Method for recycling dehydropregnenolone acetate waste liquor

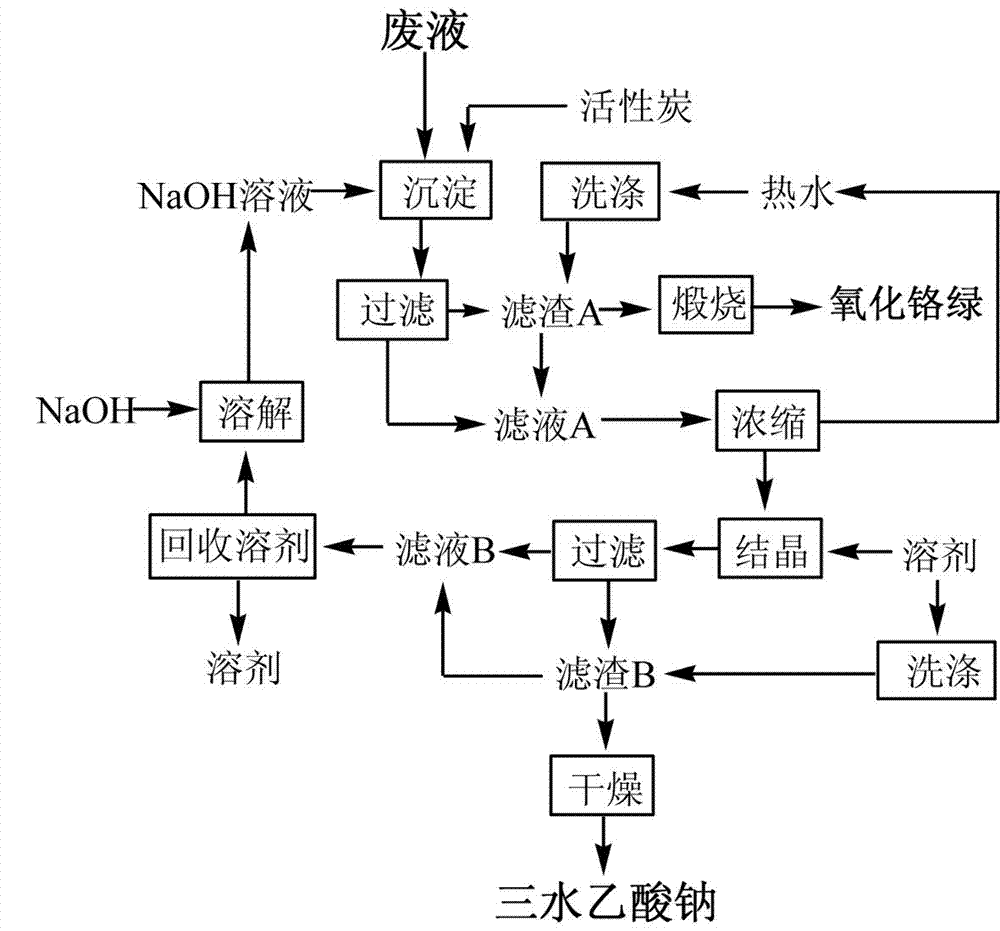

A technology of dienolone acetate and waste liquid, which is applied in the direction of carboxylate preparation, chromium trioxide, chromium oxide/hydrate, etc., can solve the problems of waste of resources, increase the difficulty of subsequent use of wastewater, and achieve water conservation , Significant economic benefits, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] Take 50g of dienolone acetate production waste liquid, adjust the pH to 8 with 20% NaOH solution under stirring, produce a large amount of precipitation, add 0.2g of activated carbon, boil for 10 minutes, filter while hot, wash four times with 20mL boiling water each time , Obtain filter residue A and filtrate A. Filtrate A was concentrated to 50mL under reduced pressure, and the evaporated hot water could be recycled, then 50mL of ethanol was added, crystallized by cooling, filtered, and washed twice with 30mL of ethanol each time to obtain filter residue B and filtrate B. Filter residue B was dried to obtain 54.1 g of white sodium acetate trihydrate crystals, and its content and other indicators were determined by the national standard GB / T 693-1996 method, and the results met the chemical purity grade standard.

[0027] Filter residue A was calcined to obtain 11.9 g of powdered chromium oxide green.

[0028] Filtrate B recovered ethanol and added 18.0g NaOH to the r...

example 2

[0030] Take 100g of dienolone acetate production waste liquid, adjust the pH to 7 with 30% NaOH solution under stirring, a large amount of precipitation occurs, add 0.5g of activated carbon, boil for 5 minutes, filter while hot, and wash four times with 30mL boiling water each time , Obtain filter residue A and filtrate A. Filtrate A was concentrated to 80mL under reduced pressure, and the evaporated hot water could be recycled. Add 70mL of methanol, cool and crystallize, filter, and wash twice with 40mL of methanol each time to obtain filter residue B and filtrate B. The filter residue B was dried to obtain 108.3 g of white sodium acetate trihydrate crystals, and its content and other indicators were determined by the national standard GB / T 693-1996 method, and the results met the chemical purity grade standard.

[0031] Filter residue A was calcined to obtain 23.8 g of powdered chromium oxide green.

[0032] Add 36.0g NaOH to the residual liquid after recovering methanol fr...

example 3

[0034] Take 10kg of dienolone acetate production waste liquid, adjust pH=7.5 with 40% NaOH solution under stirring, produce a large amount of precipitation, add 0.05kg of activated carbon, boil for 8 minutes, filter while hot, wash four times with 3kg of boiling water each time , Obtain filter residue A and filtrate A. Filtrate A was concentrated to about 8L under reduced pressure, and the evaporated hot water could be recycled. Add 7L of ethyl acetate, cool and crystallize, filter, and wash twice with 3L of ethyl acetate each time to obtain filter residue B and filtrate B. The filter residue B was dried to obtain 10.84 kg of white sodium acetate trihydrate crystals, and its content and other indicators were determined by the national standard GB / T 693-1996 method, and the results met the chemical purity grade standard.

[0035] Filter residue A was calcined to obtain 2.39kg of powdered chromium oxide green.

[0036] After recovering ethyl acetate from filtrate B, add 3.6kg N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com