A double-tower continuous feeding rectification system and control method

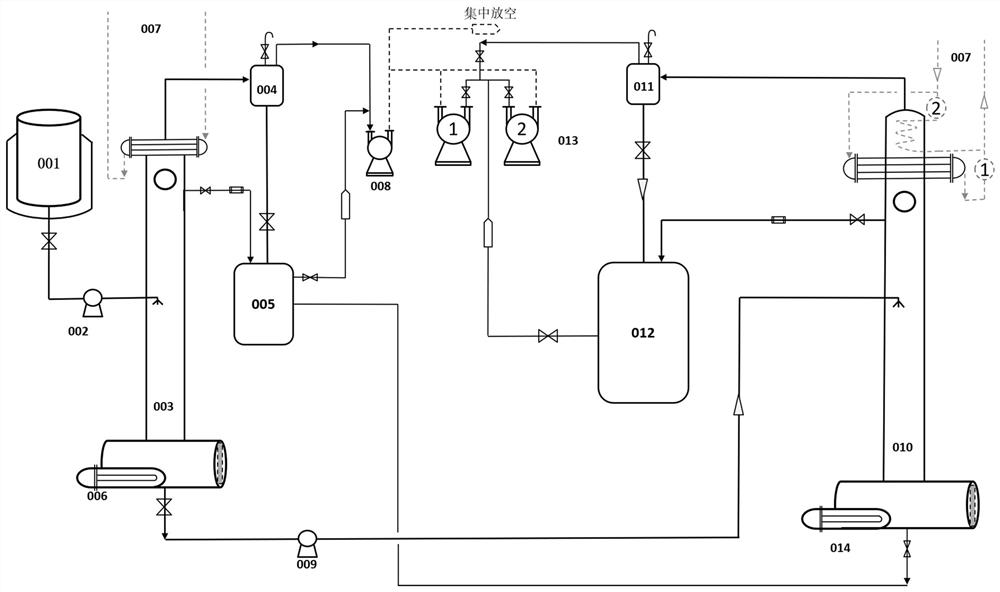

A control method and material supply technology, applied in the direction of distillation adjustment/control, fractionation, organic chemistry, etc., can solve the problems that the feeding process cannot be guaranteed to be continuous, safe, efficient, separation efficiency cannot be guaranteed, and the batching system is unreasonable, etc., to achieve Improve the efficiency of separation and purification, improve the purity of the product, and the effect of continuous feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

