Patents

Literature

34 results about "Dehydropregnenolone acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

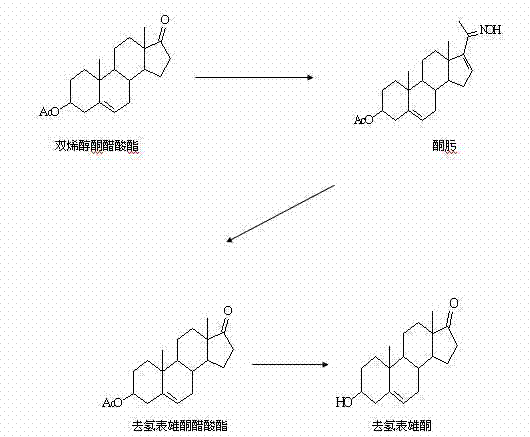

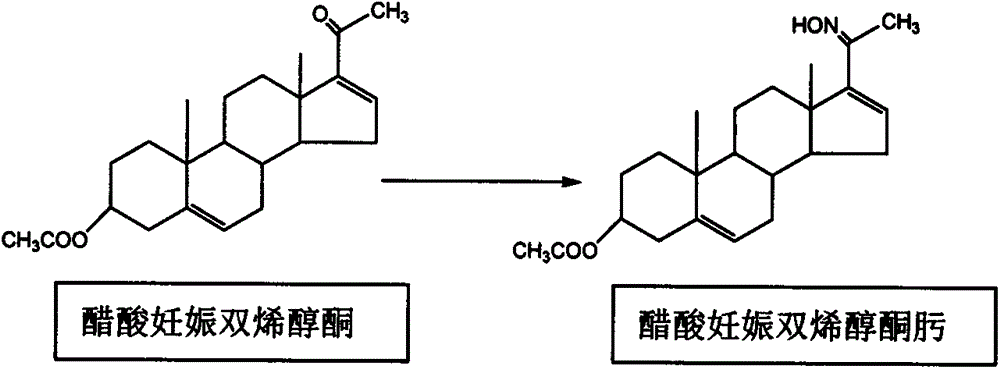

Preparation method of dehydroepiandrosterone

The invention discloses a preparation method of dehydroepiandrosterone, belongs to the technical field of medicine intermediate preparation, and is mainly used for solving the problems of higher production cost, low product yield and more serious pollution existing in the traditional dehydroepiandrosterone synthesis method. The preparation method comprises the following process steps of: (1) oximation reaction: subjecting 16-dehydropregnenolone acetate, sodium acetate and absolute ethyl alcohol with the ratio of 1:(1.2-1.5):(4-4.5) to oximation reaction to obtain 16-dehydropregnenolone acetate oxime; (2) Beckmann rearrangement hydrolysis reaction: charging the 16-dehydropregnenolone acetate oxime, chloroform, phosphorus pentoxide, hydrochloric acid and water with the ratio of 1:(6-6.5):(0.8-1.0):(0.5-0.8):(6-7.0) to obtain dehydroepiandrosterone acetate; and (3) hydrolysis reaction: charging a crude dehydroepiandrosterone acetate, methanol, potassium carbonate, hydrochloric acid, methanol and active carbon with the ratio of 1:(7.0-8.0):(0.4-0.5):(0.3-0.4):(5.0-6.0):(0.4-0.5) to obtain dehydroepiandrosterone. The preparation method has the characteristics of easiness in reaction condition control, simplicity in operation, little pollution and high yield and is mainly used for preparing dehydroepiandrosterone.

Owner:YICHENG GOTO PHARMA

Synthesis method for dehydroepiandrosterone

InactiveCN102212099AOvercoming reactivityOvercoming processingSteroidsBeckmann rearrangementSodium acetate

The invention belongs to a novel synthesis method for dehydroepiandrosterone, which comprises the following steps: oximation of 16-dehydropregnenolone acetate, Beckmann rearrangement, hydrolysis and refining to obtain a product. The synthesis method is characterized by carrying out oximation of ketone by using sodium acetate as a base and water and ethanol as solvent, carrying out Beckmann rearrangement, hydrolysis and one-pot refining reaction, reacting 16-dehydropregnenolone acetate oxime with p-toluenesulfonamide chloride, benzenesulfonyl chloride, triethylamine or N,N-dimethyl-pyridine (DMAP) in a dichloromethane solution, concentrating the solvent after reaction, adding methanol and a sodium hydroxide solution for refluxing hydrolysis, cooling and regulating the pH value to 7-8, adding activated carbon, then refluxing for 30-60 minutes, filtering, concentrating, crystallizing, and centrifuging to obtain the product. The synthesis method provided by the invention is simple to operate, and has characteristics of mild reaction conditions, high yield, low environmental pollution and the like.

Owner:HUNAN KEREY BIOTECH

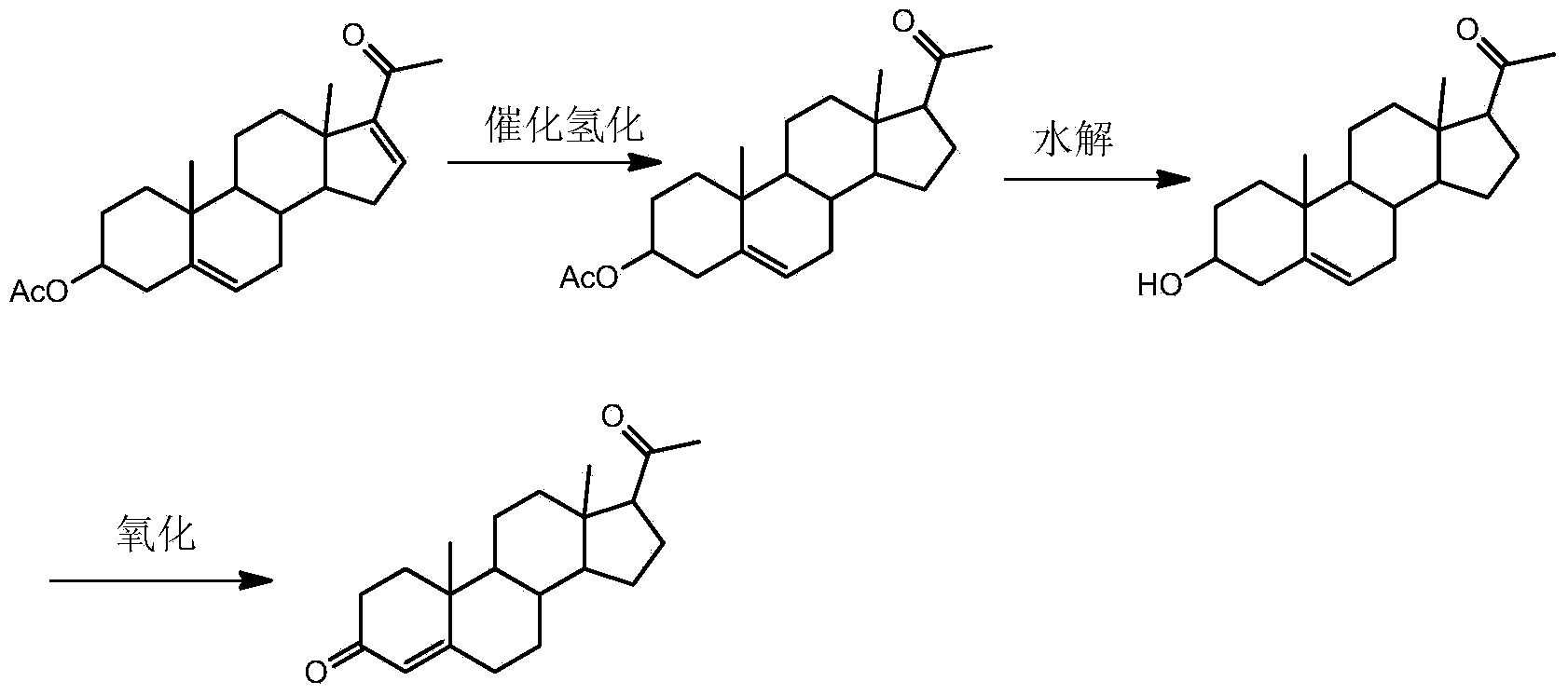

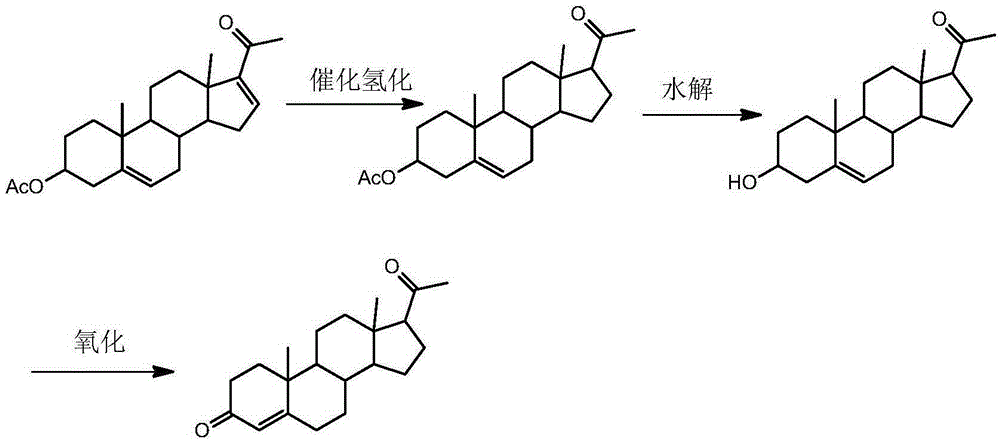

Progesterone preparation method

ActiveCN102911232ALow cost of industrializationIncrease the amount of feedSteroidsWater vaporProgesterones

A progesterone preparation method comprises the following steps: adding dehydropregnenolone acetate, a palladium-carbon catalyst and ethyl acetate in a hydrogenation tank, wherein the hydrogenation reaction temperature is 35-45 DEG C, the hydrogenation pressure is 0.02-0.03 MPa, and the reaction time is 2.0-5.0 hours; adding an inorganic alkaline solution for hydrolysis reaction about 1.5-3.0 hours under the temperature of 25-30 DEG C; swashing by Mr Wolfowitz oxide water vapor so as to obtain progesterone crude product, obtaining progesterone pretreatment product sequentially through beating processing by 120# gasoline and suction filtration, dissolving the pretreatment product in ethanol, adding active carbon so as to obtain filter cakes sequentially through heating, reflowing, filtering while the solution is hot, filtrate cooling and re-filtering, and drying filter cakes to obtain the pure progesterone. According to the invention, the palladium-carbon catalyst and the vinegar naphtha solvent are adopted, the hydrogenation reaction can be carried out at near ordinary temperature, the progesterone yield is more than 72 percent, the purity is more than 99.5 percent, and both the energy consumption and manufacturing cost are reduced.

