Inner barrel structure of wine-making distillation equipment

A technology of distillation equipment and inner cylinder, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of high temperature and time requirements, large space, and low distillation efficiency, and achieve the effect of ensuring steam channels, simple structure, and uniform distillation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

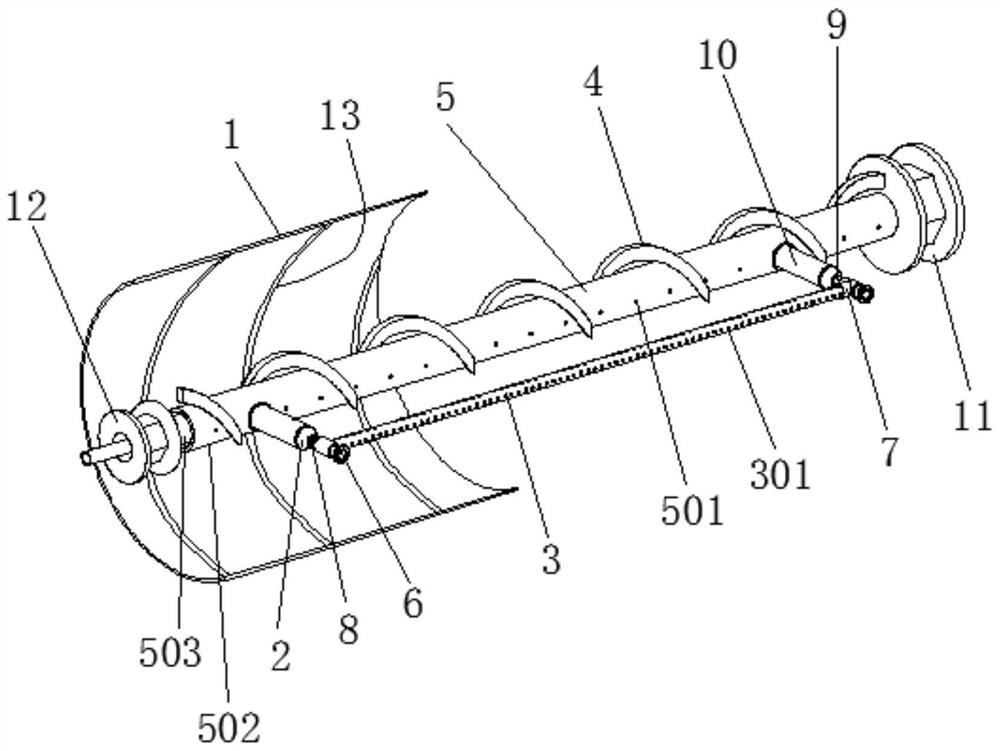

[0041] Such as figure 1 As shown, after the cylinder body 1 is connected with the connecting head 6, it becomes an integral body with the wine taking pipe assembly 5, and rotates under the drive of the large rotary joint 11 and the small rotary joint 12.

