Raw material heating system and process for preparing carbon disulfide

A carbon disulfide and heating system technology, applied in the direction of carbon disulfide, carbon sulfur compounds, etc., can solve problems such as unsatisfactory heating effect of raw materials, unreasonable heating tube layout, incomplete reaction of raw materials, etc., to achieve saving raw materials, thorough heating, and sufficient mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

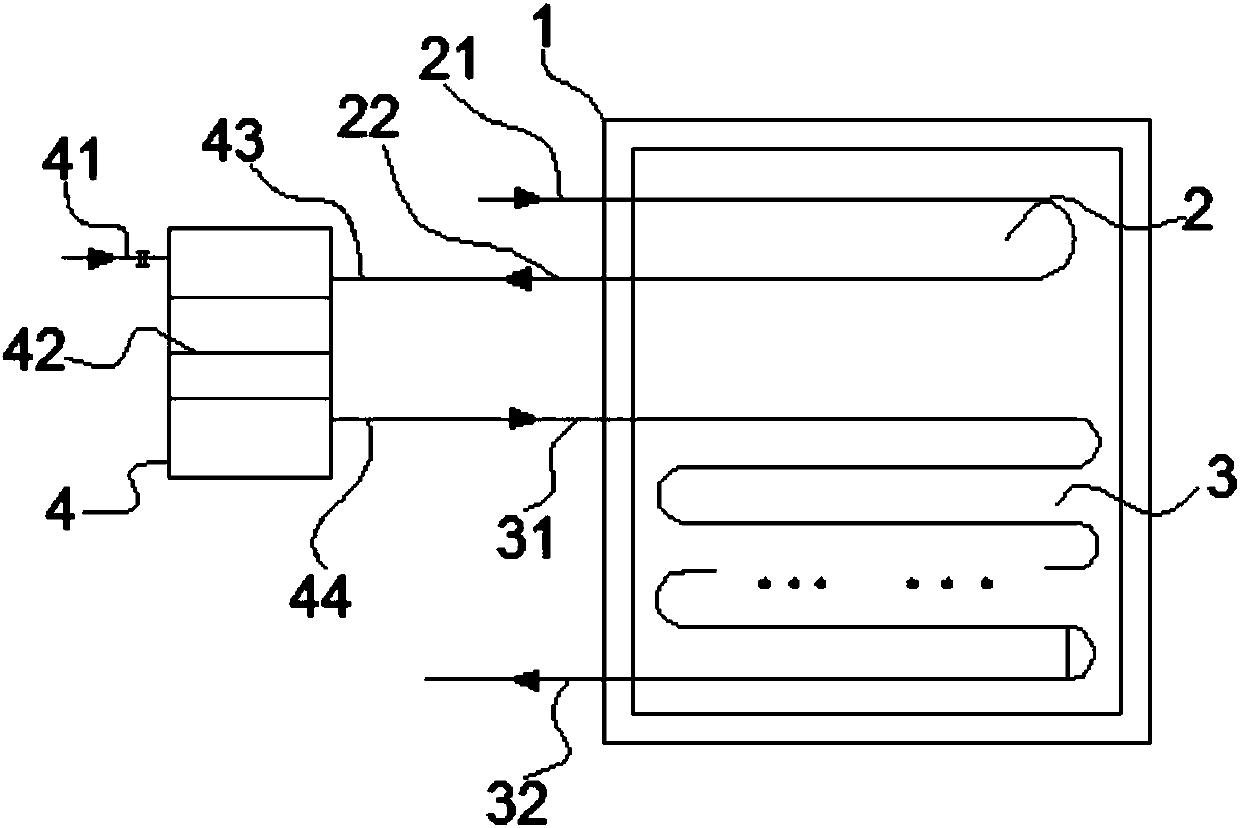

[0021] a kind of like figure 1 The raw material heating system for preparing carbon disulfide shown includes a heating furnace body 1, a preheating pipeline 2, a heating pipeline 3, and a raw material mixing device 4; the heating furnace body 1 is provided with a furnace wall heating device, which is mainly heated by an electric heating wire, Its heating temperature can reach 600 degrees Celsius, and its function is to heat the raw materials flowing through the preheating pipeline 2 and the heating pipeline 3 . Both the preheating pipeline 2 and the heating pipeline 3 are placed in the heating furnace body 1 , and the nozzles at both ends pass through the heating furnace body 1 . The heating furnace body 1 is provided with a furnace tube clamping device for respectively fixing the furnace tube of the preheating pipeline 2 and the furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com