Owner:HUBEI DANAO PHARMA CO LTD +1

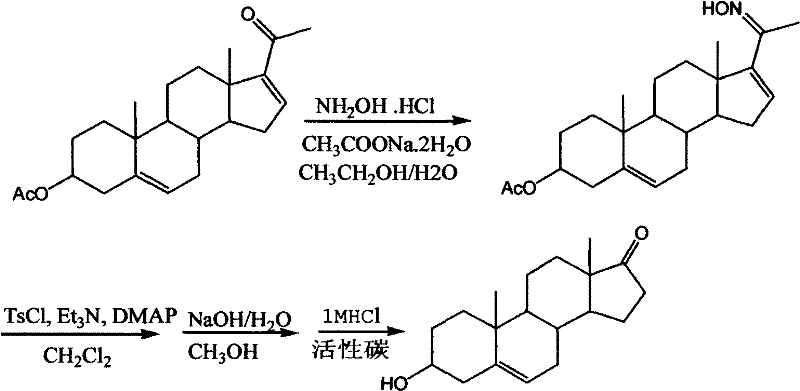

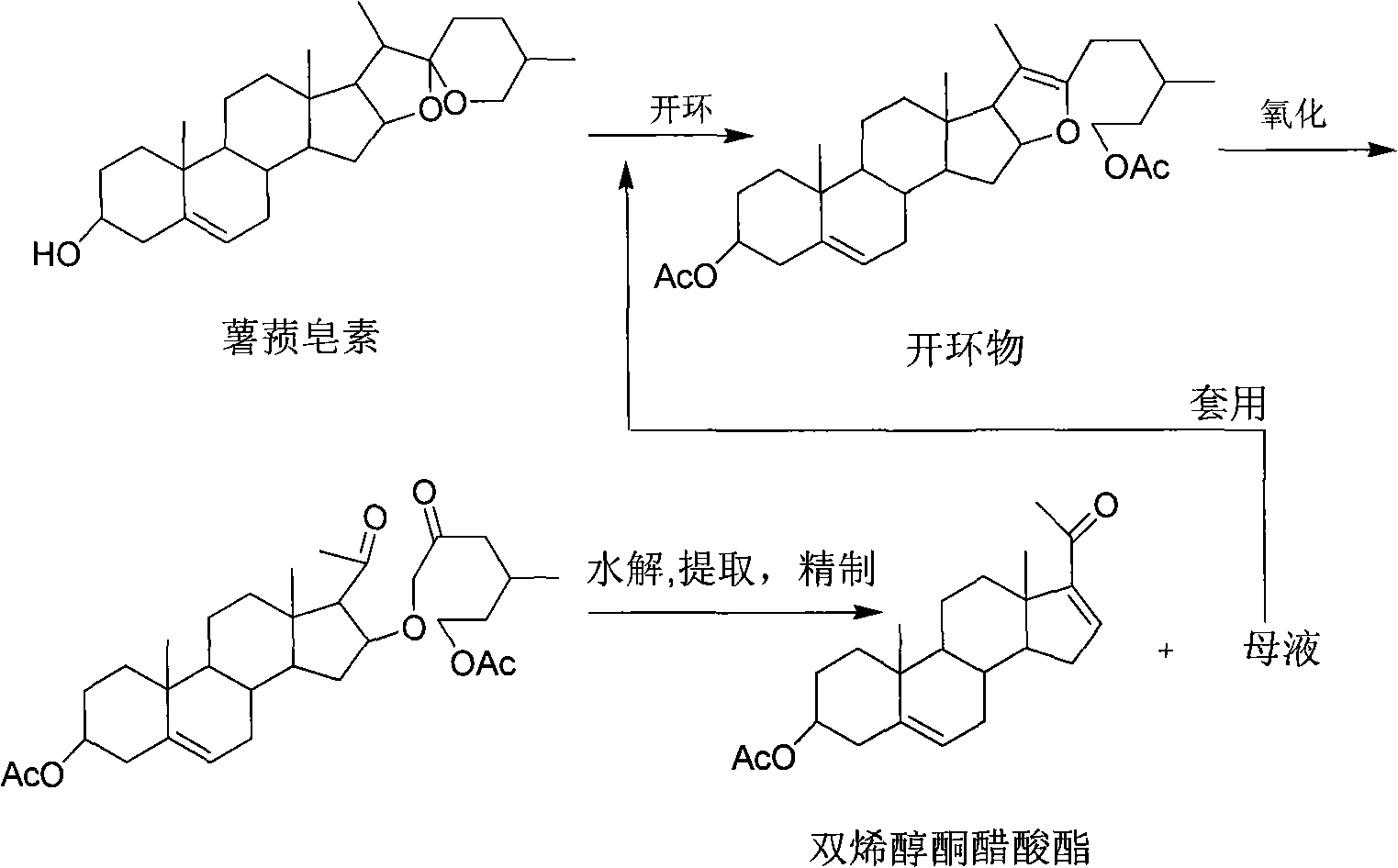

Method for preparing 16-dehydropregnenolone acetate by multistage filtration and recrystallization

The invention relates to a method for preparing 16-dehydropregnenolone acetate by multistage filtration and recrystallization, comprising the following steps of: high-pressure ring-opening (cracking), oxidizing, hydrolyzing and extracting, multistage filtering after posttreatment, recrystallizing and refining, recovering and applying mother liquor, and the like. In the method, by multistage filtration and recrystallization technologies the contents of most 16-dehydropregnenolone acetate product with low content and low-polarity impurities in the reaction processes of high-pressure ring-opening, oxidizing and hydrolyzing in the finished product and the mother liquor are reduced, therefore, the posttreatment difficulty is reduced, the stability of the next-batch reaction is increased, and the product quality and the product yield are improved.

Owner:湖北民生生物医药有限公司

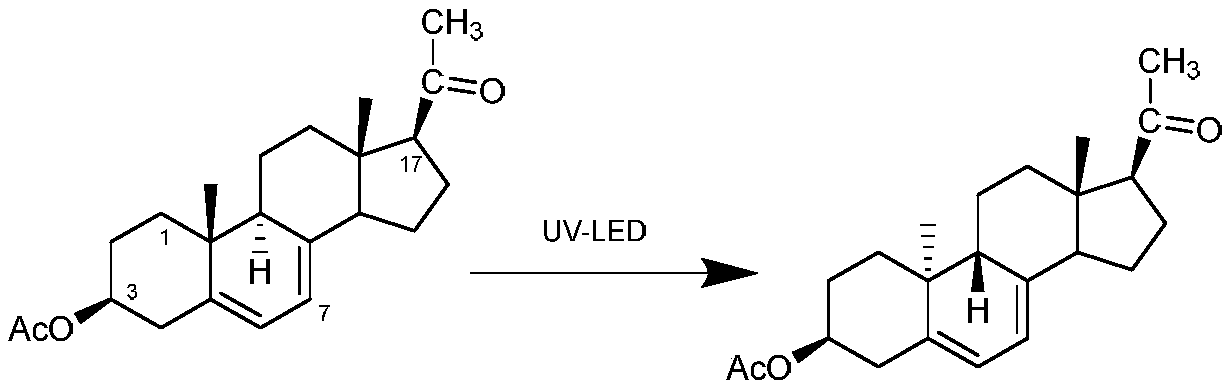

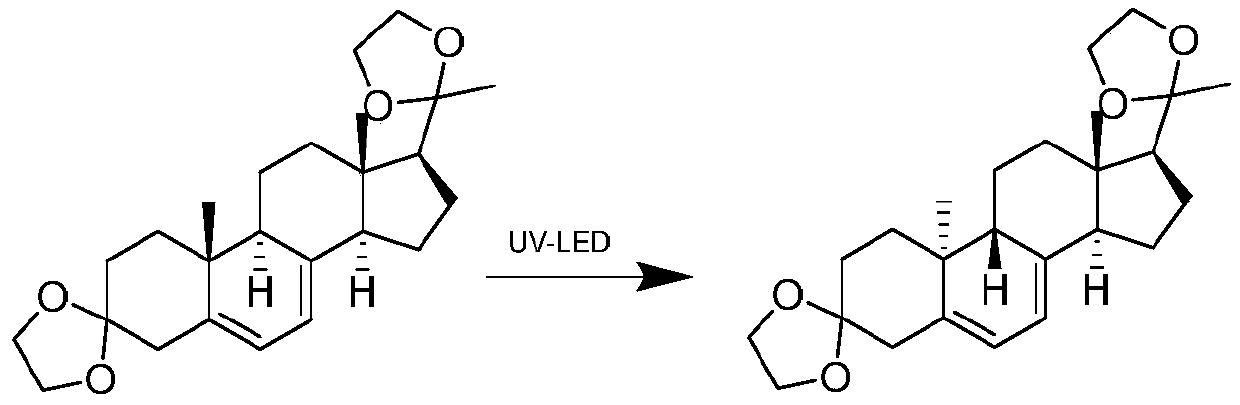

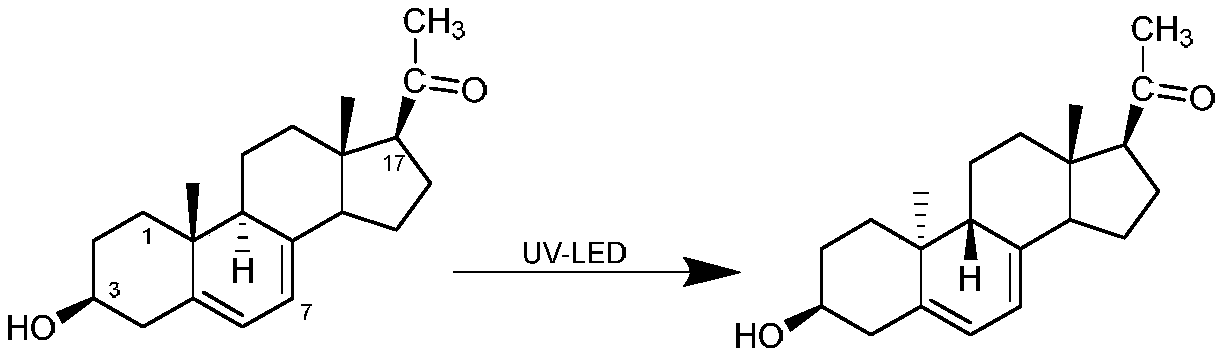

Preparation method of dydrogesterone intermediate

ActiveCN111171101AConcentrated luminous bandsHigh yieldChemical recyclingKetal steroidsPhotocatalytic reactionUltraviolet

The invention discloses a preparation method of a dydrogesterone intermediate. The preparation method is characterized by comprising the following steps: dissolving 5,7-diene steroid compound in an organic solvent to obtain a solution as a raw material; and carrying out a photocatalytic reaction and separating to obtain the dydrogesterone intermediate, wherein the 5,7-diene steroid compound is 7-dehydropregnenolone acetate, pregna-5,7-diene-3,20-diketodivinyl ketal, 7-dehydropregnenolone, ergosterol or pregna-5,7-diene-3,20-diketo-3-vinyl ketal, and a lamp used in the photocatalytic reaction comprises an LED ultraviolet lamp with the wavelength range of 295-335 nm. The preparation method of the dydrogesterone intermediate is high in yield, low in cost, safer in preparation and friendlier to environment.

