Patents

Literature

55results about How to "Shorten the heating cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

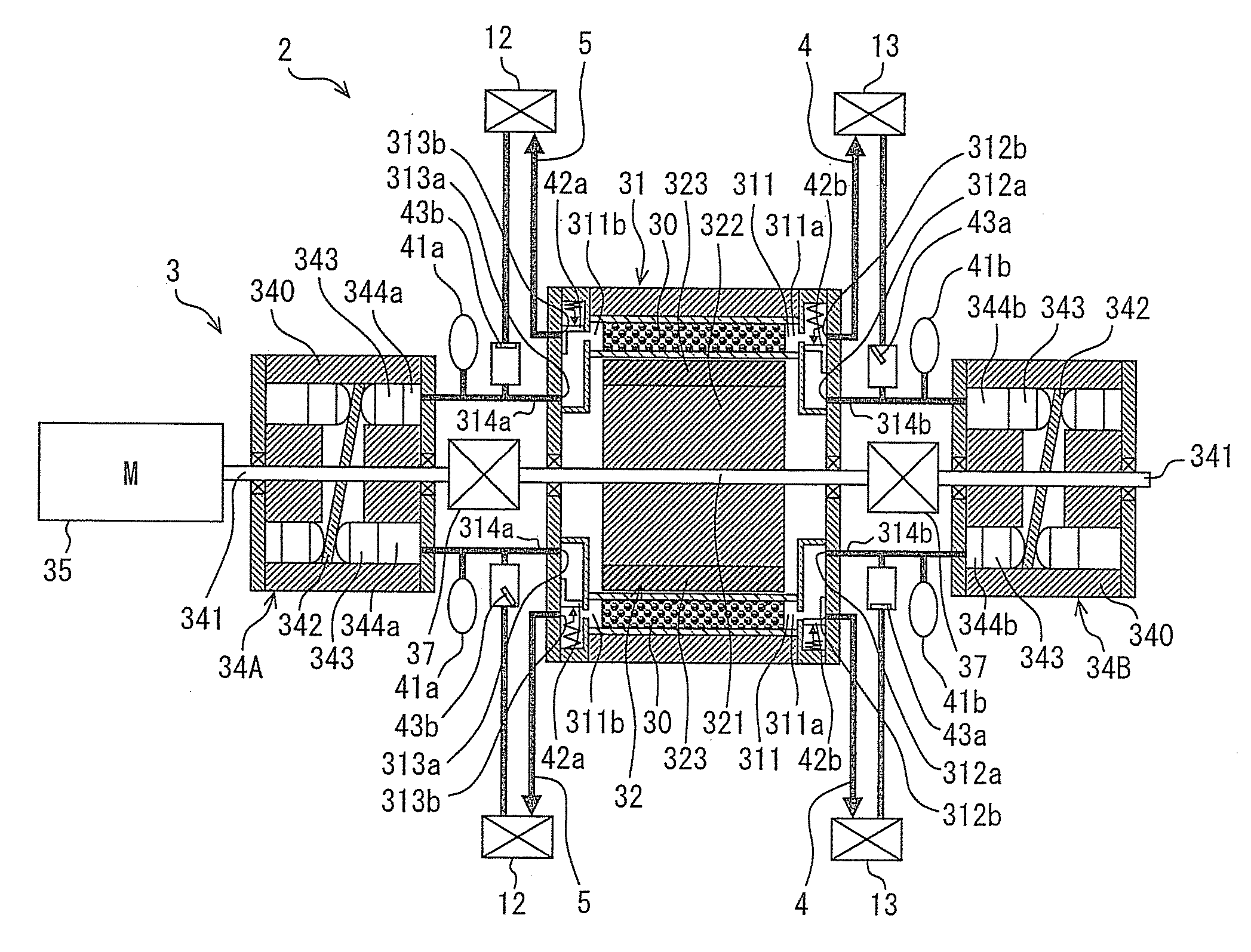

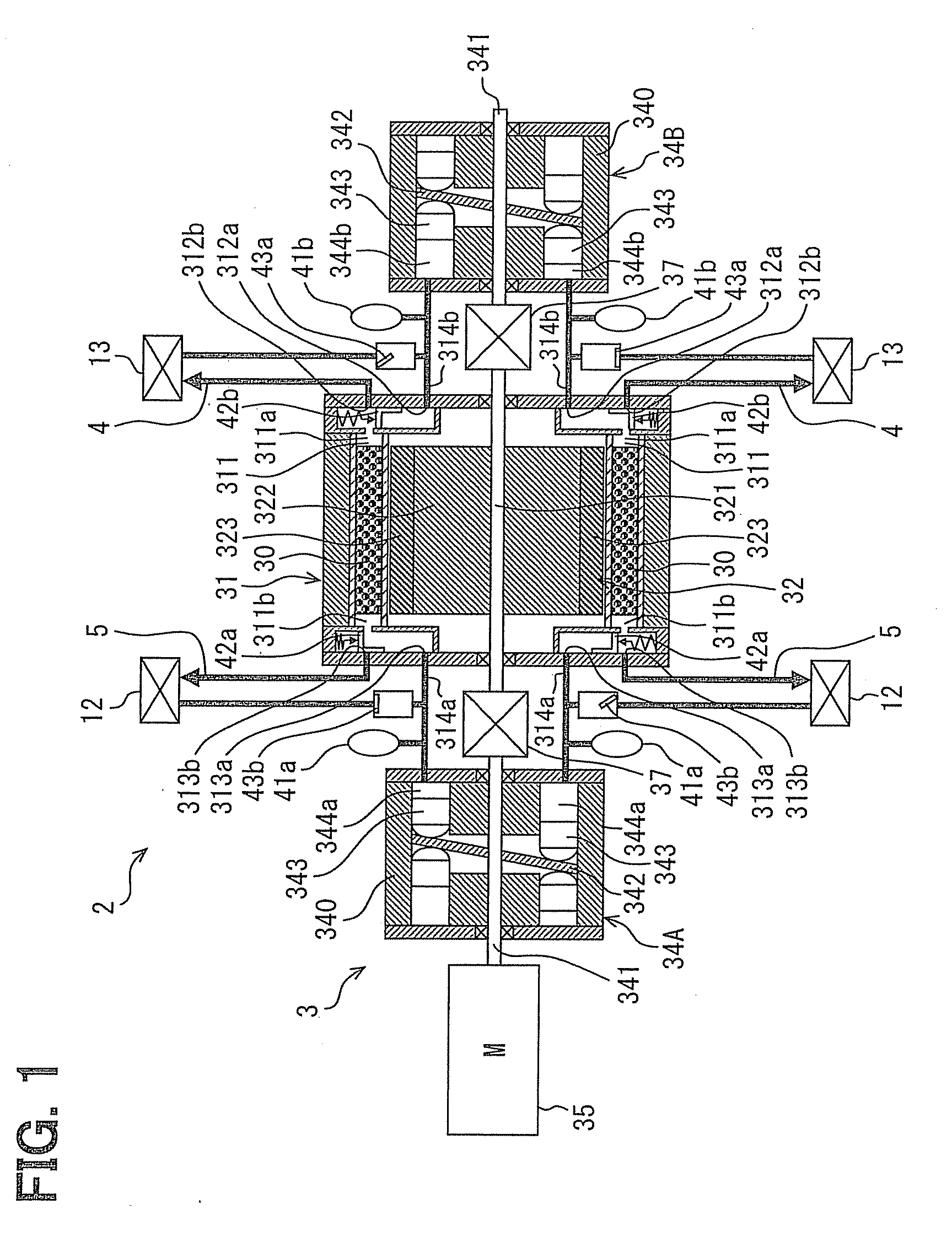

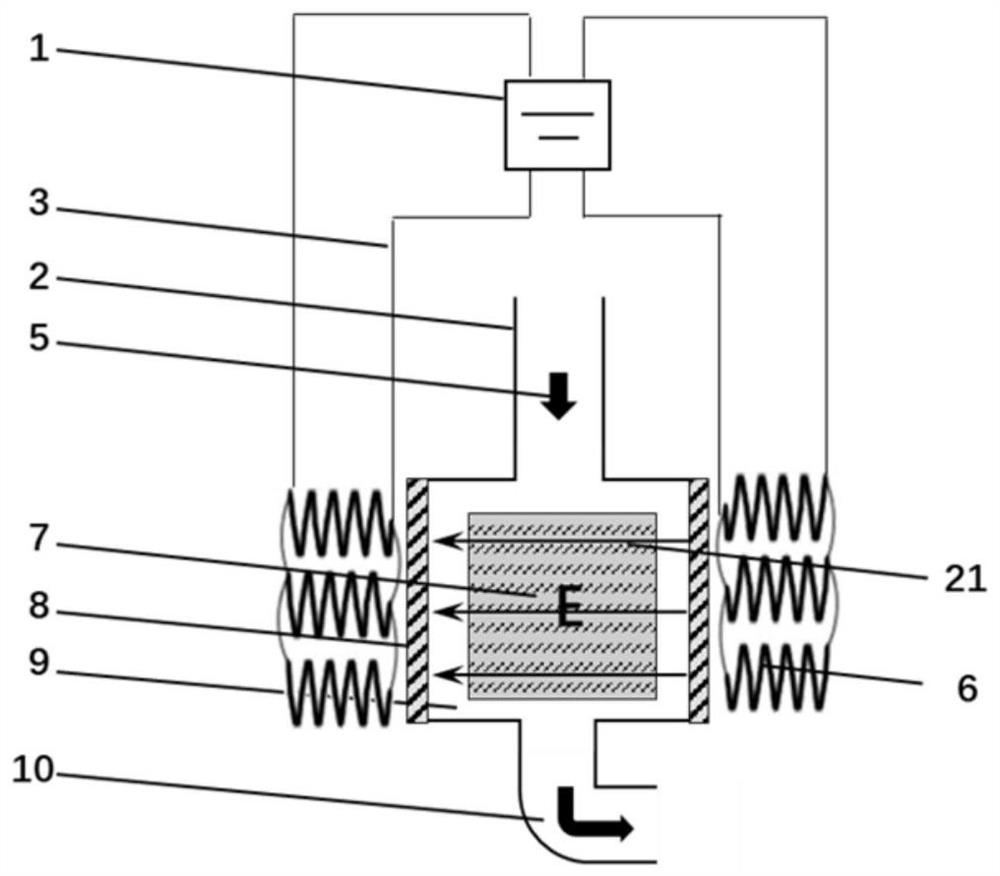

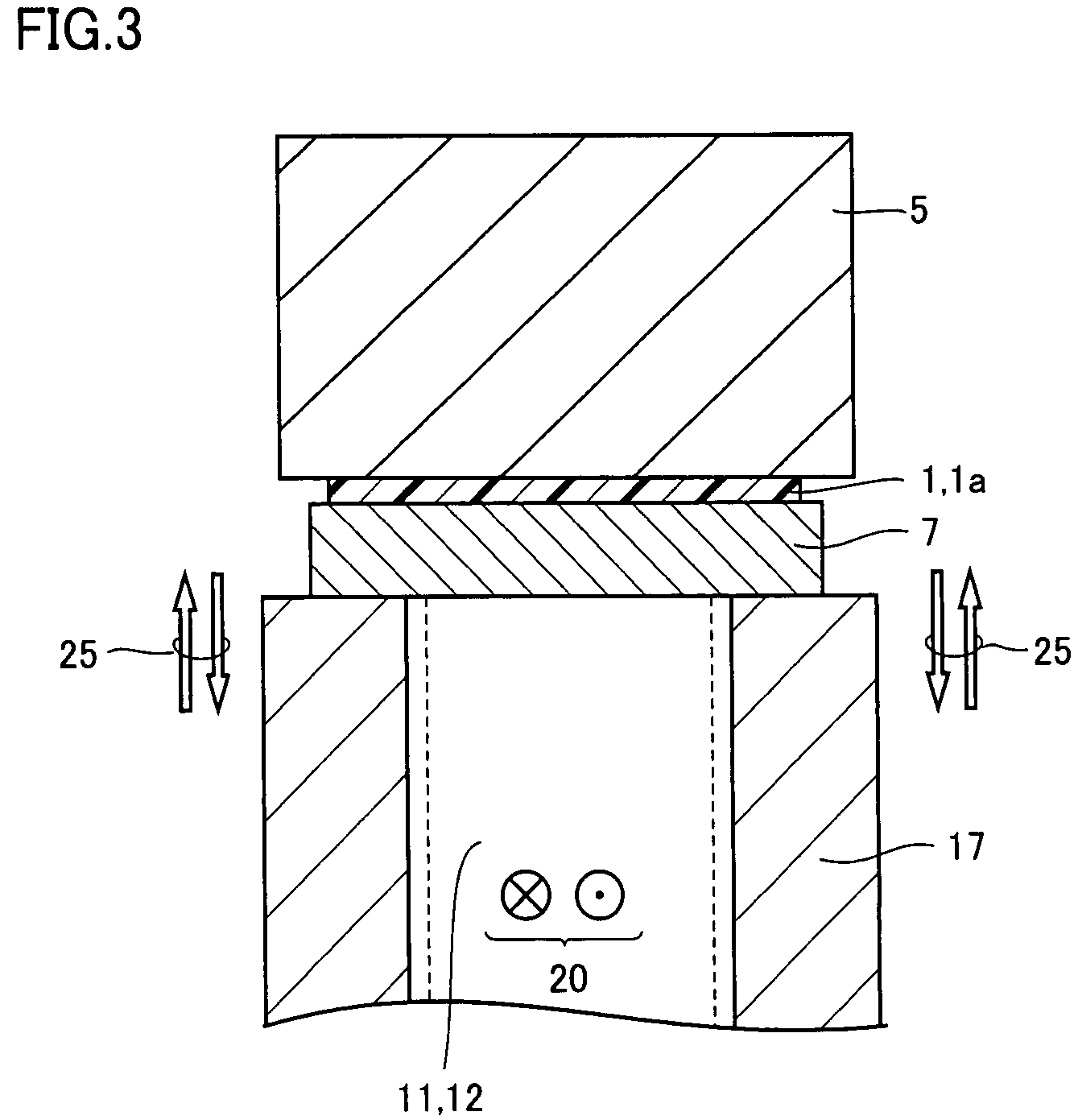

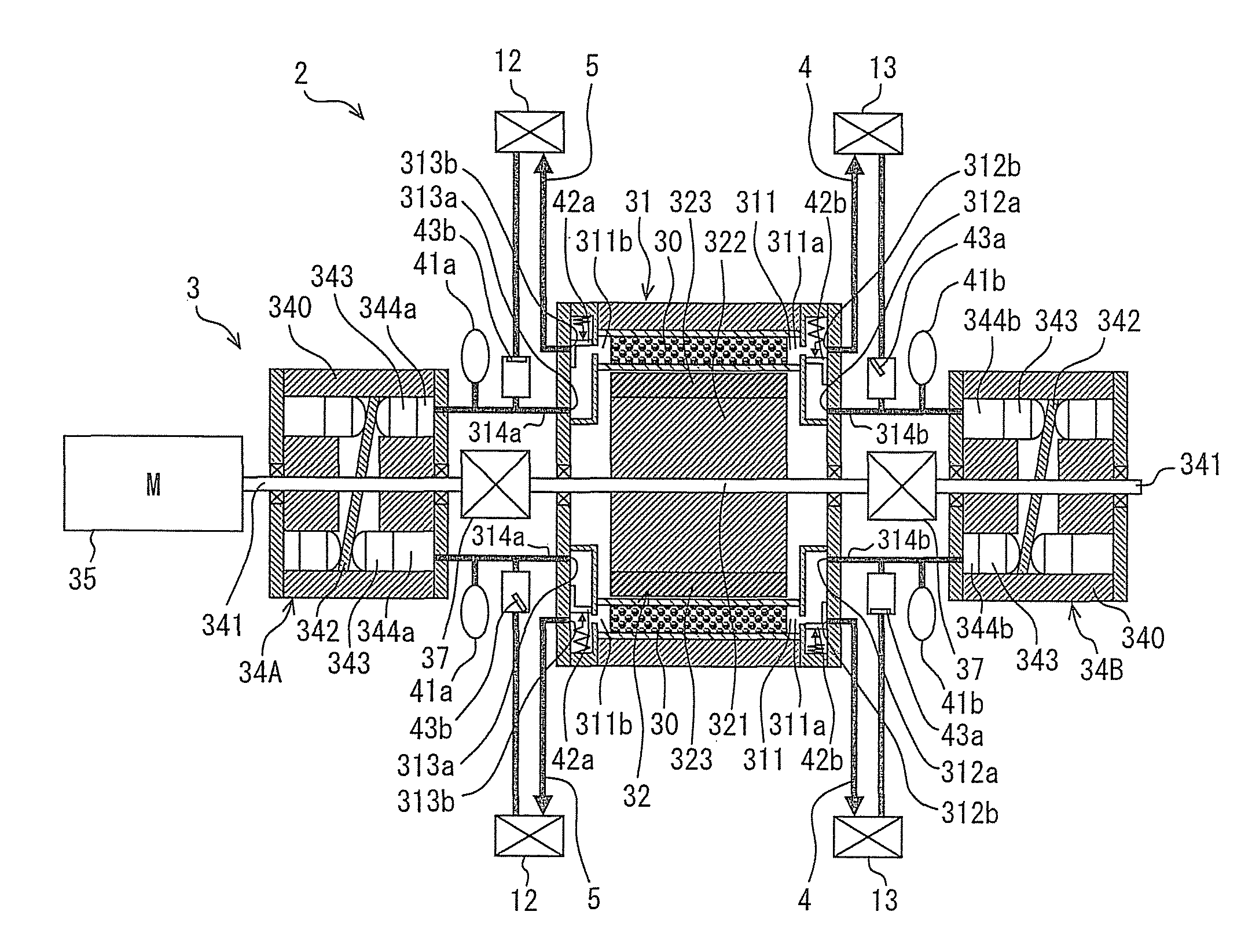

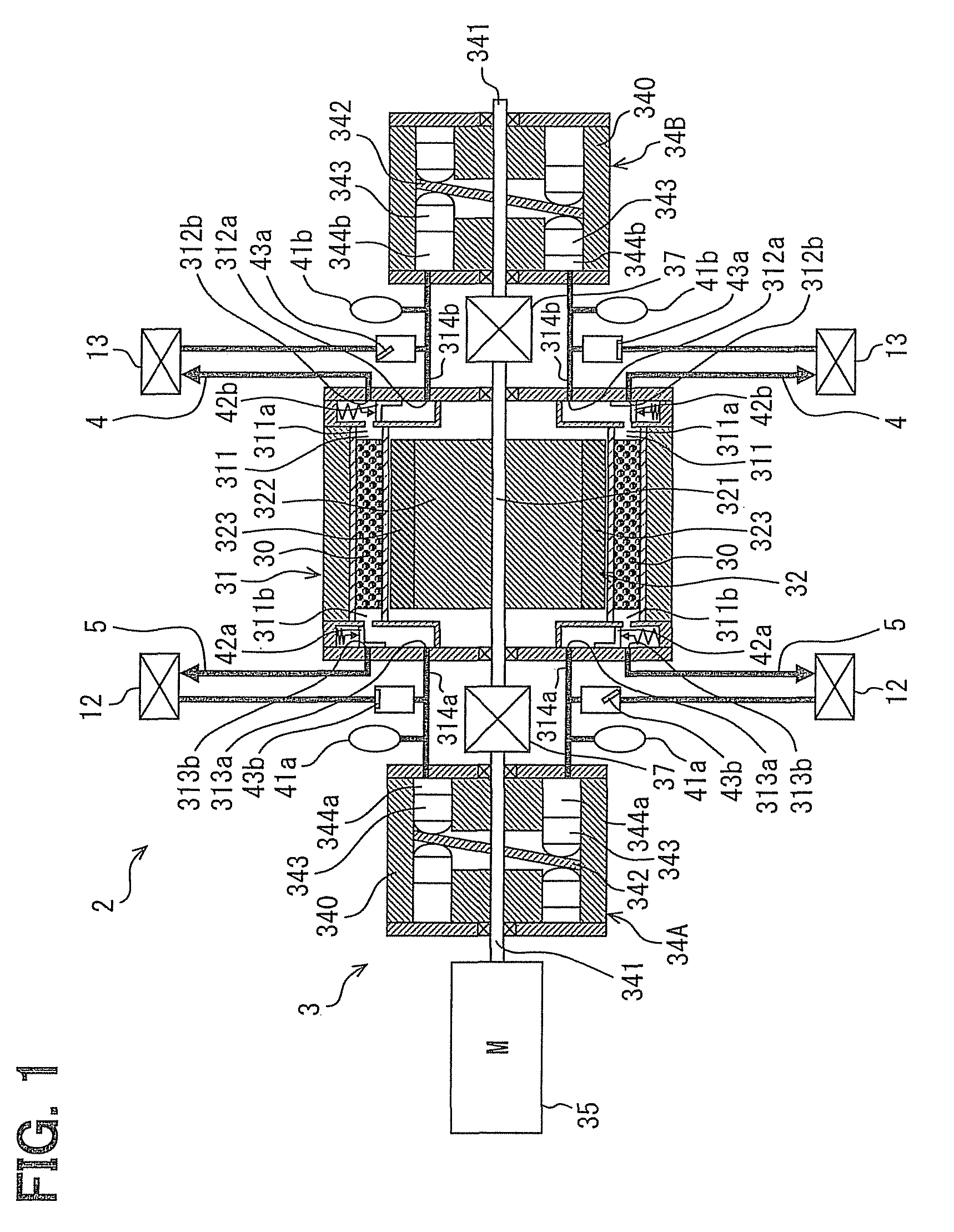

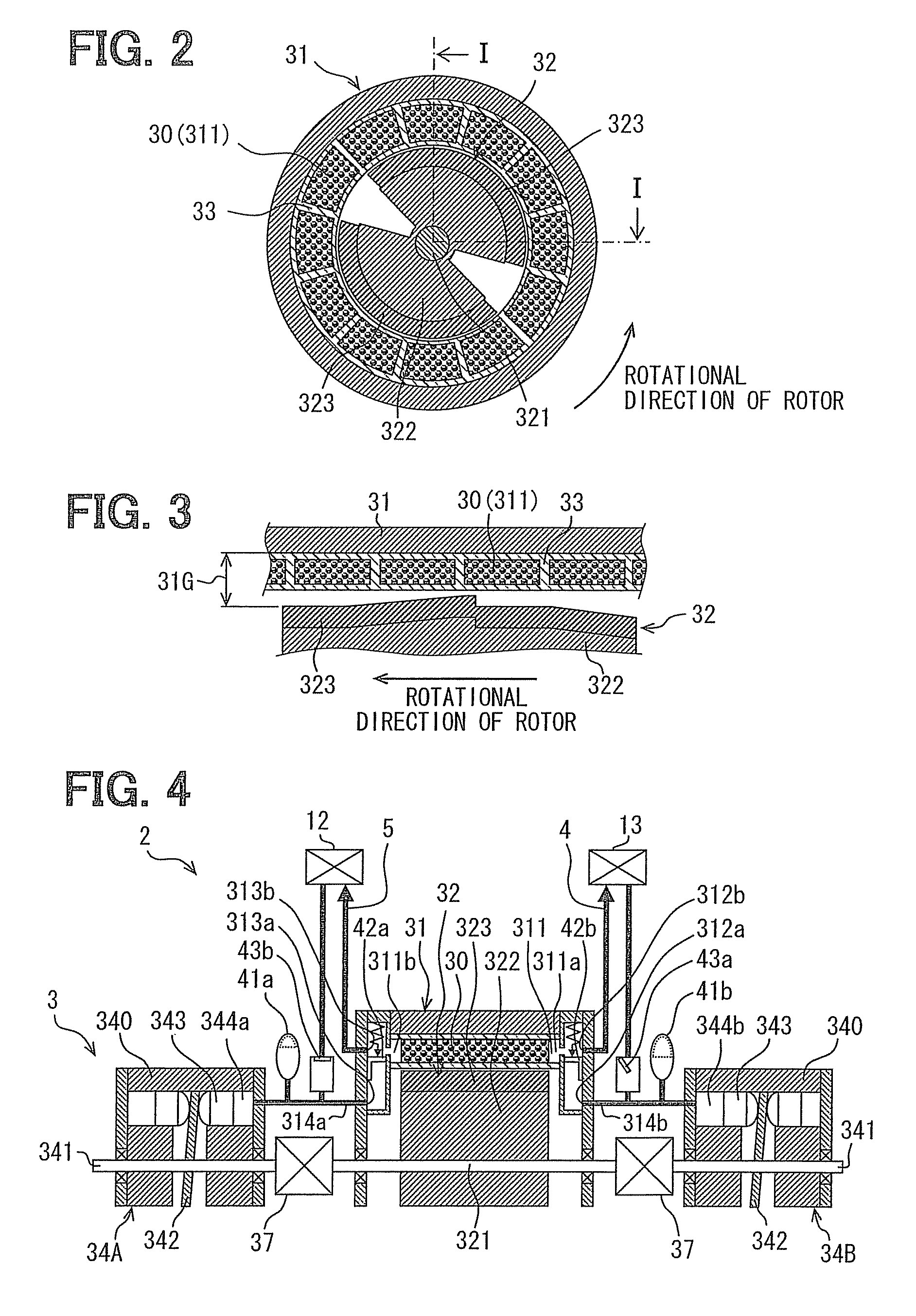

Magnetic heat pump apparatus

ActiveUS20120272665A1Improve magnetic efficiencyEffective movementEnergy efficient heating/coolingMachines using electric/magnetic effectsEngineeringHeat pump

A magnetic heat pump cycle has a first to a fourth steps, which are repeatedly carried out. In the first step, a movement of heat medium is stopped by a pressure valve and a pressure accumulating tank and a magnetic field is applied by a magnetic-field control unit to a magnetic working material. In the second step, the pressure valve is opened so that the heat medium flows in a working chamber from a second axial end to a first axial end, and the magnetic field is increased depending on a moving speed of the heat medium. In the third step, the movement of the heat medium is stopped and the magnetic field is decreased. In the fourth step, the heat medium is moved in a revered direction and the magnetic field is decreased depending on the moving speed of the heat medium.

