Method and system for treating residue-containing wastewater of dehydropregnenolone acetate

A technology for treating dienolone acetate and waste water, which is applied in the field of medicine and chemical industry, can solve the problems of difficulty in centrifugation and plate-and-frame filtration, unsatisfactory treatment cost and effect, large equipment investment, etc., so as to reduce the pressure of sewage treatment, The effect of eliminating secondary pollution and reducing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Extract and wash 2500L of slag-containing waste water after dienolone acetate is extracted and washed, and the raw water COD is 35685mg / L. Heat and stir. During heating, the steam is heated to 65°C through the inner coil, and the ultrasonic equipment is turned on at the same time, power: 2.5Kw , frequency: 19.6Khz, time: 15min. At the end of the ultrasonic wave, turn off the steam, stop the agitation, settle naturally for 2 hours, let stand to separate the phases, separate out 2190L of waste water, its COD is 15056mg / L, and the COD is reduced by 57.81%.

[0029] 2. Pump the remaining oil scum into the distillation tank, start stirring, turn on the steam jacket to raise the temperature, control the temperature at 65~80°C, and recover 150.5L of cyclohexane by vacuum distillation, the solvent recovery rate: 86%.

[0030] 3. Put the remaining oil scum into the tray while it is hot, cool down and solidify naturally, and then do solid waste incineration.

Embodiment 2

[0032] 1. Extract and wash 2500L of slag-containing waste water after dienolone acetate is extracted and washed. The COD of the raw water is 37619mg / L, and it is heated and stirred. During heating, the steam is heated to 60°C through the inner coil, and the ultrasonic equipment is turned on at the same time, power: 2.5Kw , frequency: 20Khz, time: 15min. At the end of the ultrasound, turn off the steam, stop stirring, settle naturally for 1 hour, stand still for phase separation, and separate 2214L of waste water, its COD is 17466mg / L, and the COD is reduced by 53.57%.

[0033] 2. Pump the residual oil scum into the distillation tank, start stirring, turn on the steam jacket to raise the temperature, control the temperature at 65~80°C, and recover 151L of cyclohexane by vacuum distillation. The solvent recovery rate is 86.29%.

[0034] 3. Put the remaining oil scum into the tray while it is hot, cool down and solidify naturally, and then do solid waste incineration.

Embodiment 3

[0036] 1. Heat and stir 2500L of slag-containing wastewater in the treatment of dienolone acetate mother liquor, and the raw water COD is 36769mg / L. During heating, the steam is heated to 65°C through the inner coil, and the ultrasonic equipment is turned on at the same time. Power: 2.5Kw, frequency: 19Khz, time: 15min. At the end of the ultrasound, turn off the steam, stop stirring, settle naturally for 1.5 hours, stand still and separate the phases, and separate out 2205L of waste water, its COD is 16640mg / L, and the COD is reduced by 54.74%.

[0037] 2. Pump the residual oil scum into the distillation tank, start stirring, turn on the steam jacket to raise the temperature, control the temperature at 65~80°C, and recover 150L of cyclohexane by vacuum distillation. The solvent recovery rate is 85.71%.

[0038] 3. Put the remaining oil scum into the tray while it is hot, cool down and solidify naturally, and then do solid waste incineration.

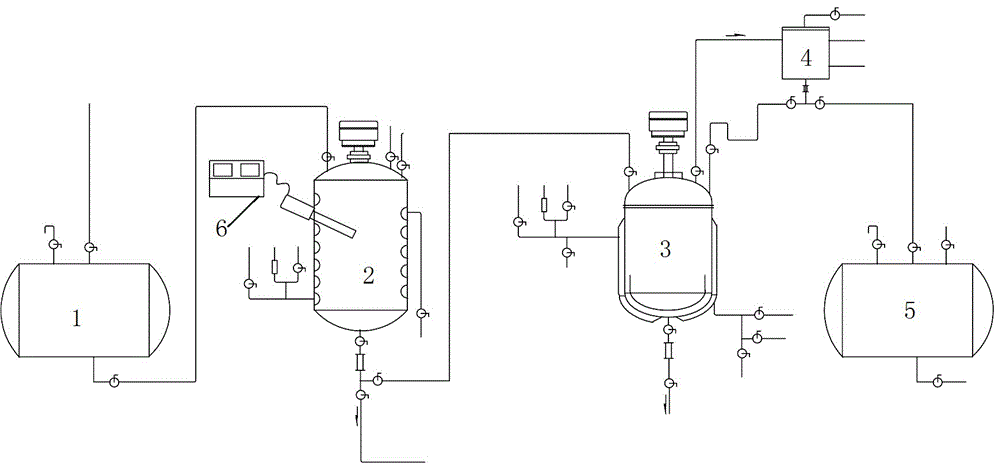

[0039] Such as figure 1 Shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com