Owner:上海璟兆实业有限公司

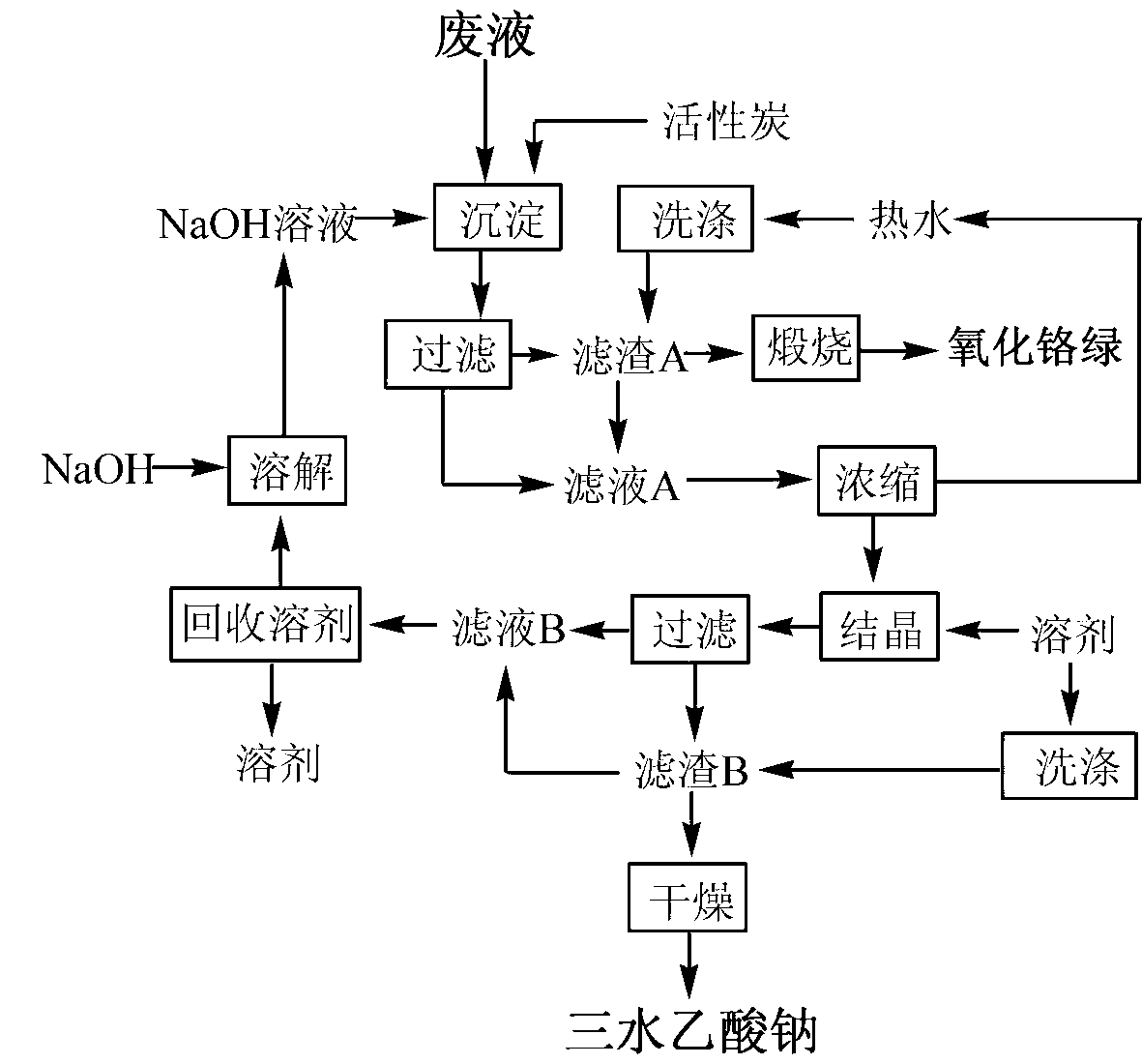

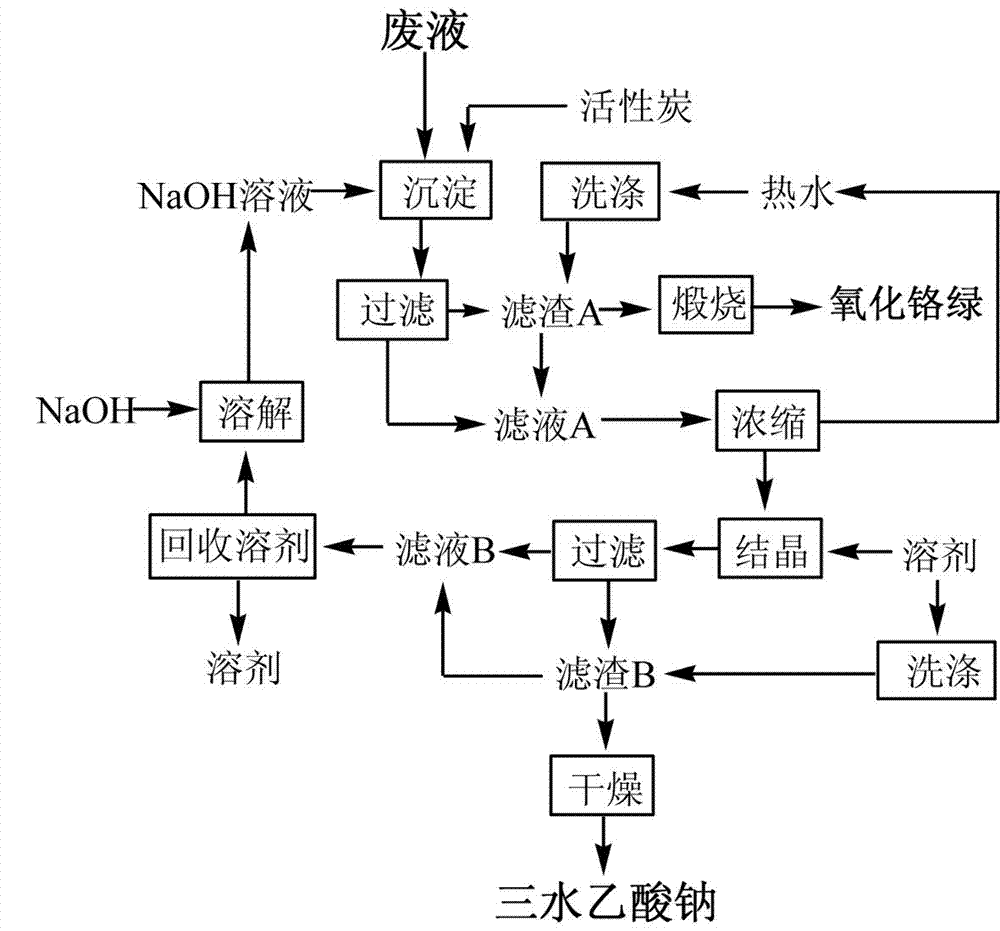

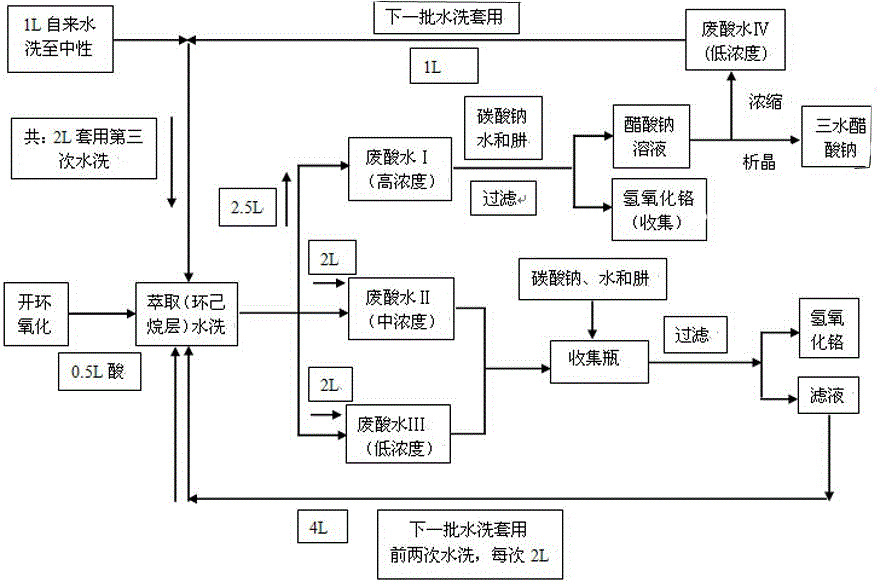

Method for recycling dehydropregnenolone acetate waste liquor

InactiveCN103274923AIncrease incomeIncrease added valueChromium trioxideCarboxylic acid salt preparationSodium acetateFiltration

The invention provides a method for recycling dehydropregnenolone acetate waste liquor. The method comprises the following steps of: separating and recycling sodium acetate from the treated waste liquor through NaOH sedimentation, decoloration, filtration, solvent washing, concentration, crystallization, drying and the like, and completely recovering sodium acetate by utilizing the hot water generated by concentration and the mother liquor generated by crystallization. Product inspection proves that the content of the active ingredient in a product is more than 98.5%, various indexes meet chemical purity grades specified by national standard GB / T693-1996, and therefore the product can be directly applied to the production of the dehydropregnenolone acetate or sold as a commodity; and at the same time, the filter residue obtained from the filtration process is calcined to obtain the chromium oxide green which has a plurality of uses and high added value. The waste liquor treatment method provided by the invention is simple in process, capable of achieving energy conservation and emission reduction, and conductive to environment protection to generate social benefit; and by adopting the method, sodium acetate can be completely recovered, and the chromium oxide green with high added value can be obtained to generate great economic efficiency.

Owner:CHINA THREE GORGES UNIV +1

Method for producing pregnenolone acetic ester and 16-dehydropregnenolone acetate by utilizing infrared heating ring opening

InactiveCN102219820AGuaranteed stabilityPrecise temperature controlSteroidsTemperature controlPower flow

A method for producing pregnenolone acetic ester and 16-dehydropregnenolone acetate by utilizing infrared heating ring opening comprises the steps of ring-opening cracking, extraction and refining, wherein infrared heating is carried out on a reaction kettle during ring-opening cracking process. In the invention, as a silicon carbide far infrared heating and radiation heating device and a tank body are assembled together, the reaction kettle is heated by controlling the voltage and current of a heating device, so that temperature and voltage can be automatically controlled, power can be automatically adjusted and randomly set, the temperature control is precise, heat buffer is small, personal errors are reduced, the stability of infrared heating ring-opening reaction is ensured, and further the reaction is more sufficient.

Owner:湖北民生生物医药有限公司

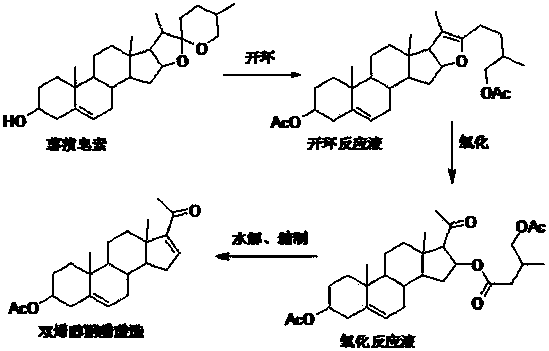

Method for producing 16-dehydropregnenolone acetate

InactiveCN104045676ALow equipment requirementsEliminate potential safety hazardsSteroidsDehydropregnenolone acetateOxidizing agent

The invention discloses a method for producing 16-dehydropregnenolone acetate. The method comprises the following steps: carrying out ring opening on diosgenine as a raw material, oxidizing, hydrolyzing, and refining to produce highly 16-dehydropregnenolone acetate. Compared with traditional 16-dehydropregnenolone acetate production methods, the method especially adopting highly active ozone as an oxidant in the oxidation reaction process has the advantages of novelty, mild reaction conditions, and easy control of the reaction product; the total yield of separated 16-dehydropregnenolone acetate reaches 79.5%, and is higher than an industrial average production level of 72-74%; and the oxidant in the reaction process can be recycled, so the method also has the advantages of realization of continuous production, production cost reduction, investment saving, labor intensity mitigation, high comprehensive utilization rate, and environmental protection, and provides a reference for the industrial production.

Owner:CHENGDU LAURELSCI TECH

Method for manufacturing dehydropregnenolone acetate by using mixed solvent

The invention provides a method for manufacturing dehydropregnenolone acetate by using a mixed solvent. In the method, with diosgenin as a raw material, the dehydropregnenolone acetate is obtained through open-loop, oxidation, hydrolysis, extraction and concentration as well as refining processes; and the refining process comprises a heating and refluxing step and a cooling and recrystallizing step, as well as a separating and drying step. According to the invention, as the mixed solvent formed by dichloromethane and alcohols replaces the traditional ethanol solvent to refine a dehydropregnenolone acetate crude product, the dehydropregnenolone acetate product with high purity, high yield and excellent appearance is obtained; in addition, in the refining process, the adding of an ethanol washing step is also beneficial for increasing the purity of the dehydropregnenolone acetate product; and the method for manufacturing the dehydropregnenolone acetate by using the mixed solvent, provided by the invention, has the advantages of simplicity in operation, short time and low production cost and is easy for large-scale industrial production.

Owner:湖北省丹江口开泰激素有限责任公司 +1

Synthetic method of pregnenolone acetate

The invention discloses a synthetic method of pregnenolone acetate. The method comprises the following steps of: 1, carrying out hydrogenation reaction of dehydropregnenolone acetate at a temperature ranging from 35 to 45 DEG C and under 0.4 MPa to 0.8 MPa by taking ethyl acetate as a solvent and a compound catalyst of a palladium / carbon catalyst and ammonium acetate; 2, filtering the reaction liquid after reaction, concentrating the filtrate under normal pressure, then adding a mixed solvent to the concentrated filtrate, and carrying out centrifugal drying after cooling to obtain crude pregnenolone acetate; 3, washing the crude pregnenolone acetate, then carrying out drip washing by using methanol, and drying to obtain white sandy solid pregnenolone acetate. The synthetic method provided by the invention is mild in reaction conditions; ethyl acetate is used as the solvent, and the solvent is high in recovery and low in dosage; as the palladium / carbon catalyst and ammonium acetate are used as the compound catalyst, the catalytic hydrogenation selectivity is high and no impurity is generated; besides, the aftertreatment is simple and the yield is high; the mass purity of the product can be higher than 99.5%.