Owner:DENSO CORP

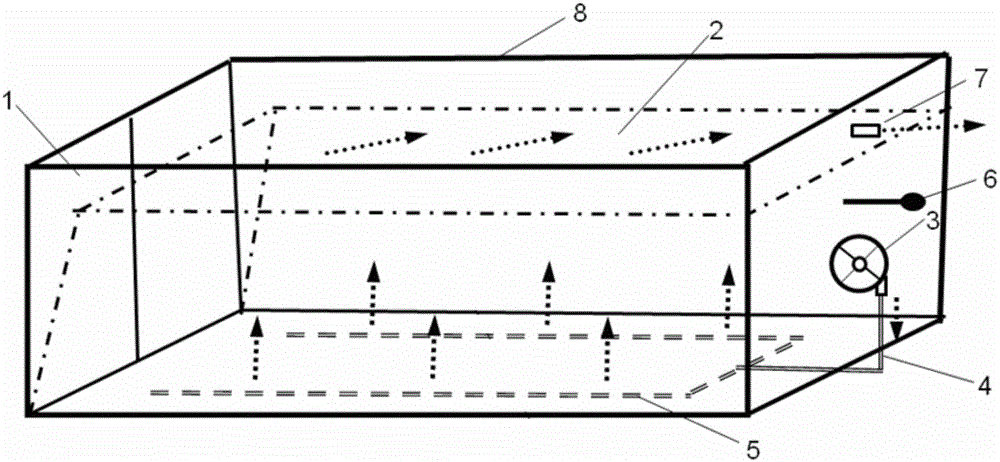

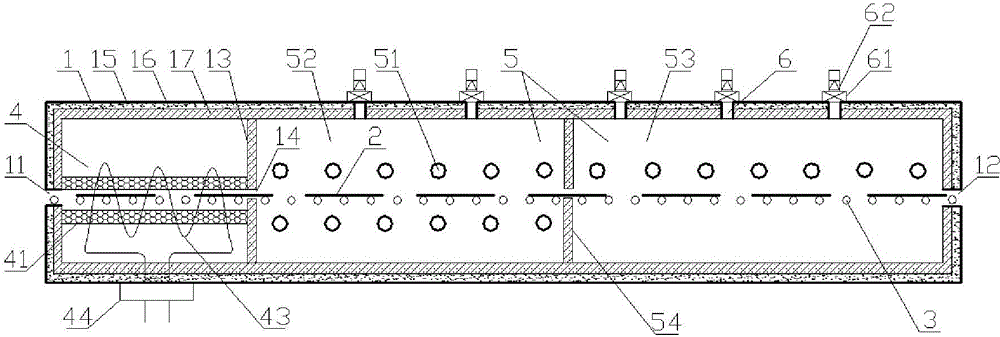

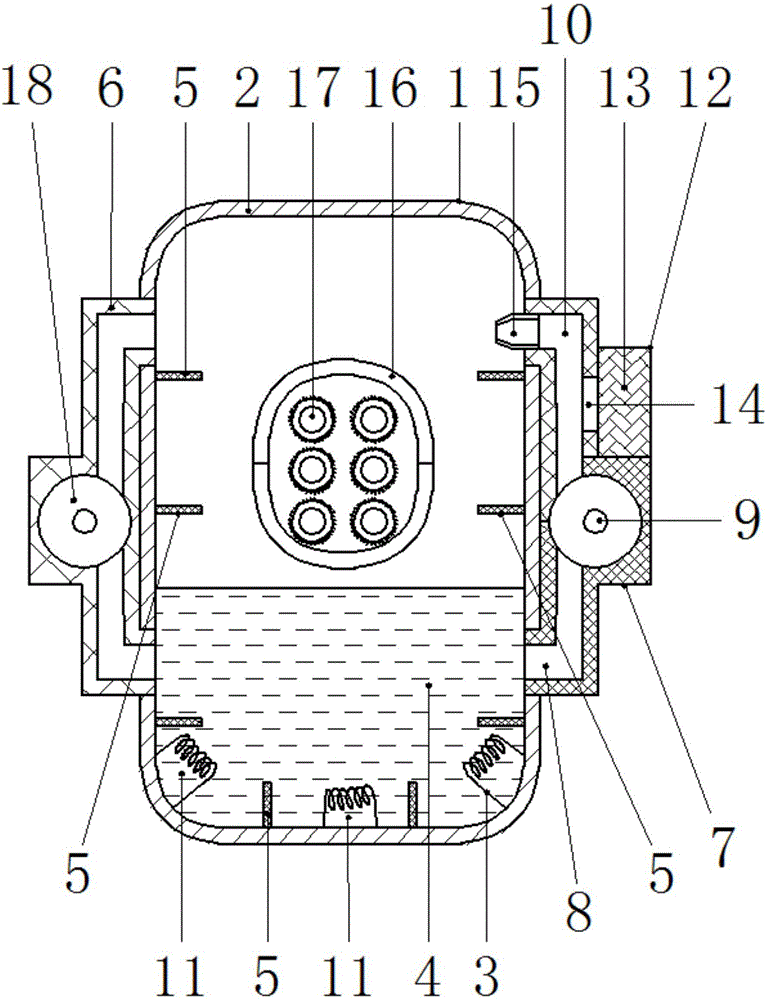

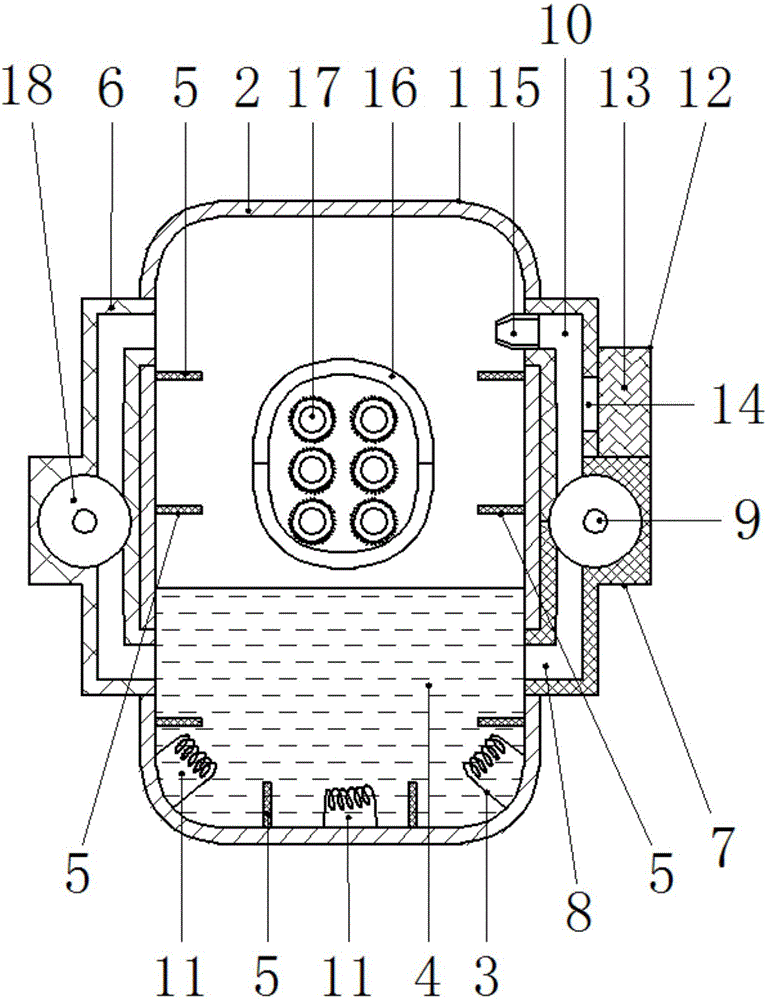

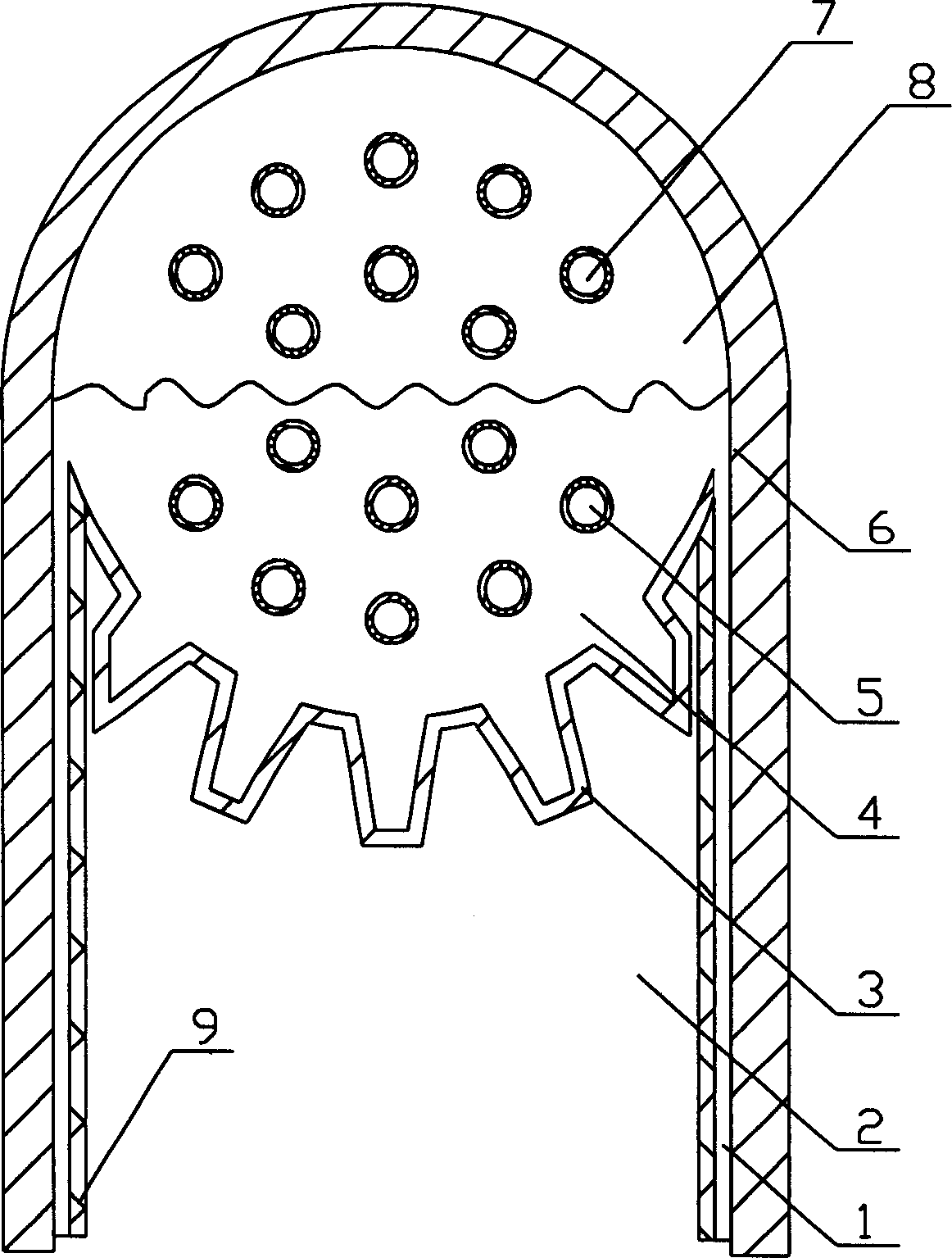

Membrane lining container type fermentation device and compost and deodorization method using same

ActiveCN105084966ASimple equipmentReduce odor pollutionBio-organic fraction processingChemical industryExhaust gasCompost

The invention discloses a membrane lining container type fermentation device and a compost and deodorization method using the same, and relates to a compost device and a compost and deodorization method using the device. The problems that an existing container type compost mode is high in operating cost, an existing biological filter is inconvenient to move and the construction period is long can be solved. The device comprises a container door, a waterproof and breathable membrane, an air blower, an air inlet pipe, a perforation breather pipe, a temperature detector, an air outlet pipe and a container body. The method includes the steps that first, materials are put in; second, when the temperature is lower than 60 DEG C, intermittent ventilation is conducted; when the fermentation temperature is higher than 60 DEG C, continuous ventilation is conducted, and fermentation tail gas is exhausted; third, the materials are taken out after being fermented for 10-15 days. According to the membrane lining container type fermentation device, the body is improved from a container or a waste container, equipment is simple and convenient to use, waste can be utilized, equipment cost is saved, and the construction period is short; the air blower is controlled to operate through time and temperatures, so that electric energy is saved; transportation is facilitated; occupied area is reduced obviously.

Owner:HARBIN INST OF TECH

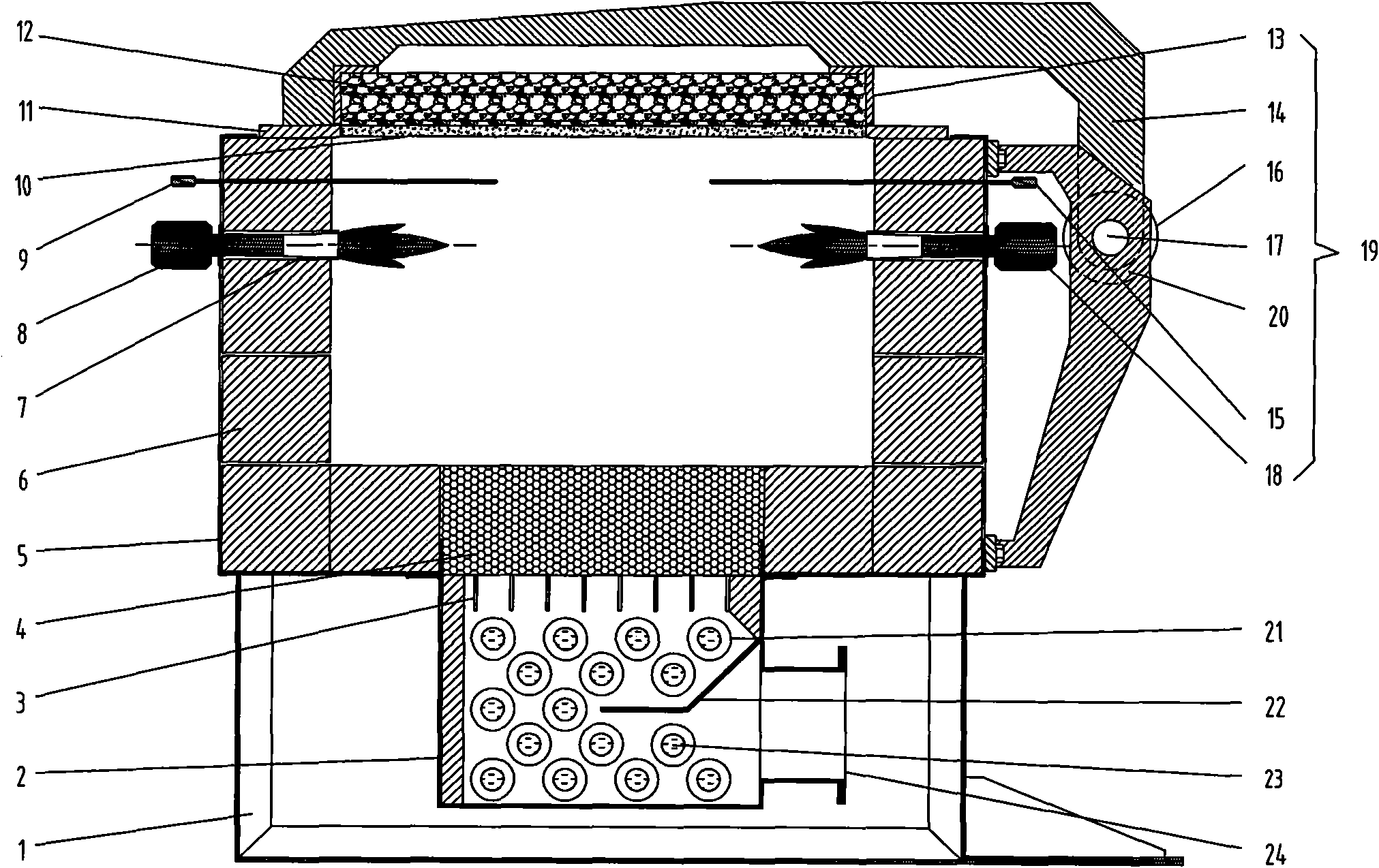

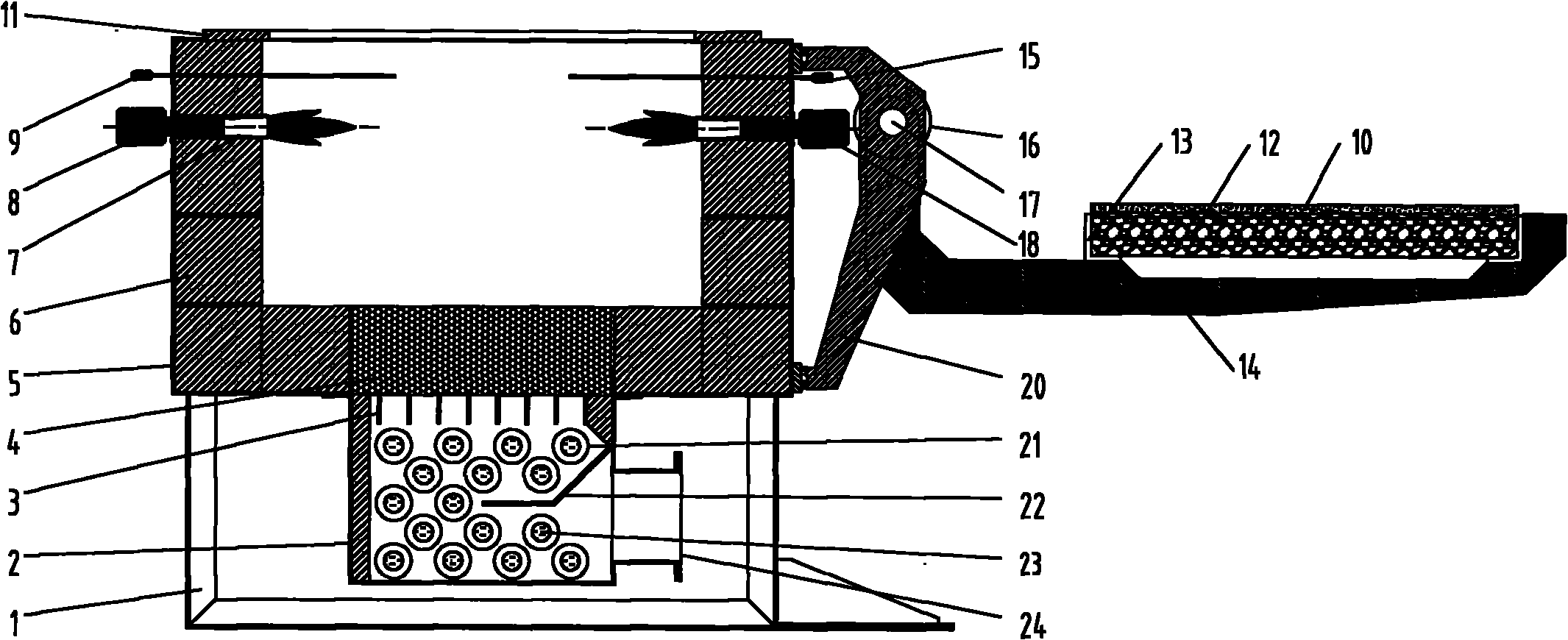

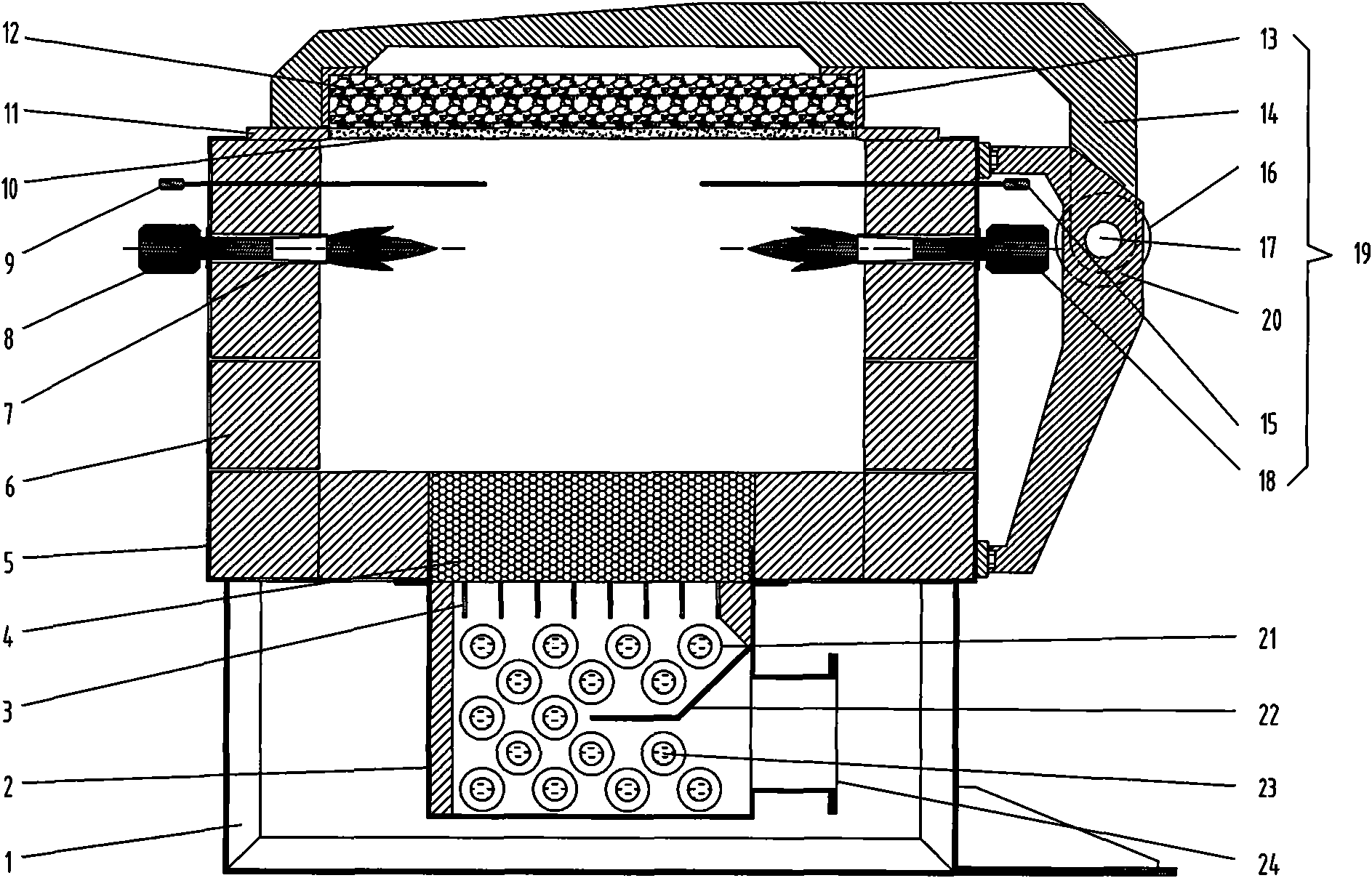

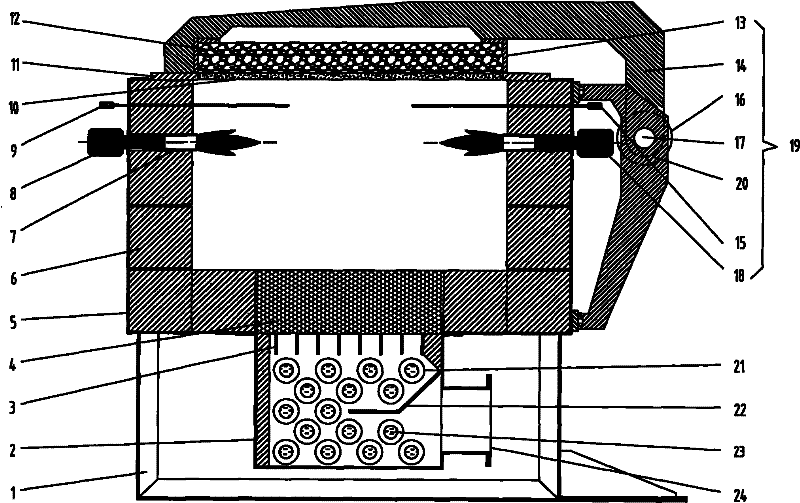

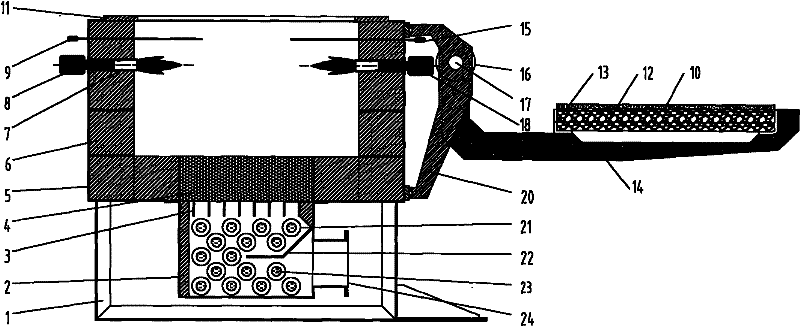

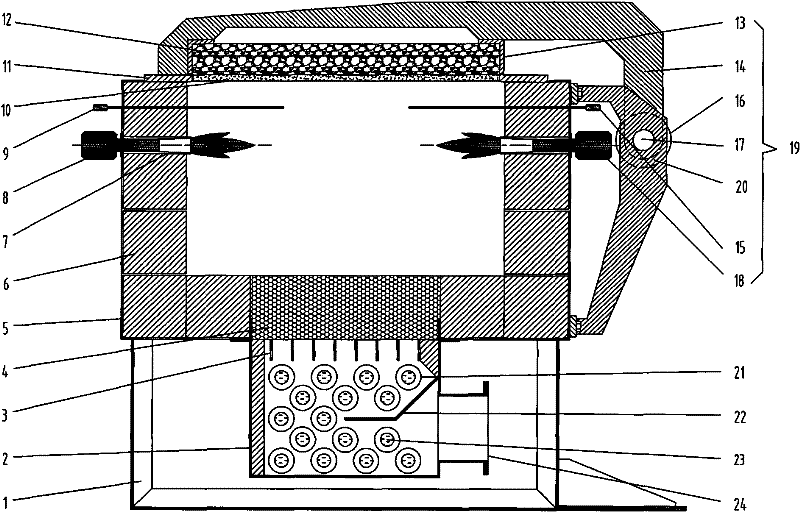

Furnace for testing limit of fire resistance of tunnel fire-proof protective material

InactiveCN101846453AReasonable structureUniform and stable lateral temperatureFurnace typesMaterial thermal analysisCombustorFlue gas

The invention relates to a furnace for testing the limit of fire resistance of a tunnel fire-proof protective material, which is characterized in that when a sample is tested, the sample is covered at the top of a furnace body, and a burning device is placed at the bottom of the sample to be used for heating the sample. The furnace body comprises a furnace lining, short-flame burners, a sample clamping and turning device and a cellular heat absorbing board, wherein the furnace lining in a modular structure is arranged in a furnace shell; the cellular heat absorbing board is arranged at the opening part of the bottom of the furnace shell; the cellular heat absorbing board is connected with a water-cooled multi-tube cooler; the sample clamping and turning device is arranged at one side of the furnace shell; the internal dimension of the furnace lining is matched with the external boundary dimension of the sample; and a plurality of temperature thermocouples and the short-flame burners are sequentially arranged in the furnace lining from top to bottom. The invention has the advantages that (1) the sample is arranged at the top of a furnace chamber and is reasonably heated, thereby reducing the fuel consumption and enabling the transverse temperature of the furnace chamber to be more uniform and stable; (2) the corner-type electric sample clamping and turning device is adopted, thereby relieving the labor intensity of experimenters and ensuring that the experiment operating process is more simple, more convenient and more reliable; and (3) the flue gas emission temperature reaches the specified emission standard.

