Grinding machine for outer peripheral surface of bearing outer ring

A technology for the outer ring and outer peripheral surface of a bearing, which is applied to the grinding frame, the machine tool designed for grinding the rotating surface of the workpiece, the grinding machine, etc., which can solve the problems of no grinding and achieve the goal of improving the grinding performance and grinding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

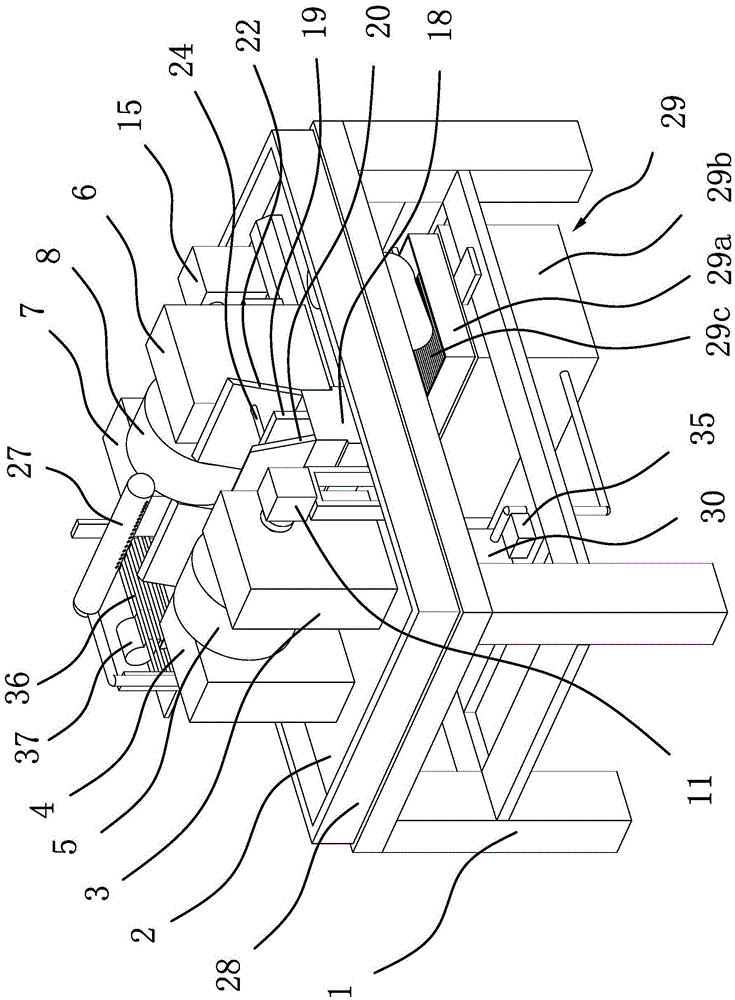

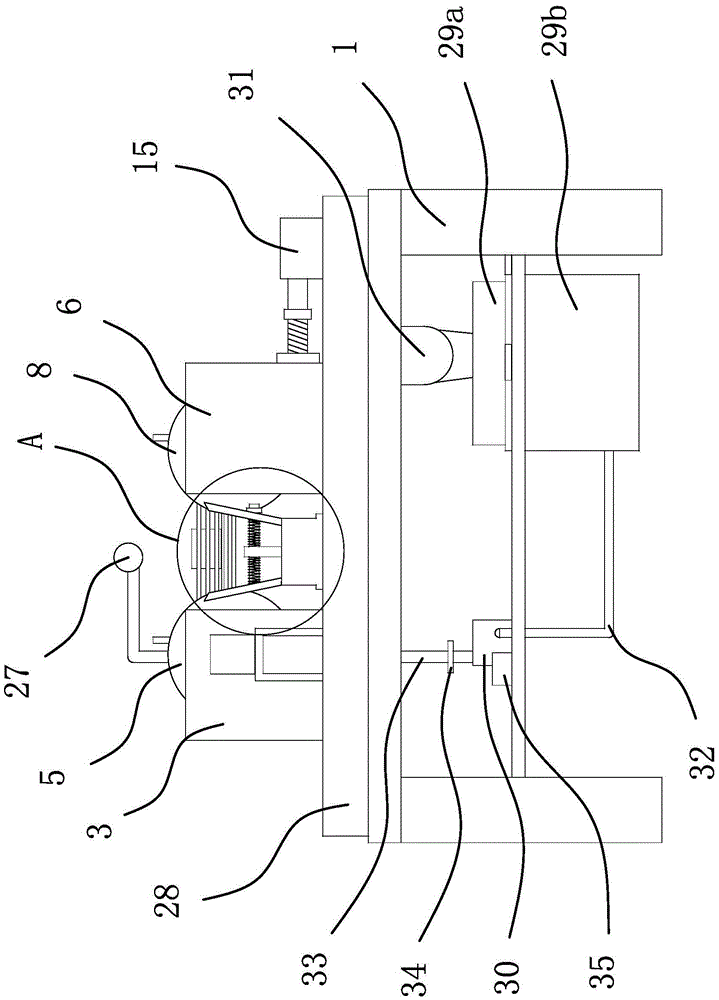

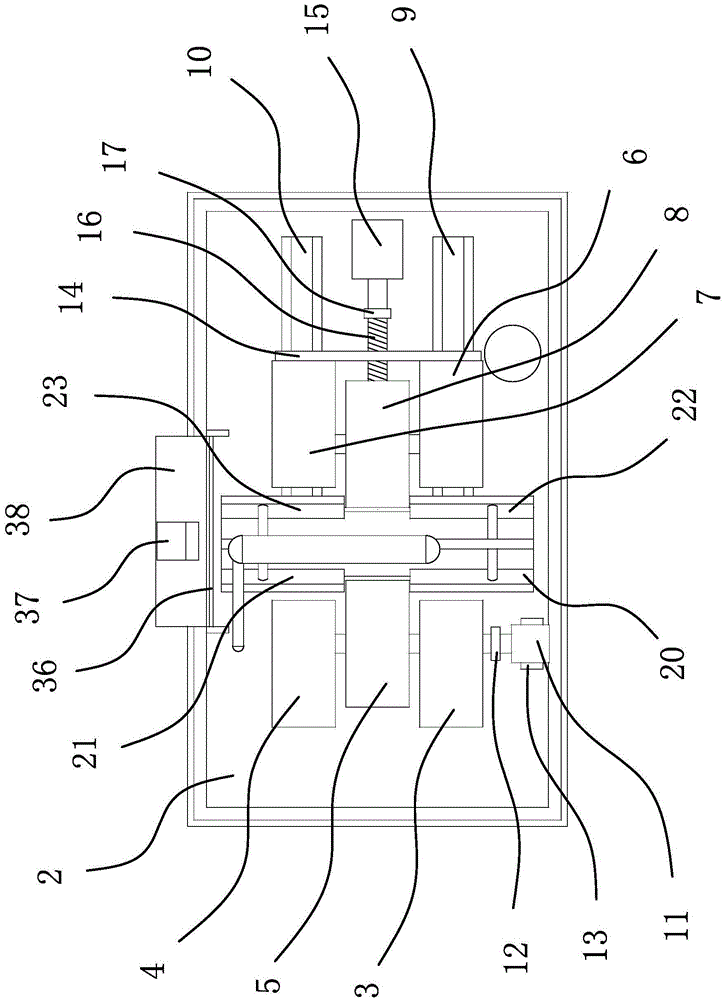

[0036] like figure 1 , 2 As shown in and 3, a grinding machine for the outer peripheral surface of a bearing outer ring includes a frame 1, on which a worktable 2 is fixed, and four water baffles 28 are fixed on the edge of the worktable 2, and the four baffles The water plate 28 is surrounded into a rectangle and can surround the workbench 2, so as to prevent the water on the workbench 2 from flowing around the workbench 2. The workbench 2 is also provided with a return hole to make the workbench The water on the plate 2 can flow out from the return hole.

[0037] like figure 1 As shown, the frame 1 includes four legs and an installation frame fixed on the upper part of the legs, the workbench 2 is installed in the installation frame, and the middle part of the frame 1 is fixed with a horizontal plate 1 and a horizontal plate 2 parallel to each other. A vertical board one and a vertical board two parallel to each other. A substrate is also fixed between the first horizont...

Embodiment 2

