Device and method for performing spheroidizing treatment on powder by using line-focus solar furnace

A technology of spheroidization treatment and powder spheroidization section, which is applied in the field of concentrated solar energy utilization and materials, to achieve the effects of high spheroidization efficiency, high quality, and controllable delivery volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In order to facilitate the understanding of this embodiment, some terms in the field of solar energy utilization and material processing involved in this embodiment are briefly introduced as follows:

[0045] "Heliostat" refers to an optical device that reflects the light of the sun or other celestial bodies in a fixed direction, also known as a star-fixing mirror.

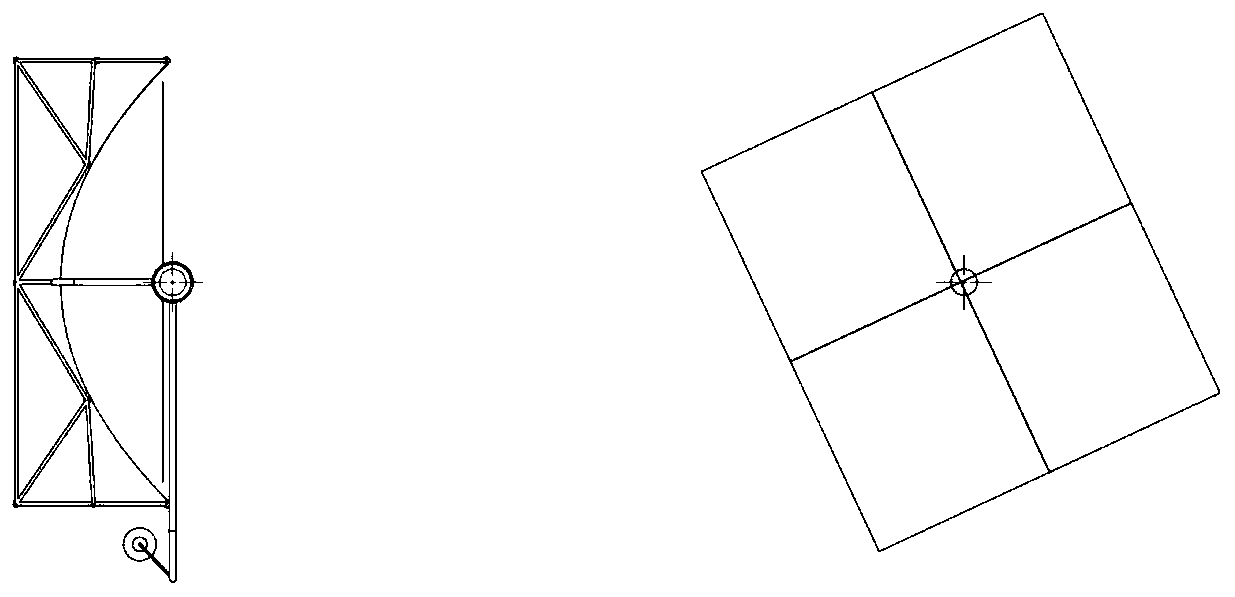

[0046] "Slot concentrator" refers to a line-focus concentrator with a trough-shaped reflector section for reflecting and converging solar radiation.

[0047] "Protective gas" means a gas that prevents chemical reactions of powders at high temperatures, especially oxidation reactions. In the scheme of the present invention, it can be N 2 Or rare gases such as helium (He), neon (Ne), argon (Ar), krypton (Kr), xenon (Xe) or their mixtures.

[0048] "Vacuum tube" refers to a tube with double-ended openings and a vacuum interlayer. In order to absorb sunlight, the outer tube is a glass light-transmitting tube,...