Owner:辽宁同辉科技发展有限公司

Low-fire-consumption pure-titanium forging heating technology

The invention relates to the field of metal forging, in particular to a low-fire-consumption pure-titanium forging heating technology. The technology comprises the steps of pretreatment, preheating for 60 minutes to 100 minutes at the temperature ranging from 500 DEG C to 700 DEG C, heat preservation for 50 minutes to 70 minutes at the temperature ranging from 850 DEG C to 880 DEG C at a second heating stage, heat preservation for 20 minutes to 30 minutes at the temperature ranging from 920 DEG C to 9600 DEG C and the like. According to the technology, by means of a three-stage heating mode, defects of cracks produced in a traditional one-step heating mode and oxide skin and hard and brittle phases which are produced on the surface can be effectively overcome, the heating cycle can be shortened, the energy consumption can be reduced, the production cost is saved, and energy-saving and emission reduction purposes are achieved.

Owner:CHANGZHOU UNIV

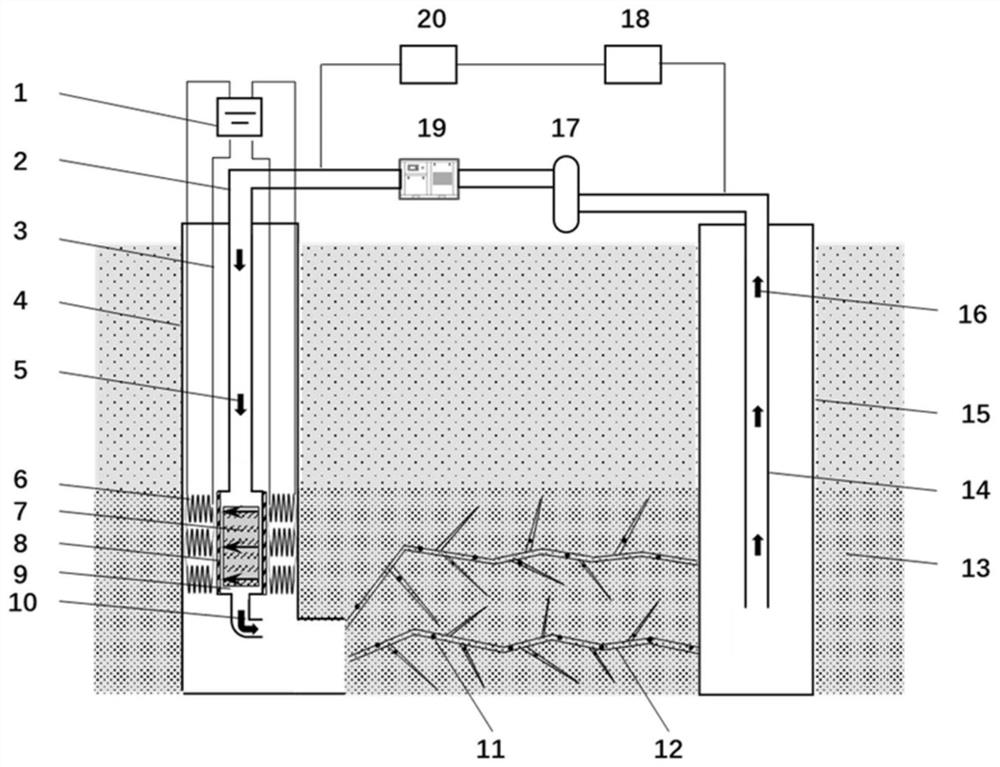

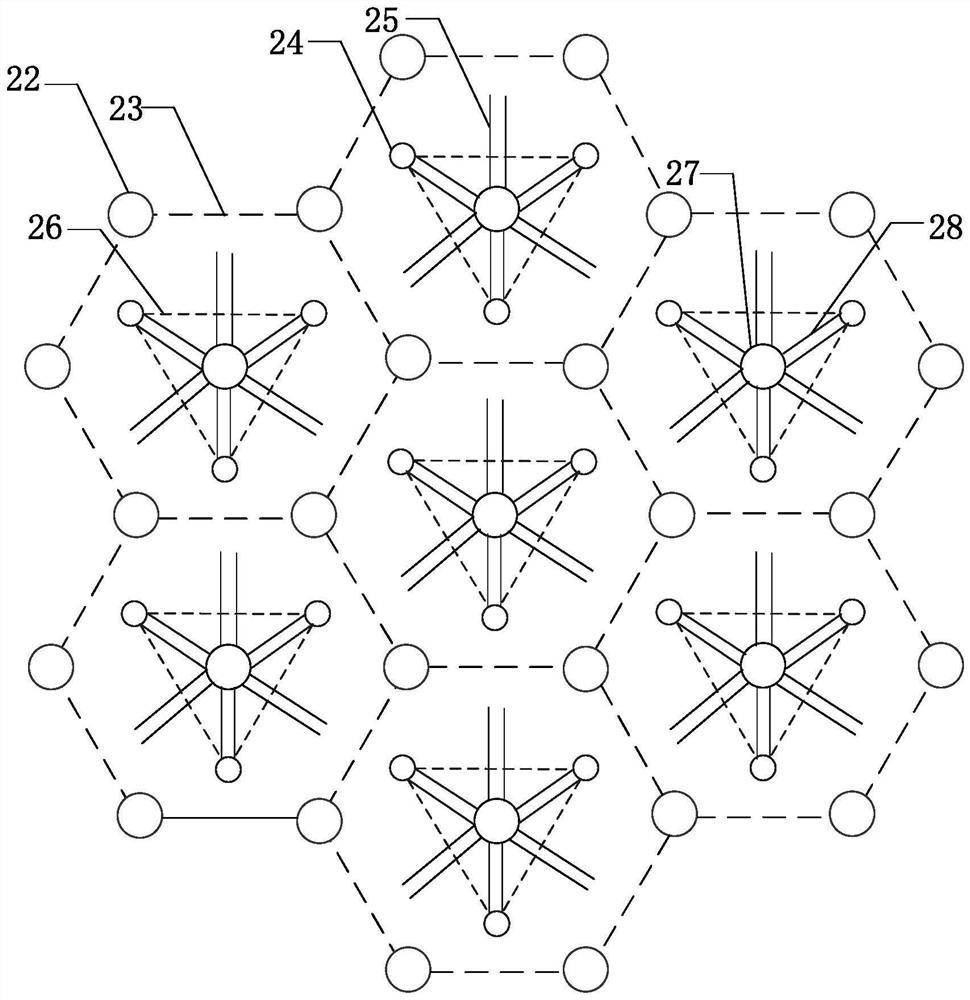

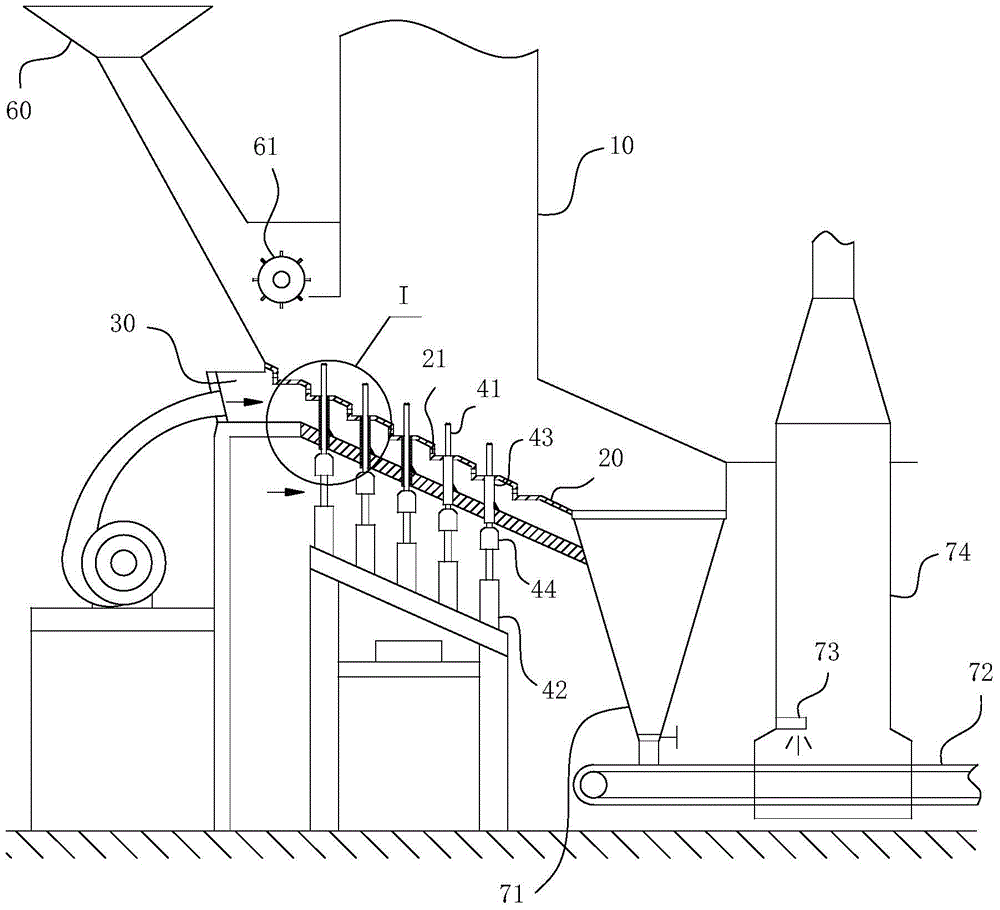

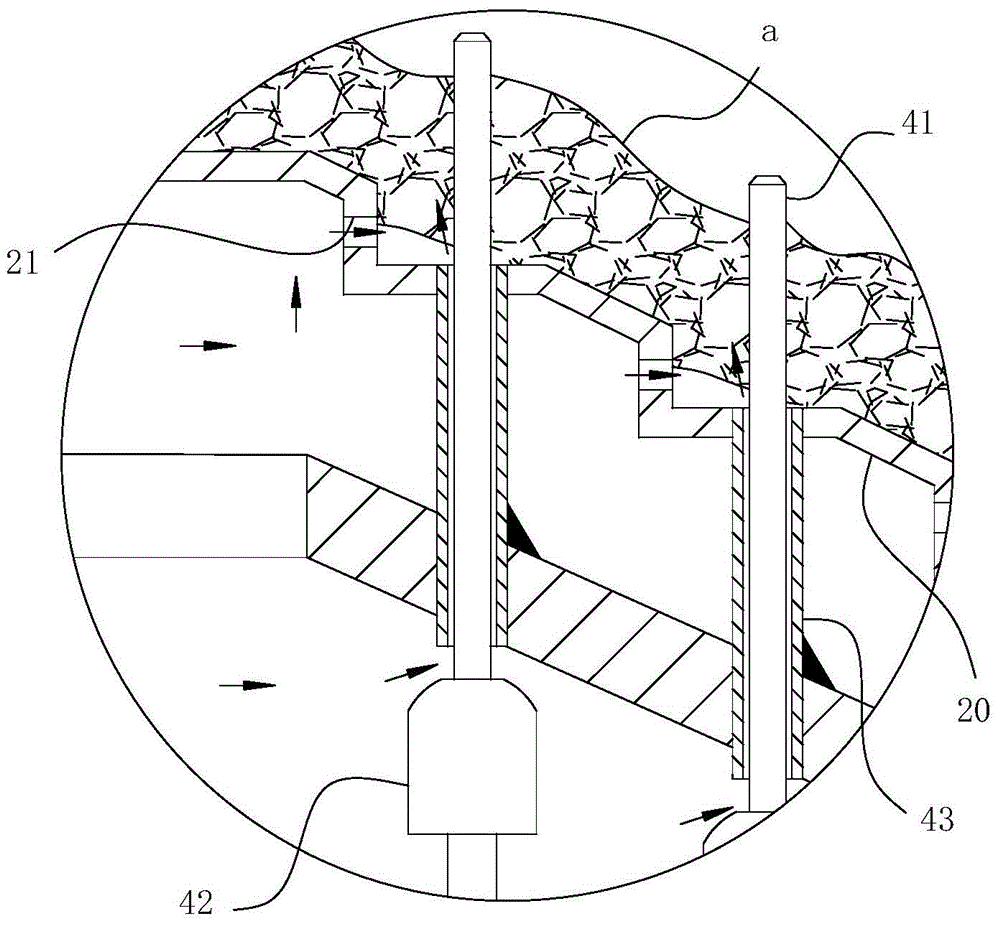

Coal seam convection heating system and method for in-situ pyrolysis of oil-rich coal

ActiveCN112177579AShorten the heating cycleImprove temperature uniformityUnderground miningEnergy inputHeating cycleConvective heating

The invention discloses a coal seam convection heating system and method for in-situ pyrolysis of oil-rich coal. The system comprises a fluid electromagnetic heating device arranged at the bottom of aheat injection well or a mining well, wherein the heat injection well is communicated with the mining well through a fracturing gap; the fluid electromagnetic heating device comprises a heating cavity, a heating core is arranged in the heating cavity, a heat preservation layer is arranged outside the heating cavity, and a coil assembly is arranged outside the heat preservation layer. When the fluid electromagnetic heating device is arranged in the heat injection well, a gas conveying pipeline is arranged in the heat injection well, the heating cavity is communicated with the bottom of the gasconveying pipeline, and when the coil assembly is powered on, compressed fluid conveyed into the heating cavity through the gas conveying pipeline is heated by the heating core, passes through the fracturing gap and is discharged out of the mining well. By means of the method, the coal seam heating period can be greatly shortened, the coal seam temperature uniformity is improved, high heating efficiency and energy utilization rate are obtained, and pollution to the stratum environment is little.

Owner:XI AN JIAOTONG UNIV

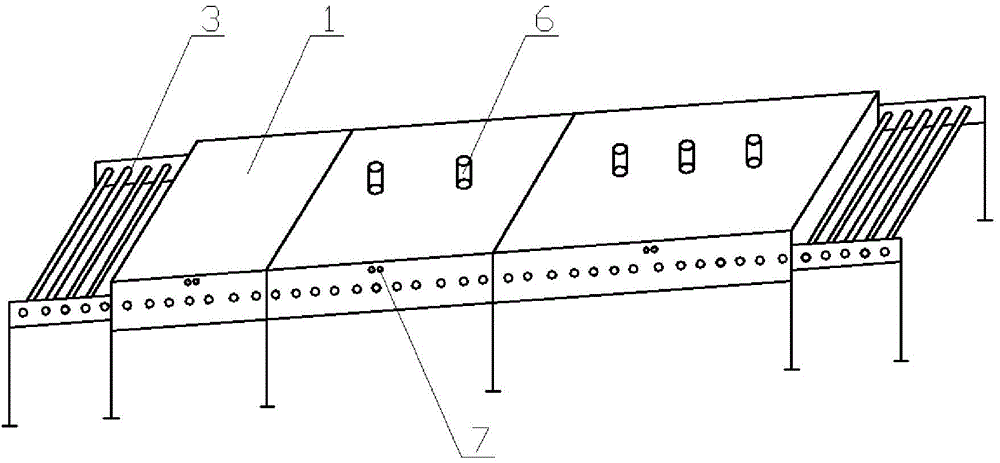

Heat stamping forming board heating furnace

The invention discloses a heat stamping forming board heating furnace. The board heating furnace comprises a furnace wall and conveying rollers for conveying a heated board. A board input opening and a board output opening are formed in the front end and the back end of the furnace wall respectively; and the conveying rollers are driven by an external driving system to rotate so as to convey the board. The furnace wall and furnace interior space defined by the furnace wall are sequentially divided into an induction area and a radiation area in the direction of board conveying. A partition board is arranged between the induction area and the radiation area, and a partition board channel is arranged in the middle of the partition board; the induction area is provided with a supporting part, an induction coil and a heating controller; the radiation area is provided with radiation pipes; and protection gas connection pipes are arranged on the furnace wall. The board heating furnace has the advantages that the board on the heat stamping forming production line is fully austenitized, and meanwhile the requirements for the continuous production takt and energy saving are met; the quality of heat formed products and quality stability are ensured; and heating efficiency is improved; and the heating period is shortened, and the heat energy loss is reduced.