Owner:西安高远生物科技有限公司

Method for producing high purity diene alcohol ketone acetic ester

The invention provides a method for producing dehydropregnenolone acetate with high purity. The method takes diosgenin as a raw material, and comprises the steps of pressure pyrolysis, oxidation, hydrolysis, extraction, column fractionation, and condensation. Compared with the traditional method for producing the dehydropregnenolone acetate, particularly the treating process of mother liquor, the method is simpler, easier to control and more liable to large-scale production, lowers production cost and overcomes the shortages that the traditional method for producing the dehydropregnenolone acetate recycles the mother liquor and causes the low yield rate and poor quality of the product; simultaneously, the method obtains high-purity dehydropregnenolone acetate with content over 99 percent and melting point over 169 DEG C.

Owner:HUNAN KEYUAN BIO PRODS

Method for recovering 16-dehydropregnenolone acetate from 16-dehydropregnenolone acetate mother liquor

InactiveCN103554208AApplication utilization rate is highLow priceSteroidsDehydropregnenolone acetateChromatography liquid

The invention relates to a method for recovering 16-dehydropregnenolone acetate from a 16-dehydropregnenolone acetate mother liquor, wherein the method is intended to provide the method with advantages of simple technology, high recovery rate and good product quality. The method for recovering 16-dehydropregnenolone acetate from the 16-dehydropregnenolone acetate mother liquor comprises the following steps of: mother liquor condensation, solvent extraction, chromatography to remove impurities, condensation of a chromatography liquid, refining, crystallization, centrifugation and drying, to obtain 16-dehydropregnenolone acetate. The method for recovering 16-dehydropregnenolone acetate from the 16-dehydropregnenolone acetate mother liquor can make an overall yield of the 16-dehydropregnenolone acetate reach 72%, raising 4-7% compared with a traditional technology; a used reagent belongs to a common chemical product, and has advantages of easy availability, low cost, simple technology operation and convenient industrialization; and the method is used for recovering the 16-dehydropregnenolone acetate from the 16-dehydropregnenolone acetate mother liquor, wherein the purity of the 16-dehydropregnenolone acetate obtained after refining is larger than 99%, the obtained 16-dehydropregnenolone acetate can be directly used as a product, and a secondary mother liquor can be reused into the 16-dehydropregnenolone acetate production.

Owner:XIANGXI HUALI PHARMA

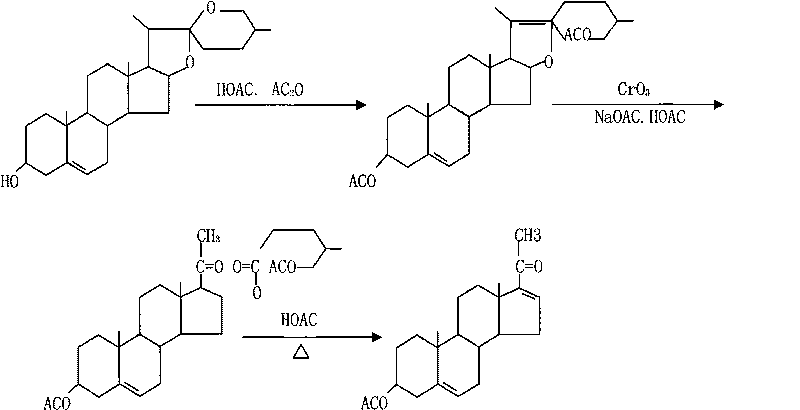

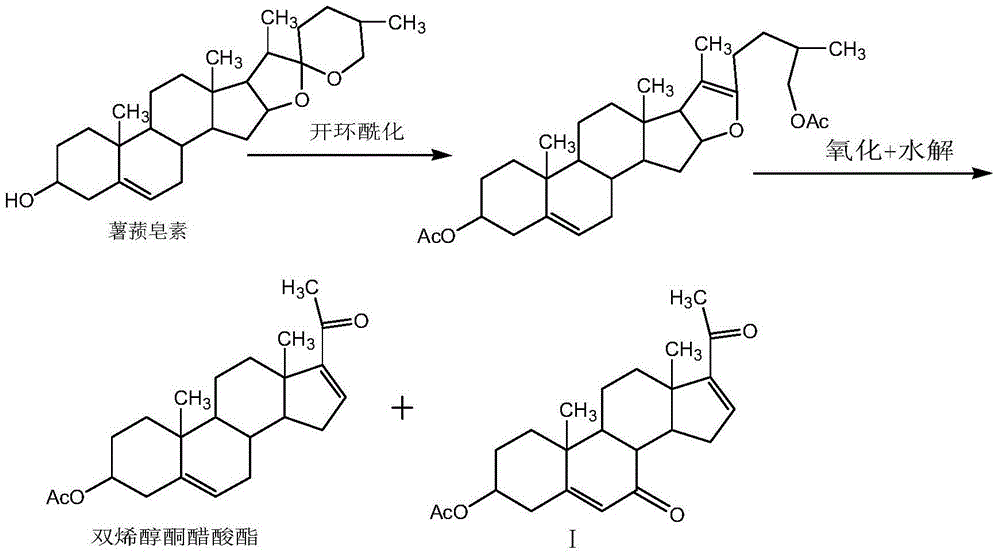

Process for the oxidation of pseudodiosgenin diacetate to diosone for the production of 16-dehydropregnenolone acetate

The invention relates to a process for the production of 16-dehydropregnenolone acetate of the formula comprising the oxidation of pseudodiosgenin diacetate in the presence of a phase transfer catalyst at a temperature between 0-15 DEG C. to produce diosone followed by the hydrolysis and degradation of diosone to produce 16-dehydropregnenolone acetate.

Owner:COUNCIL OF SCI & IND RES

Method for recycling dehydropregnenolone acetate waste liquor

InactiveCN103274923BIncrease incomeIncrease added valueChromium trioxideCarboxylic acid salt preparationSodium acetateFiltration

The invention provides a method for recycling dehydropregnenolone acetate waste liquor. The method comprises the following steps of: separating and recycling sodium acetate from the treated waste liquor through NaOH sedimentation, decoloration, filtration, solvent washing, concentration, crystallization, drying and the like, and completely recovering sodium acetate by utilizing the hot water generated by concentration and the mother liquor generated by crystallization. Product inspection proves that the content of the active ingredient in a product is more than 98.5%, various indexes meet chemical purity grades specified by national standard GB / T693-1996, and therefore the product can be directly applied to the production of the dehydropregnenolone acetate or sold as a commodity; and at the same time, the filter residue obtained from the filtration process is calcined to obtain the chromium oxide green which has a plurality of uses and high added value. The waste liquor treatment method provided by the invention is simple in process, capable of achieving energy conservation and emission reduction, and conductive to environment protection to generate social benefit; and by adopting the method, sodium acetate can be completely recovered, and the chromium oxide green with high added value can be obtained to generate great economic efficiency.

Owner:CHINA THREE GORGES UNIV +1

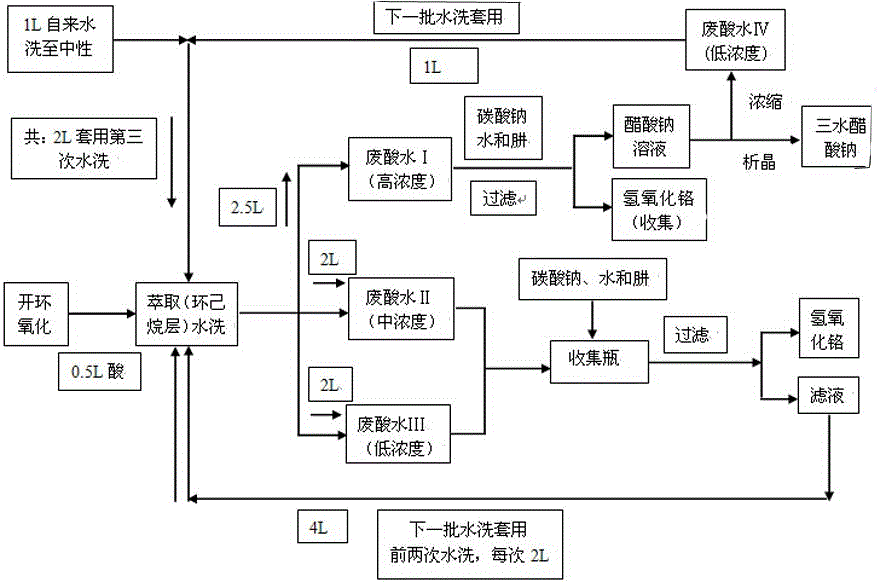

Method of recycling acid wastewater generated during production of dehydropregnenolone acetate

ActiveCN105061191AHigh puritySave production waterTreatment involving filtrationChromium trioxideSodium acetateWater use

The invention relates to a method of recycling acid wastewater generated during the production of dehydropregnenolone acetate. The method starts with the diene production process and recycles the acid wastewater which can be recycled and reused in all the processes. The obtained by-product contains high-purity chromic hydroxide and sodium acetate, both of which can be sold. Compared with the conventional acid wastewater treatment method, the method provided by the invention is simple and easy to operate and low in energy consumption, improves the utilization rate of the acid wastewater, reduces the production water using amount, lowers the cost and burden of the wastewater treatment, and reduces the pollution caused by the acid wastewater to the environment.

Owner:湖北竹溪人福药业有限责任公司

Production method of 16-dehydropregnenolone acetate oxime

InactiveCN104151387AQuick responseShorten the timeSteroidsHalohydrocarbonDehydropregnenolone acetate

The invention provides a novel production method of 16-dehydropregnenolone acetate oxime. The novel production method comprises the following steps: on the basis of taking 16-dehydropregnenolone acetate as a raw material, alcohol or halohydrocarbon or arene as a solvent and organic base or inorganic base as an acid-binding agent, reacting by using hydroxylammonium chloride, then crystallizing and drying to obtain 16-dehydropregnenolone acetate oxime. The novel production method has the remarkable characteristics that the dissolving property problem of 16-dehydropregnenolone acetate and hydroxylammonium chloride is solved by using the mixed solvent, and meanwhile, a water absorbent and a catalyst are added, so that the influences of oximation reaction speed and the generated water on the reaction are eliminated. Compared with the traditional method, the novel production method provided by the invention has the remarkable advantages that the reaction speed is high, and the reaction time is at least shortened to less than 1 / 2 of the time needed by using the traditional method; the reaction selectivity is good, the yield is high, and the molar yield is up to 99% which is five times as high as that of the traditional method; the quality of 16-dehydropregnenolone acetate oxime is high, and the content of 16-dehydropregnenolone acetate oxime is up to more than 98%; the process is clean, and less wastewater is generated; and the novel production method is simple and convenient to operate and can be used for easily realizing industrial production.

Owner:TIANJIN FOREVER GREEN BIOLOGICAL PHARMA TECH

Improved synthesis method of 3beta-hydroxy-16alpha, 17alpha-epxoy-5-pregnenolone-20-ketone

The invention discloses an improved synthesis method of 3beta-hydroxy-16alpha, 17alpha-epxoy-5-pregnenolone-20-ketone (hereinafter referred to epoxy prognenolone). The improved synthesis method comprises the following steps of: putting dehydropregnenolone acetate to a mixed solvent, controlling temperature, respectively and sequentially dropwise adding hydrogen peroxide, alkaline water, hydrogen peroxide and alkaline water, after heat preservation reaction is ended, cooling, centrifuging, circularly applying mother liquid, washing filter cakes till the filter cakes are neutral, and drying to obtain an epoxy prognenolone product; and after using the mother liquid for enough times, dropwise adding a quenching reagent, and preprocessing to obtain the epoxy prognenolone product. According to the improved synthesis method, the dosage and consumption of the solvent are substantially reduced, the distillation process of the solvent is substantially shortened, the lot production capacity of a reaction kettle is substantially improved, and the content of the obtained epoxy prognenolone is above 99.0%. The improved synthesis method has the advantages of low production cost, high production safety and material stability and is suitable for large-scale industrial production.

