Method of recycling acid wastewater generated during production of dehydropregnenolone acetate

A technology of dienolone acetate and diene waste acid water, which can be applied in chemical instruments and methods, carboxylate preparation, chromium oxide/hydrate and other directions, and can solve the waste of resources, increase the treatment cost, waste of water resources, etc. problem, to achieve the effect of convenient operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

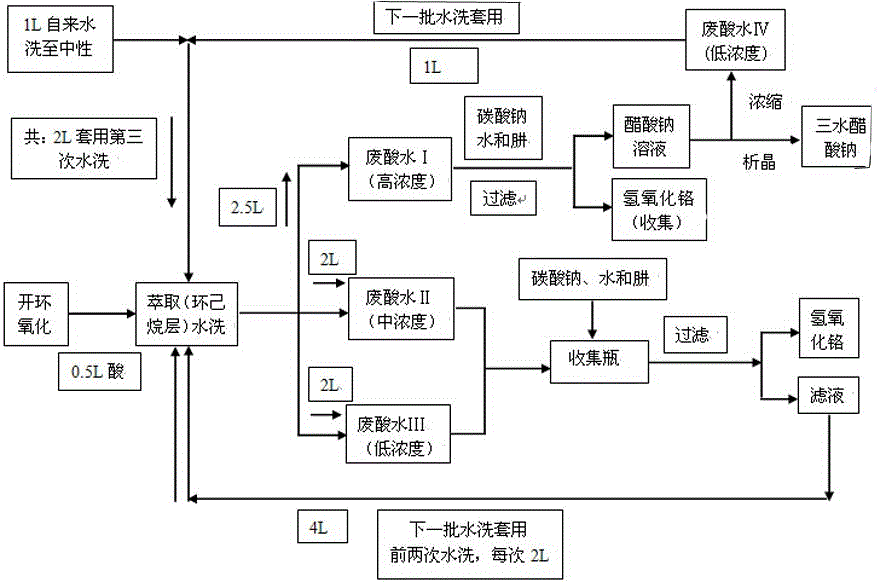

Image

Examples

example 1

[0025] 1) Take 100g of saponin through ring-opening, oxidative hydrolysis to synthesize dienolone acetate, extract with 2L of cyclohexane, wash the cyclohexane layer with 2L of drinking water three times until neutral, and collect three times respectively The acidic aqueous layer was separated.

[0026] 2) Add 125g of sodium carbonate to the first high-concentration waste acid water to adjust pH=8, add 2.5g of water and hydrazine, stir for 1 hour, filter to obtain Cr(OH)3, content: 98.1%; concentrate the filtrate until When 2 / 5 of the filtrate is concentrated, cool down to 10°C and crystallize for 4 hours, and filter to obtain sodium acetate trihydrate, content: 60%; 1L of concentrated waste water and 1L of fresh drinking water will be used for the third batch of the next batch of production. wash.

[0027] 3) Add 4g of sodium carbonate to the second and third waste acid water to adjust pH=8, add 1g of water and hydrazine, stir for 1 hour, filter to obtain Cr(OH)3, content: 9...

example 2

[0029] 1) Take 100g of saponin through ring-opening, oxidative hydrolysis to synthesize dienolone acetate, extract with 2L of cyclohexane, and wash with the waste acid water from the previous batch until neutral.

[0030] 2) Use the 2L filtrate from the second water wash of the previous batch for the first wash. After washing and stratification, high-concentration waste acid water is obtained. Add 200g of sodium carbonate to the high-concentration waste acid water to adjust pH = 9, and add 3.75g Water and hydrazine, stirred for 1 hour, filtered to obtain Cr(OH)3, content: 98%; the filtrate was concentrated until 3 / 5 of the filtrate was concentrated, cooled to 15°C for crystallization for 6 hours, filtered to obtain sodium acetate trihydrate, content: 61%, a total of 2L of concentrated wastewater and 1L of fresh drinking water are used for the third washing in the next batch of production.

[0031] 3) Add 10g of sodium carbonate to the second and third waste acid water to adjus...

example 3

[0033] 1) Take 100g of saponin through ring-opening, oxidative hydrolysis to synthesize dienolone acetate, extract with 2L of cyclohexane, and wash with the waste acid water from the previous batch until neutral.

[0034] 2) Use 2L of the filtrate from the second water wash of the previous batch for the first wash, and after washing and stratification to obtain high-concentration waste acid water, add 125g of sodium carbonate to the high-concentration waste acid water to adjust pH = 8, and add 2.5g Water and hydrazine, stirred for 1 hour, filtered to obtain Cr(OH)3, content: 98.3%; the filtrate was concentrated until 2 / 5 of the filtrate was concentrated, cooled to 10°C for crystallization for 4 hours, filtered to obtain sodium acetate trihydrate, content: 60%; the concentrated wastewater is used for the third washing in the next batch of production.

[0035] 3) Add 4g of sodium carbonate to the second and third waste acid water to adjust pH=8, add 1g of water and hydrazine, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com