Crop dryer

A technology for drying devices and crops, applied in dryers, heating devices, drying chambers/containers, etc. of static materials, can solve the problems of large loss of index components, high operating costs, poor quality of dry products, etc., and achieve the index components of dry products. High, low operating costs, the effect of improving the content of index components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

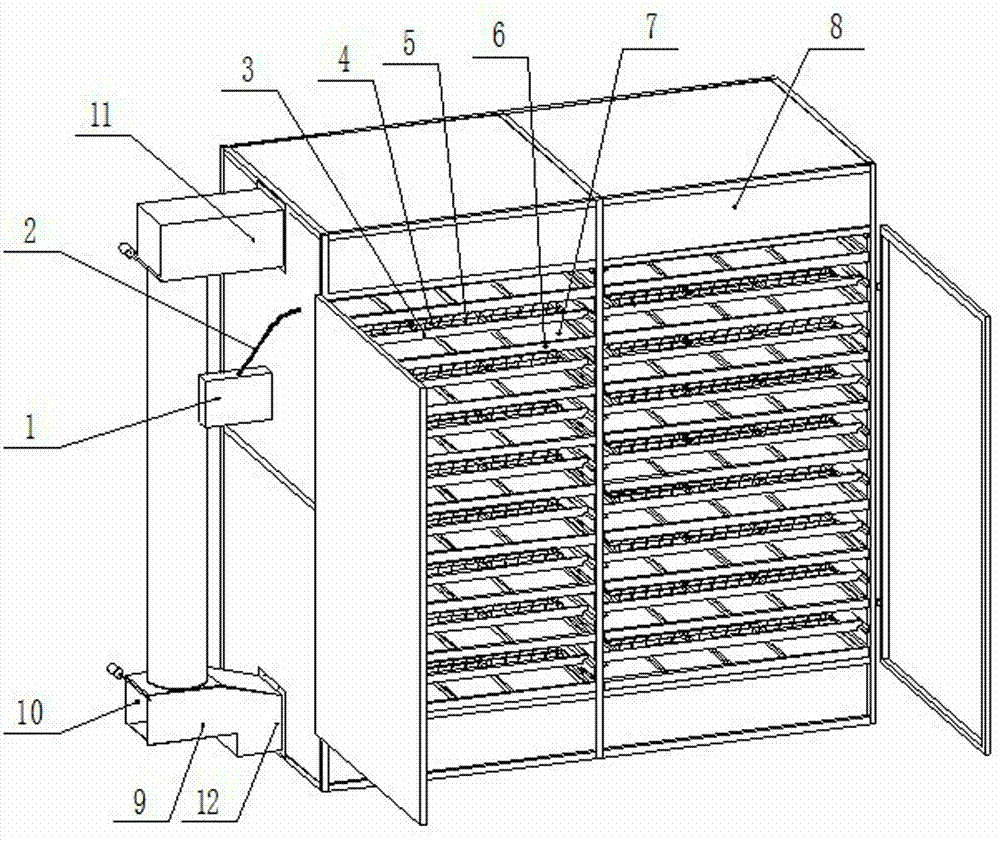

Embodiment 1

[0014] refer to figure 1 , a crop drying device, consisting of a rectangular box body 8, a metal receiving plate 6 arranged in the box body 8, an electrode frame 3 on the metal receiving plate 6, and a dehumidifier 9 connected to the box body 8 outside the box body 8 It is composed of an electrostatic generator 1, the box body 8 is connected to the positive pole of the high voltage cable 2, the electrode frame 3 is connected to the negative pole of the high voltage cable 2, the material receiving plate 6 is grounded, the box body 8 is provided with an air inlet 12 and an air outlet 11, and the dehumidifier 9 is provided with There is an air inlet and outlet reversing plate 10, an air inlet 12 and an air outlet 11 are arranged on the box body 8, the air outlet 11 of the box body 8 is connected to the return air outlet of the dehumidifier 9, and the air inlet 12 of the box body 8 is connected to the outlet of the dehumidifier 9. tuyere,. The electrode frame 3 is also provided w...