Owner:HUAZHONG PHARMA

A kind of method of dienolone acetate waste acid water recycling

ActiveCN105061191BHigh puritySave production waterTreatment involving filtrationChromium trioxideSodium acetateWater use

The invention relates to a method of recycling acid wastewater generated during the production of dehydropregnenolone acetate. The method starts with the diene production process and recycles the acid wastewater which can be recycled and reused in all the processes. The obtained by-product contains high-purity chromic hydroxide and sodium acetate, both of which can be sold. Compared with the conventional acid wastewater treatment method, the method provided by the invention is simple and easy to operate and low in energy consumption, improves the utilization rate of the acid wastewater, reduces the production water using amount, lowers the cost and burden of the wastewater treatment, and reduces the pollution caused by the acid wastewater to the environment.

Owner:湖北竹溪人福药业有限责任公司

Method and system for treating residue-containing wastewater of dehydropregnenolone acetate

ActiveCN106145499ARelieve stressReduce COD53~58%Water treatment parameter controlFatty/oily/floating substances removal devicesCavitationDistillation

The invention discloses a method and system for treating residue-containing wastewater of dehydropregnenolone acetate. The method comprises the following steps: subjecting wastewater, generated from a production process of the dehydropregnenolone acetate, to heated stirring, then, carrying out precipitation, subjecting a precipitated aqueous phase to further treatment at a sewage treatment section, carrying out distillation at other sections so as to recover cyclohexane, finally, cooling obtained oil scum, and then, carrying out solid waste incineration treatment. According to the method and the system, by an additional ultrasonic treatment step, the rate of mass transfer of a multiphase system is increased by using mechanical action and cavitation of ultrasonics, so that oil-bearing scum and emulsified substances are broken to release moisture, and later-stage precipitation layering is promoted; water-residue separation is carried out through precipitation; residues are distilled to dryness through distillation so as to recover cyclohexane from the residues; many defects of a treatment process can be overcome, the sewage treating pressure is alleviated, the cost is reduced, and thus the method and the system are energy-saving and environmentally friendly.

Owner:湖北民生生物医药有限公司

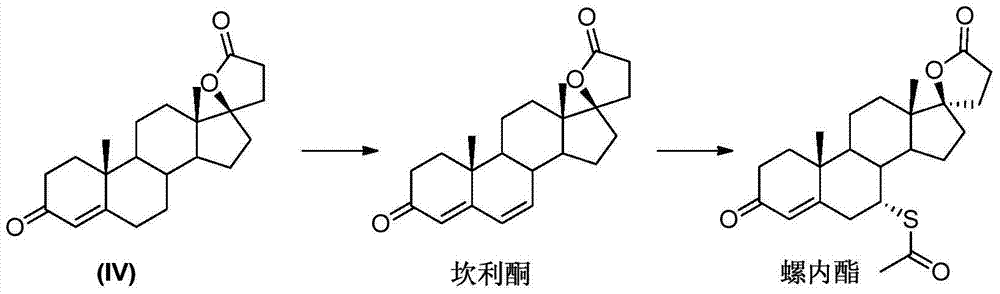

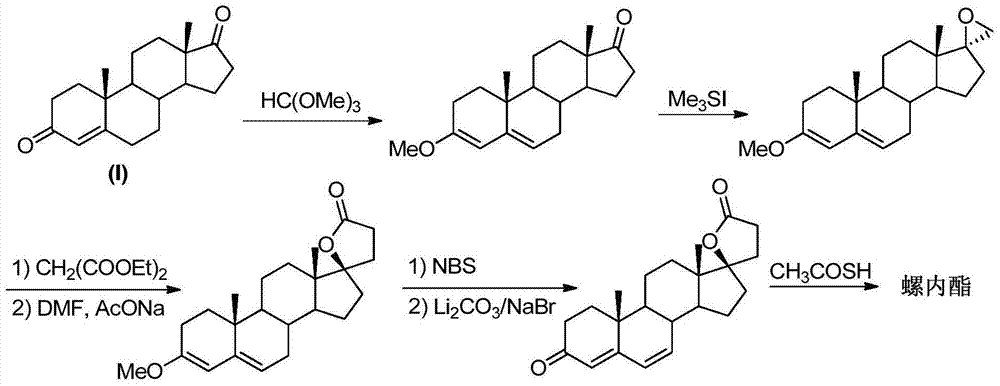

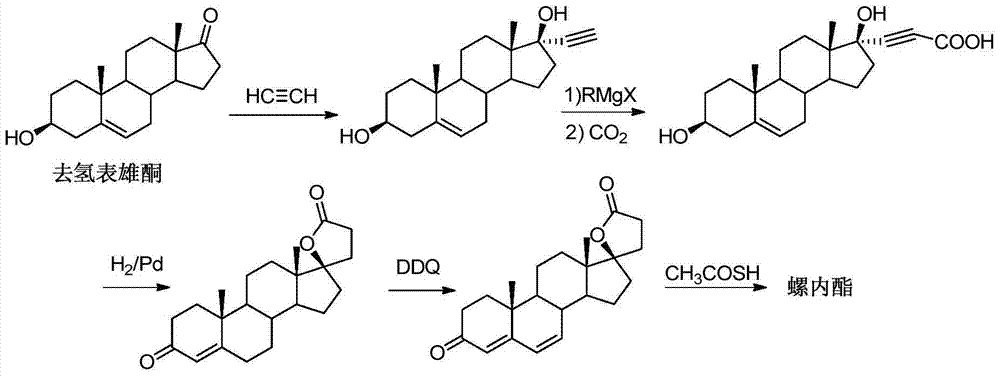

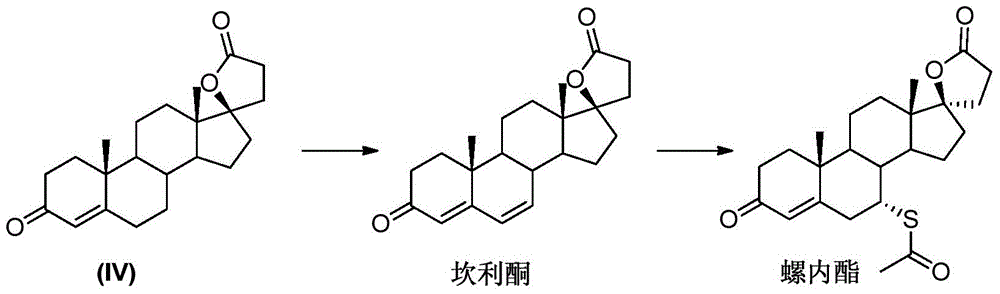

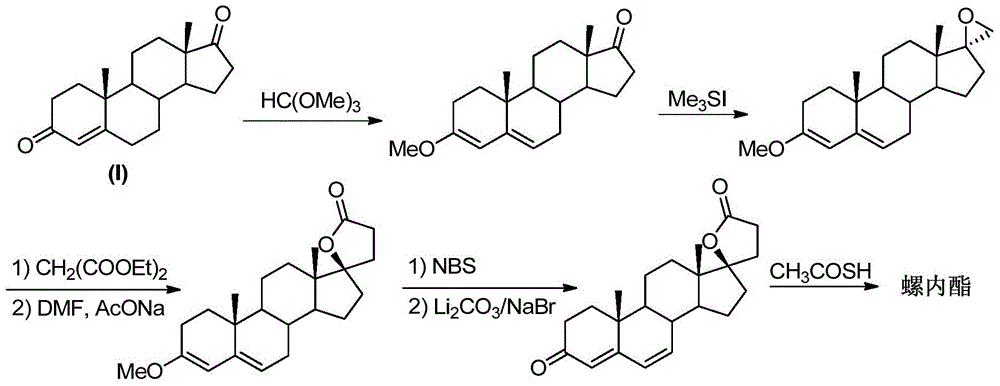

Synthesis method of spironolactone intermediate testosterone lactone

ActiveCN104327149AIncrease production capacityImprove economyLactone steroidsDehydropregnenolone acetateSynthesis methods

The invention relates to a synthesis method of a chemical medicine, and concretely relates to a synthesis method of a spironolactone intermediate testosterone lactone. The method is characterized in that a compound I 4-androstenedione (4AD) undergoes a two-step reaction of addition siloxane removal and oxidation cyclization to obtain the compound III testosterone lactone, and the reaction route is shown in the specification. Compared with traditional methods adopting a traditional raw material 16-dehydropregnenolone acetate with high price, the method provided by the invention adopting the cheap and easily available 4-androstenedione (4AD, I) as an initial raw material has extremely high production application and economic values under the affection of market supply and demand.

Owner:ZHEJIANG SHENZHOU PHARMA

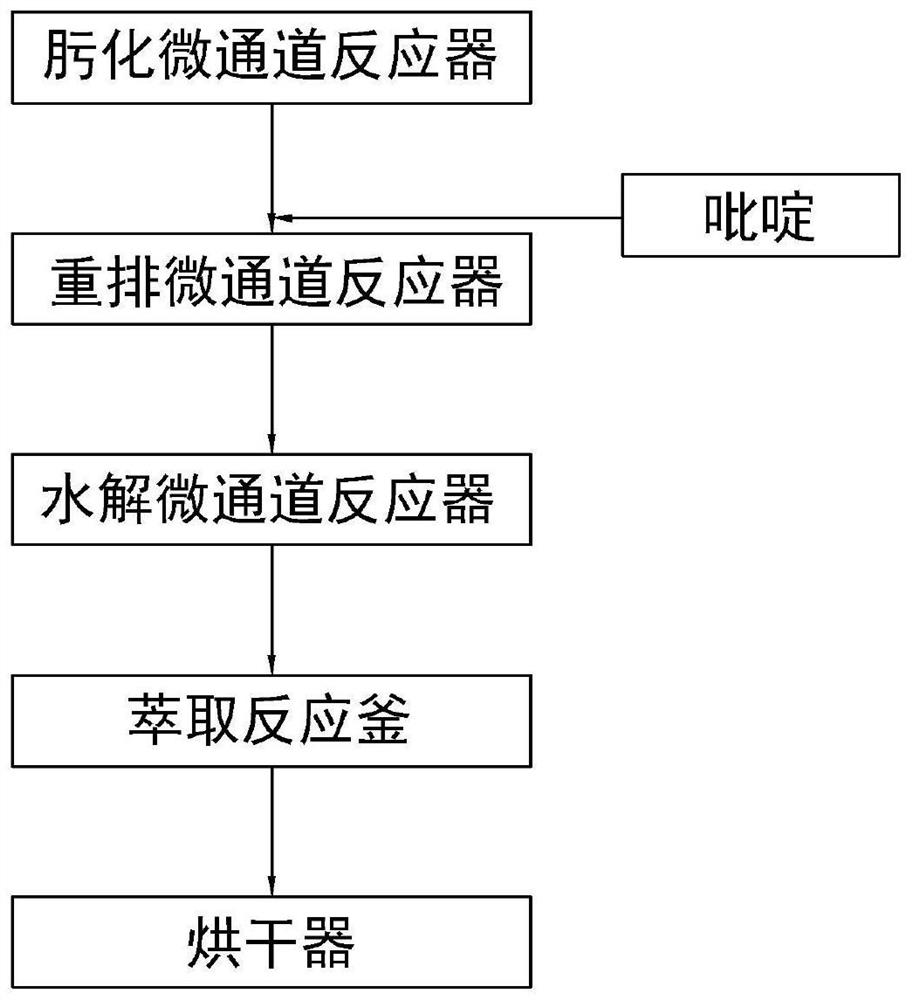

Preparation method of dehydroepiandrosterone acetate

PendingCN114276397AReduce difficultyReduce control difficultySteroidsHydroxylamineDehydropregnenolone acetate

The invention provides a preparation method of dehydroepiandrosterone acetate, which comprises the following steps: firstly, mixing hydroxylamine hydrochloride and pyridine to obtain a hydroxylamine hydrochloride solution, mixing dehydropregnenolone acetate and pyridine to obtain a dehydropregnenolone acetate solution, respectively pumping the hydroxylamine hydrochloride solution and the dehydropregnenolone acetate solution into an oximation micro-channel reactor, and carrying out oximation reaction to obtain dehydroepiandrosterone acetate. Pumping the oximation reaction liquid into a rearrangement micro-channel reactor, carrying out a rearrangement reaction to obtain a rearrangement reaction liquid, pumping the rearrangement reaction liquid and hydrochloric acid into a hydrolysis micro-channel reactor, carrying out a hydrolysis reaction to obtain a hydrolysis reaction liquid, and extracting the hydrolysis reaction liquid by using an extraction solvent, and drying the extraction solvent to obtain the dehydroepiandrosterone acetate. The preparation method disclosed by the invention is simple in process, free of unit operation of an intermediate product, efficient and continuous, and has a good application prospect.