Owner:武汉钢铁有限公司

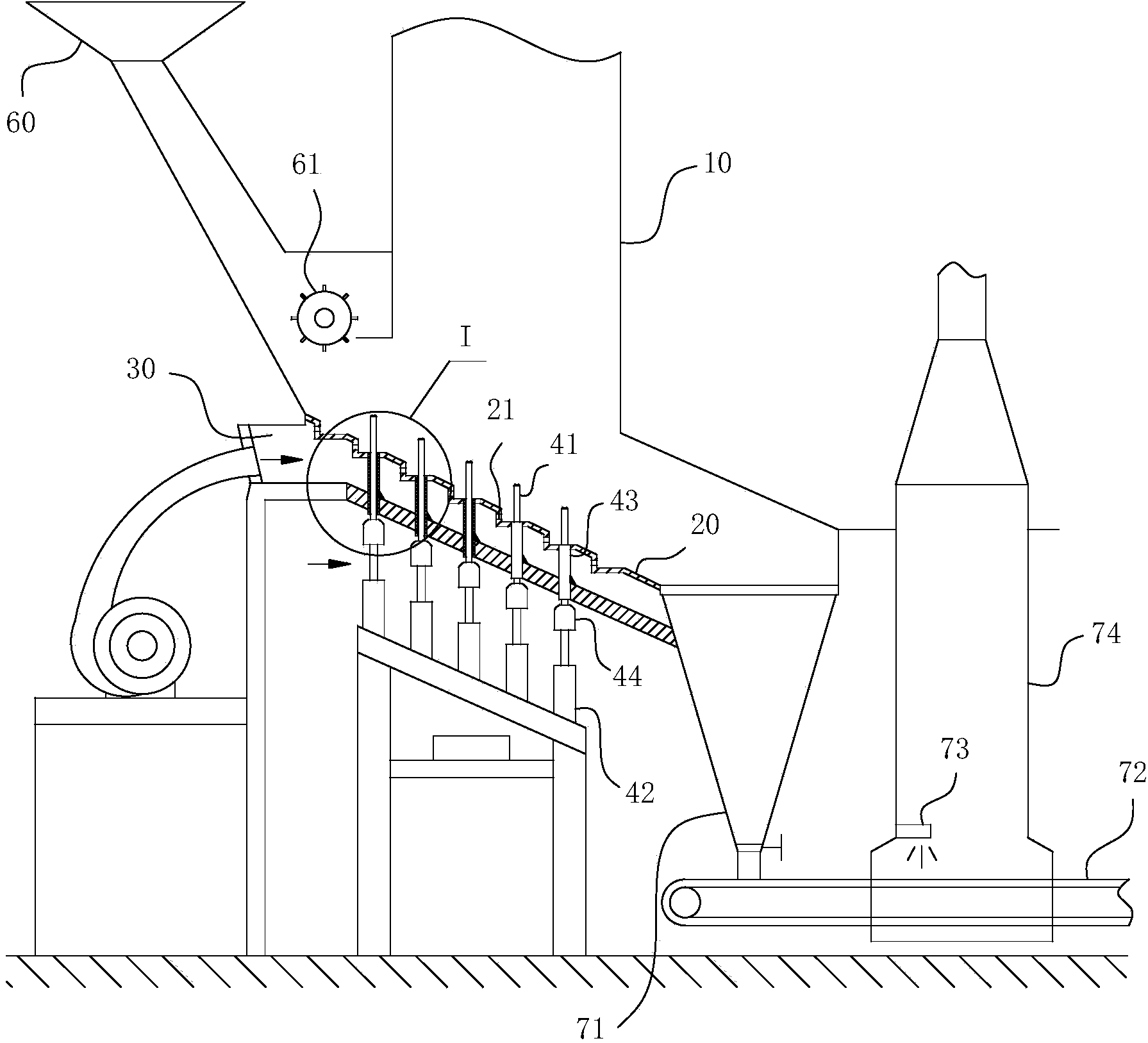

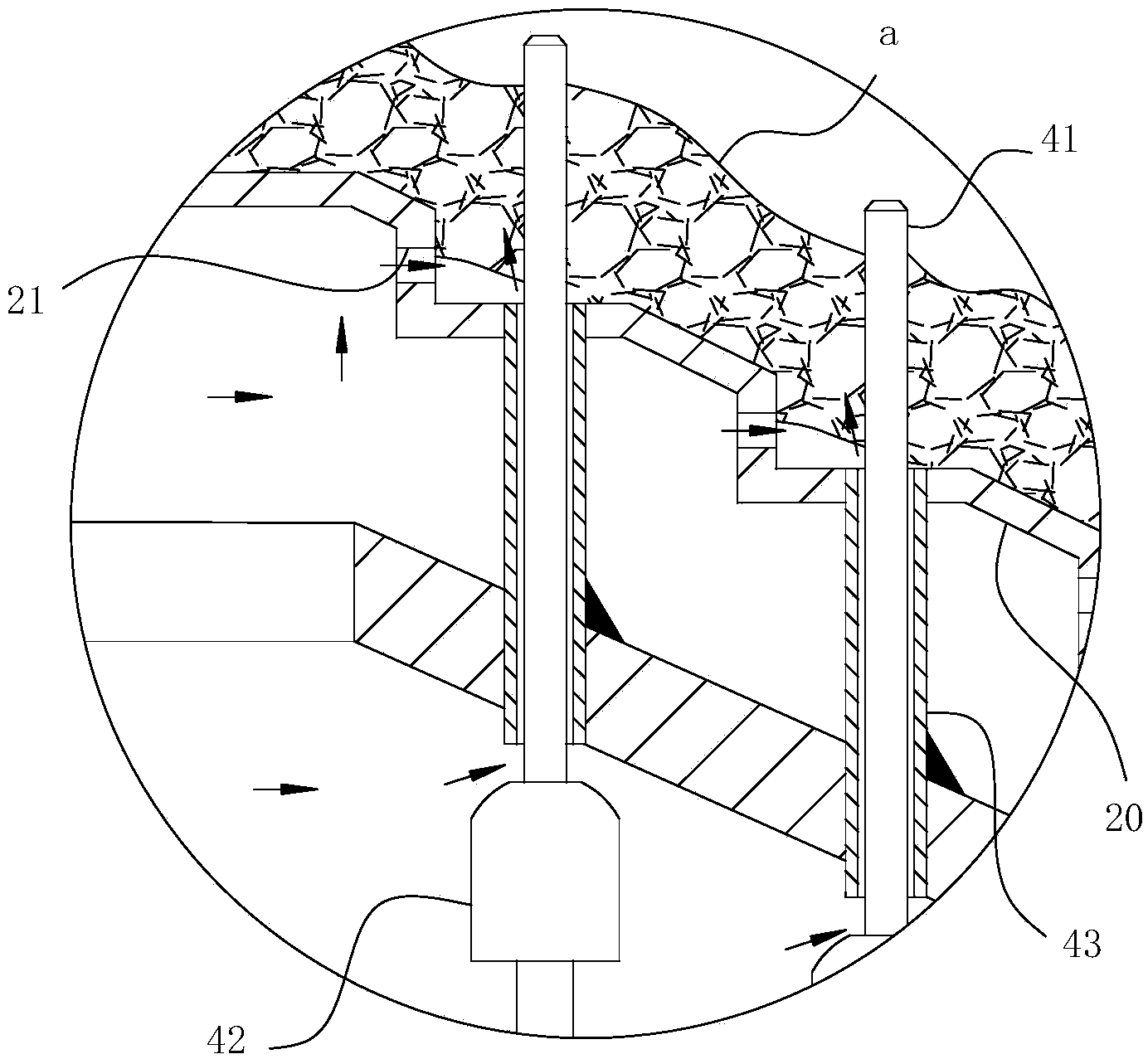

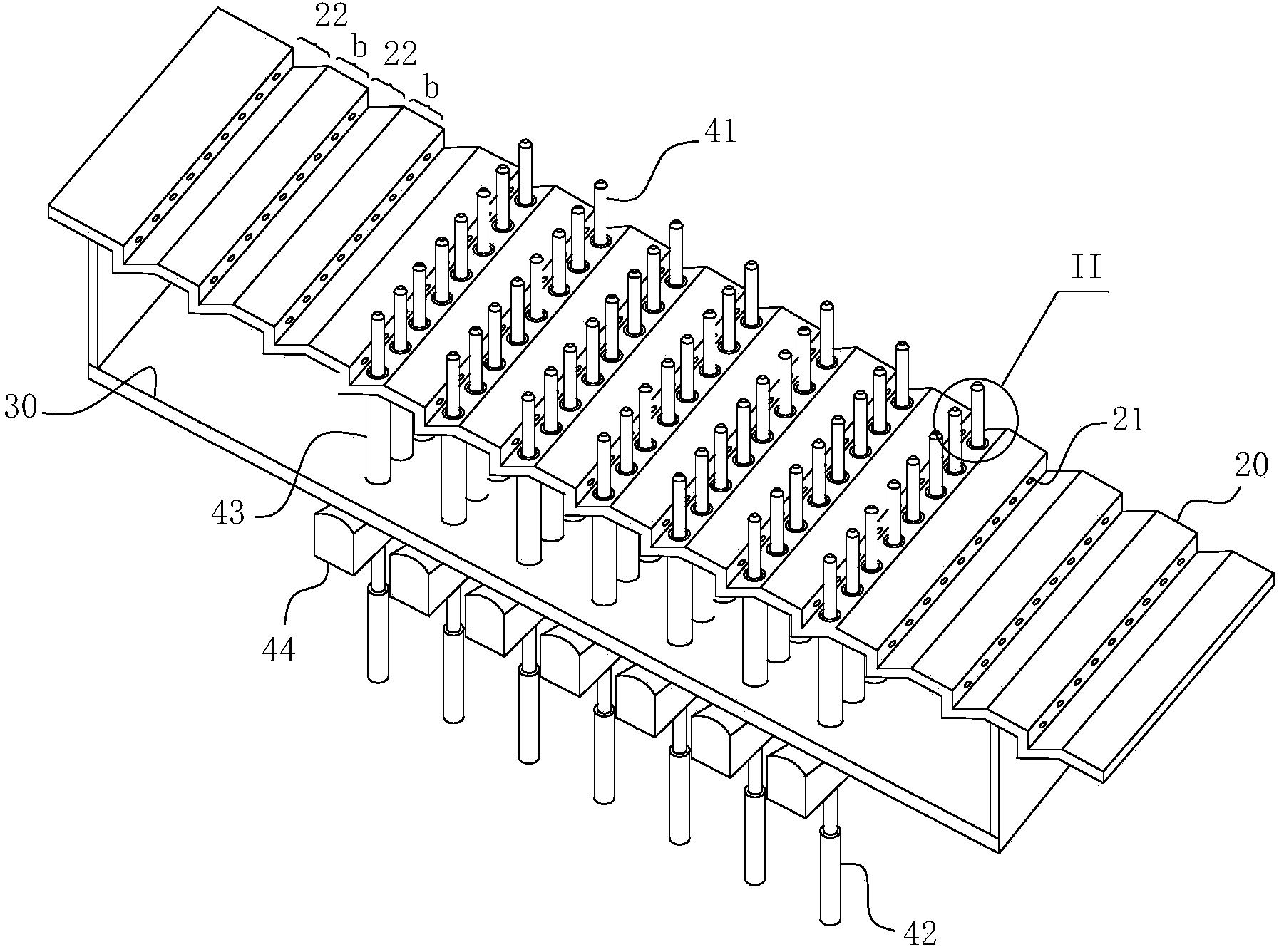

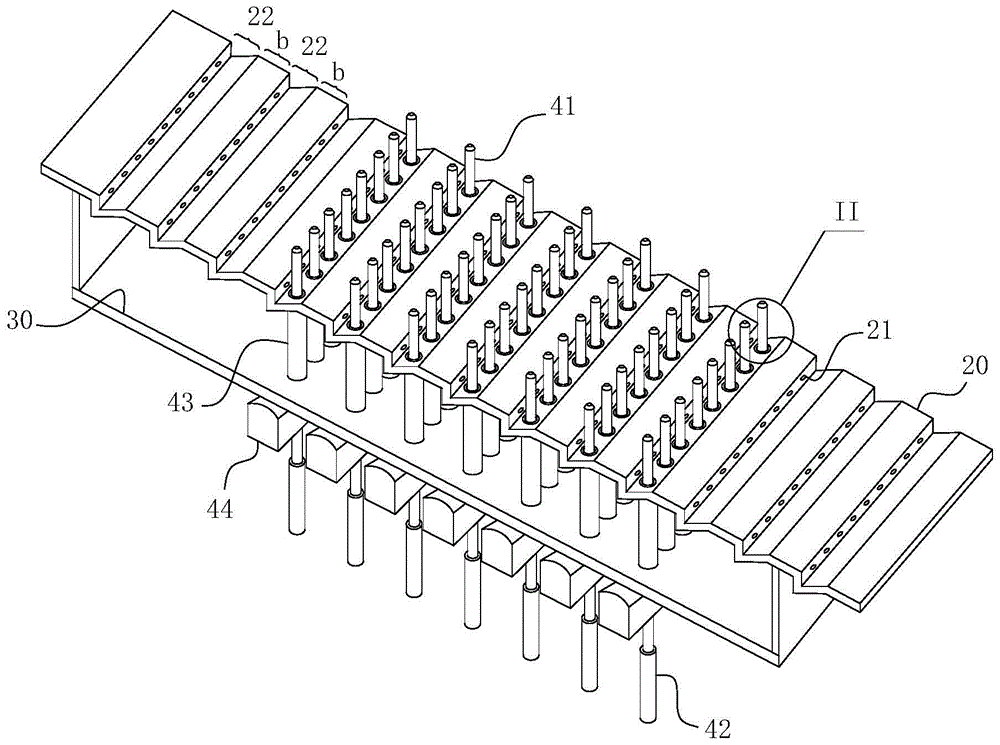

Fixed grate incinerator

InactiveCN104296148AAvoid subsequent continuous thermal expansion until it becomes soft and stuck.With self-cooling functionIncinerator apparatusCombustion chamberSlag

The invention belongs to the field of waste incineration equipment and particularly relates to a fixed grate incinerator comprising a main combustion chamber and a fixed fire grate. The fixed fire grate is arranged obliquely, the higher end is provide with a material input end, the lower end is provided a slag outlet for slags after material combustion, and the slag outlet is communicated with a slag discharging component; a hot air chamber is arranged below the main combustion chamber; a hot air supply path penetrates the fixed fire grate; the fixed grate incinerator further comprises an ejecting rod and a power portion; the maximum lift of the ejecting rod penetrates the material layer of the fixed fire grate; an ejecting rod component further comprises a shaft sleeve with the preset length, one end of the shaft sleeve penetrates and is fixedly connected to the fixed fire grate along the moving direction of the ejecting rod, a vent gap allowing the air to penetrate is formed between the shaft sleeve and the ejecting rod, and the other end of the shaft sleeve is communicated with the outside and / or an air cooling chamber. The fixed grate incinerator has the advantages that material burning efficiency is high, the component operation reliability is high, and the service life is prolonged effectively.

Owner:安徽盛燃焚烧炉科技有限公司

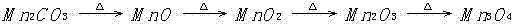

Method for preparing trimanganese tetroxide

InactiveCN102849800AFast heatingShorten the heating cycleManganese oxides/hydroxidesManganese(II) carbonateManganous-manganic oxide

The invention discloses a method for preparing trimanganese tetroxide. Manganese carbonate is used as a raw material, added with a carbon source, placed in sealed microwave equipment, then heated to 650-750 DEG C with a heating rate of 8-20 DEG C / min, and sintered for 0.5-2 h; and the product is ground by a wet grinding after tapping, so as to obtain trimanganese tetroxide. According to the present invention, rapid and comprehensive heating of the microwave equipment and ''non-thermal effect'' enable carbon dioxide generated from decomposition of manganese carbonate to timely react with manganese oxide at a low temperature, so as to produce trimanganese tetroxide; and the method has the advantages of simple process, easy control process, low energy consumption, complete reaction process and stable specific surface area.

Owner:湖南隆泰环保能源科技有限公司

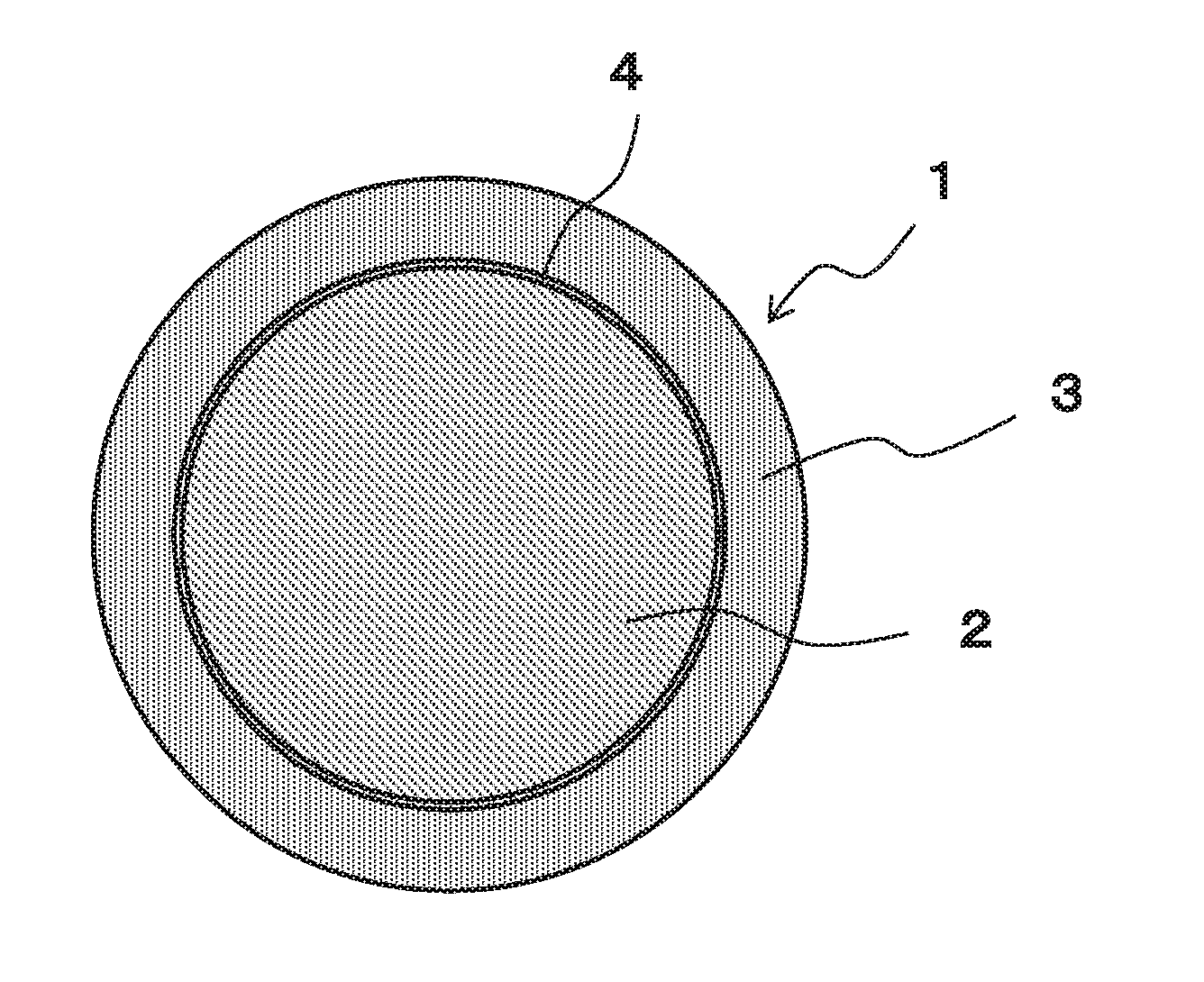

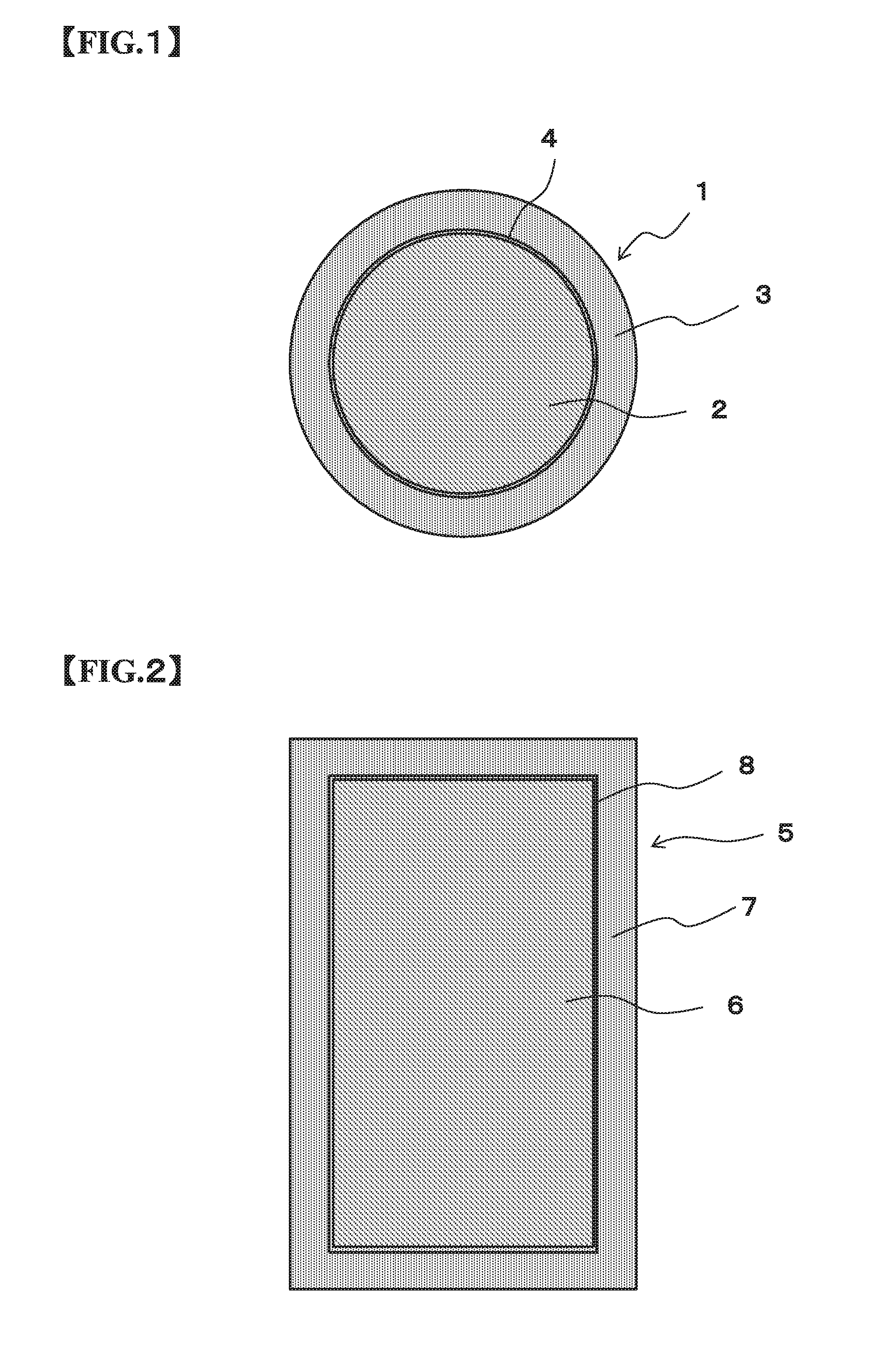

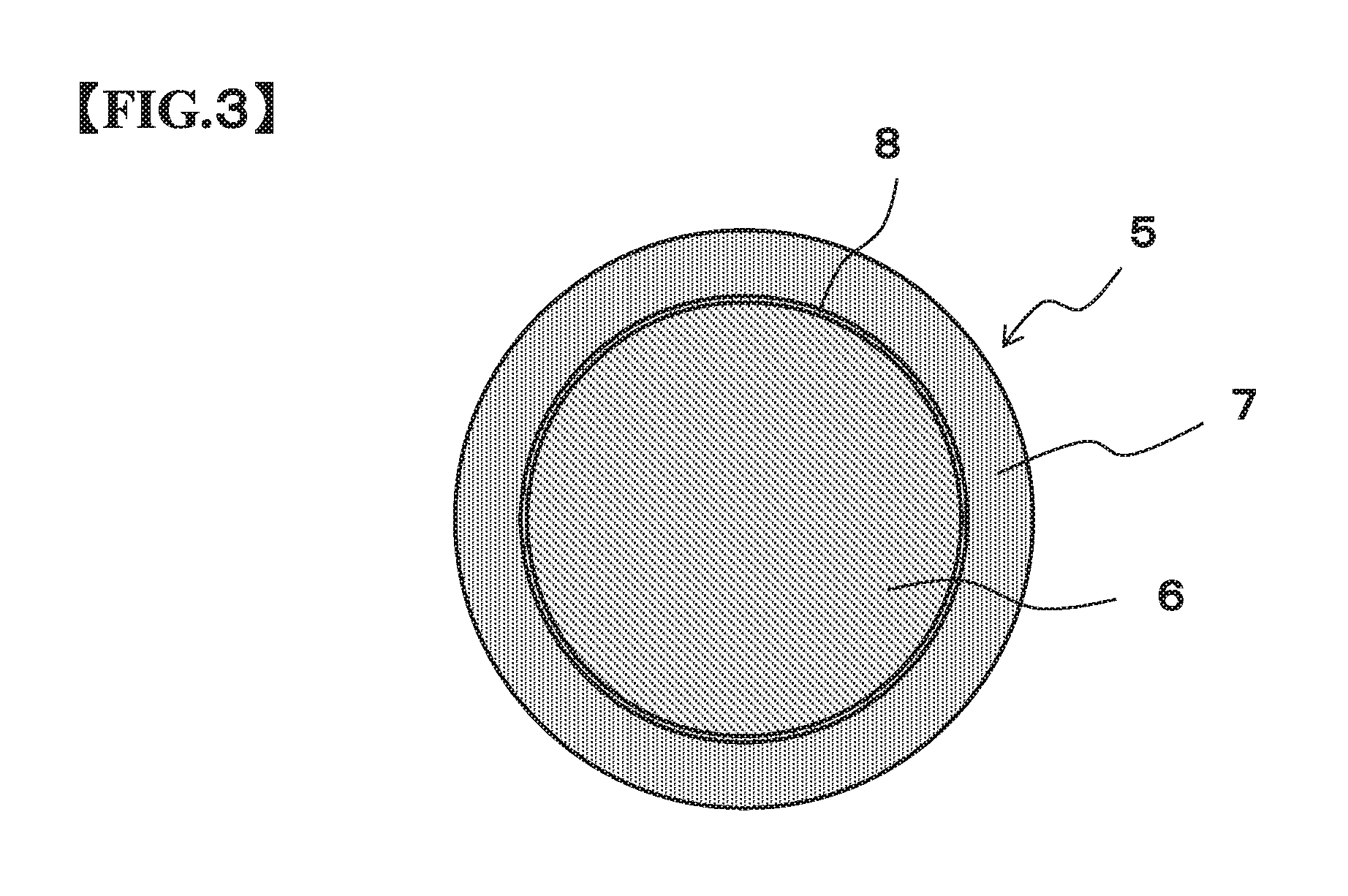

Cu Core Ball, Solder Paste, Formed Solder, Cu Core Column, and Solder Joint

ActiveUS20160368105A1Reduced strength against heat cycleImproved strength against heat cycleTransportation and packagingSemiconductor/solid-state device detailsSolder ballCopper

Provided are a Cu core ball and a cu core column, which achieve dropping strength and strength against heat cycle. The Cu core ball (1) contains a Cu ball (2) made of Cu or a Cu alloy and a solder layer (3) which is made of a solder alloy composed of Sn and Cu and covers the Cu ball (2). The solder layer (3) contains not less than 0.1% through not more than 3.0% of Cu and the remainder is composed of Sn and impurities.

Owner:SENJU METAL IND CO LTD

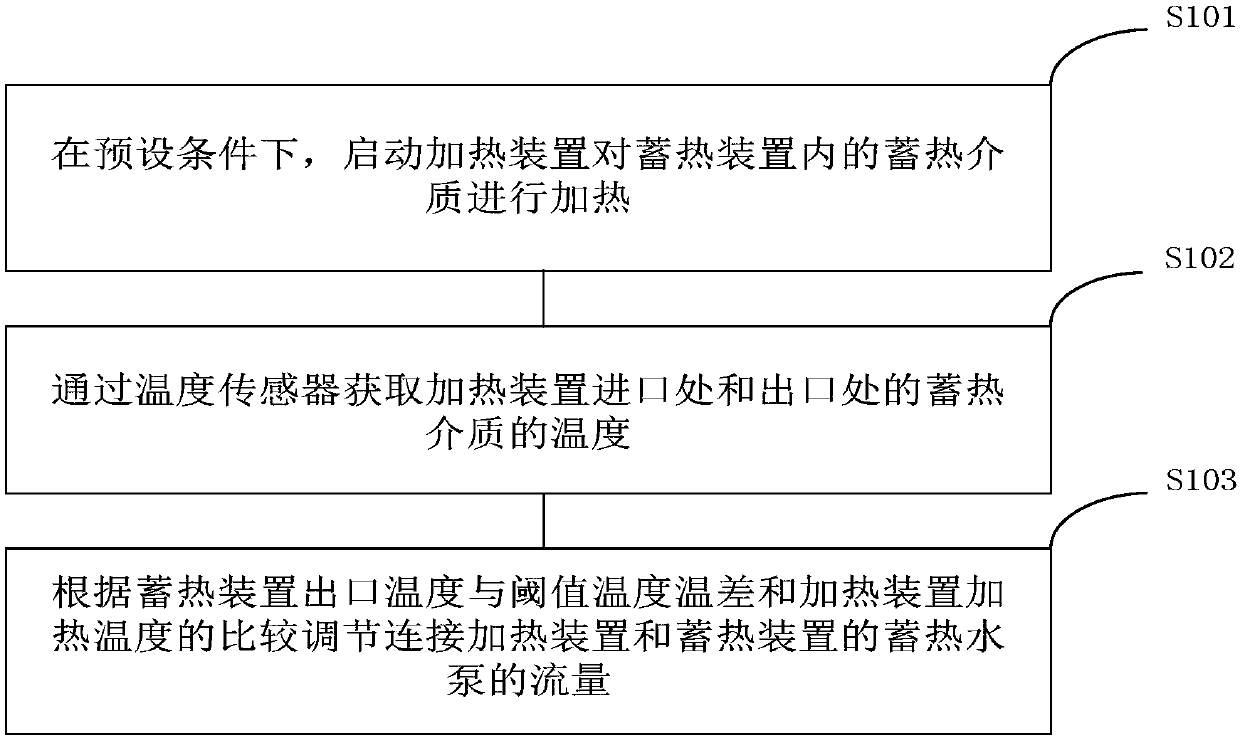

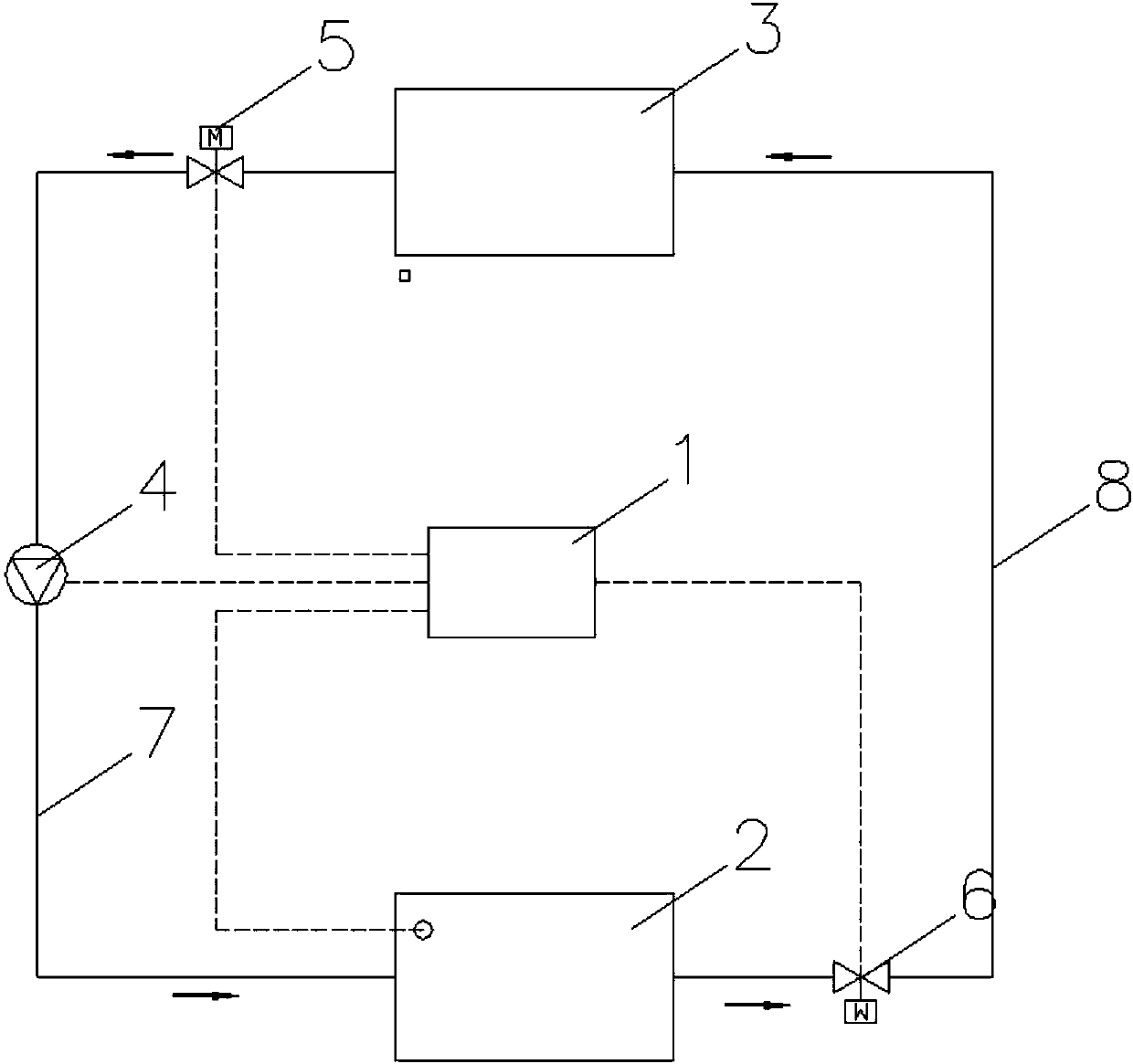

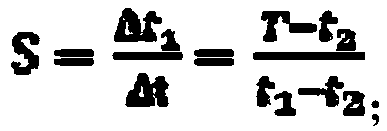

Temperature control method of heat storage device and heat supply system

ActiveCN107726427ANo jump actionReduce lossCentral heating with accumulated heatLighting and heating apparatusTemperature controlControl system

The invention belongs to the technical field of control systems and particularly relates to a temperature control method of a heat storage device and a heat supply system. The temperature control method of the heat storage device comprises the steps that that under a preset condition, a heating device is started to heat a heat storage medium in the heat storage device; the temperature of the heatstorage medium at an inlet and an outlet of the heating device is obtained; according to comparison of the temperature difference between the outlet temperature of the heat storage device and the threshold value temperature and the heating temperature of the heating device, the flow of a heat storage water pump connected with the hearting device and the heat storage device is adjusted; and the flowing speed of the heat storage medium from the heating device to the heat storage device is increased to enable the temperature of the heat storage medium in the heat storage device to reach the threshold valve temperature. During heat storage of the heat supply system, the voltage-instability action of the heating device is avoided, the repeatedly heating process is avoided, the heating period isshortened, the energy loss is reduced, and equipment abrasion is reduced.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