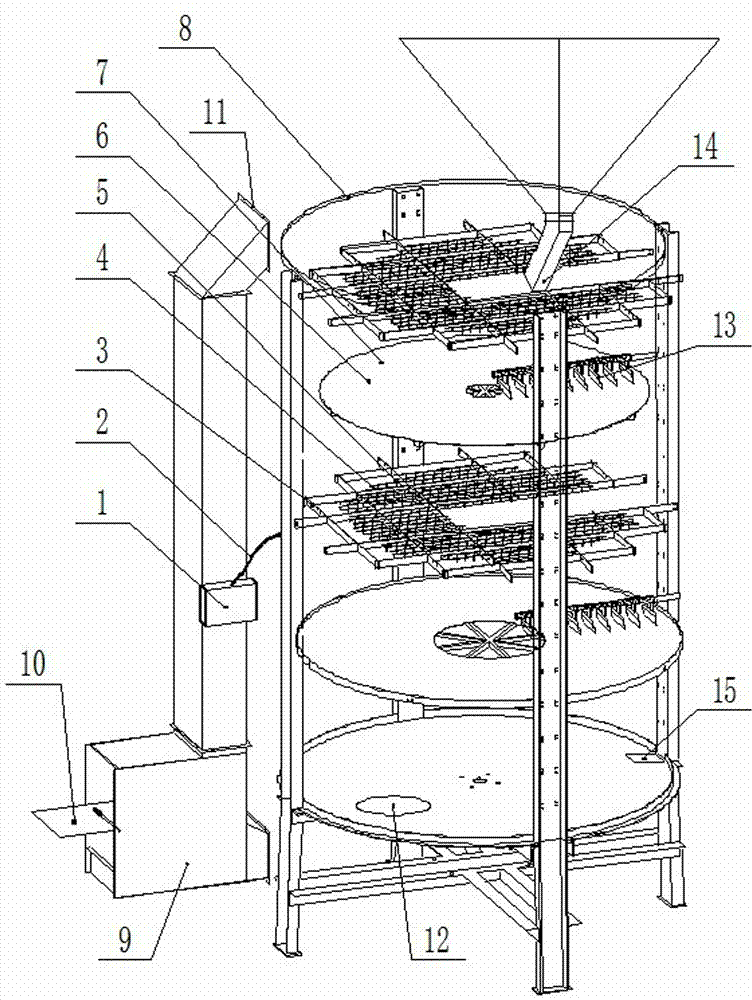

Embodiment 2

[0017] The box body 8 is cylindrical, a rake plate 13 is also arranged on the material receiving plate 6, and a discharge port 15 is arranged at the bottom of the cylindrical box body 8, and the rest are the same as those in Embodiment 1.

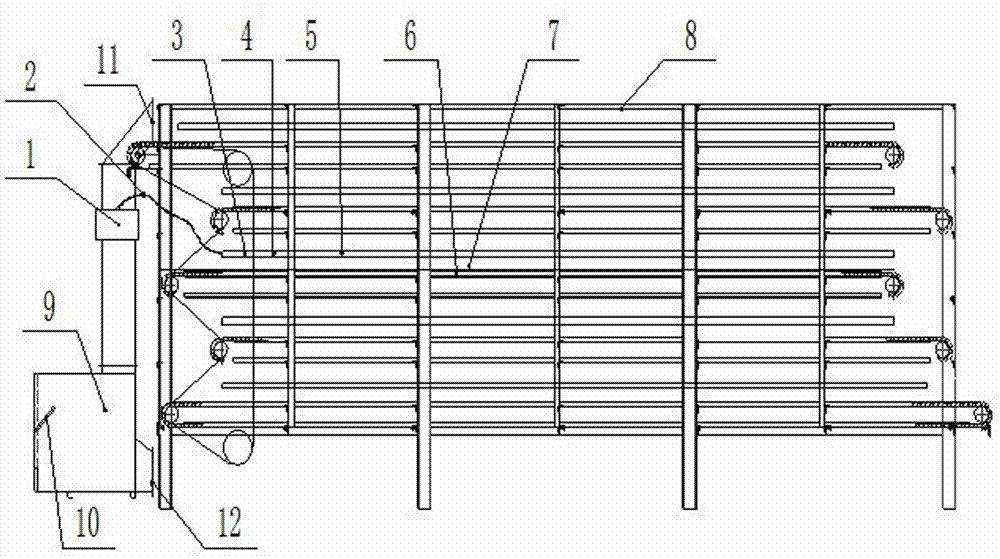

Embodiment 3

[0019] The box body 8 is in the shape of a tunnel, and the rest are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com