Owner:湖北武当安泰药业有限公司

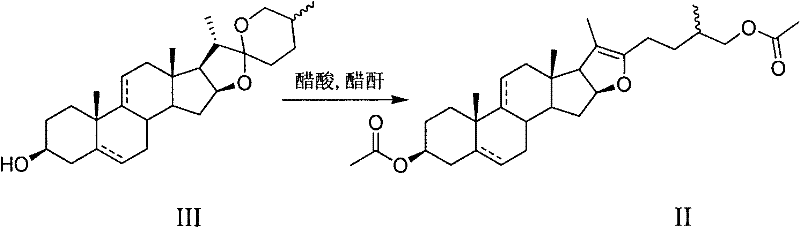

Dehydropregnenolone acetate extraction process

PendingCN112608363AEasy to handleReduce pollutionOrganic chemistry methodsSteroidsChromium trioxideAcetic anhydride

The invention relates to the technical field of dehydropregnenolone acetate extraction, and discloses a dehydropregnenolone acetate extraction process which comprises the following steps: mixing 5-15 parts of acetic anhydride and 10-30 parts of acetic acid, and adding 10-30 parts of saponin into the mixed solution of acetic anhydride and acetic acid. According to the dehydropregnenolone acetate extraction process, acetic anhydride, acetic acid and saponin are subjected to a ring-opening reaction, an obtained solution can be oxidized, then hydrogen peroxide is used for replacing traditional chromium trioxide to serve as an oxidizing agent, the production cost is low, almost no pollution is caused, and redundant hydrogen peroxide is simple to treat; sodium sulfite is only required to be poured to react with hydrogen peroxide to obtain sodium sulfate and water, sodium sulfate can be recycled in a layered manner in the last step of filtration, and compared with the adoption of chromium trioxide as an oxidant, the production cost is low, the pollution is low, the obtained product can be recycled, and the reaction process is relatively mild and easy to control; and the purpose of good environmental protection is achieved.

Owner:湖北民生生物医药有限公司

Method for synthetizing dehydropregnenolone acetate and isotype substance thereof

The invention discloses a method for preparing dehydropregnenolone acetate and an isotype substance thereof. The method comprises the following steps of: adding pseudo steroid sapogenin acetic ester, a vanadium-containing compound catalyst and hydrogen peroxide into acetic acid according to a molar ratio; performing a stirring reaction for 2 to 10 hours at a temperature of 5 to 110 DEG C; adding sodium acetate into the obtained product and preserving heat for 0.5 to 4 hours at a temperature of 80 to 110 DEG C; adding water to precipitate; and crystallizing precipitates by methanol or ethanol to obtain the dehydropregnenolone acetate and the isotype substance thereof. The method has the advantages that various defects of the existing method are overcome; the product does not need to be subjected column chromatography purification; the production and labor cost is reduced; a great amount of organic solvents are saved; and a used oxidizing agent is hydrogen peroxide and is low and safe, no byproduct is generated, and the method has low production cost and is beneficial to the environment.

Owner:TIANJIN UNIV

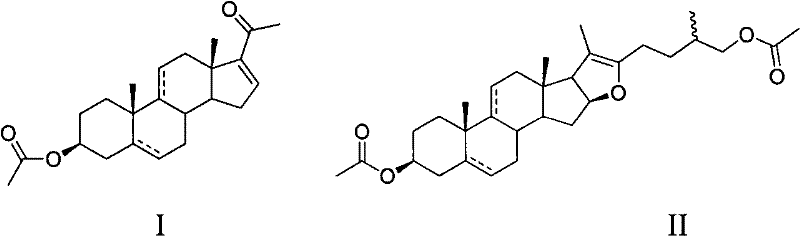

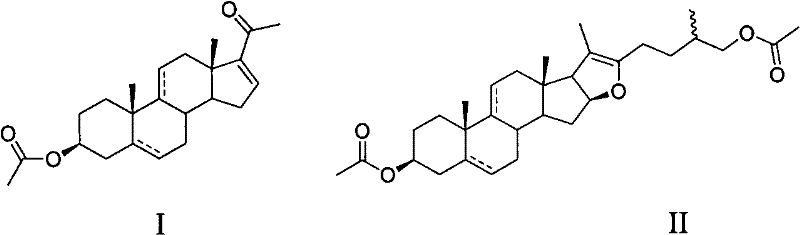

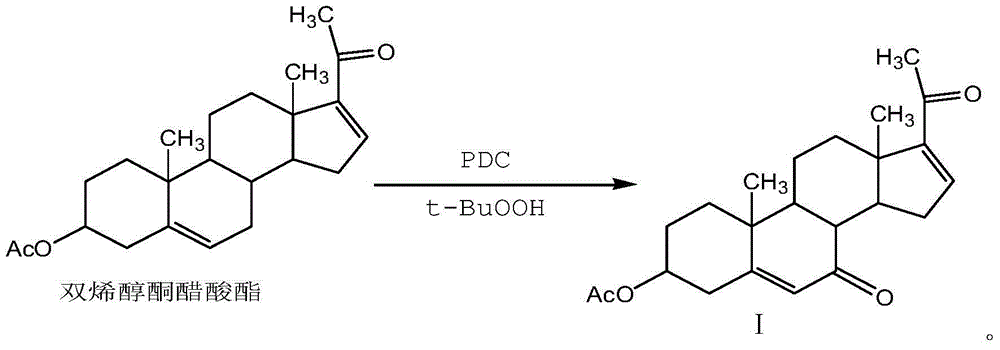

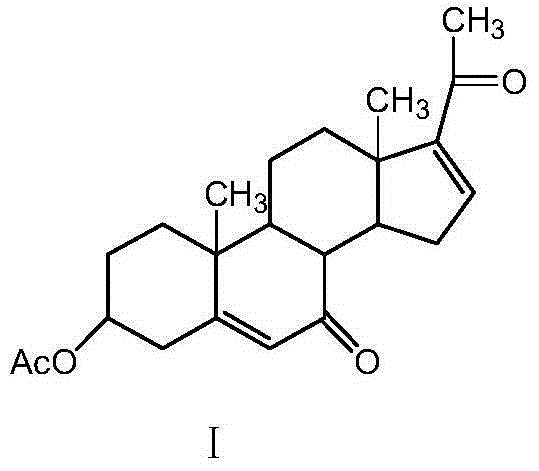

Synthesis method of main impurities of dehydropregnenolone acetate

The invention relates to a synthesis method of main impurities of dehydropregnenolone acetate. The synthesis method comprises the following steps: dissolving dehydropregnenolone acetate in benzene, stirring and adding tert-butyl hydroperoxide, pyridinium dichromate and kieselguhr, reacting for 2-3h at a room temperature, filtering materials, concentrating a filtrate to obtain a compound I crude product; adding dichloromethane to dissolve the crude product; and carrying out chromatographic column separation to obtain a compound I. The method is simple and rapid in process and high in product purity, and the product can be used as a standard substance and used for optimizing a production process for dehydropregnenolone acetate and improving the qualities of diene products.

Owner:湖北竹溪人福药业有限责任公司

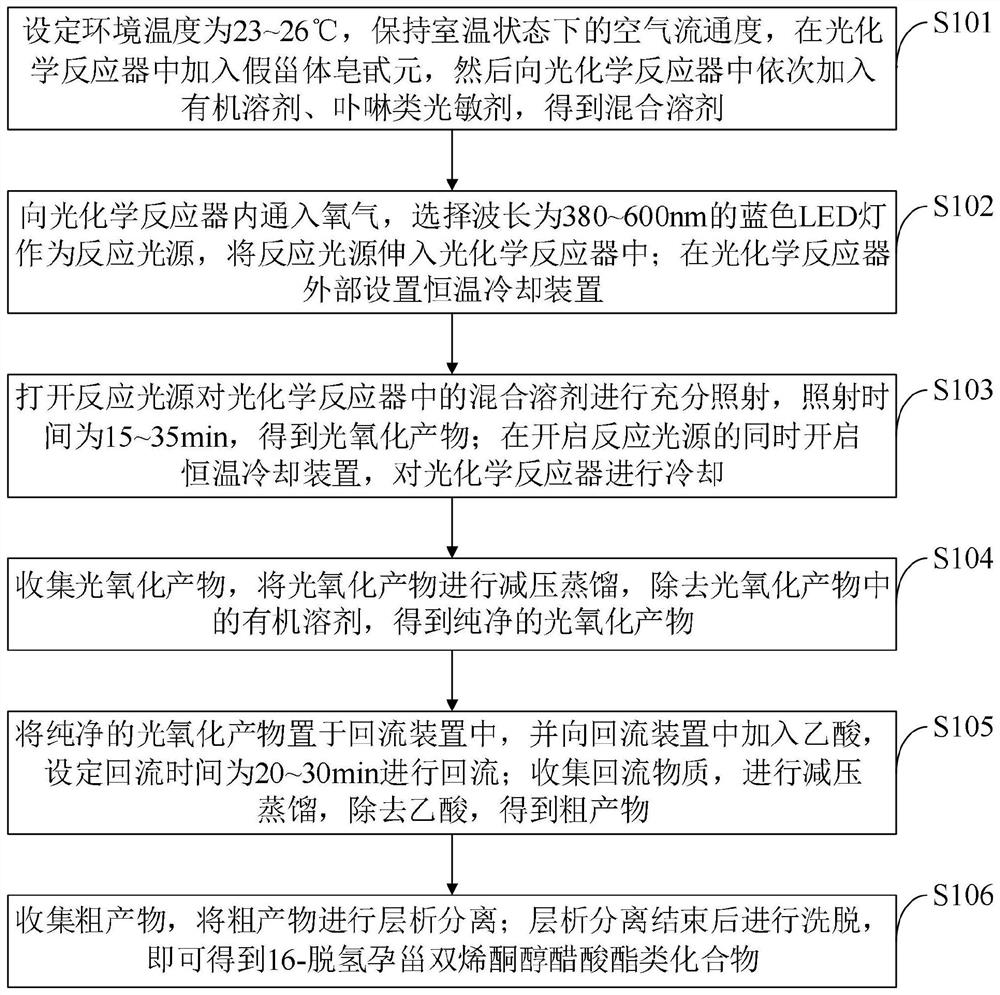

16-dehydropregnane dehydropregnenolone acetate compound and preparation method thereof