Embodiment 2

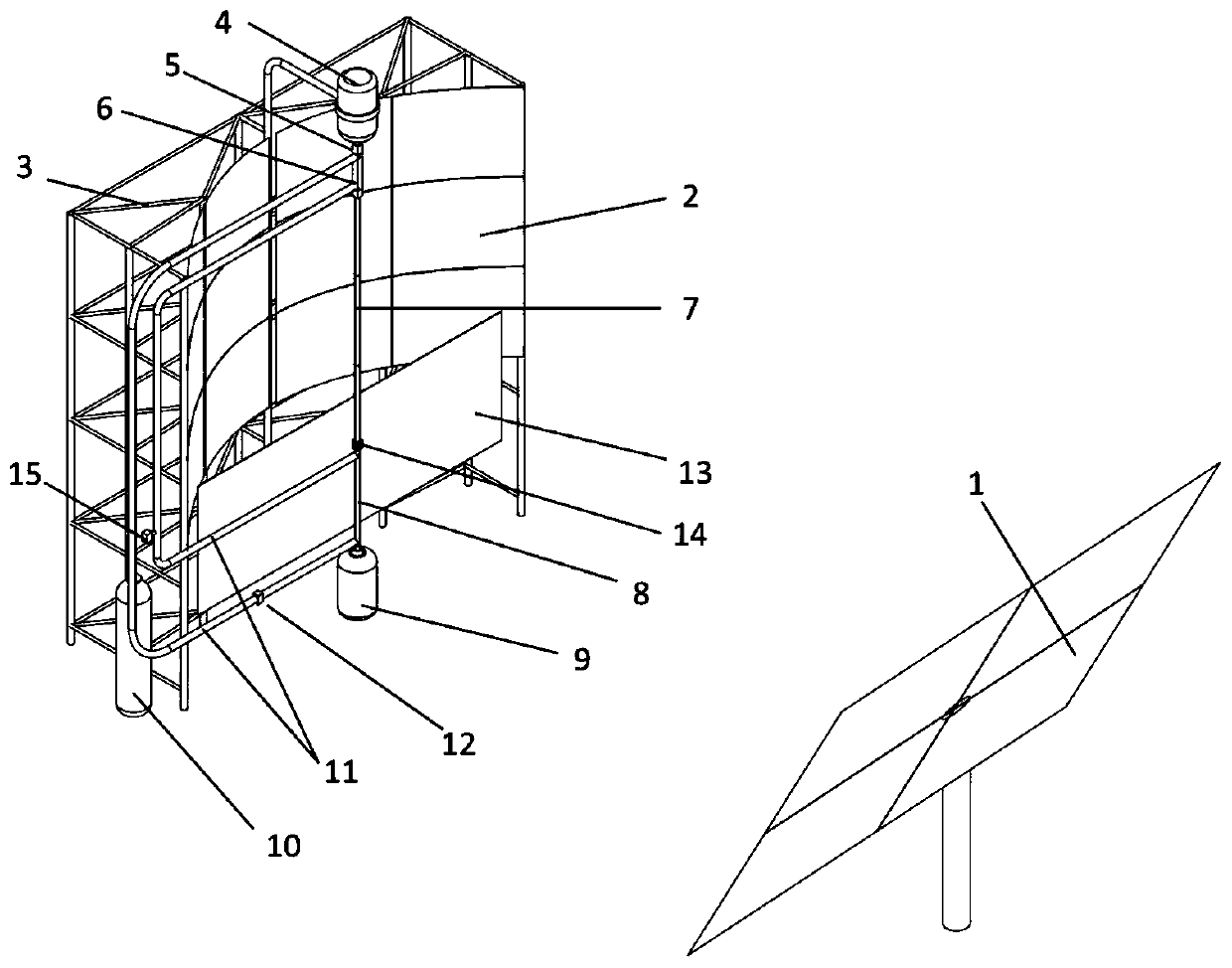

[0054] In this embodiment, the method of spheroidizing powder is introduced in detail.