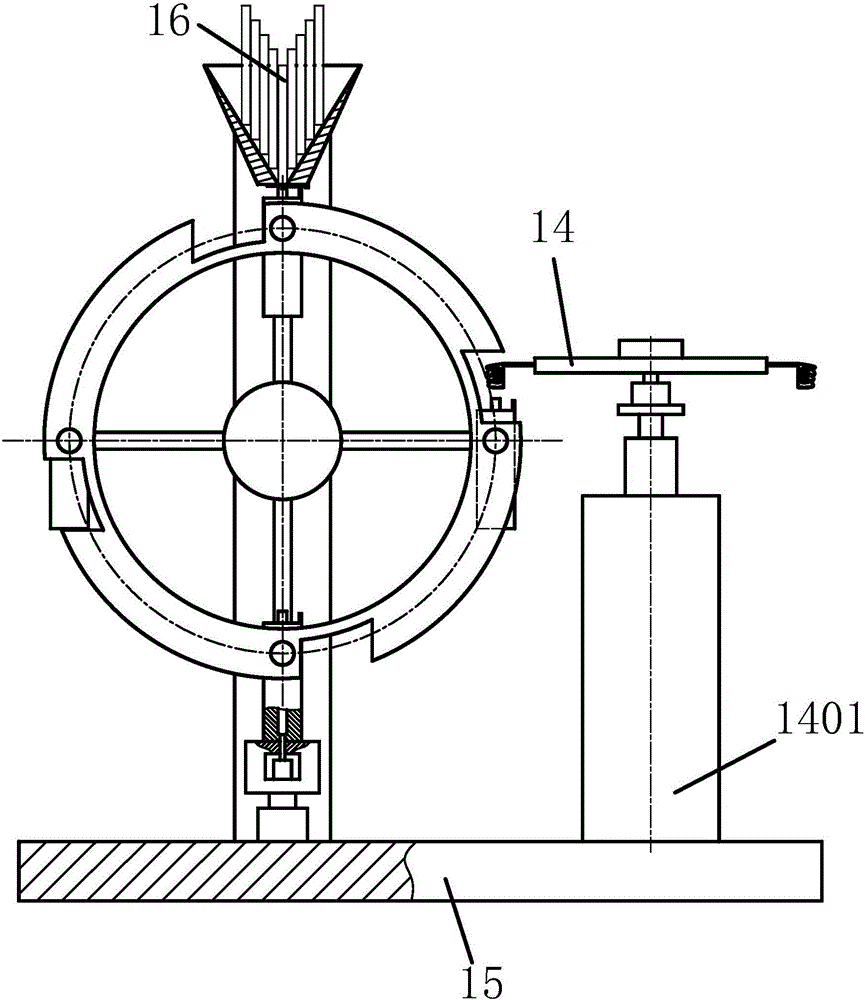

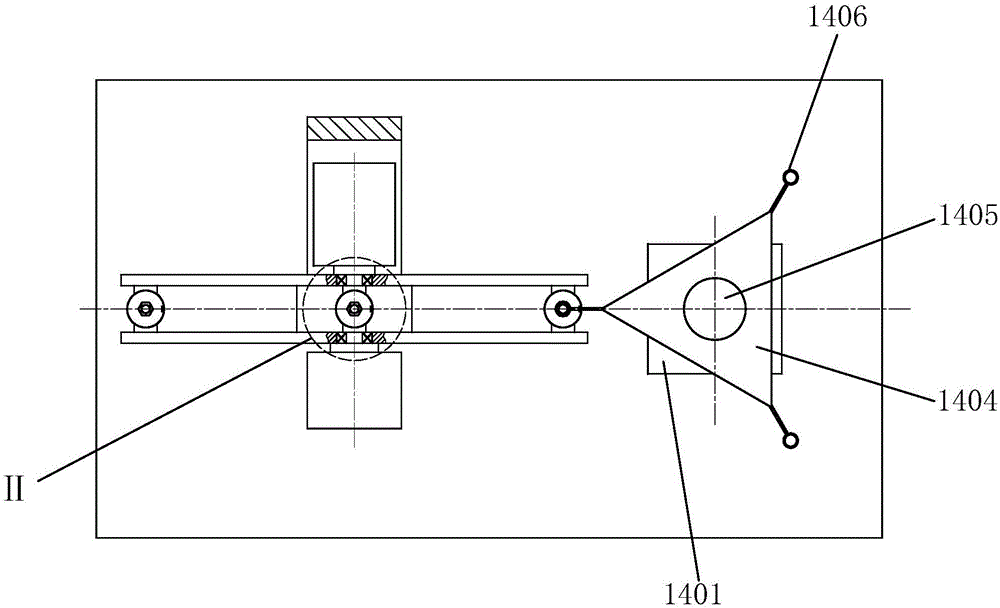

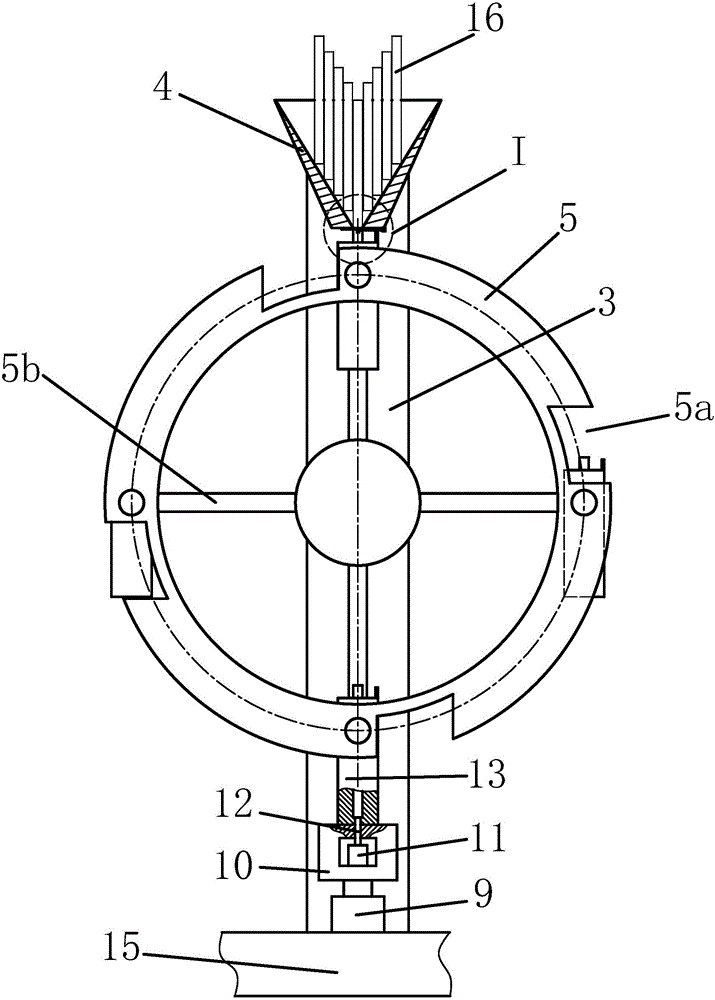

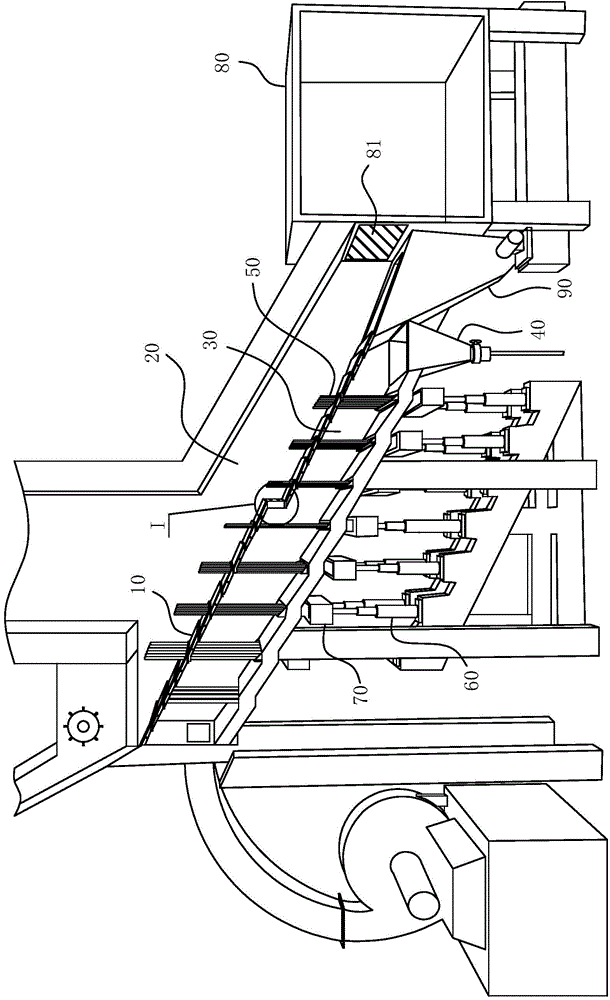

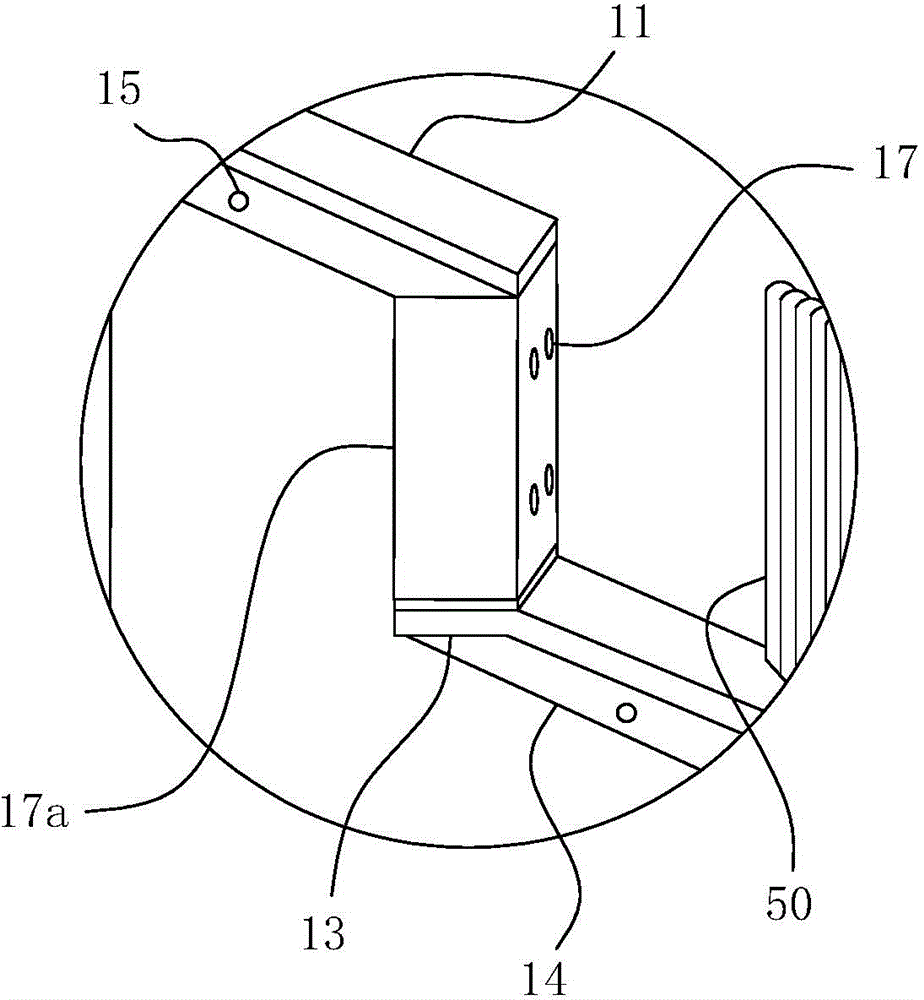

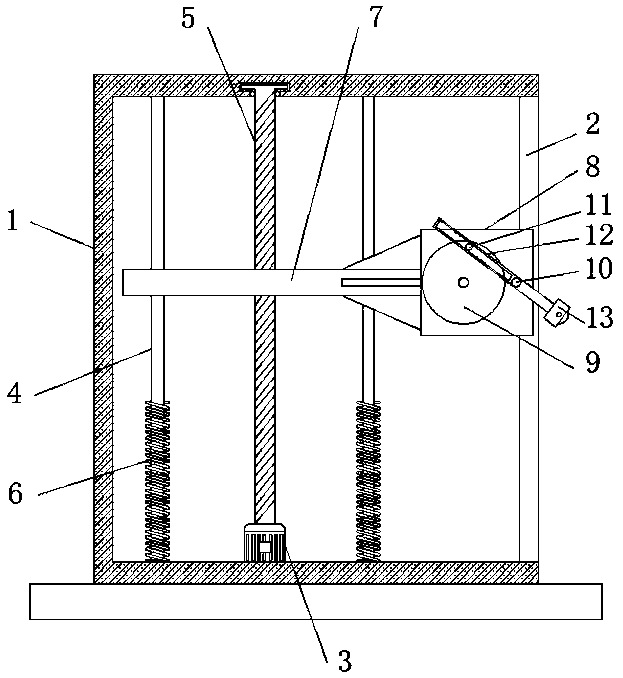

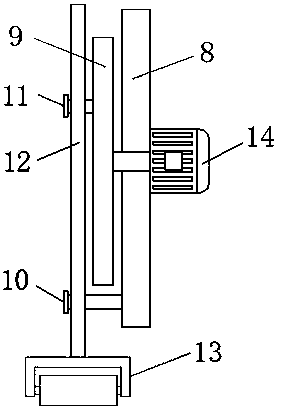

Automatic punch device of mold push rod

InactiveCN105013913AReduce energy consumptionImprove energy utilizationShaping toolsMetal-working feeding devicesElectric machineryEngineering

The invention relates to an automatic punch device of a mold push rod. The device comprises a basal plate, a revolving heater, a stand, a main driving motor, a vertical lifting beam, a funnel type storage tank, a circular taking suppler, a support pad device and a punching device, wherein the stand is mounted at the left part of the upper end surface of the basal plate; the revolving heater is mounted at the right part of the upper end surface of the basal plate; the main driving motor is horizontally fixed in middle of the upper end of the stand; the vertical lifting beam is vertically mounted on the upper end surface of the stand; the funnel type storage tank is fixed at the upper end of the vertical lifting beam; the circular taking suppler is mounted on the main driving motor; the support pad device is connected with the basal plate; and the punching device is fixed on the basal plate. The device has such advantages as reasonable structure design, high automation degree and short production period, can realize the batch punch machining of the push rod, replaces the traditional manual operation, greatly improves the production efficiency, reduces the labor cost, shortens the machining period of the push rod, and improves the energy utilization rate.

Owner:安徽省振华科技工业有限公司

Pressure quenching process and equipment for diaphragm spring

InactiveCN102433423AExtend your lifeHigh hardnessFurnace typesHeat treatment furnacesRapid prototypingMartensite

The invention discloses a pressure quenching process and equipment for a diaphragm spring, aiming to provide a pressure quenching process and equipment which are short in heating period and good in energy-saving effect, and can improve the hardness and prolong the fatigue life. The pressure quenching equipment comprises a rotating device, an induction coil and a high-frequency current generator, wherein the high-frequency current generator is electrically connected with the induction coil; and the diaphragm spring is arranged on the rotating device for rotating and cutting a high-frequency magnetic field generated by the induction coil to generate an induction current. According to the invention, a high-frequency quenching mode is adopted to rapidly form and cool the diaphragm spring so as to achieve the hardness and metallographic structure required by heat treatment, thus reducing the heating period, having short time without oxidation, being free from atmosphere oxidation protection, and having an obvious energy-saving effect. Simultaneously, the high-frequency quenching mode can lead the metallographic structure of a material to be switched in a short period of time and form fine invisible martensite on the surface of the material, thus improving the surface hardness of the material and prolonging the service life of the diaphragm spring.

Owner:CHINA & CANTON CLUTCH

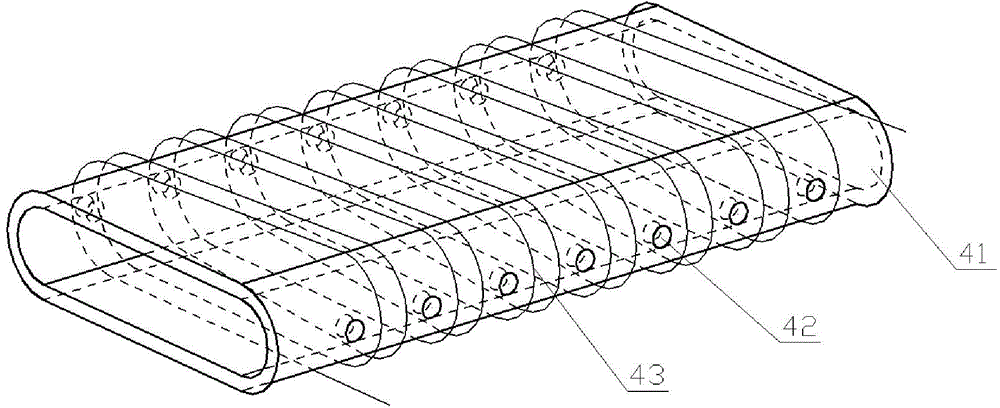

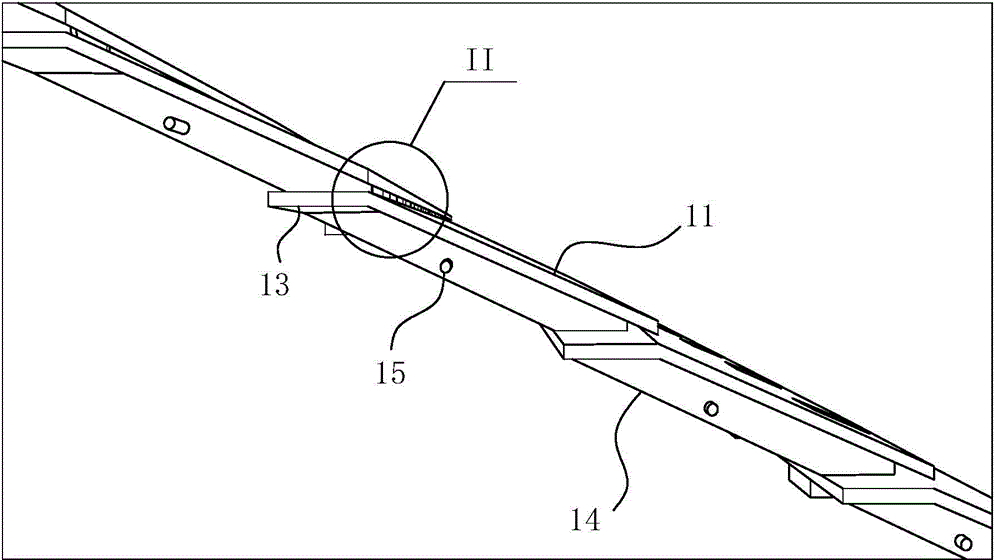

Fixed grate and incineration system applying same

InactiveCN104595907AGuaranteed structural rigidityGuaranteed to be constantInclined grateIncinerator apparatusCombustion chamberHot blast

The invention belongs to the field of waste incineration equipment and particularly relates to a fixed grate and an incineration system applying the same. The fixed grate at least comprises grate plates; the arrangement heights of the grate plates are gradually reduced so as to form a step type grate body structure of the fixed grate; a spacing is formed between plate bodies of each two adjacent grate plates in the perpendicular direction so as to form a ventilation pore running through a grate body; the grate plates are provided with extending plates; the plate faces of each extension plate and the plate body of the previous grate plate are crossed mutually to form a wind guide port structure. The incineration system comprises a main combustion chamber, the fixed grate and a grate ejector rod, wherein the main combustion chamber is isolated and divided into a combustion cavity and a hot blast cavity by the fixed grate; the air inlet end of the hot blast cavity is also the feed end of the fixed grate; the grate ejector rod is used for overturning and ejecting materials on the incineration face; the grate ejector rod passes through a through hole and runs through the material layer on the fixed grate in the maximum lift range. The fixed grate and the incineration system have reasonable and practical structures; the grate body has a good ventilation effect; material incineration efficiency is high.

Owner:安徽盛燃焚烧炉科技有限公司

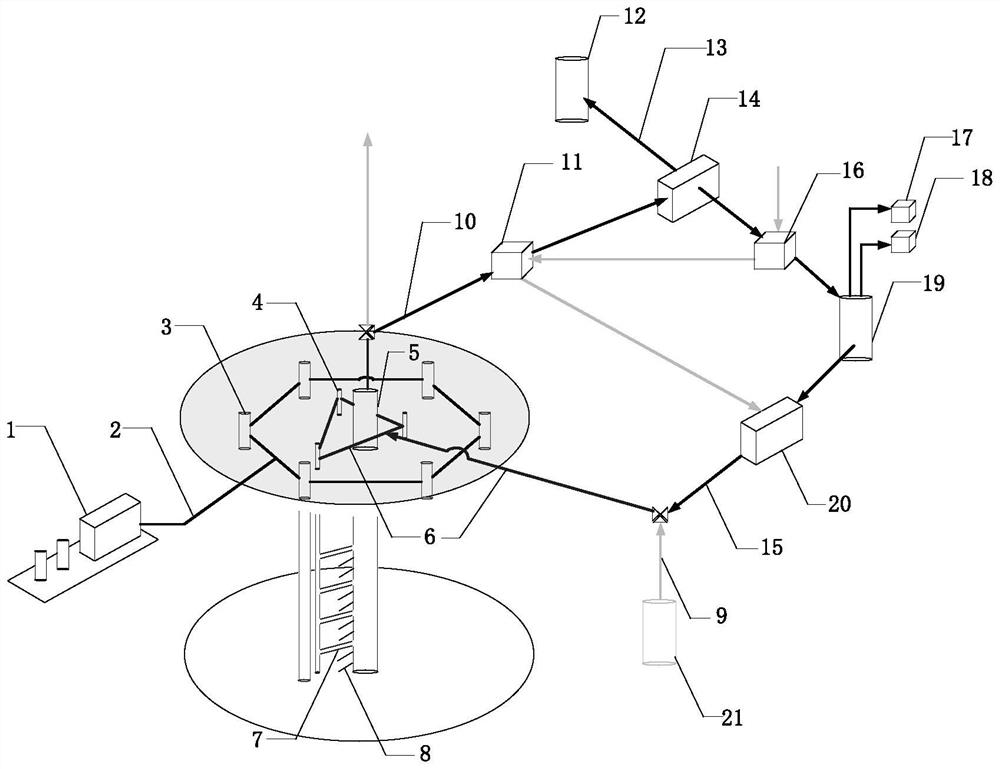

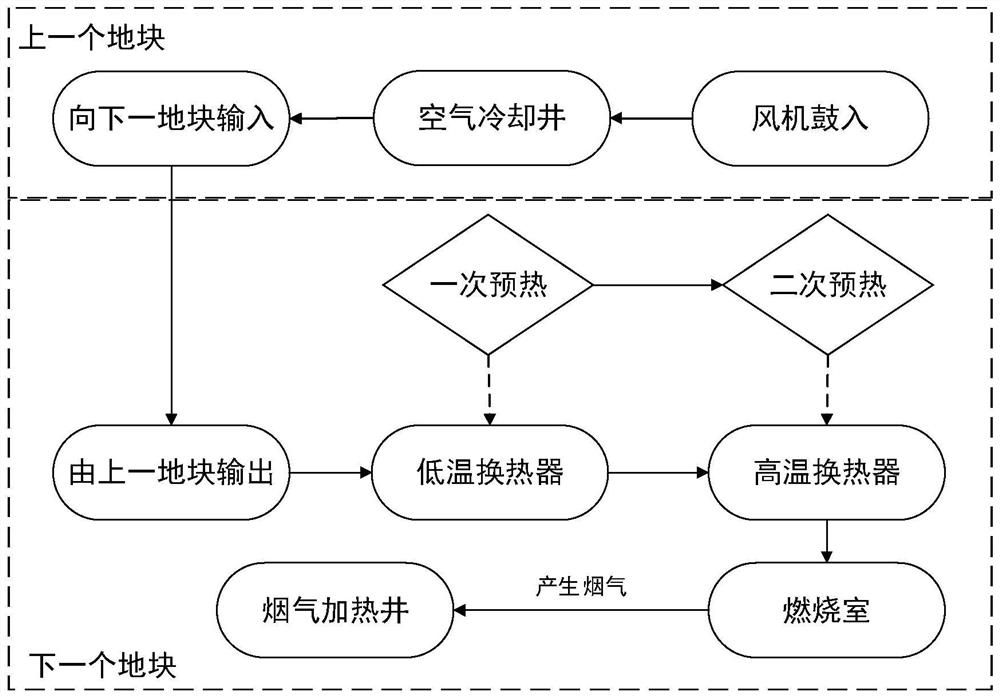

Underground electric heating direct oil extraction and waste heat utilization system for oil-rich coal

InactiveCN114016990AReduce heatTake advantage ofWind motor with solar radiationConstructionsCombustion chamberEngineering

The invention discloses an underground electric heating direct oil extraction and waste heat utilization system for oil-rich coal. The underground electric heating direct oil extraction and waste heat utilization system comprises a wind-light complementary power generation device, an electric heating well, a flue gas heating vertical shaft / air cooling vertical shaft, a high-temperature heat exchanger, a gas-liquid separation device, a low-temperature heat exchanger combustion chamber, a fan and the like. Aiming at a long period required by underground direct pyrolysis of the oil-rich coal, the invention adopts a method of introducing high-temperature flue gas into a flue gas heating vertical shaft to assist an electric heating well to heat up a land parcel, an air cooling system is constructed aiming at a large amount of waste heat generated by underground direct pyrolysis of the oil-rich coal, the waste heat is effectively transferred to a next land parcel for use, and the energy utilization rate is improved. The whole system inputs electric energy, outputs oil, captures CO2 and carries out geological sequestration, so that emission of CO2 to the atmosphere is reduced, atmospheric pollution and the greenhouse effect are relieved, and other substances and energy are fully utilized. According to the method, resource waste and environmental pollution caused by underground direct pyrolysis of the oil-rich coal are effectively reduced, and the system has high economic benefits and use values.