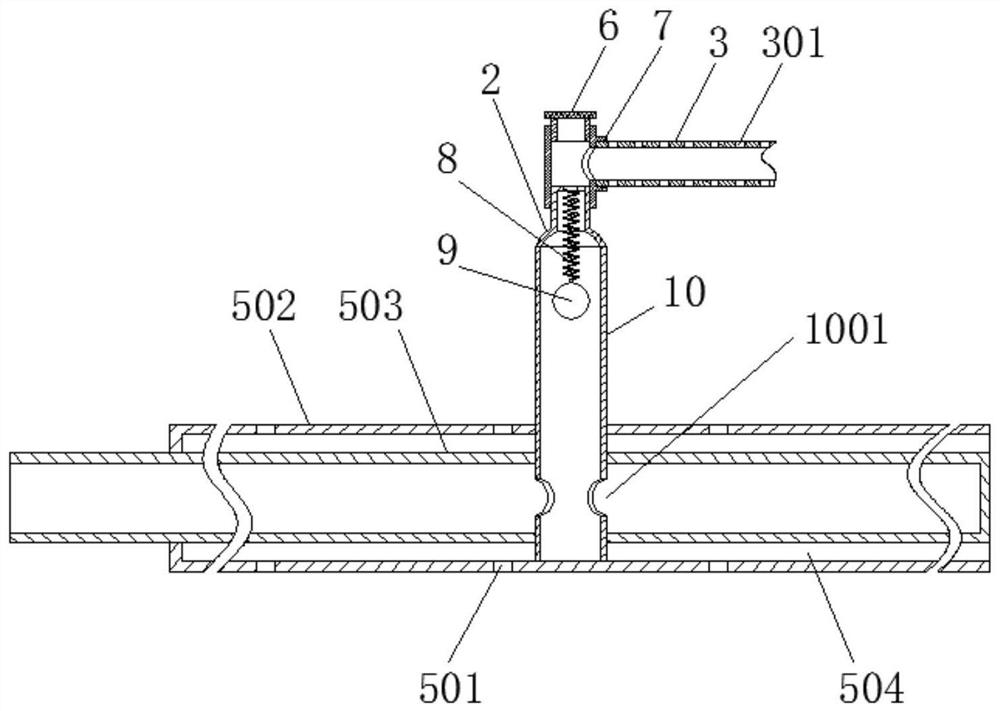

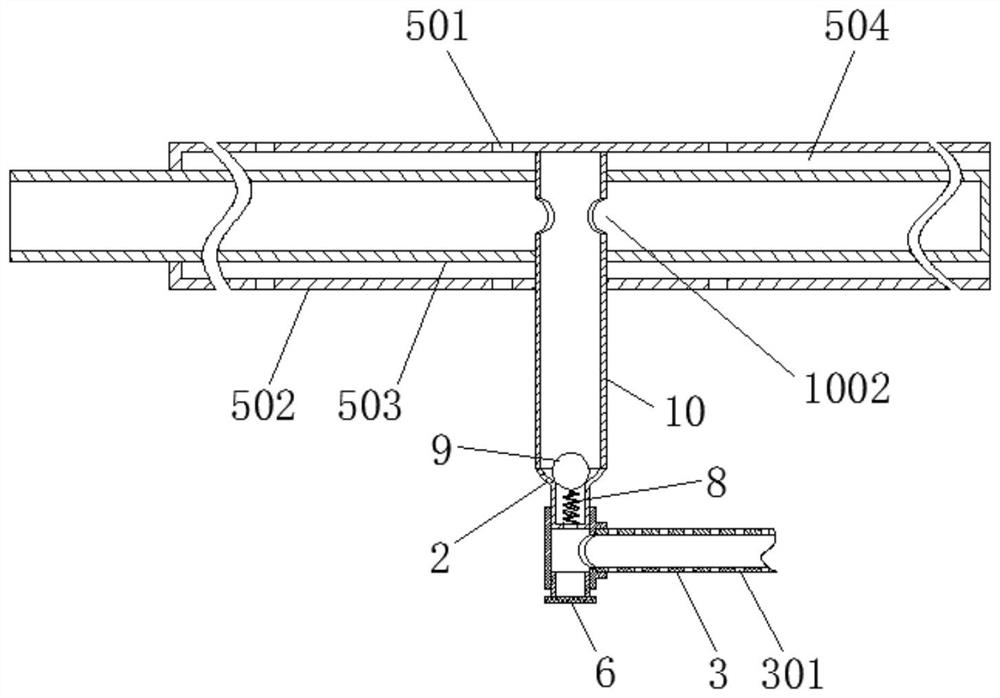

[0042] During the working process, the high-temperature steam is sent in from the open end of the steam delivery pipe 502, and because the end of the wine-taking pipe 503 inside the steam delivery pipe 502 is closed, the high-temperature steam can only enter the space between the steam delivery pipe 502 and the wine-taking pipe 503 That is, in the steam passage 504, because the other end of the steam passage 504 is closed, high-temperature steam can only be ejected from the steam discharge hole 501 to heat the fermented grains and realize the distillation process. Due to the external spraying of high-temperature steam and the loose rotation of the wine grains, the wine grains will not block the wine steam collection hole 301...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com