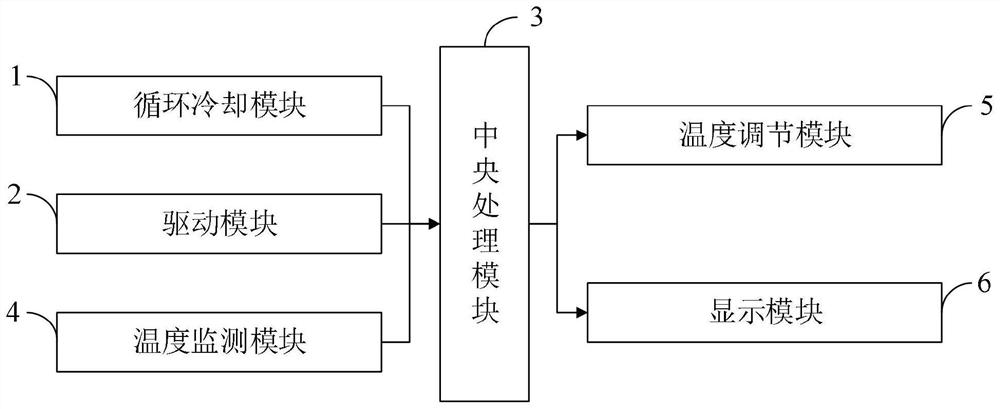

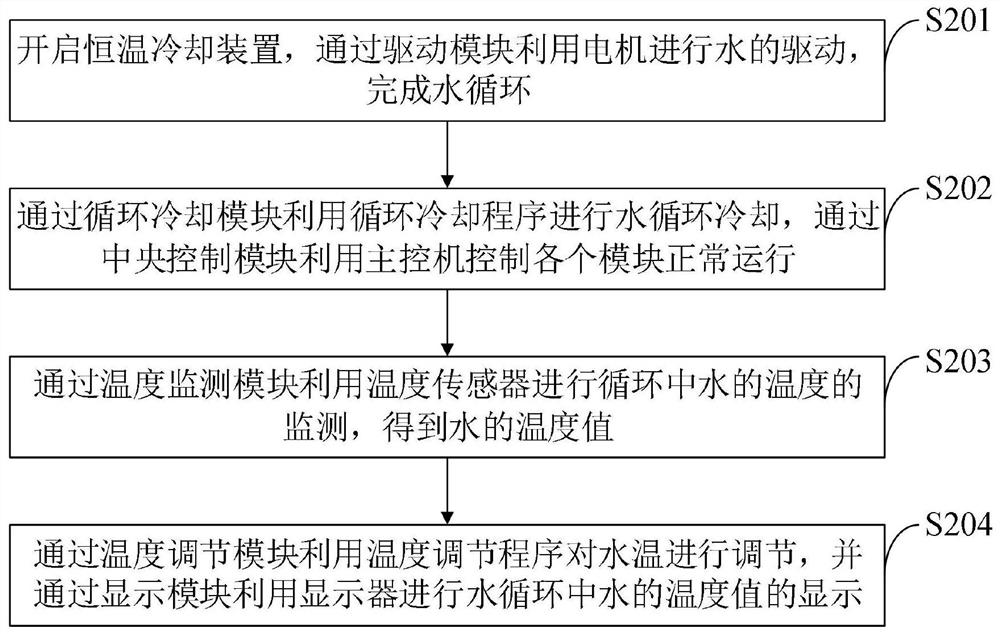

The invention belongs to the technical field of organic photochemical synthesis, and discloses a 16-dehydropregnane dehydropregnenolone acetate compound and a preparation method, the 16-dehydropregnane dehydropregnenolone acetate compound comprises the following components by mass: 8-12 parts of pseudosteroid sapogenin, 35-50 parts of an organic solvent, 3-5 parts of a porphyrin photosensitizer, and 10-20 parts of acetic acid. According to the invention, the 16-dehydropregnane dehydropregnenolone acetate compound is prepared by a photosensitized oxidation method, so that the problem of environmental pollution is eliminated from the source. Meanwhile, a constant-temperature cooling device is arranged outside a photochemical reactor, constant-temperature cooling is carried out in the reaction, the reaction is cooled, a constant-temperature reaction environment is constructed, the water consumption can be reduced by the cooling method, and resources are saved. According to the invention, column chromatography separation is carried out after preparation, the operation is simple, the repeatability is good, the product purity is high, and the method is more suitable for industrial large-scale production.

Owner:XINJIANG UNIVERSITY

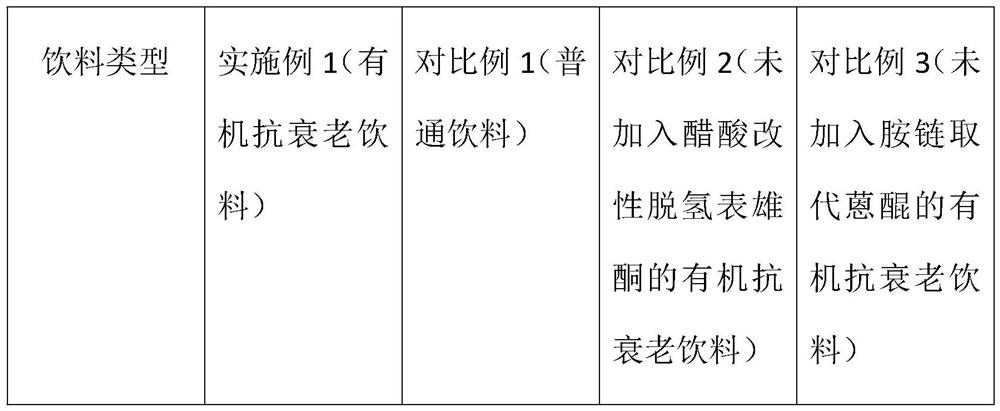

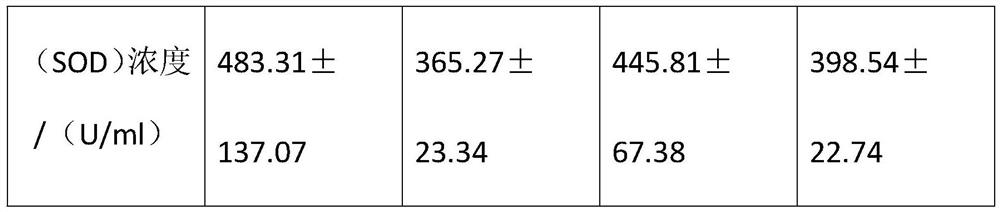

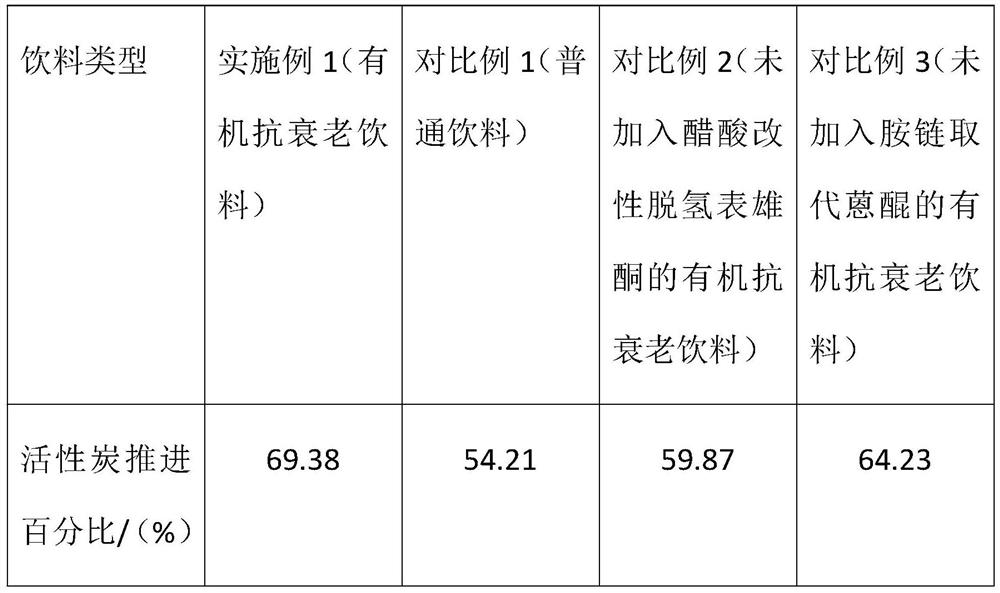

Organic anti-aging beverage and preparation method thereof

PendingCN112795457AGood water solubilitySlow down the degree of agingOrganic chemistryOrganic compound preparationBiotechnologyEthylic acid

The invention discloses an organic anti-aging beverage and a preparation method thereof. The organic anti-aging beverage comprises the following raw materials: dehydropregnenolone acetate, ethanol, pyridine, 1-aminoanthraquinone, epichlorohydrin, ethyl acetate, tetrahydrofuran, edible essence, a preservative, vitamins, a sweetening agent, purified water and the like. According to the invention, dehydroepiandrosterone reacts with free radicals under the catalysis of acetic acid so as to block a peroxidation reaction, so the aging degree of an organism is relieved; the side amine chain of amine chain-substituted anthraquinone reacts with cell telomerase, so the content of D-galactose is increased, the atrophy and degeneration of thymus are delayed, and the aging phenomenon of an organism is relieved; an amine N-oxyalkyl side chain is reduced and activated into amine molecules with positive charges by hormone enzyme in a body, so anthraquinone can be diffused to the whole body to play a role; and after a traditional process is conducted, a crude 1-aminoanthraquinone product is dissolved in tetrahydrofuran, chloroform is used for packing a column for column chromatography separation, and a hydroxyl group is not easy to reduce after being immobilized by the tetrahydrofuran, so the quality and yield of the product are improved.