Owner:XI AN JIAOTONG UNIV +1

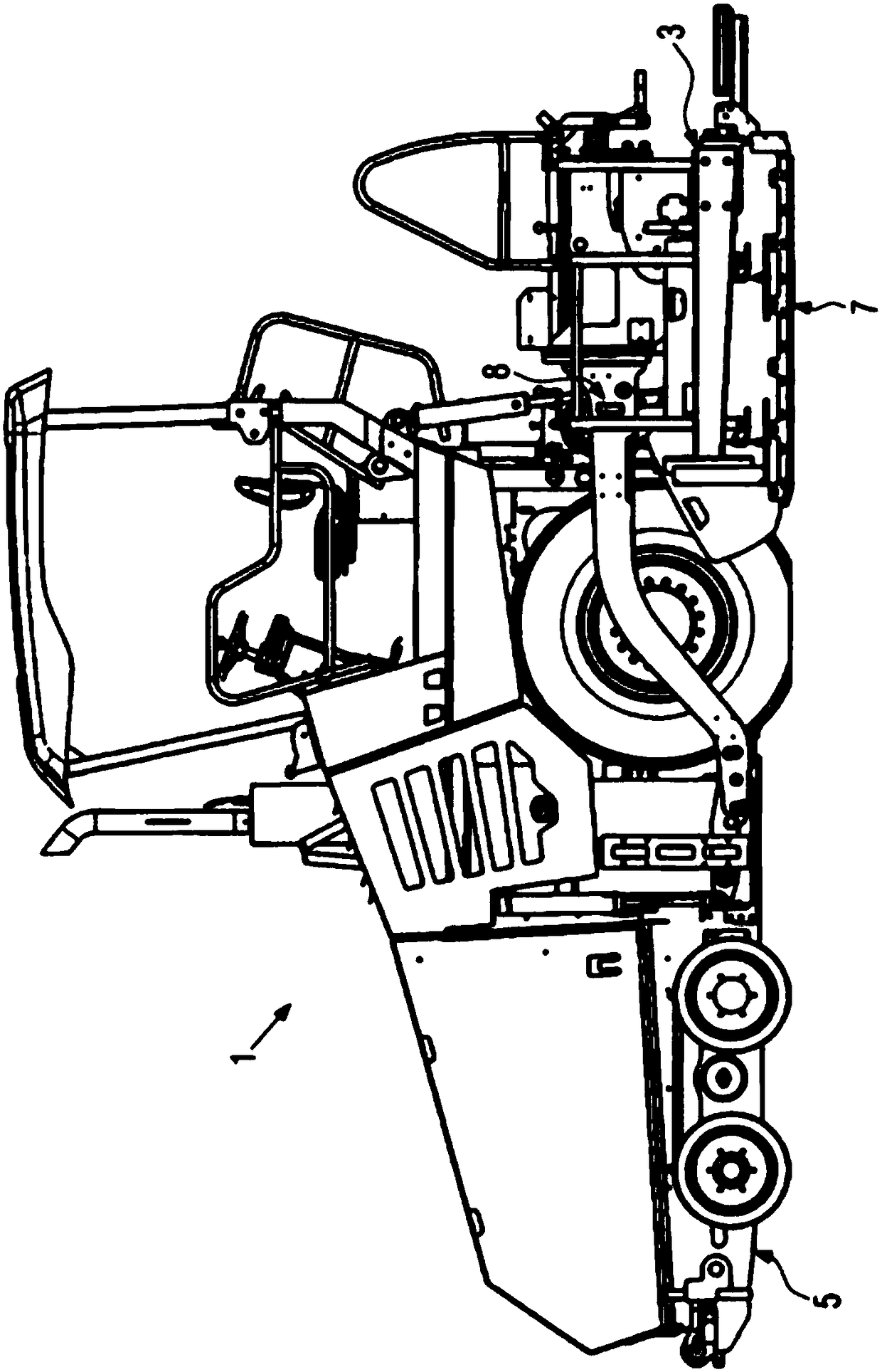

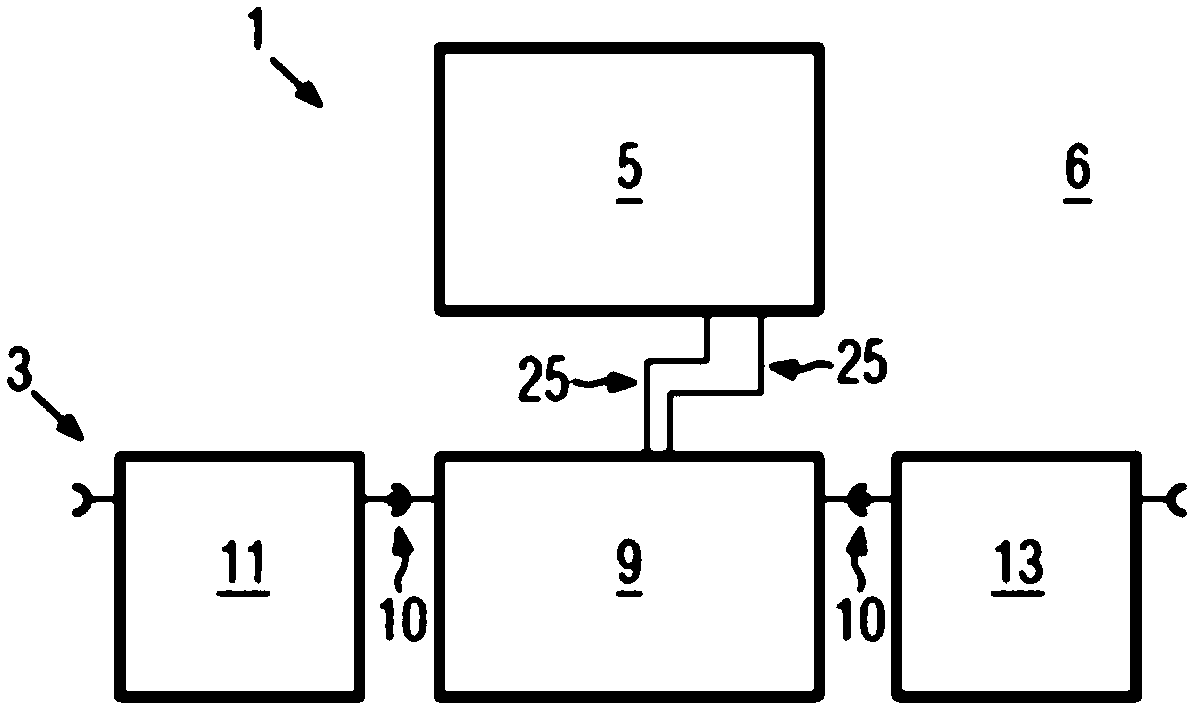

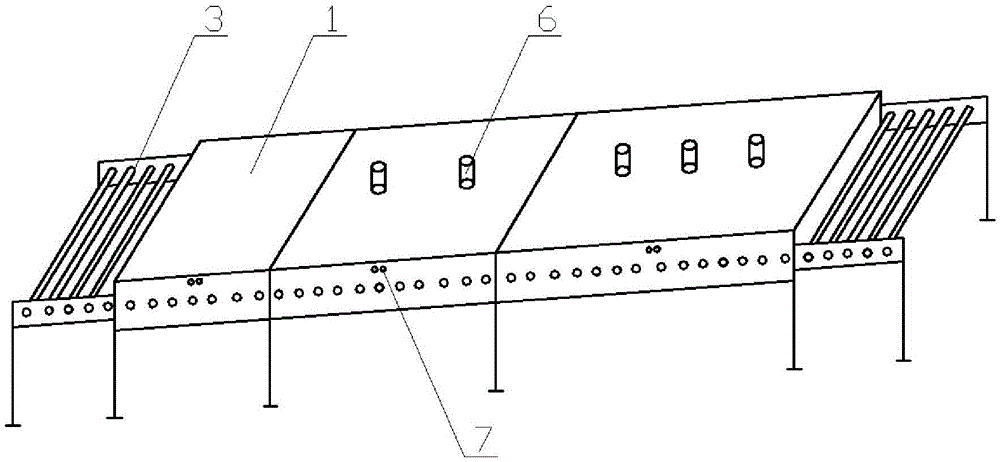

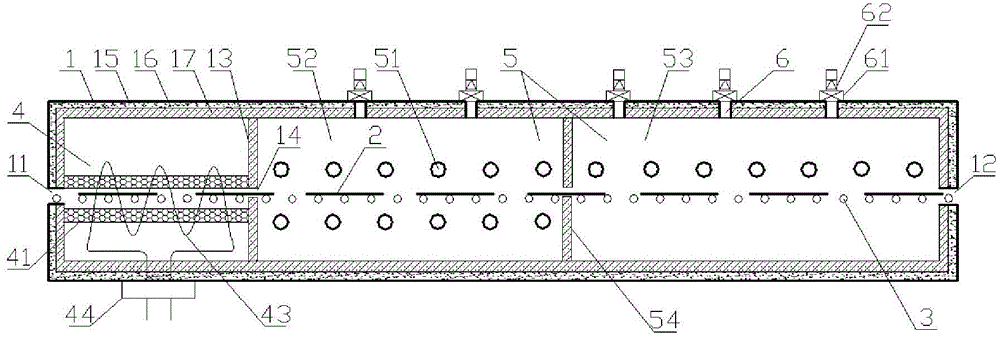

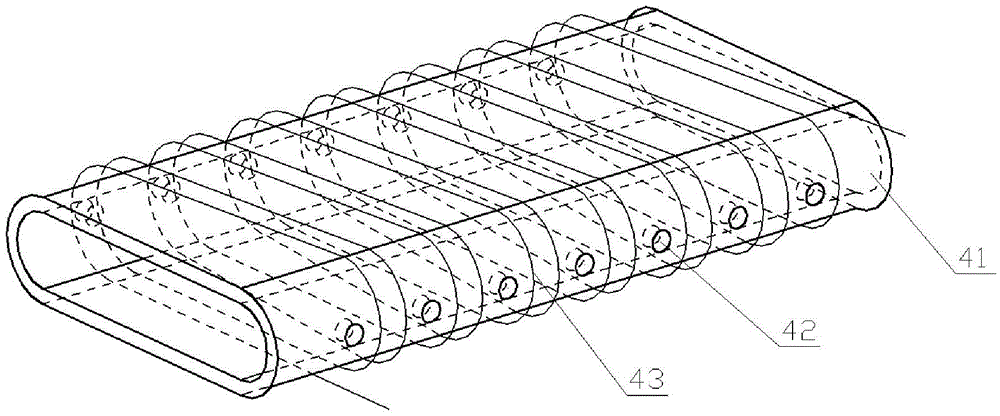

Road finisher with heating element for screed

ActiveCN108691259APrevent overloadShorten the heating cycleRoads maintainenceClassical mechanicsStructural engineering

A road paver (1) comprises a generator (G), a control device (15) and a screed (3), the screed (3) comprising a basic screed (9) and being suited to be modified, by selectively attaching or detachingbroadening parts (11, 13), from a first to at least a second, different screed configuration. The basic screed (9) and the broadening parts (11, 13) each comprise one compacting unit (7) and one electric heating element (27) to be supplied with power from the generator (G) for heating the compacting unit (7) to prevent the laying material from adhering to the compacting unit (7) and to finish a high-quality road pavement. The control device (15) is configured to individually switch on or off each one of the two resistance wire windings of the heating element (27) of the basic screed (9) depending on the screed configuration determined by the control device (15) to distribute electrical power generated by the generator (G) to the individual resistance wire windings (41).

Owner:JOSEPH VOEGELE AG

Hot stamping forming sheet heating furnace

Owner:武汉钢铁有限公司

Heating device for hot-melting butt welding machine

The invention discloses a heating device for a hot-melting butt welding machine. The heating device for the hot-melting butt welding machine comprises a device body. The device body is a cavity structure. One side of the device body is provided with a moveable long port. The inner wall of the bottom of the device body is provided with a first motor. An output shaft on the top of the first motor isprovided with a vertically installed thread vertical rod. Two sides of the thread vertical rod are provided with vertically installed positioning slide rods. The positioning slide rods are provided with a spring. A horizontally installed adjusting cross plate is connected between the two positioning slide rods and the thread vertical rod. One end of the adjusting cross plate is welded with a vertically installed fixing plate. One side of the fixing plate is rotatably provided with a rotation plate and a positioning rod. An edge part of one side, away from the fixing plate, of the rotation plate is provided with a linkage slider. The linkage slider is slidably connected with a rotation long rod. The heating device is rational in design, simple in operation, and capable of rapidly and uniformly heating the different parts of a product, shortening a heating period, and effectively improving the working efficiency of the hot-melting butt welding machine.

Owner:贵州枫叶管业有限公司

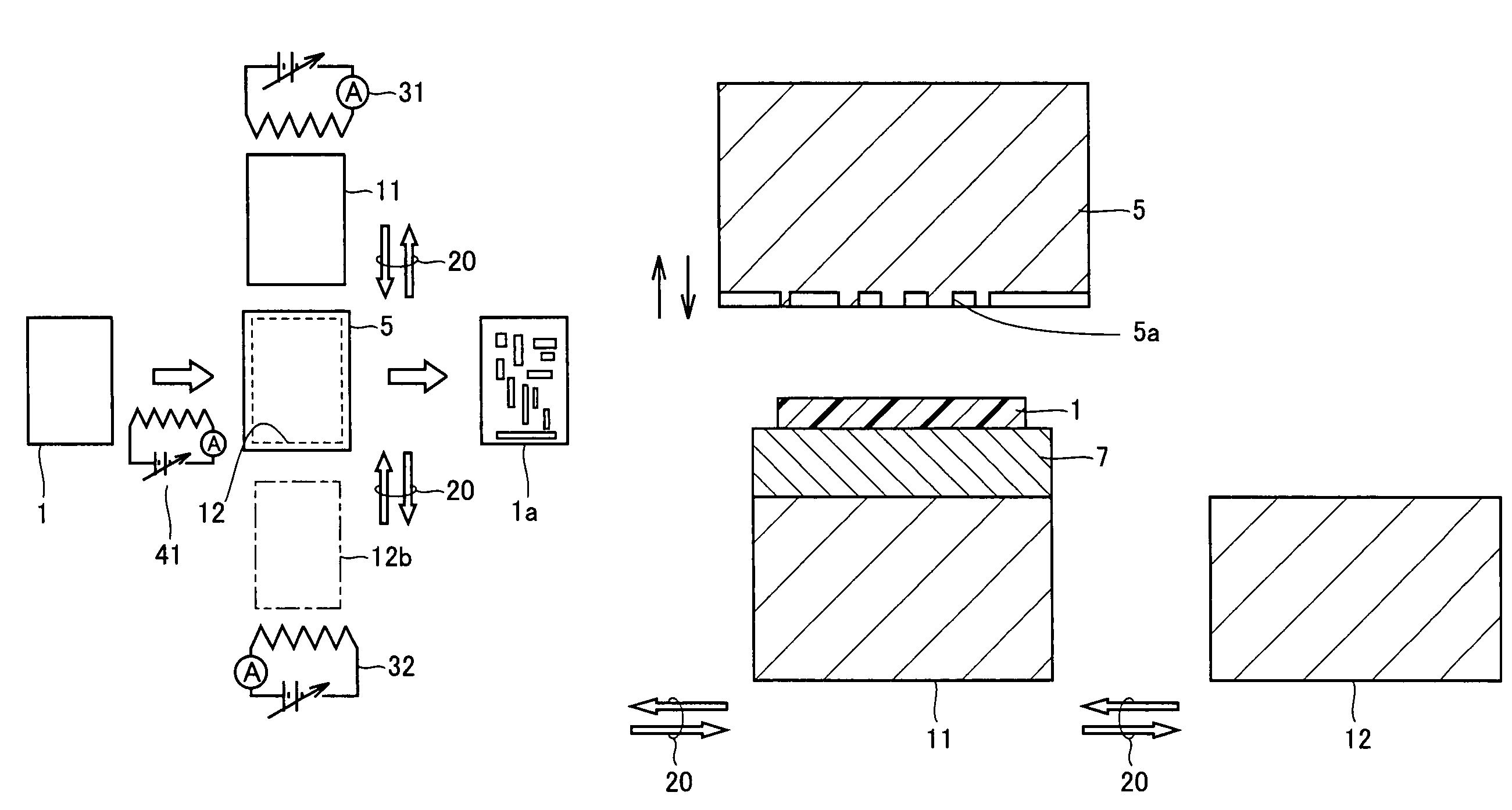

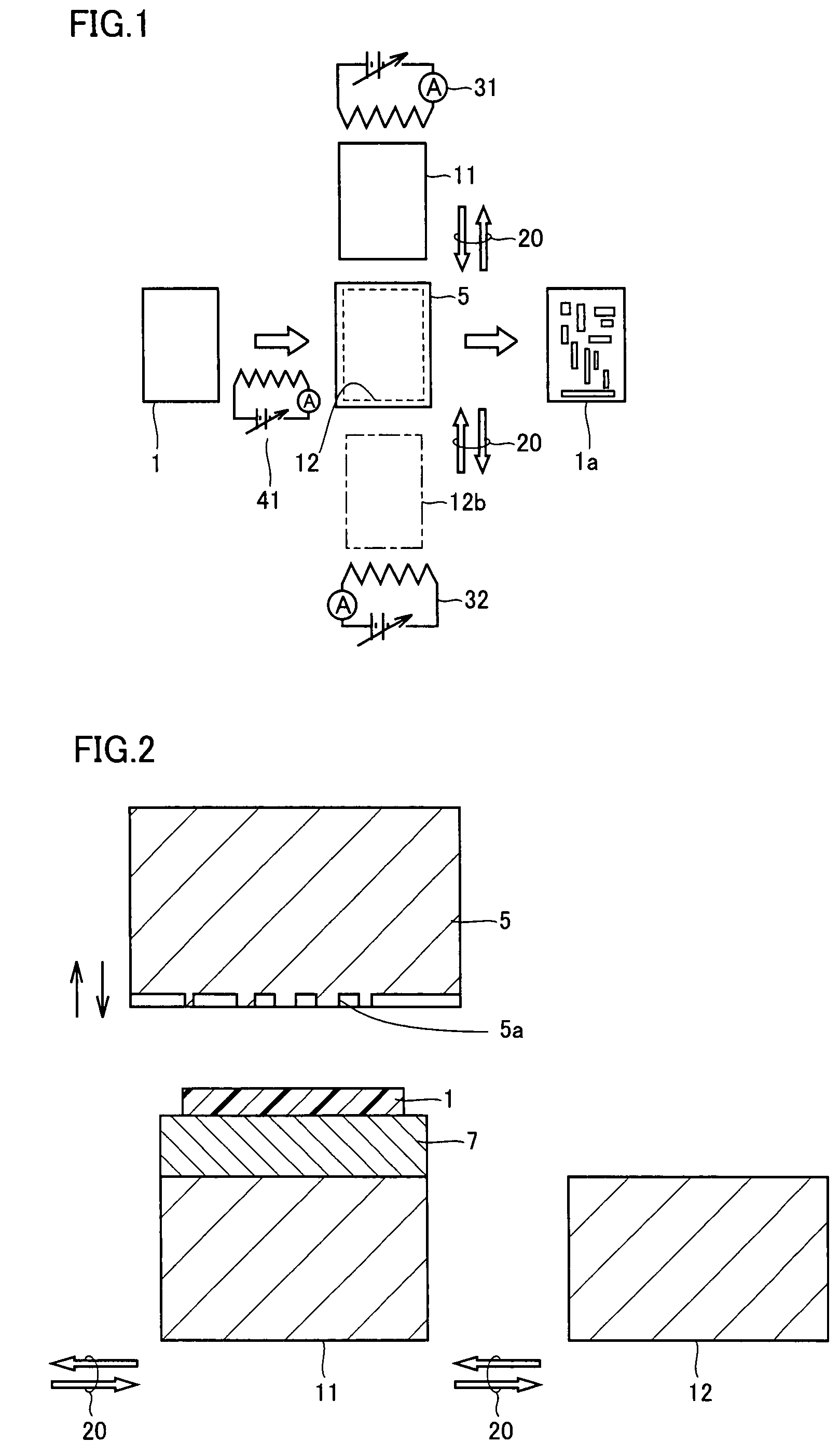

Processing method of fine structure and processing equipment for fine structure

InactiveUS7713052B2Suitable for processingImprove throughputConfectioneryCeramic shaping apparatusFine structureEngineering

In a processing method of a fine structure according to the present invention, an opposed platen (211) is moved from a retreat position to a molding / processing position, so that a film (1) is pressed against a mold (5) and processed. Thereafter a second block (211b) is separated from a first block (211a). Thus, improvement of the cooling rate for the opposed platen (211) can be attained by reducing the total thermal capacity of the opposed platen (211) by reducing the volume of the opposed platen (211) in cooling and physically discharging heat stored in the opposed platen (211). Thus, cooling efficiency for the opposed platen (211) is improved, and the heat cycle of the opposed platen (211) can be reduced.

Owner:SUMITOMO ELECTRIC IND LTD

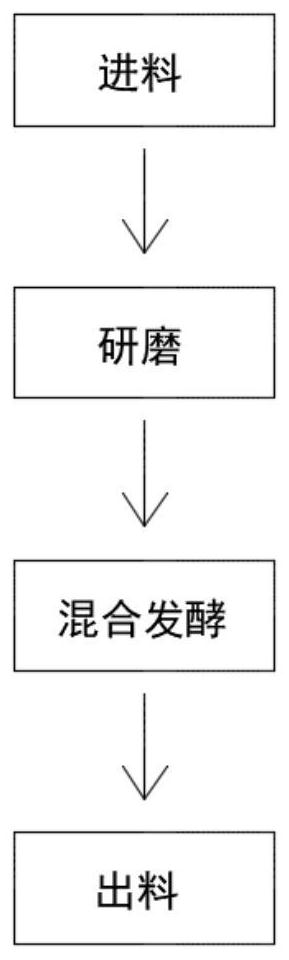

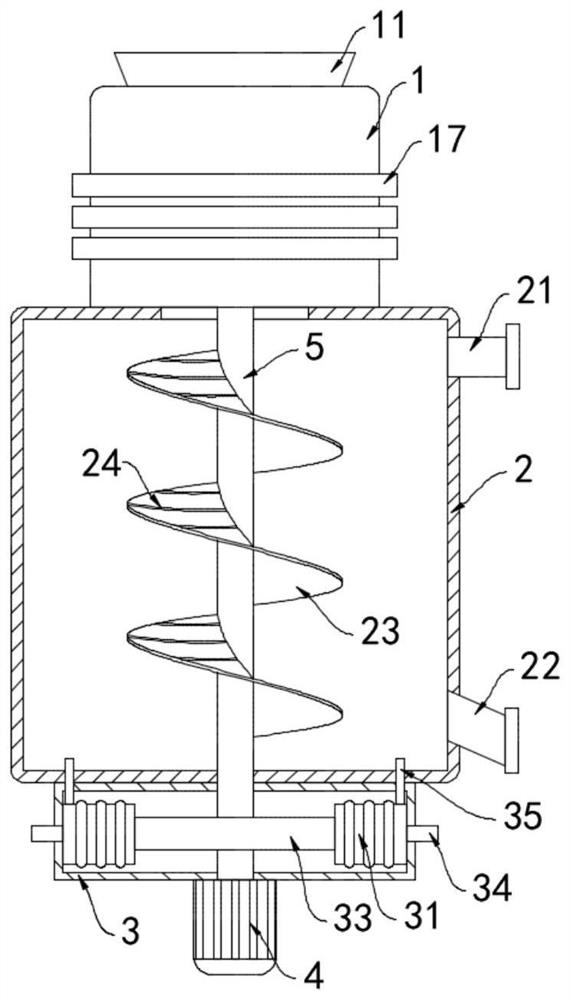

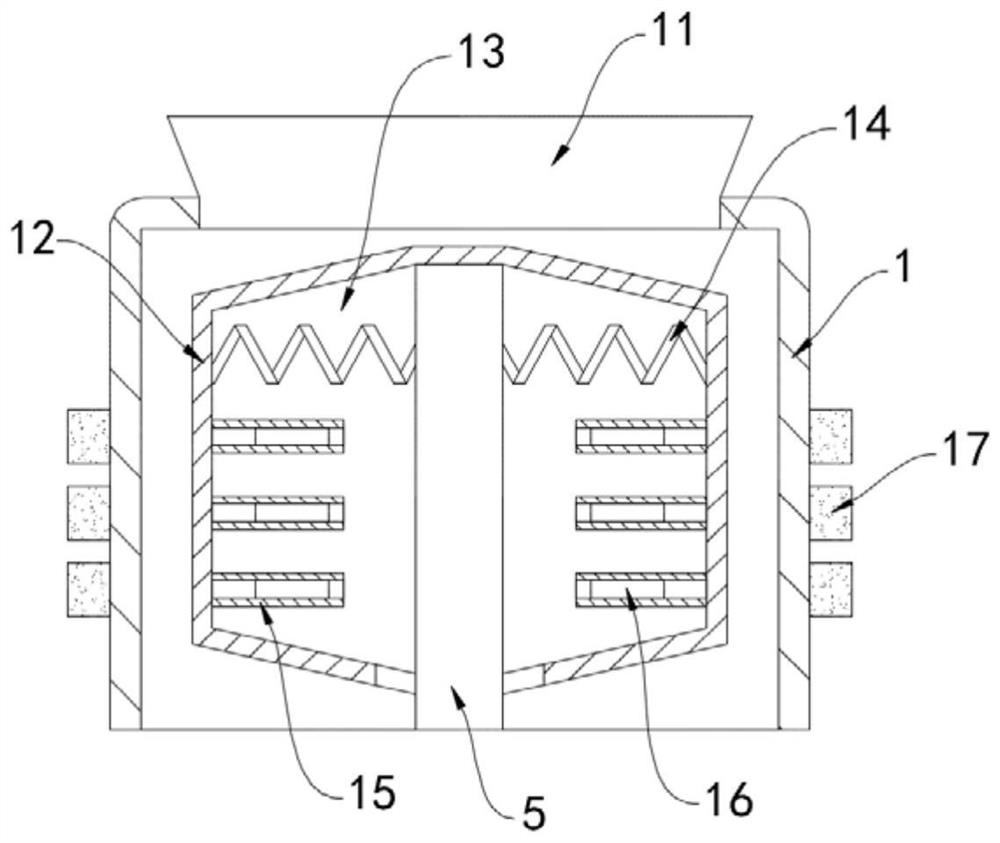

Production fermentation method of microbial fertilizer

ActiveCN112125719AIncrease profitReduce complexityBio-organic fraction processingFertiliser treatment heating/coolingAgricultural scienceAgricultural engineering

The invention belongs to the technical field of microbial fertilizer production, and relates to a production fermentation method of a microbial fertilizer. The method comprises the following steps of:S1, feeding: carrying out moisture content and carbon nitrogen ratio adjustment on microbial raw materials and fertilizers, and conveying the microbial raw materials and the fertilizers into a feeding funnel; S2, grinding: grinding and crushing the plurality of microbial raw materials and fertilizers with different particle sizes until the particle size range is 12mm-60mm; S3, mixed fermentation:feeding the ground and crushed microbial biomass raw materials and fertilizers into a fermentation tank for fermentation, maintaining the temperature within 35-40 DEG C, and continuously turning thematerials and fertilizers and performing ventilation; and S4, discharging: discharging the fermented microbial fertilizer through a discharging pipe, granulating, packaging, and transporting the fertilizer to a finished product area. According to the method of the invention, the vibration of a grinding head can form a vibration effect on the fertilizer, promote the crushing of the fertilizer and improve the grinding efficiency; in the rotation process of a spiral impeller, the mixing and exchange of the fertilizer at different positions are promoted, so that the fertilizer is in uniform contact with air, the turning effect is good, and the quality and fermentation efficiency of the microbial fertilizer are effectively improved.

