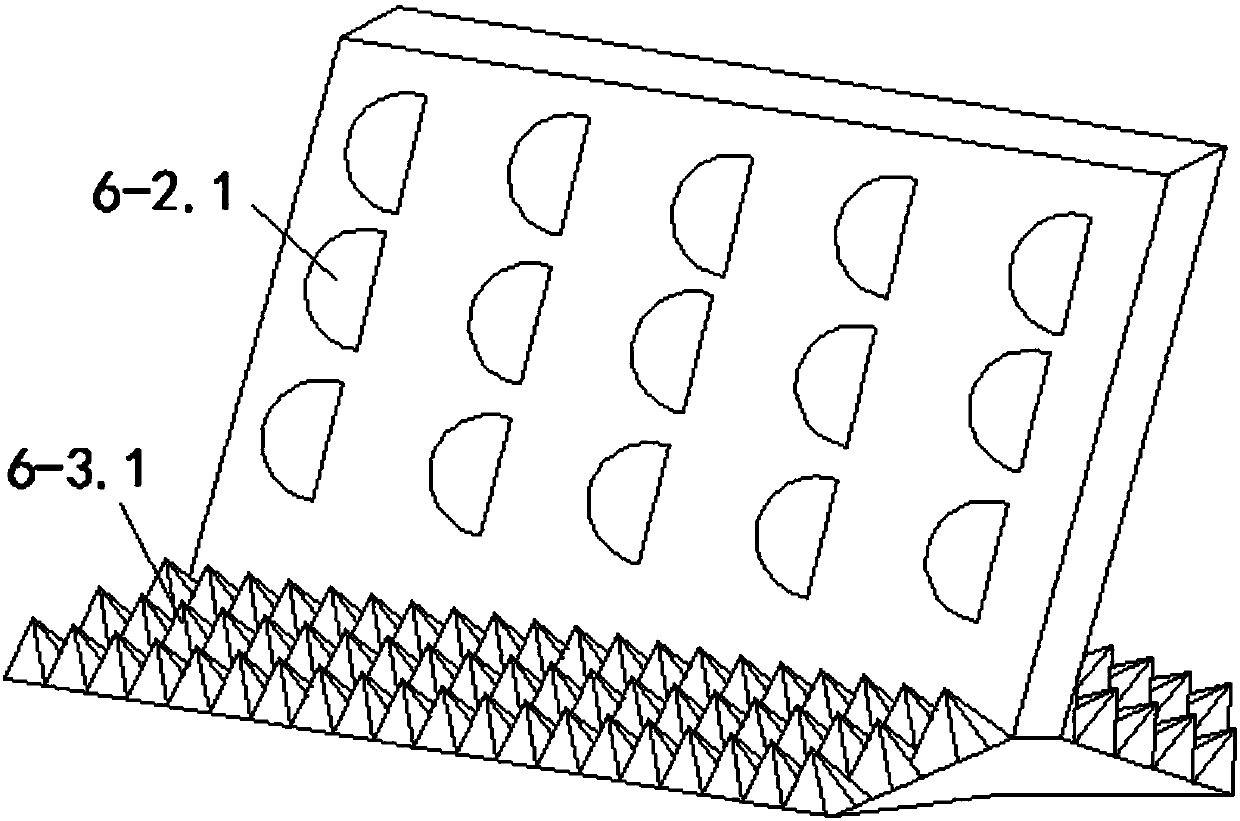

[0024] Such as image 3 and Figure 4 As shown, this embodiment is further optimized on the basis of Embodiment 1, specifically: the anti-clogging assembly 8 includes two rotating shafts 8 that are arranged at the inner bottom of the feed hopper 1-1 and are located at the same height and turn in opposite directions -1, each rotating shaft 8-1 is staggered with a number of inclined protruding rods 8-1.1, and the two rotating shafts 8-1 are driven by two motors that turn in opposite directions, which can guide the tea leaves and prevent the tea leaves Block the outlet of the feed hopper 1-1, a number of pulverizing pieces 6-2.1 are evenly arranged on the stirring plate 6-2, and a number of pulverizing teeth 6-3.1 are arranged on the inclined surface of the stirring block 6-3, and the pulverizing pieces are passed through 6-2.1 and crushing teeth 6-3.1 Preliminarily crushing the tea tree leaves during the stirring process can make the tea tree leaves more fully contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com