Owner:陈广会

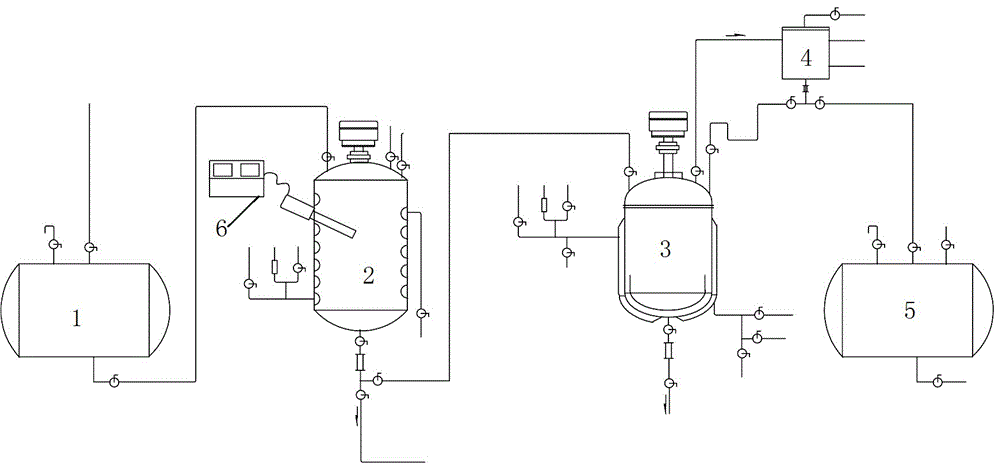

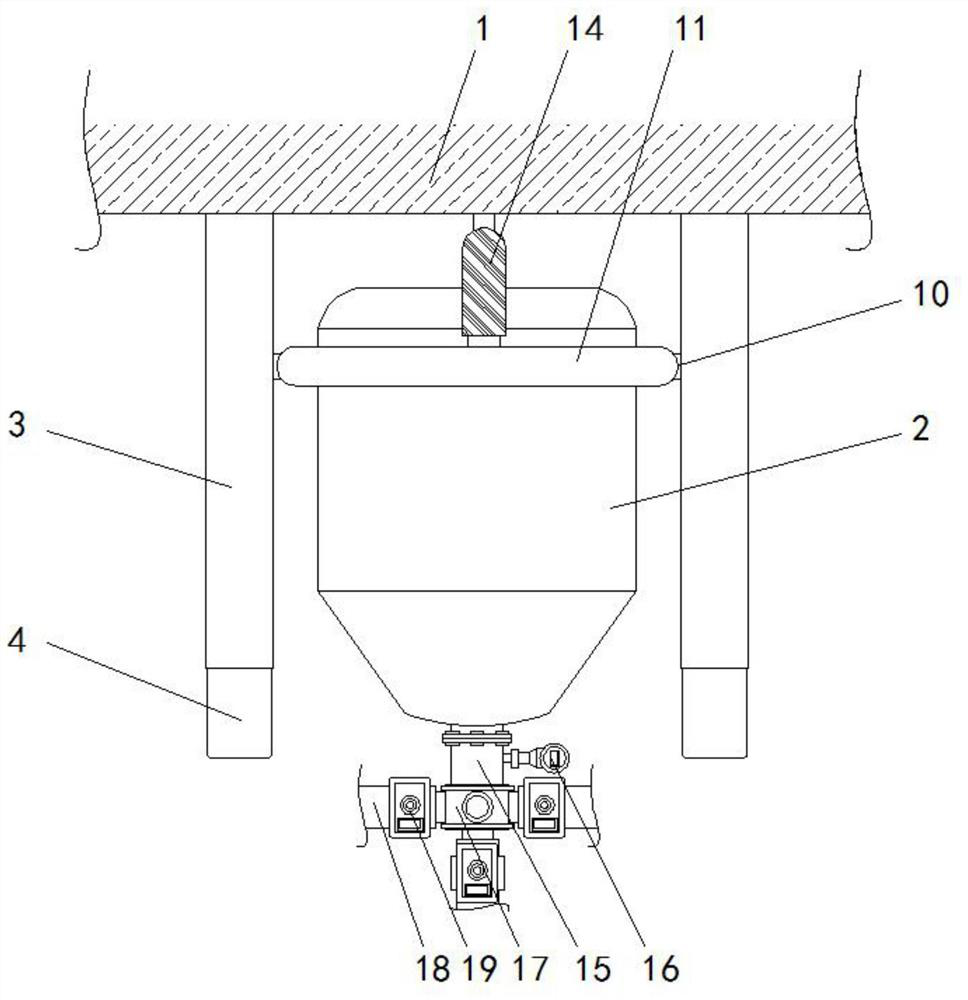

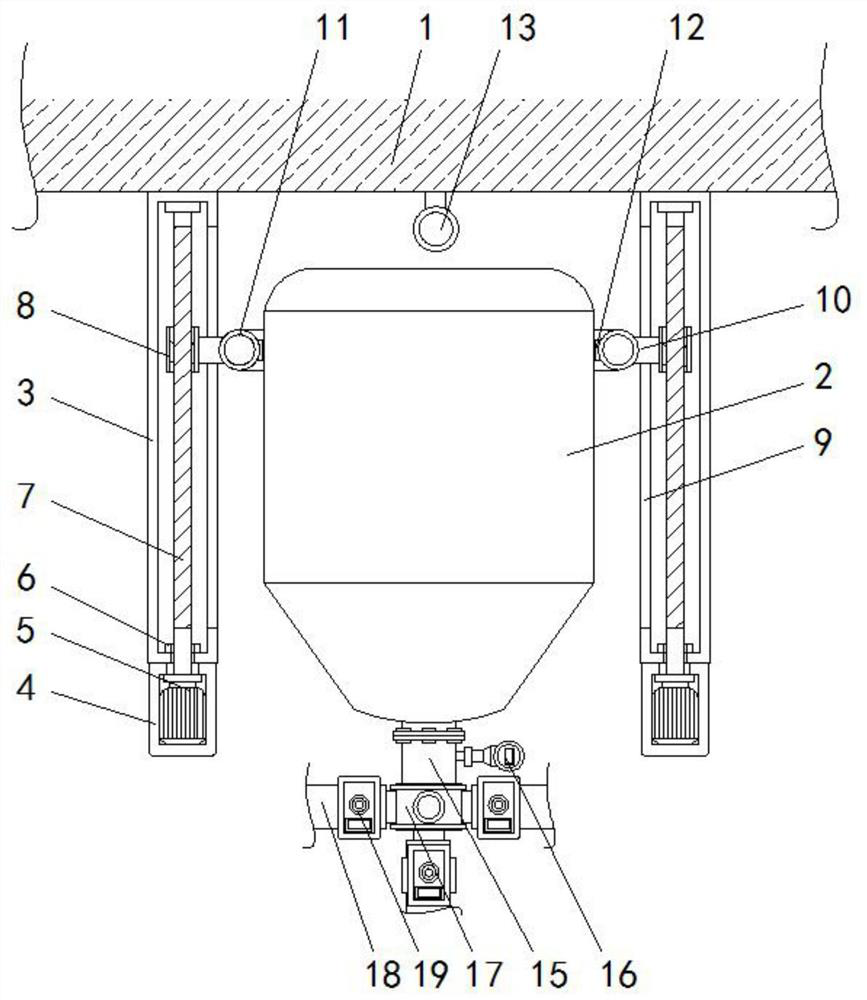

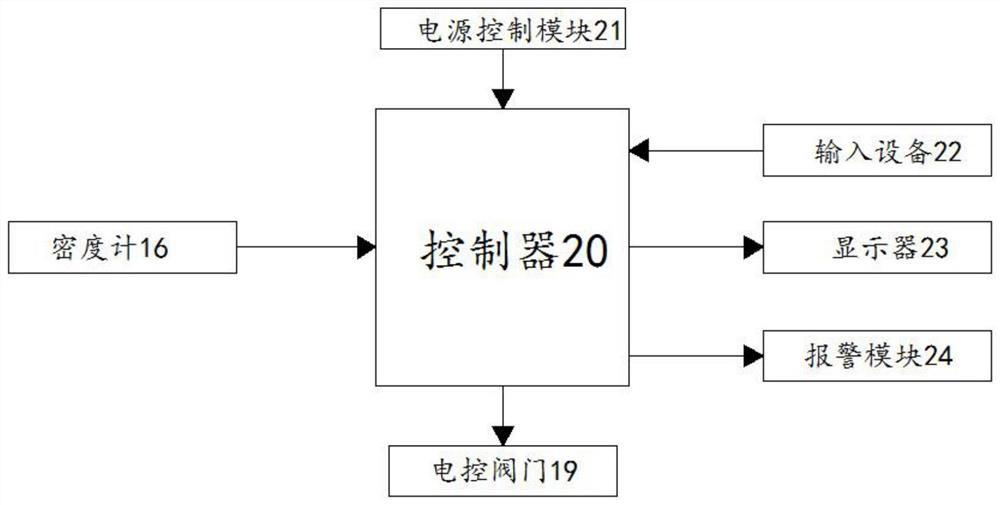

Automatic dehydropregnenolone acetate extraction device

PendingCN112587953AEasy to alertEasy to liftSolvent extractionSteroidsRotational axisDehydropregnenolone acetate

The invention relates to the technical field of dehydropregnenolone acetate, and discloses an automatic dehydropregnenolone acetate extraction device, which comprises a wall body and an extraction kettle, and the extraction kettle is positioned at the bottom of the wall body. According to the automatic dehydropregnenolone acetate extraction device, a rotary screw rod rotates in a lifting box through a rotary motor and a rotary bearing, a lifting shaft moves up and down outside the lifting box through rotation of a rotary screw rod, and therefore a lifting pipe is driven by an extension block to ascend and descend outside an extraction kettle; and a water supply pipe guides cooling water into the lifting pipe through a telescopic water guide pipe, the extraction kettle is cooled through spraying of an atomizing spray head, meanwhile, the telescopic water guide pipe facilitates lifting of the lifting pipe, a densimeter is used for conducting sealing detection on materials in a discharging pipe, and meanwhile information is transmitted to a controller. An electronic control valve opposite is opened to extract the dehydropregnenolone acetate, an input device and a display screen are convenient for manual operation of the device, and an alarm module is convenient for alarming unexpected situations.

Owner:湖北民生生物医药有限公司

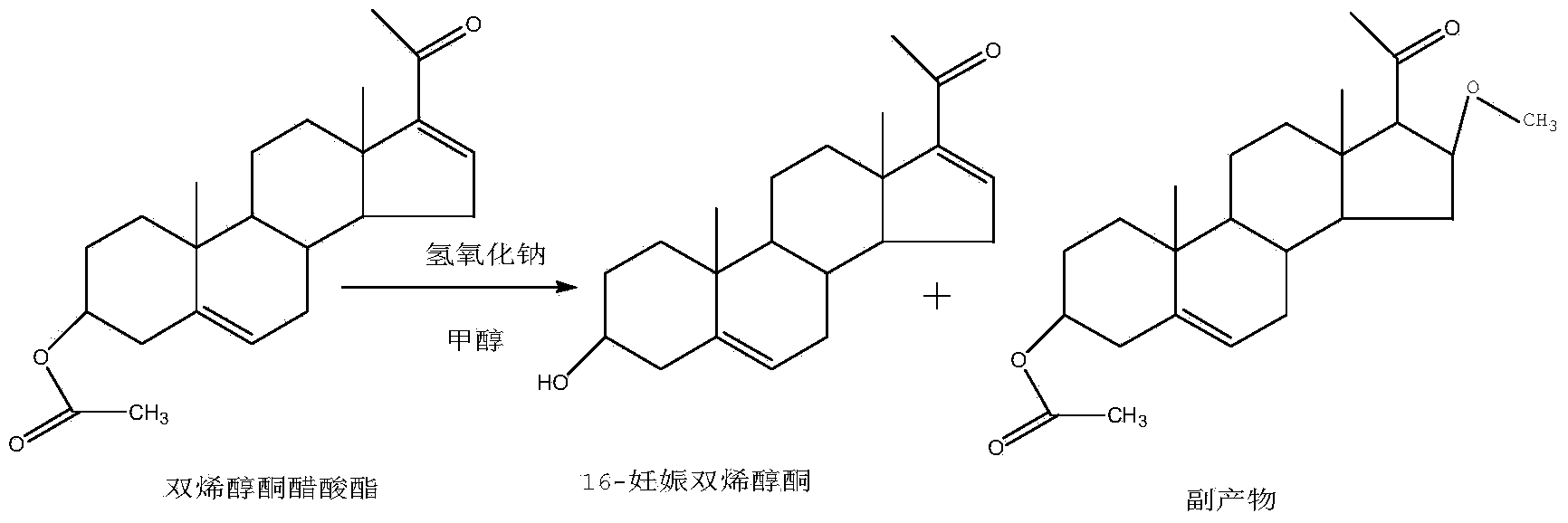

Method for synthesizing 16-dehydropregnenolone by taking dehydropregnenolone acetate as raw material

The invention discloses a method for synthesizing 16-dehydropregnenolone by taking dehydropregnenolone acetate as a raw material. The method comprises the following steps: dissolving dehydropregnenolone acetate by taking an aprotic solvent as a solvent, adding an aqueous solution of an inorganic base, controlling the reaction temperature to 20-30 DEG C, regulating the pH value to be neutral after the reaction is detected to be finished, raising the temperature to recover the solvent, performing atmospheric distillation and reduced pressure recovery, and adding water for filtering, wherein the filter cake is the 16-dehydropregnenolone. According to the method, protic solvents such as alcohols are avoided, hydrophilic aprotic solvents are used, a few byproducts are produced, and high-purity 16-dehydropregnenolone is obtained.

Owner:JIANGSU GRAND XINYI PHARMA

A kind of synthetic method of spironolactone intermediate testosterone lactone

ActiveCN104327149BIncrease production capacityImprove economyLactone steroidsDehydropregnenolone acetateSynthesis methods

The invention relates to a synthesis method of a chemical medicine, and concretely relates to a synthesis method of a spironolactone intermediate testosterone lactone. The method is characterized in that a compound I 4-androstenedione (4AD) undergoes a two-step reaction of addition siloxane removal and oxidation cyclization to obtain the compound III testosterone lactone, and the reaction route is shown in the specification. Compared with traditional methods adopting a traditional raw material 16-dehydropregnenolone acetate with high price, the method provided by the invention adopting the cheap and easily available 4-androstenedione (4AD, I) as an initial raw material has extremely high production application and economic values under the affection of market supply and demand.

Owner:ZHEJIANG SHENZHOU PHARMA

A kind of synthetic method of pregnenolone acetate

The invention discloses a synthetic method of pregnenolone acetate. The method comprises the following steps of: 1, carrying out hydrogenation reaction of dehydropregnenolone acetate at a temperature ranging from 35 to 45 DEG C and under 0.4 MPa to 0.8 MPa by taking ethyl acetate as a solvent and a compound catalyst of a palladium / carbon catalyst and ammonium acetate; 2, filtering the reaction liquid after reaction, concentrating the filtrate under normal pressure, then adding a mixed solvent to the concentrated filtrate, and carrying out centrifugal drying after cooling to obtain crude pregnenolone acetate; 3, washing the crude pregnenolone acetate, then carrying out drip washing by using methanol, and drying to obtain white sandy solid pregnenolone acetate. The synthetic method provided by the invention is mild in reaction conditions; ethyl acetate is used as the solvent, and the solvent is high in recovery and low in dosage; as the palladium / carbon catalyst and ammonium acetate are used as the compound catalyst, the catalytic hydrogenation selectivity is high and no impurity is generated; besides, the aftertreatment is simple and the yield is high; the mass purity of the product can be higher than 99.5%.

Owner:西安高远生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com