Owner:清原满族自治县宏运有机肥有限公司

Fixed grate incinerator

InactiveCN104296148BAvoid subsequent continuous thermal expansion until it becomes soft and stuck.With self-cooling functionIncinerator apparatusCombustion chamberSlag

The invention belongs to the field of waste incineration equipment and particularly relates to a fixed grate incinerator comprising a main combustion chamber and a fixed fire grate. The fixed fire grate is arranged obliquely, the higher end is provide with a material input end, the lower end is provided a slag outlet for slags after material combustion, and the slag outlet is communicated with a slag discharging component; a hot air chamber is arranged below the main combustion chamber; a hot air supply path penetrates the fixed fire grate; the fixed grate incinerator further comprises an ejecting rod and a power portion; the maximum lift of the ejecting rod penetrates the material layer of the fixed fire grate; an ejecting rod component further comprises a shaft sleeve with the preset length, one end of the shaft sleeve penetrates and is fixedly connected to the fixed fire grate along the moving direction of the ejecting rod, a vent gap allowing the air to penetrate is formed between the shaft sleeve and the ejecting rod, and the other end of the shaft sleeve is communicated with the outside and / or an air cooling chamber. The fixed grate incinerator has the advantages that material burning efficiency is high, the component operation reliability is high, and the service life is prolonged effectively.

Owner:安徽盛燃焚烧炉科技有限公司

Heat treatment technology for automobile transmission gears

ActiveCN105838851APerfect control of process detailsAdjust the difference in real timeSolid state diffusion coatingFurnace typesTemperature controlSprayer

The invention discloses a heat treatment technology for automobile transmission gears. The heat treatment technology comprises a heat treatment container which is indispensable for heat treatment, heat treatment liquid and heat treatment operation technological procedures, wherein the heat treatment container comprises a heat treatment tank, heat treatment tank temperature control devices, the heat treatment liquid, a material supplement device, tank liquid observation sensors, an oil fume treatment device and a heat treatment liquid circulation device; the heat treatment liquid circulation device comprises an adjustable sprayer for spraying the heat treatment liquid; the sprayer can spray the heat treatment liquid on the to-be-treated automobile transmission gears; and the material supplement device is provided with a preparation material. By adopting the heat treatment technology, each technological detail of the heat treatment can be perfectly controlled; values between practical heat treatment technology and ideal technology can be adjusted and corrected in real time; the heat treatment is stable in quality, and is high-efficient and energy-saving; pollution is reduced; environment protection is promoted; and heat treatment cost can be reduced.

Owner:FUJIAN SHANGKUN GEARBOX MFG

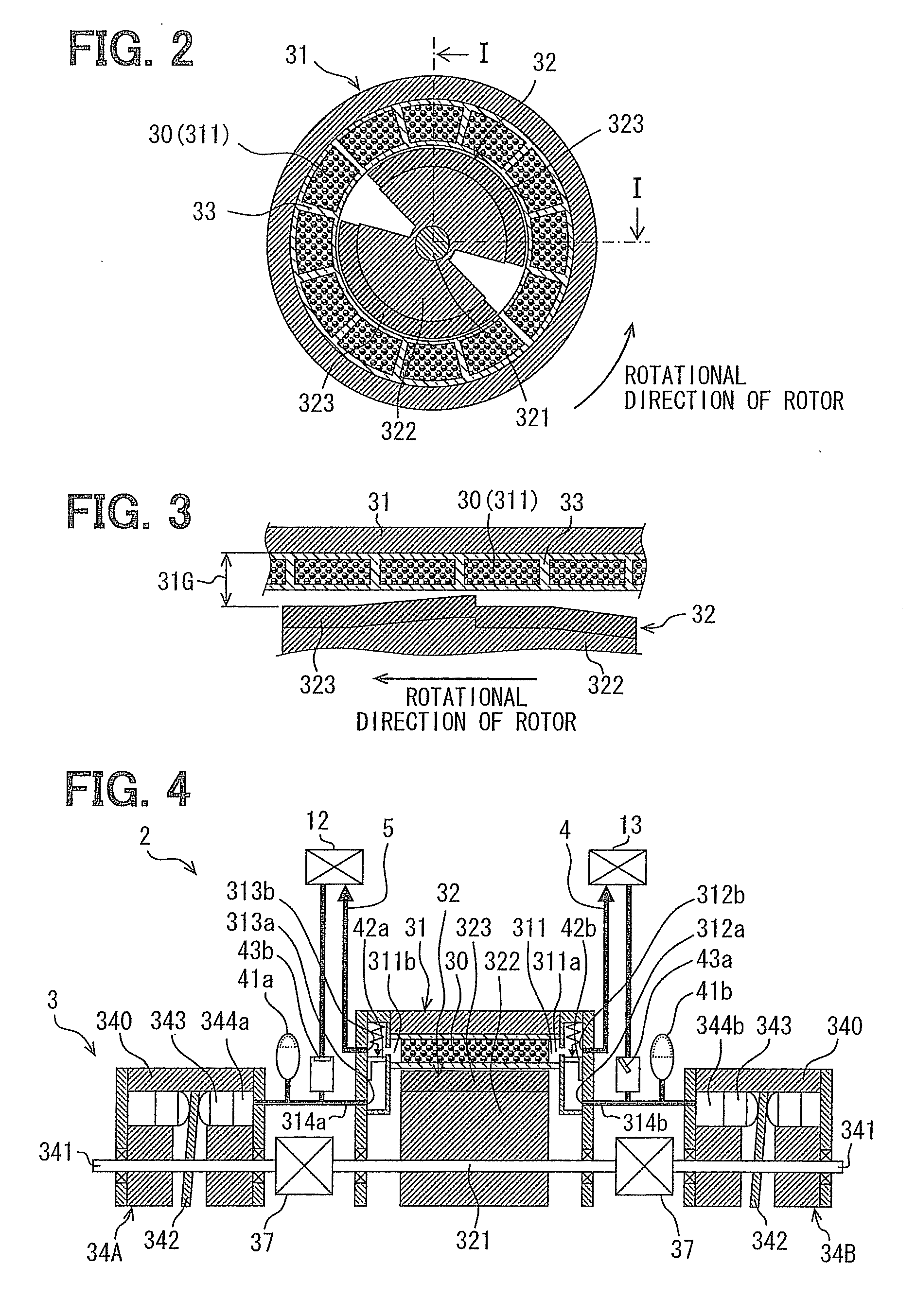

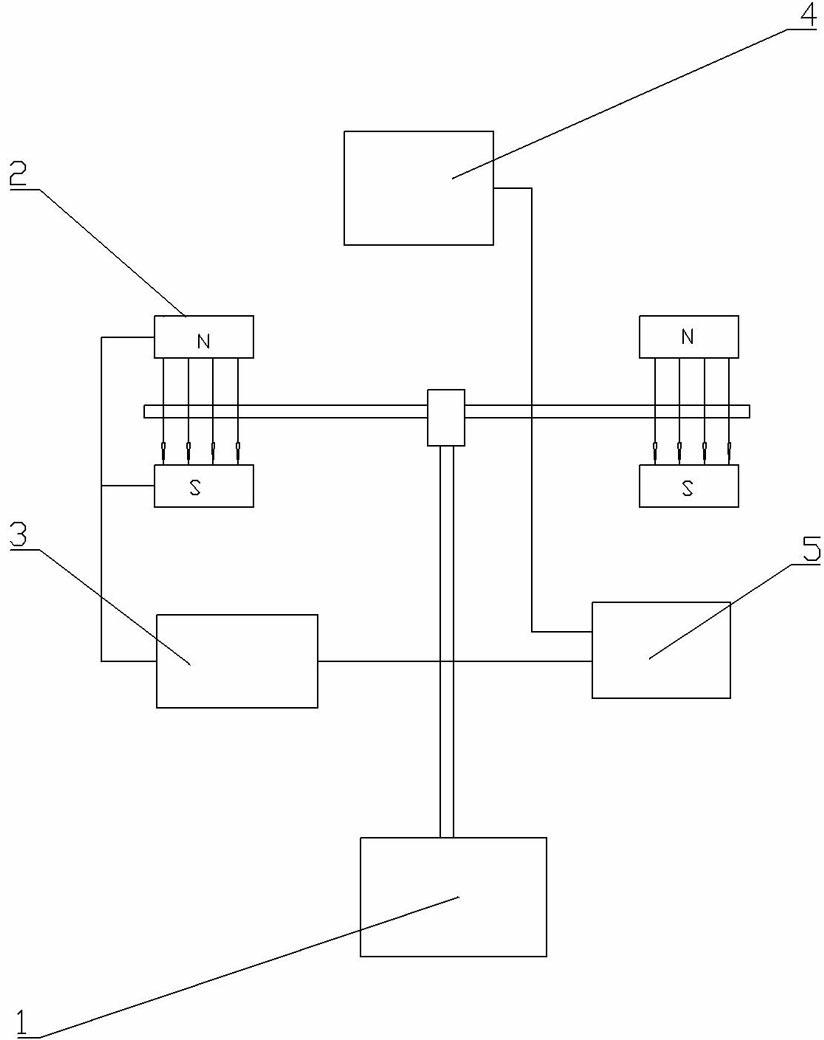

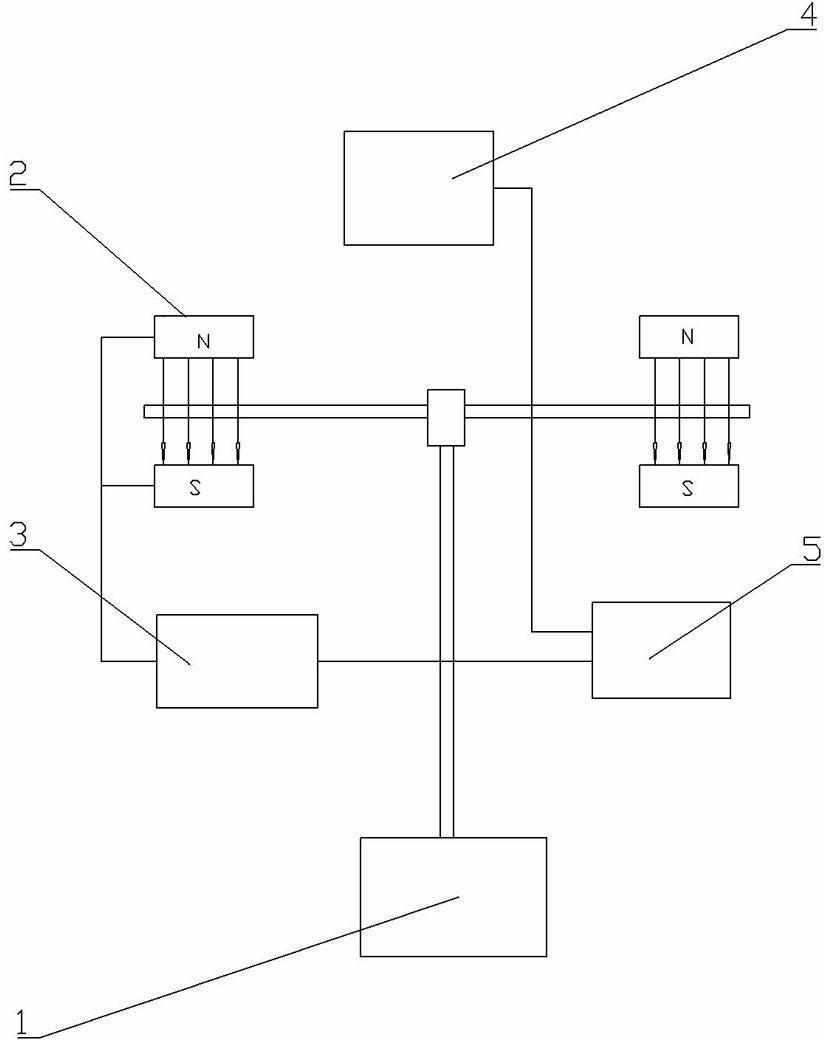

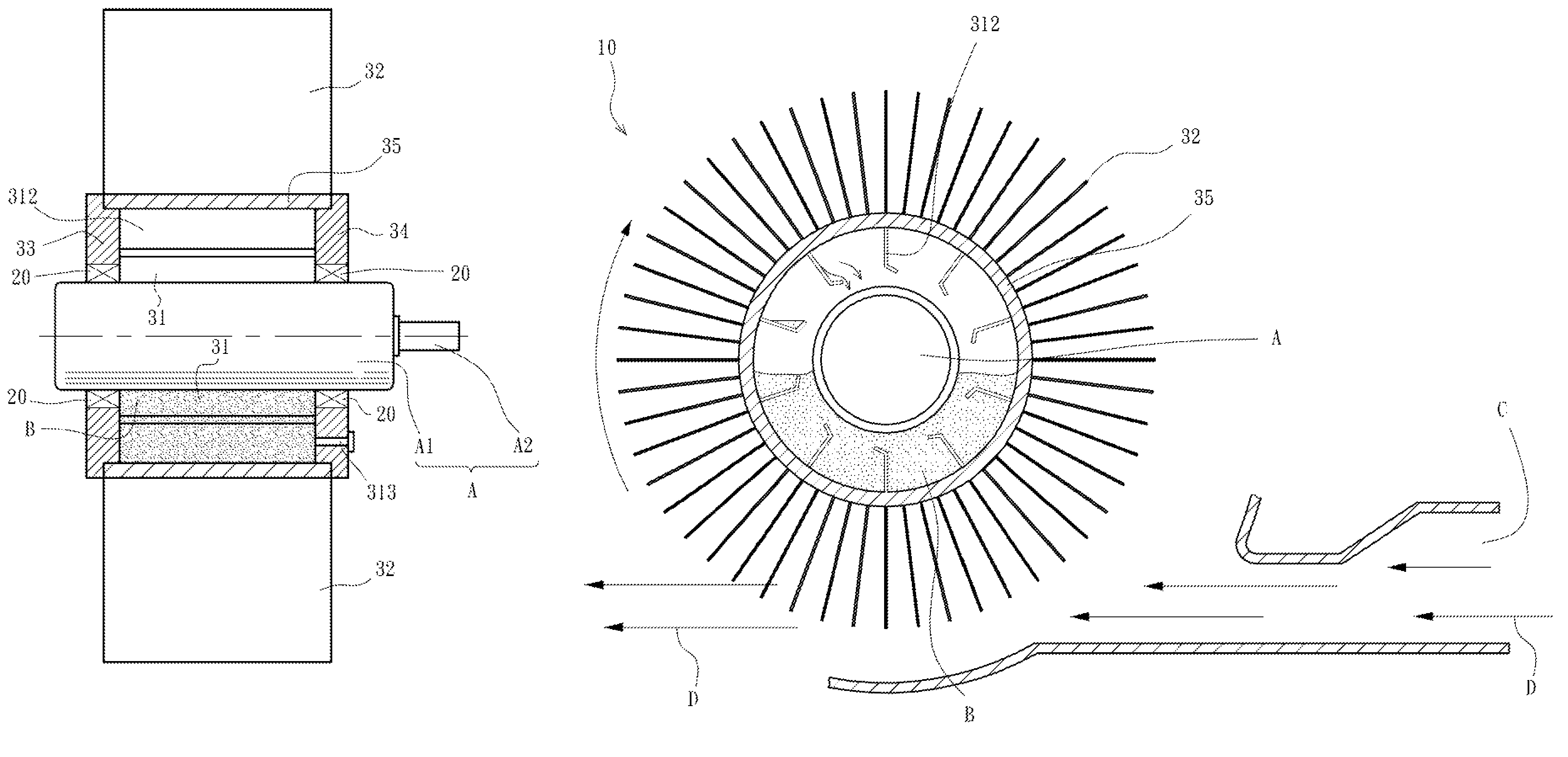

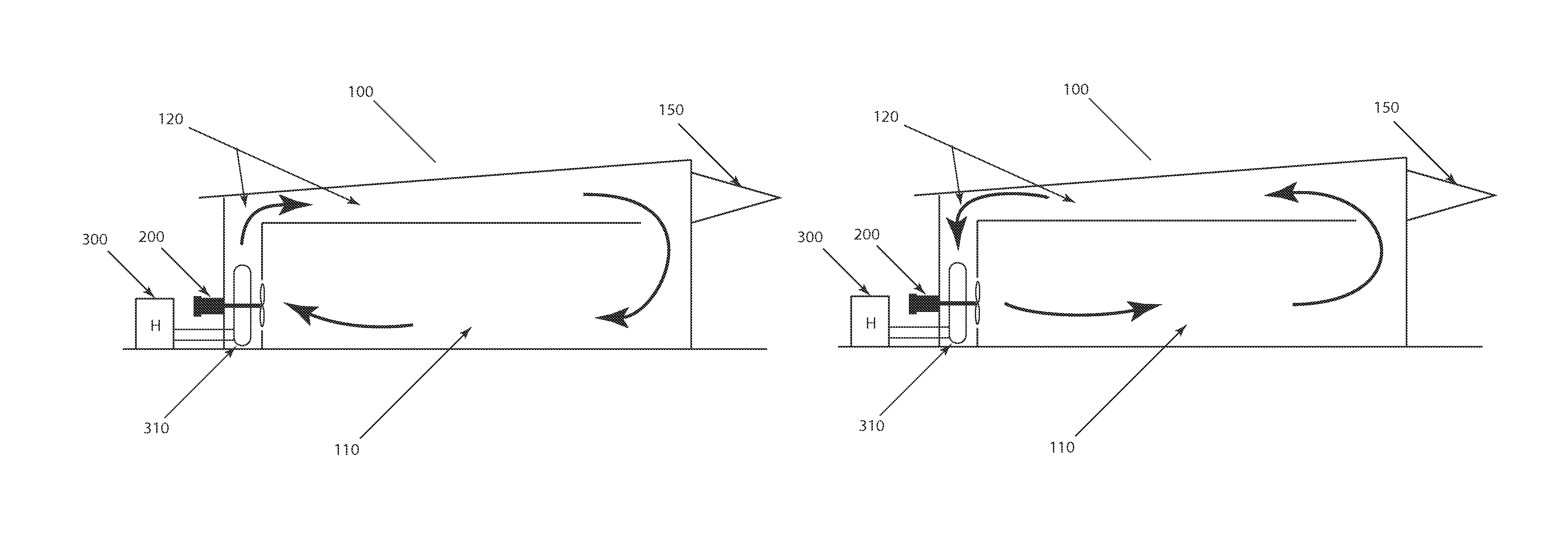

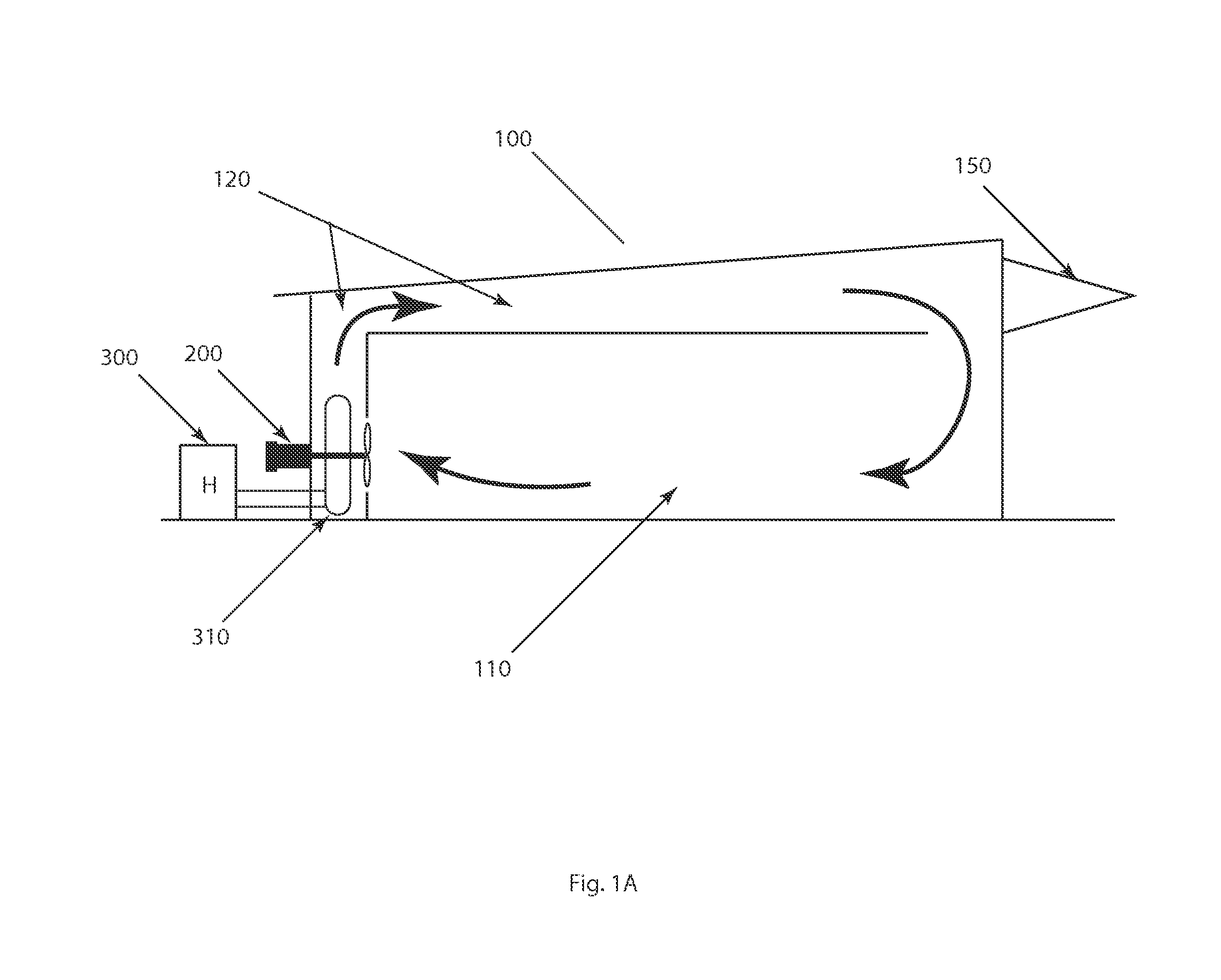

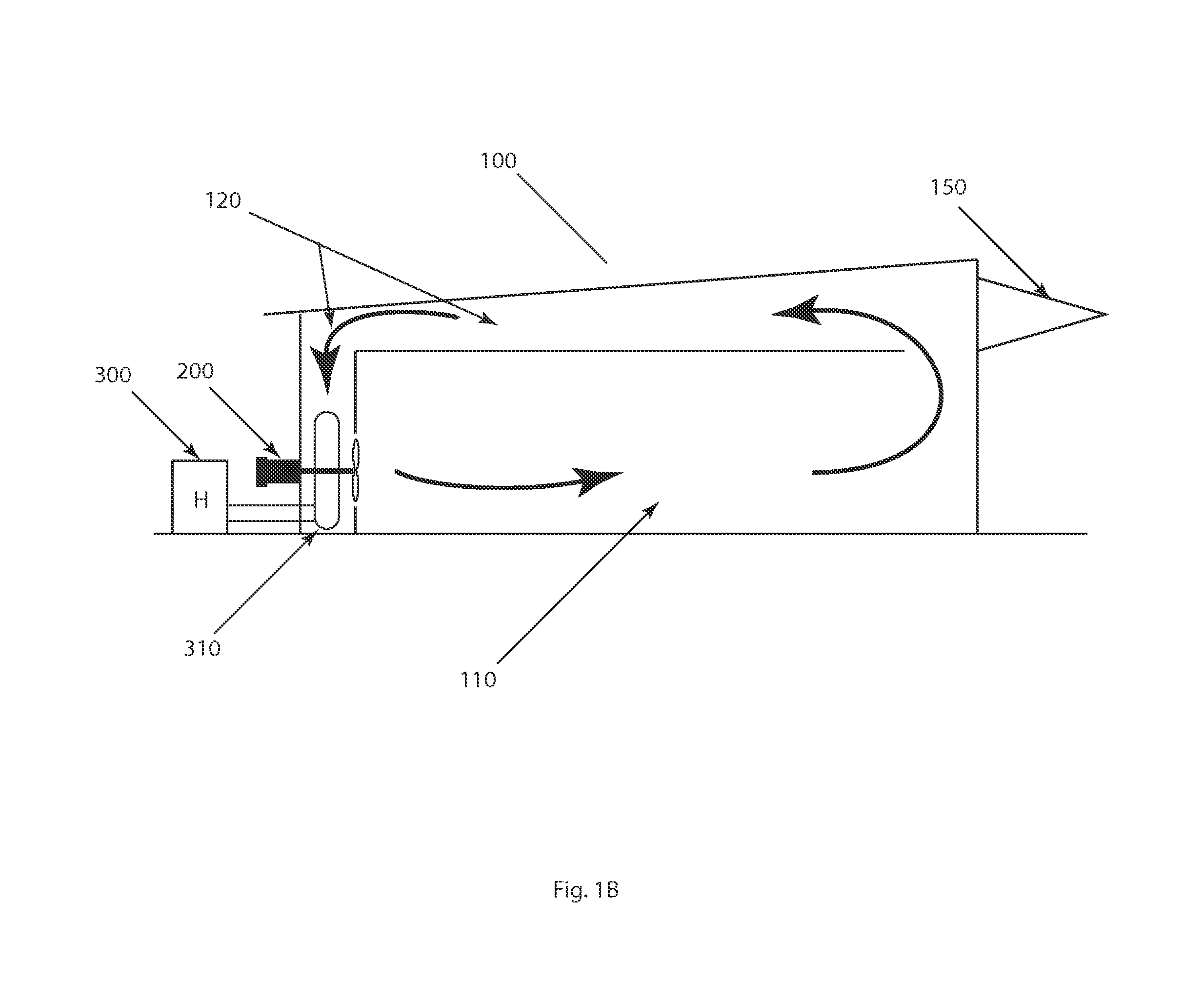

Reciprocating magnetic heat pump apparatus with multiple permanent magnets in different configurations

ActiveUS9546803B2Increased and decreasedShorten the heating cycleEnergy efficient heating/coolingMachines using electric/magnetic effectsHeat pumpMagnet

A magnetic heat pump cycle has a first to a fourth steps, which are repeatedly carried out. In the first step, a movement of heat medium is stopped by a pressure valve and a pressure accumulating tank and a magnetic field is applied by a magnetic-field control unit to a magnetic working material. In the second step, the pressure valve is opened so that the heat medium flows in a working chamber from a second axial end to a first axial end, and the magnetic field is increased depending on a moving speed of the heat medium. In the third step, the movement of the heat medium is stopped and the magnetic field is decreased. In the fourth step, the heat medium is moved in a reversed direction and the magnetic field is decreased depending on the moving speed of the heat medium.

