Method for recycling dimethyl sulfoxide from explosive-containing dimethyl sulfoxide waste liquid

A technology for recovering dimethyl sulfoxide and waste liquid, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of increasing equipment energy consumption, not being able to discharge directly, and producing micro-odor, etc., to achieve Fast and efficient recovery, pollution reduction, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

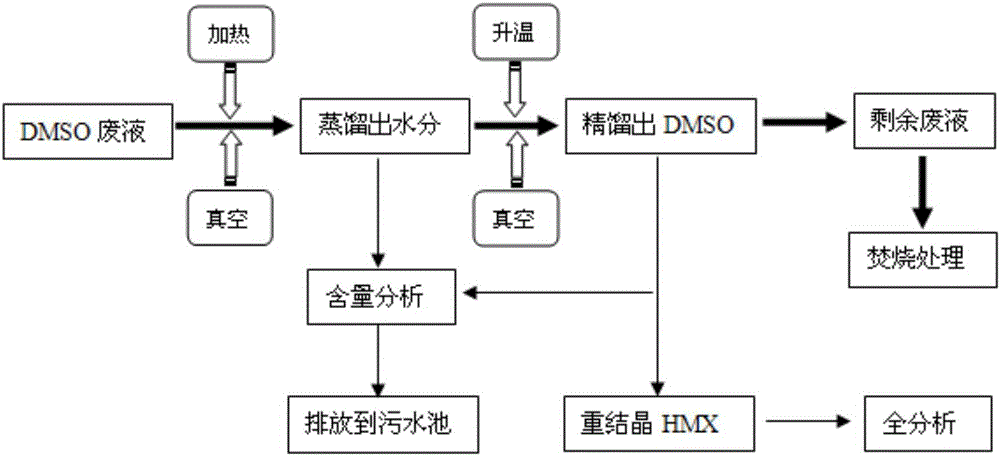

Method used

Image

Examples

Embodiment 1

[0025] Add 600ml of explosive dimethyl sulfoxide waste liquid (DMSO waste liquid) into a 1L distillation flask, turn on the condensed water, vacuum degree controller, and turn on the oil bath heating device. As the temperature rises, when the oil bath temperature reaches 66 ℃, when the vacuum reaches 0.084MPa, there will be reflux liquid, and the reflux temperature is 50℃. Continue to increase the heating temperature, the oil bath temperature is 90°C, and the vacuum degree is 0.088Mpa. After the liquid is extracted for a period of time, the reflux liquid is significantly reduced. Stop heating, turn off the vacuum system, and turn off the condensed water.

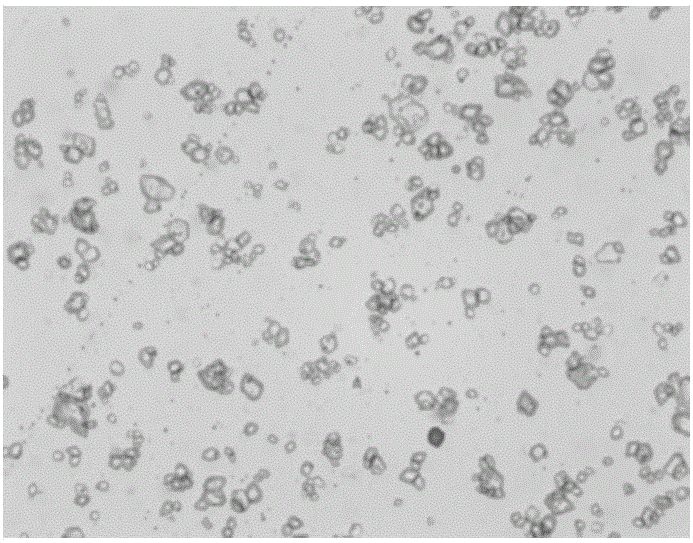

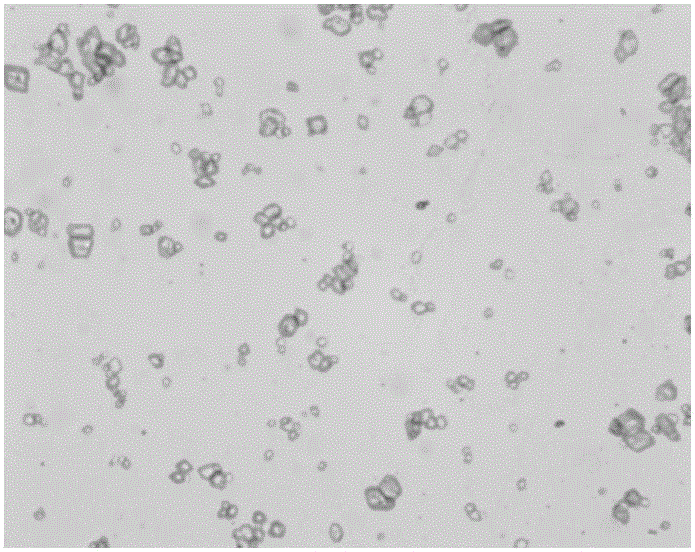

[0026] Add the remaining DMSO waste liquid after distillation into the rectification bottle, and carry out vacuum distillation operation. Gradually increase the heating temperature and vacuum degree. When the solution temperature reaches about 110°C and the vacuum degree reaches about 0.092Mpa, liquid reflux occurs. At this ...

Embodiment 2

[0034] Add 600ml of DMSO waste liquid into a 1L distillation bottle, turn on the condensed water and vacuum degree controller, and turn on the oil bath heating device. As the temperature rises, when the oil bath temperature reaches 66°C and the vacuum degree reaches 0.082Mpa, there will be reflux A liquid developed and the reflux temperature was 52°C. Continue to increase the heating temperature, the oil bath temperature is 88°C, and the vacuum degree is 0.088Mpa. After the liquid is produced for a period of time, the reflux liquid is significantly reduced. Stop heating, turn off the vacuum system, and turn off the condensed water.

[0035] Add the remaining DMSO waste liquid after distillation into the rectification bottle, and carry out vacuum distillation operation. Gradually increase the heating temperature and vacuum degree. When the solution temperature reaches about 110°C and the vacuum degree reaches about 0.092Mpa, liquid reflux occurs. At this time, the reflux temper...

Embodiment 3

[0037] Add 600ml of DMSO waste liquid into a 1L distillation bottle, turn on the condensed water and vacuum degree controller, and turn on the oil bath heating device. As the temperature rises, when the oil bath temperature reaches 66°C and the vacuum degree reaches 0.084Mpa, there will be reflux A liquid developed and the reflux temperature was 50 °C. Continue to increase the heating temperature, the oil bath temperature is 86°C, and the vacuum degree is 0.088Mpa. After the liquid is extracted for a period of time, the reflux liquid is significantly reduced. Stop heating, turn off the vacuum system, and turn off the condensed water.

[0038] Add the remaining DMSO waste liquid after distillation into the rectification bottle, and carry out vacuum distillation operation. Gradually increase the heating temperature and vacuum degree. When the solution temperature reaches about 112°C and the vacuum degree reaches about 0.091Mpa, liquid reflux occurs. At this time, the reflux temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com