Construction waste purifying and separating device

A technology for purification and separation of construction waste, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve problems such as large water consumption, achieve high purification and separation efficiency, good market promotion prospects, and low manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is further described in detail through specific implementation methods:

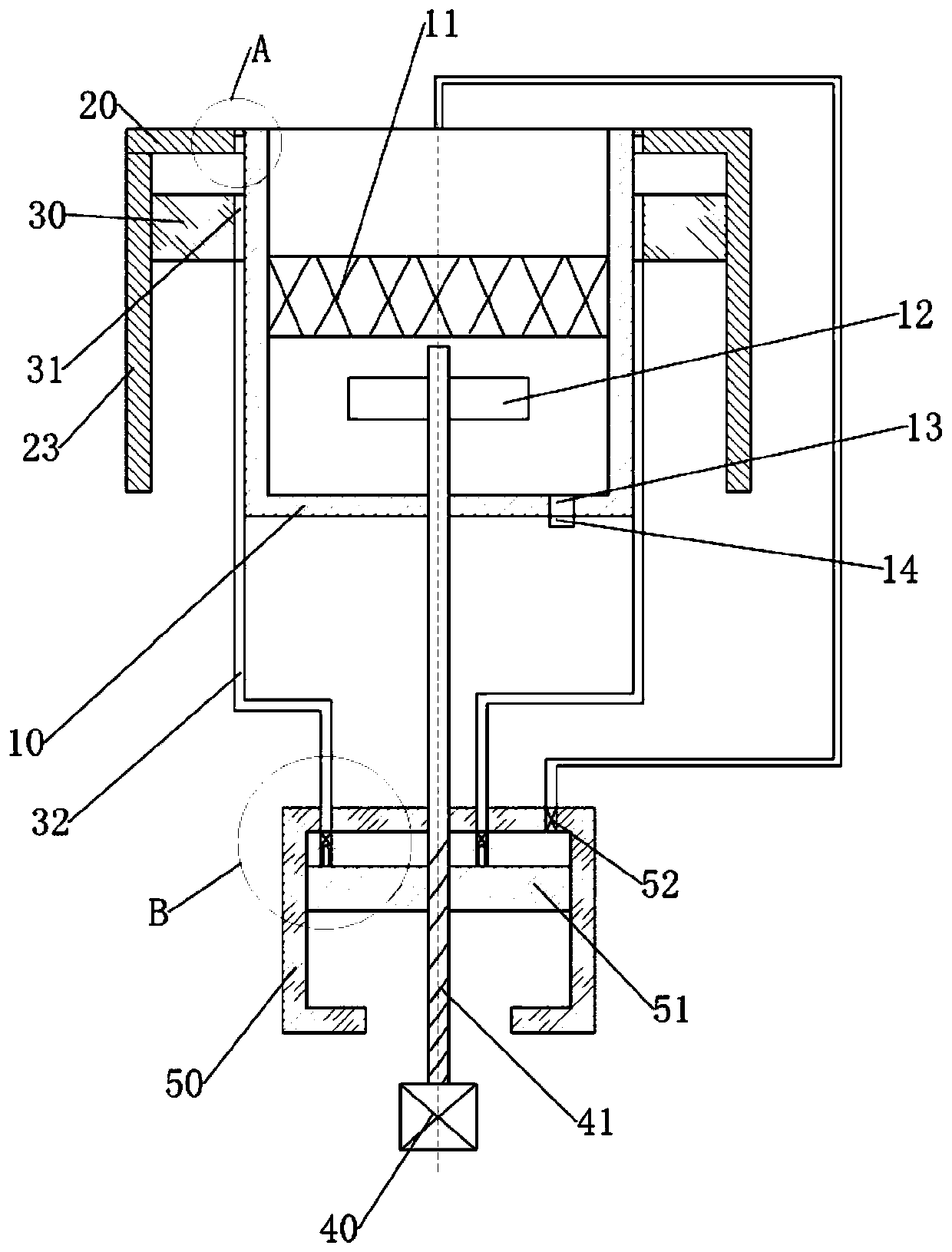

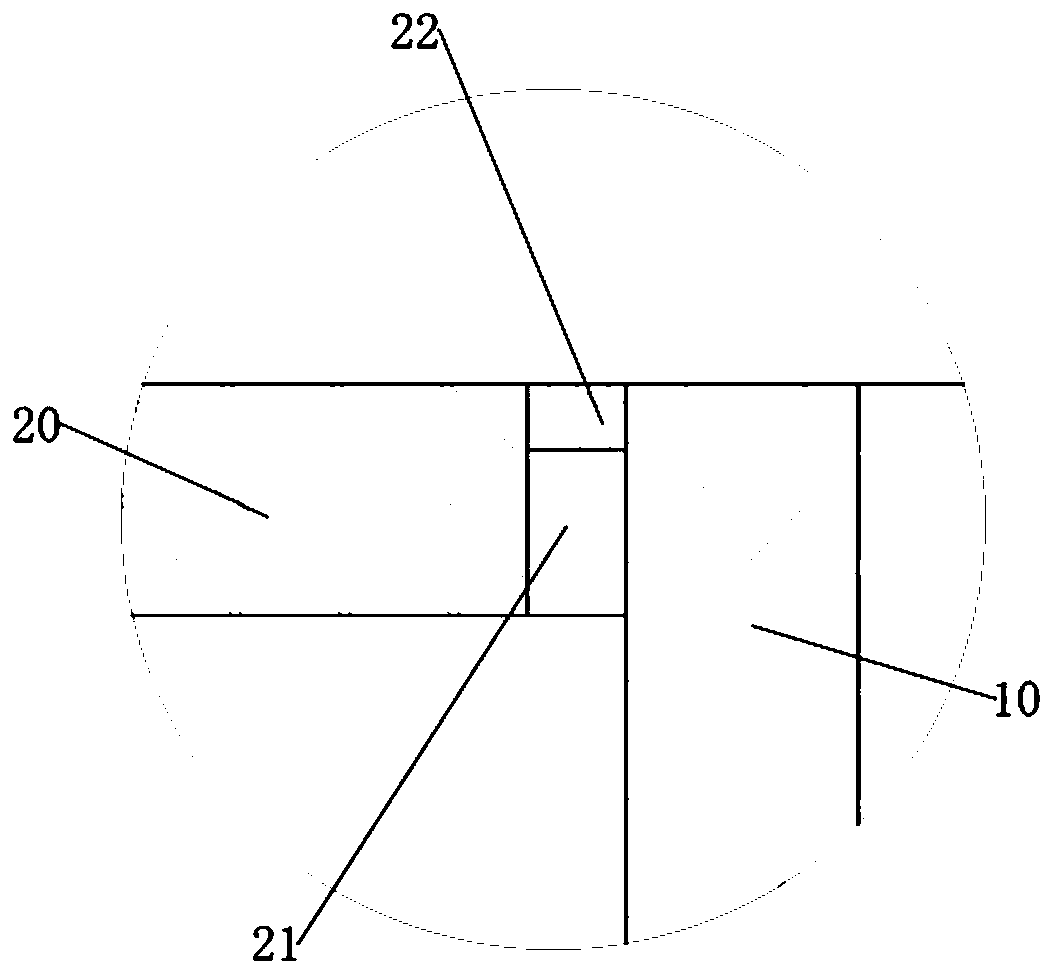

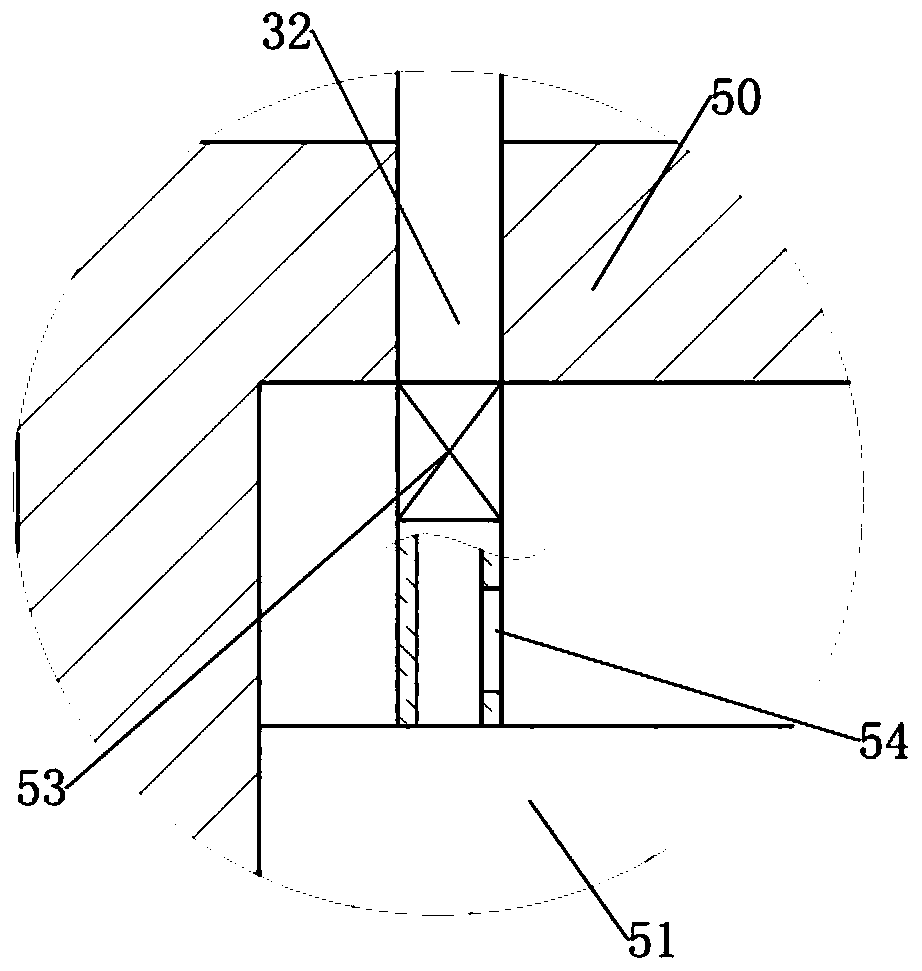

[0031] The reference signs in the drawings of the description include: box body 10, filter frame 11, blade 12, drain port 13, cock 14, ring disc 20, first through hole 21, filter screen 22, cylinder 23, ring Slider 30, second through hole 31, connecting rod 32, motor 40, threaded rod 41, cylinder body 50, piston 51, one-way water outlet valve 52, one-way water inlet valve 53, third through hole 54.

[0032] The embodiment is basically as attached figure 1 , attached figure 2 , attached image 3 Shown:

[0033] A construction waste purification and separation device, such as figure 1 As shown, it includes a box body 10 and a frame, the box body 10 is fixed on the frame, the box body 10 is filled with water, the box body 10 is cylindrical, the top of the box body 10 is open, and a filter frame is slidably connected in the box body 10 11. The filter frame 11 is cylindrical, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com