[0055] First, open the protective gas cylinder 10, turn on the fan 12, and discharge the air in the protective gas circuit and the powder drop channel, wherein the powder drop channel is composed of the powder dispersing device 5, the powder preheating section 6, the powder spheroidizing section 7, and the powder drop channel. The cooling sections 8 are sequentially connected to form;

[0056] Secondly, start the heliostat to track the sun, reflect the sunlight to the trough concentrator, and the trough concentrator will reflect the sunlight twice to form a stable line concentration at the position of the powder spheroidizing section 7 ;

[0057] Finally, the powder storage device 4 is opened, and the powder falls freely in the powder preheating section 6 , powder spheroidizing section 7 , powder cooling section 8 and powder collecting device 9 after passing through the powder dispersing ...

Embodiment 3

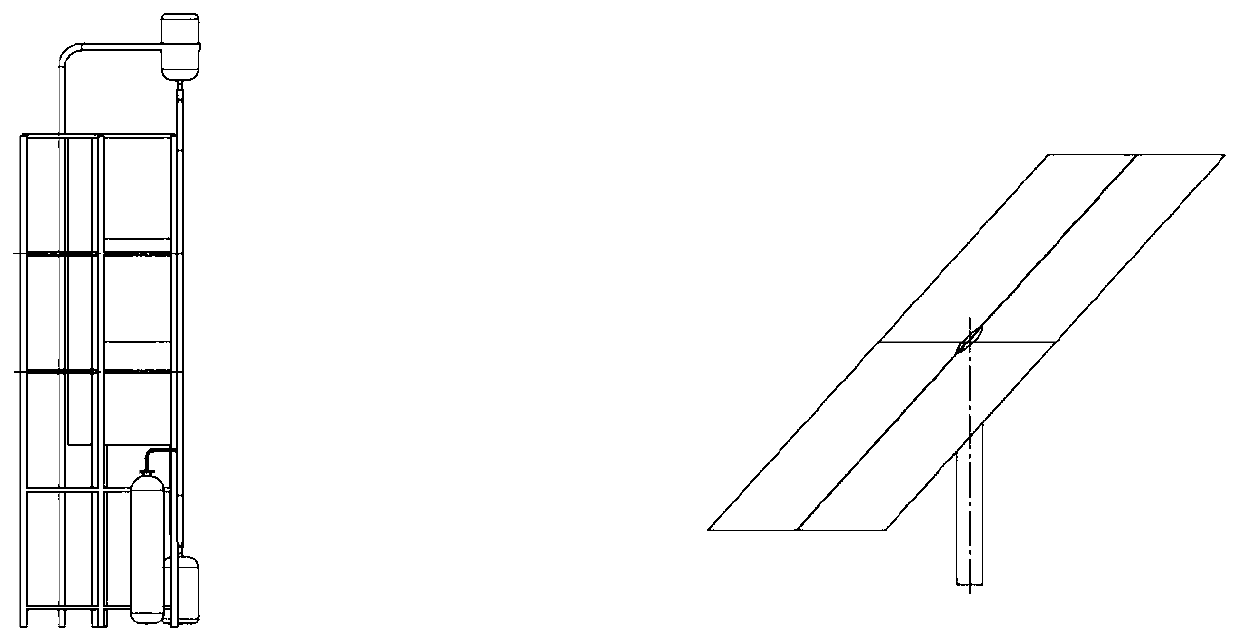

[0060] This embodiment discloses an aluminum alloy powder spheroidization device utilizing concentrated solar energy, according to figure 1 The powder spheroidization processing system is established as shown. Among them, a 10m×12m heliostat is used, a trough concentrator with an opening of 5.77m and a height of 8m is used, and a solar trough vacuum heat collection tube with an outer diameter of 120mm is used for the powder spheroidization section (the inner tube is a metal tube with an outer diameter of 70mm , metal tube thickness 3mm). Nitrogen was used as a protective gas. In the solar radiation is 600W / M 2 Under moderate weather conditions, the metal tube can be heated to 850 degrees Celsius. The aluminum alloy powder falls in a pipe diameter of 64mm—the average temperature of the pipe wall is 850 degrees Celsius—and at 7.5m, it can ensure that the aluminum alloy powder with a particle size of less than 60 microns is completely melted, and the melted aluminum alloy powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com