[0061] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in Embodiment 1, the power mechanism includes a driving motor 11 and a shaft coupling 12, and the driving motor 11 is fixed on the working side by a mounting frame 13. On the platen 2, one end of the coupling one 12 is connected with the output shaft of the driving motor 11, and the other end is connected with the rotating shaft one; and in the second embodiment, the power mechanism includes a driving motor 11, a driving pulley, and a driven pulley And the belt, the driving motor 11 is fixed on the worktable 2 by screws, and the output shaft of the driving motor 11 is parallel to the first rotating shaft, the driving pulley is fixed on the output shaft of the driving motor 11, and the driven pulley is fixed on the first rotating shaft , the belt is set between the driving pulley and the driven pulley. Open drive motor 11, the output shaft of drive motor ...

Embodiment 3

[0063] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that in Embodiment 1, the adjustment mechanism includes an adjustment motor 15, a connecting plate 14 and a screw rod 16, and the adjustment motor 15 is fixed on the worktable 2 and adjust the output shaft of the motor 15 towards the positioning wheel 8, one end of the connecting plate 14 is fixed to the bearing seat 3 6, and the other end is fixed to the bearing seat 4 7, the middle part of the connecting plate 14 is provided with an adjustment hole, and the screw rod 16 One end is threadedly connected in the adjusting hole on the connecting plate 14, and the other end is fixedly connected with the output shaft of the adjusting motor 15 through the coupling two 17; and in the third embodiment, the adjusting mechanism includes a cylinder and a connecting block, and the cylinder It is fixed on the worktable 2, and the piston rod of the cylinder faces the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com