Device for inhibiting fluidizing gas short circuit of bubbling bed-transport bed stacked reactor

A technology of fluidized gas and bubbling bed, applied in the field of fluidized bed, can solve problems such as escape, achieve high accuracy, solve material carrying, and improve the efficiency of gas-solid reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

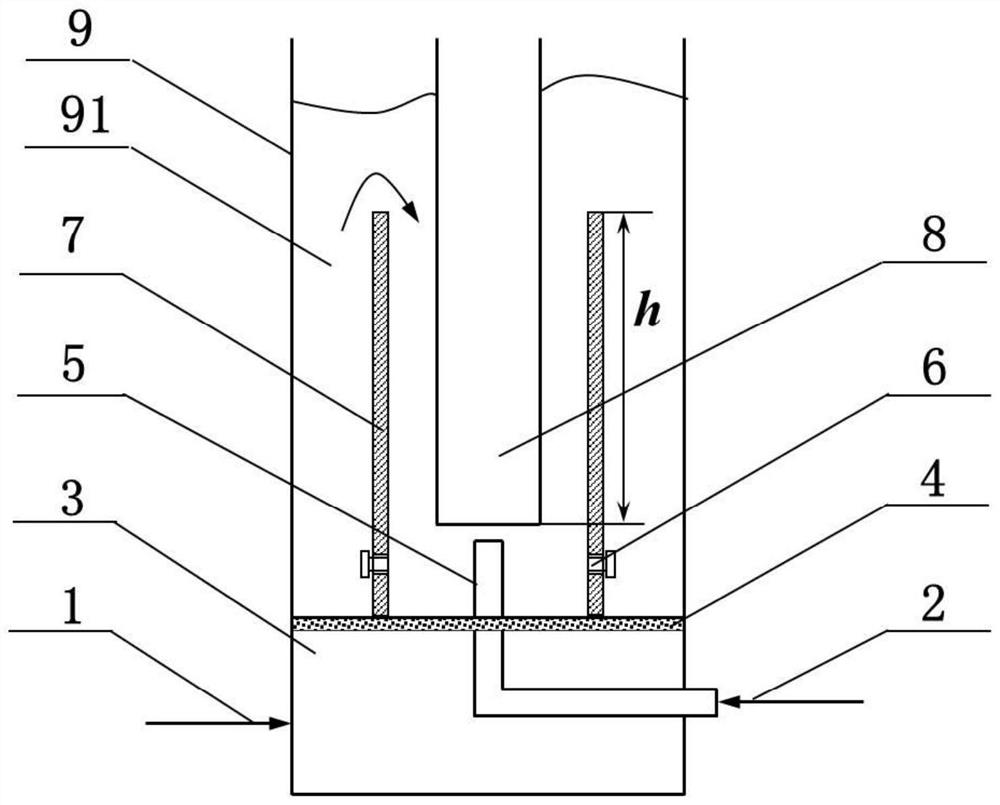

[0025] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0026] see figure 1 , a device for suppressing the short circuit of the bubbling bed-transportation bed stacking reactor fluidized gas of the present application comprises a bubbling bed 9, the bottom of the bubbling bed 9 is an air chamber 3, the top of the air chamber 3, the bubbling bed 9 An air distribution plate 4 is arranged between the bottoms; a central air duct 5 and a riser 8 are arranged coaxially with the bubbling bed 9, and the entrance of the central air duct 5 passes through the air distribution plate 4 and extends into the bubbling bed 9 , the inlet of the riser 8 and the outlet of the central air duct 5 are arranged at intervals up and down, and the inner diameter of the riser 8 is larger than the inner diameter of the central air duct 5, so that the material can enter the riser 8 from the space between the two under the action of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com