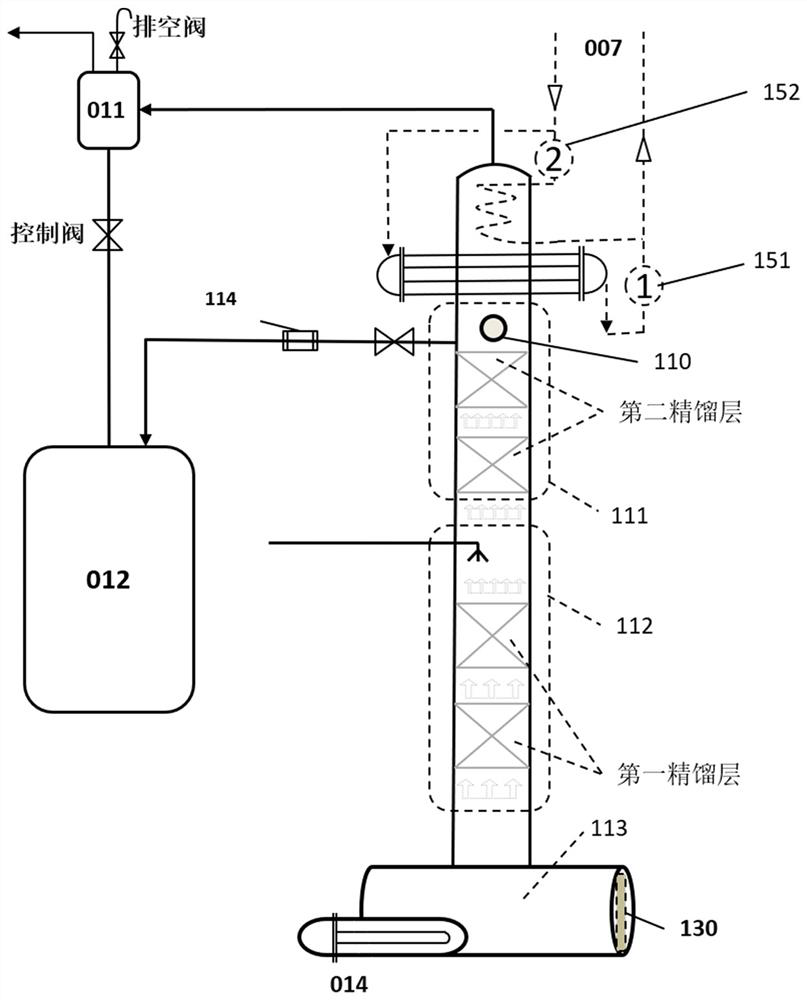

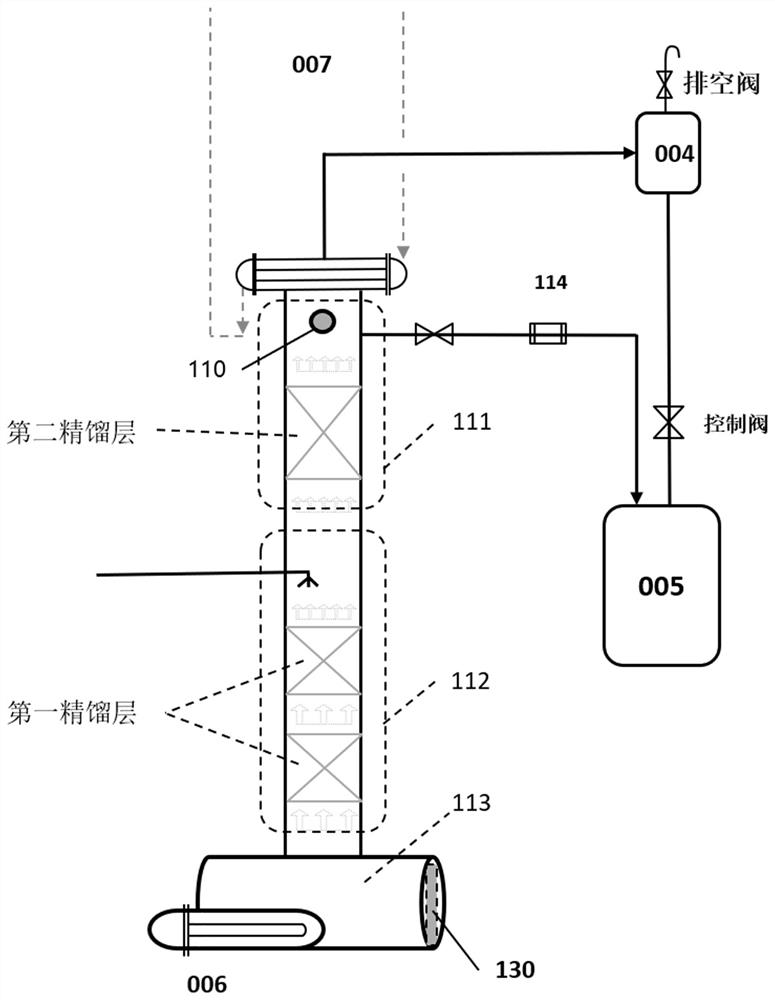

[0073] Embodiment 1 A kind of control method of double-tower continuous feeding rectification

[0074] This implementation case provides a kind of rectification purification process of chemical raw material butyrolactam, and its steps are as follows:

[0075] Step 1: Loading Control

[0076] Send the butyrolactam to be rectified to the 1# rectification tower, the purity is 83%, the moisture content is 14%, and the other impurity content is 3%, and the liquid level of the tower kettle is controlled to 90%.

[0077] Step 2: Initial distillation process control

[0078] Turn on the vacuum pump, adjust the emptying valve of the vacuum buffer tank, control the vacuum degree of the tower kettle to -80±1kpa, control the temperature of the tower kettle at 160±2℃, and keep the pressure difference of the tower top and tower kettle at 0.5±0.1kpa, and wait until the tower top temperature reaches At about 60±1°C, light components can be seen from the sight glass. When the temperature of ...

Embodiment 2

[0083] Embodiment 2 A kind of control method of two-tower continuous feeding rectification

[0084] This implementation case provides a kind of rectification purification process of chemical raw material butyrolactam, and its steps are as follows:

[0085] Step 1: Loading Control

[0086] Send the butyrolactam to be rectified to the 1# rectification tower, the purity is 90%, the moisture content is 8%, and the other impurity content is 2%, and the liquid level in the tower kettle is controlled to 80%.

[0087] Step 2: Initial distillation process control

[0088] Turn on the vacuum pump, adjust the emptying valve of the vacuum buffer tank, control the vacuum degree of the tower kettle to -70±1.5kpa, control the temperature of the tower kettle at 200±3℃, keep the pressure difference of the tower top and tower kettle at 1.5±0.2kpa, wait for the tower top temperature When it reaches about 70±1°C, light components can be seen from the sight glass. When the temperature of the dis...

Embodiment 3

[0093] Embodiment 3 A kind of control method of two-tower continuous feeding rectification

[0094] This implementation case provides a kind of rectification purification process of chemical raw material butyrolactam, and its steps are as follows:

[0095] Step 1: Loading Control

[0096] Send the butyrolactam to be rectified to the 1# rectification tower, the purity is 95%, the moisture content is 4%, the other impurity content is 1%, and the liquid level of the tower still is controlled to 60%.

[0097] Step 2: Initial distillation process control

[0098]Turn on the vacuum pump, adjust the emptying valve of the vacuum buffer tank, control the vacuum degree of the tower kettle to -50±1kpa, control the temperature of the tower kettle at 240±2℃, keep the pressure difference of the tower top and tower kettle at 1±0.2kpa, wait until the temperature of the tower top reaches At about 85±1°C, light components can be seen from the sight glass. When the temperature of the discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com