Owner:DENSO CORP

Automobile gearbox gear heat treatment device

ActiveCN105861805APerfect control of process detailsAdjust the difference in real timeFurnace typesHeat treatment process controlTemperature controlElectric machine

The invention discloses an automobile gearbox gear heat treatment device which comprises a heat treatment container, wherein the heat treatment container comprises a heat treatment tank, a heat treatment tank temperature control device, a heat treatment solution, a material supplementing device, a tank solution observing sensor, a lampblack treatment device and a heat treatment solution circulating device; the heat treatment solution circulating device comprises a liquid inlet pipeline, a motor pump and a liquid discharge pipeline which are connected in sequence; the heat treatment solution is located at the bottom of the heat treatment tank, the heat treatment tank temperature control device is provided with an electric heater soaked in the heat treatment solution, the heat treatment solution contains ingredients; and the tank solution observing sensor monitors the temperature of gas and the heat treatment solution in the heat treatment tank and the real-time concentration content of the ingredients. The device can perfectly control all technological details of heat treatment, can adjust and correct differences between actual heat treatment process and ideal treatment process in real time, is steady in heat treatment quality, efficient and energy-saving, and can reduce pollution, promote environmental protection and save heat treatment cost.

Owner:FUJIAN SHANGKUN GEARBOX MFG

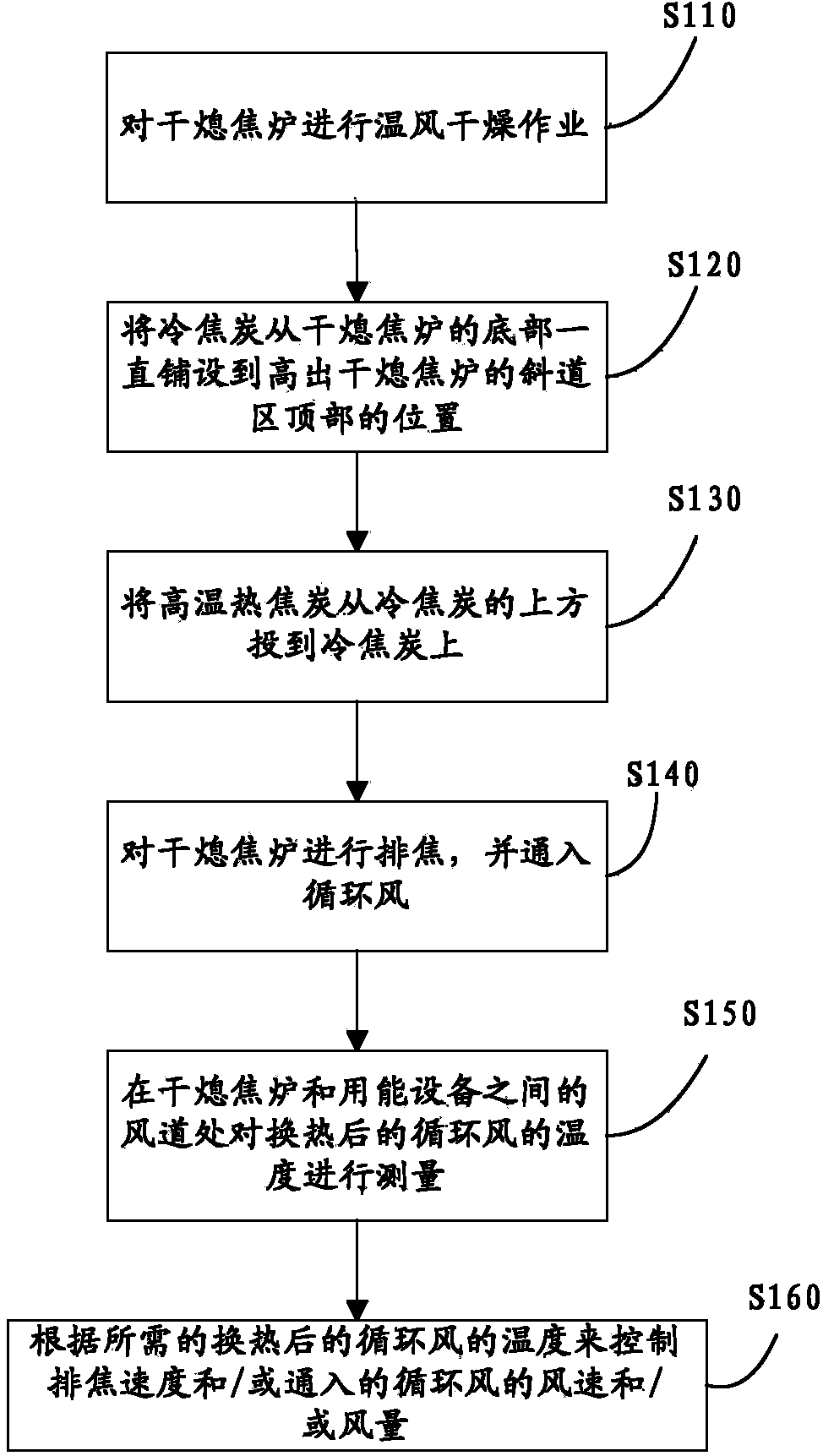

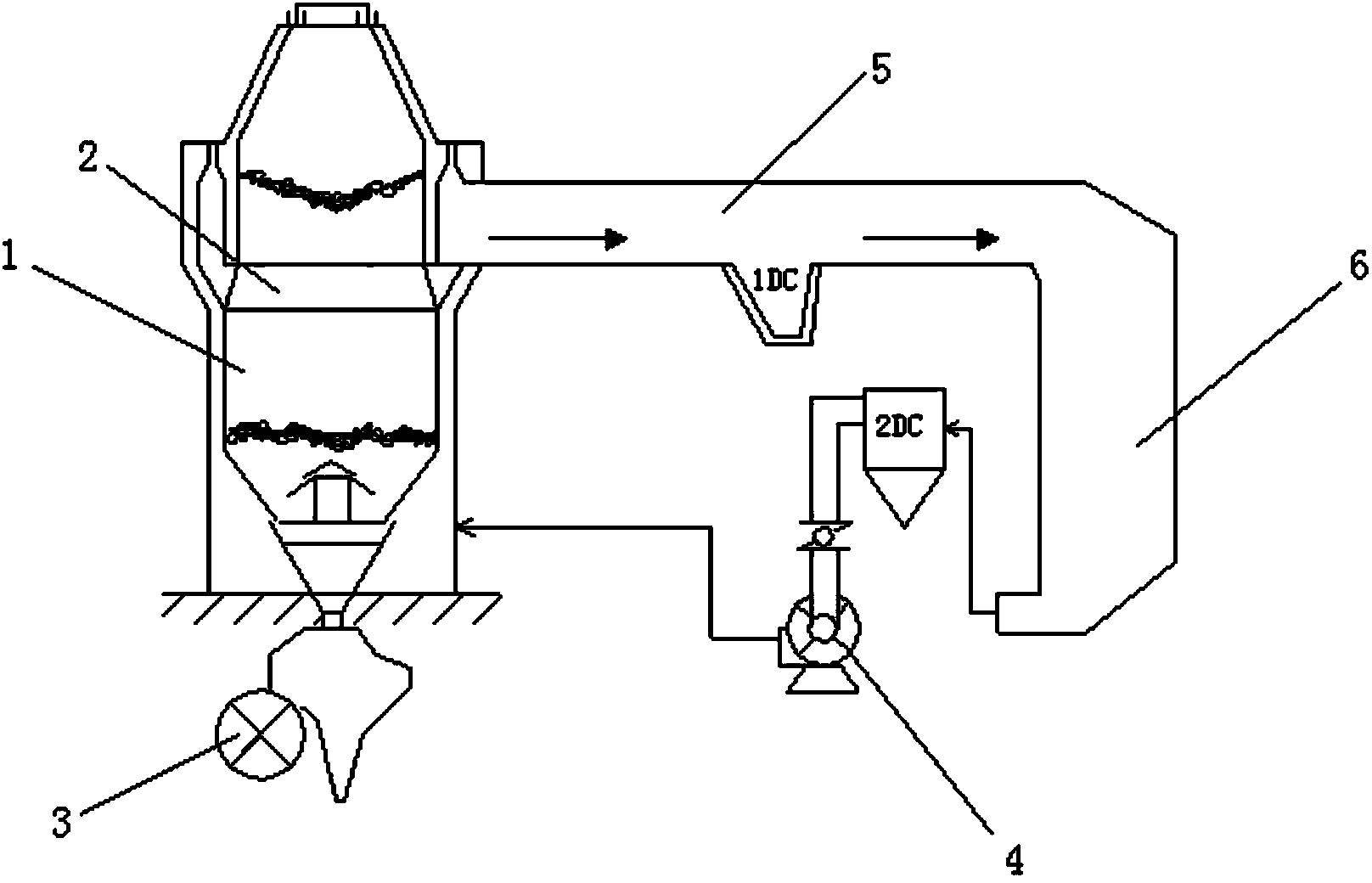

Temperature-raising method and system for coke dry quenching furnace

The invention relates to the technical field of energy recovery and discloses a temperature-raising method and a temperature-raising system for a coke dry quenching furnace. The method comprises the steps of laying cold coke from the bottom of the coke dry quenching furnace to a position higher than the top of the chute zone of the coke dry quenching furnace; putting hot coke on cold coke from the position above cold coke; carrying out coke discharging on coke dry quenching furnace, and introducing the circulating air; and controlling the coke discharging speed and / or air speed and / or air quantity of the introduced circulating air according to the temperature of the circulating air required for heat exchange. By virtue of the method disclosed by the invention, cold coke in the coke dry quenching furnace is slowly heated, the direct contact between the chute zone of the coke dry quenching furnace and high-temperature hot coke is avoided, the degree of change of the thermal stress is reduced, the integrity of the refractory material at the chute of the coke dry quenching furnace is ensured, the temperature-raising period is shortened and the service life of the refractory material is prolonged.

Owner:唐山首钢京唐西山焦化有限责任公司 +2

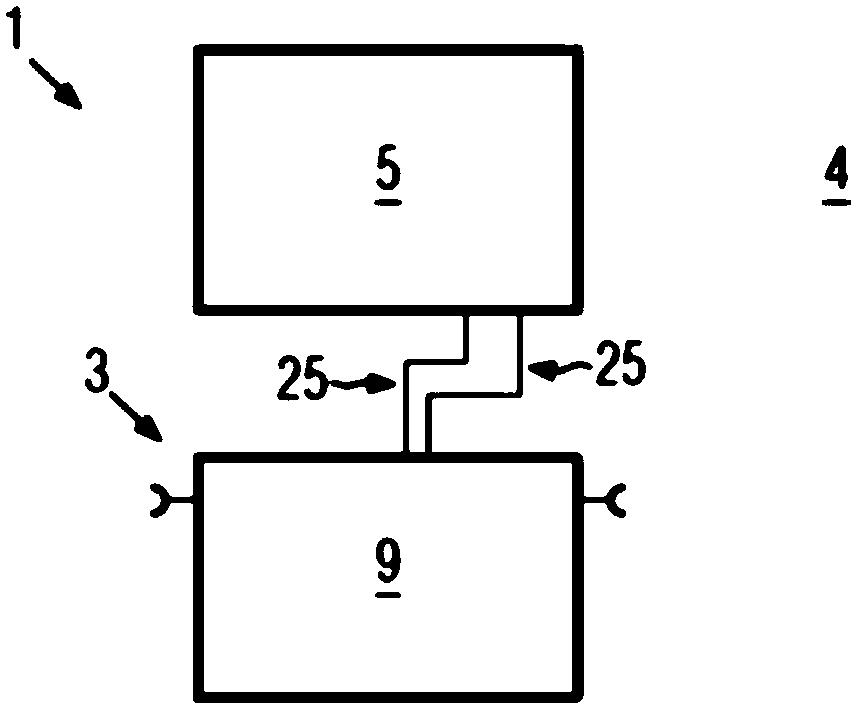

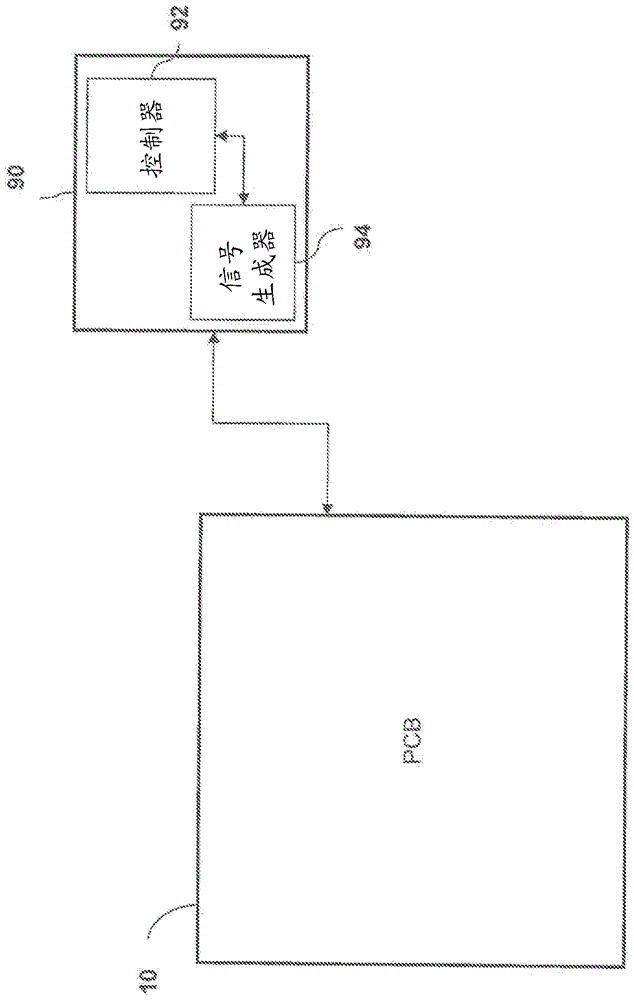

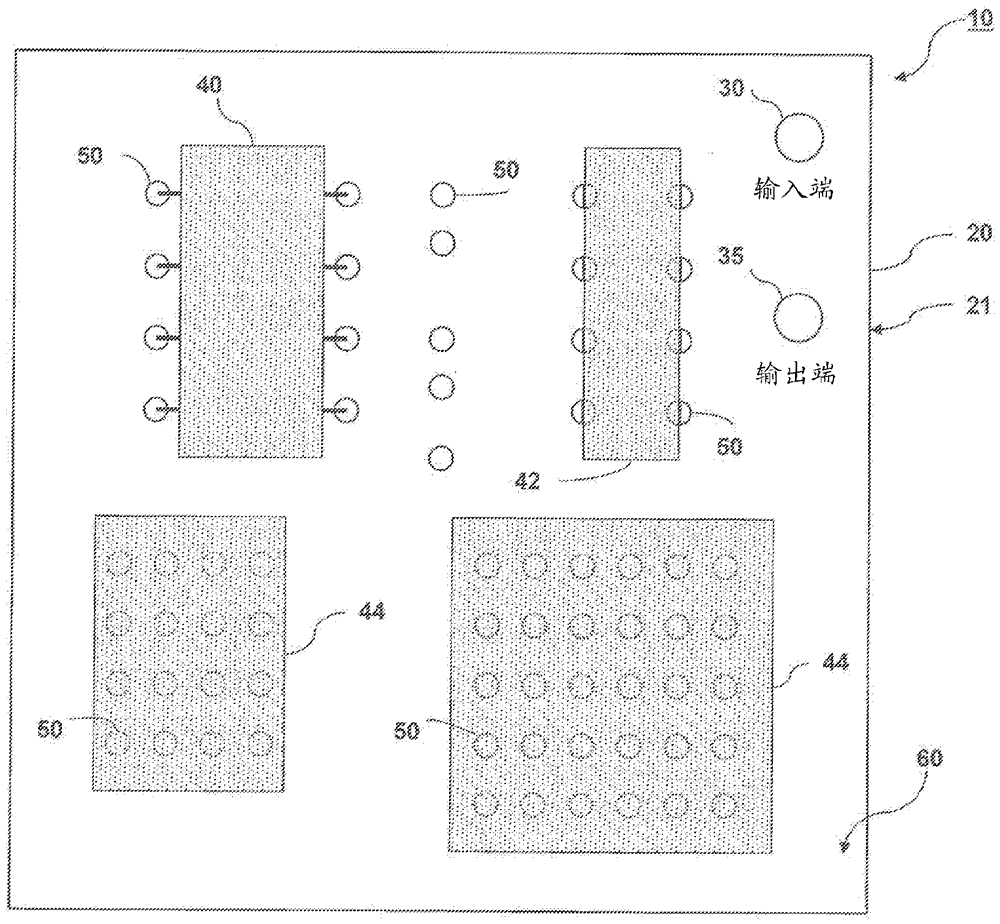

Printed circuit board with embedded heater

InactiveCN104380837BEasy to operateShorten the heating cyclePrinted resistor incorporationOhmic-resistance heatingEngineeringElectronic component

Aspects of the present invention relate to providing a printed circuit board comprising a top conductive layer; a bottom conductive layer; a plurality of electronic components arranged on at least one of the top conductive layer or the bottom conductive layer; A heater layer interposed between the conductive layers and configured to generate and transfer heat to at least one of the electronic components.

Owner:惠亚集团科技有限责任公司

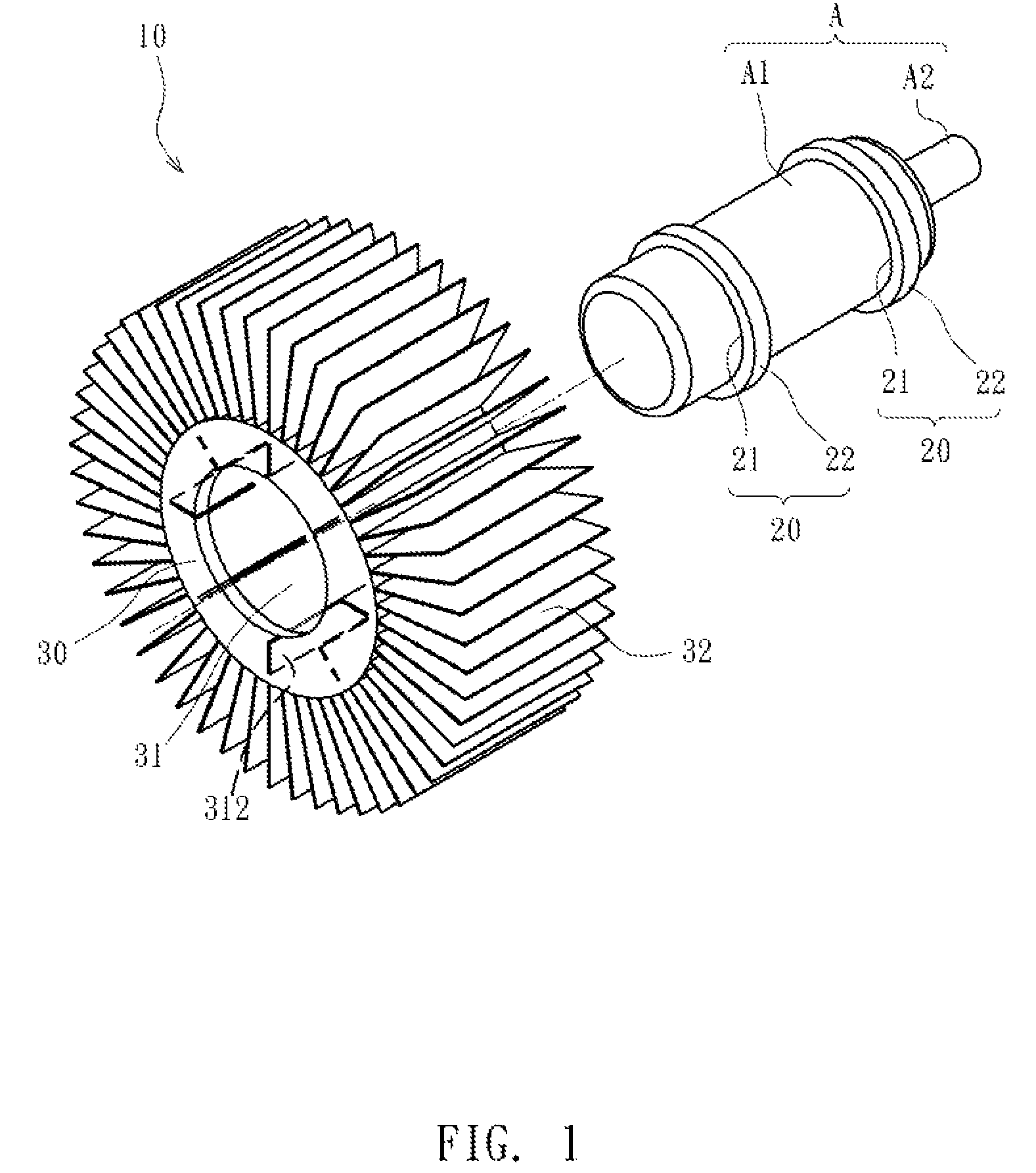

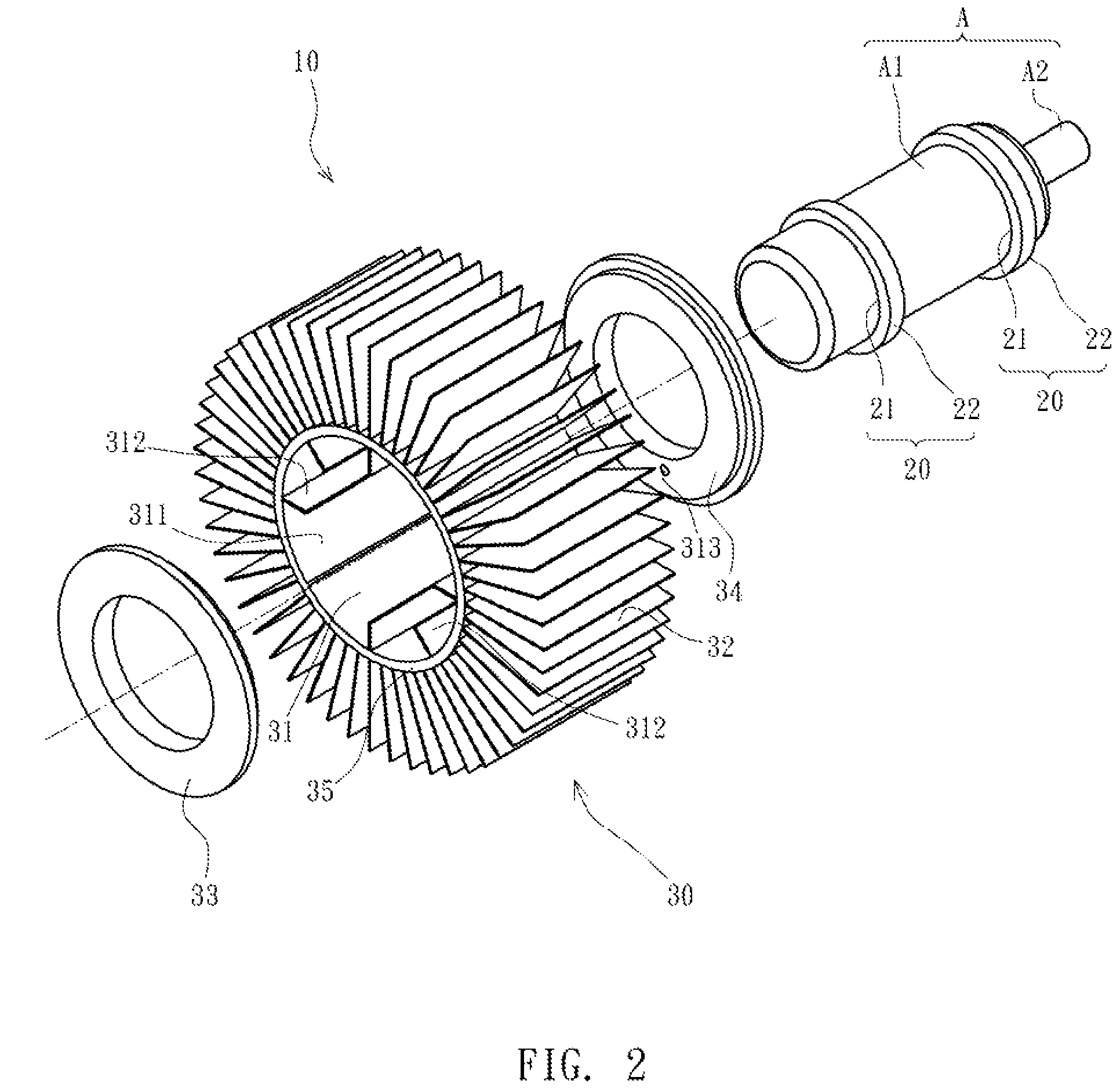

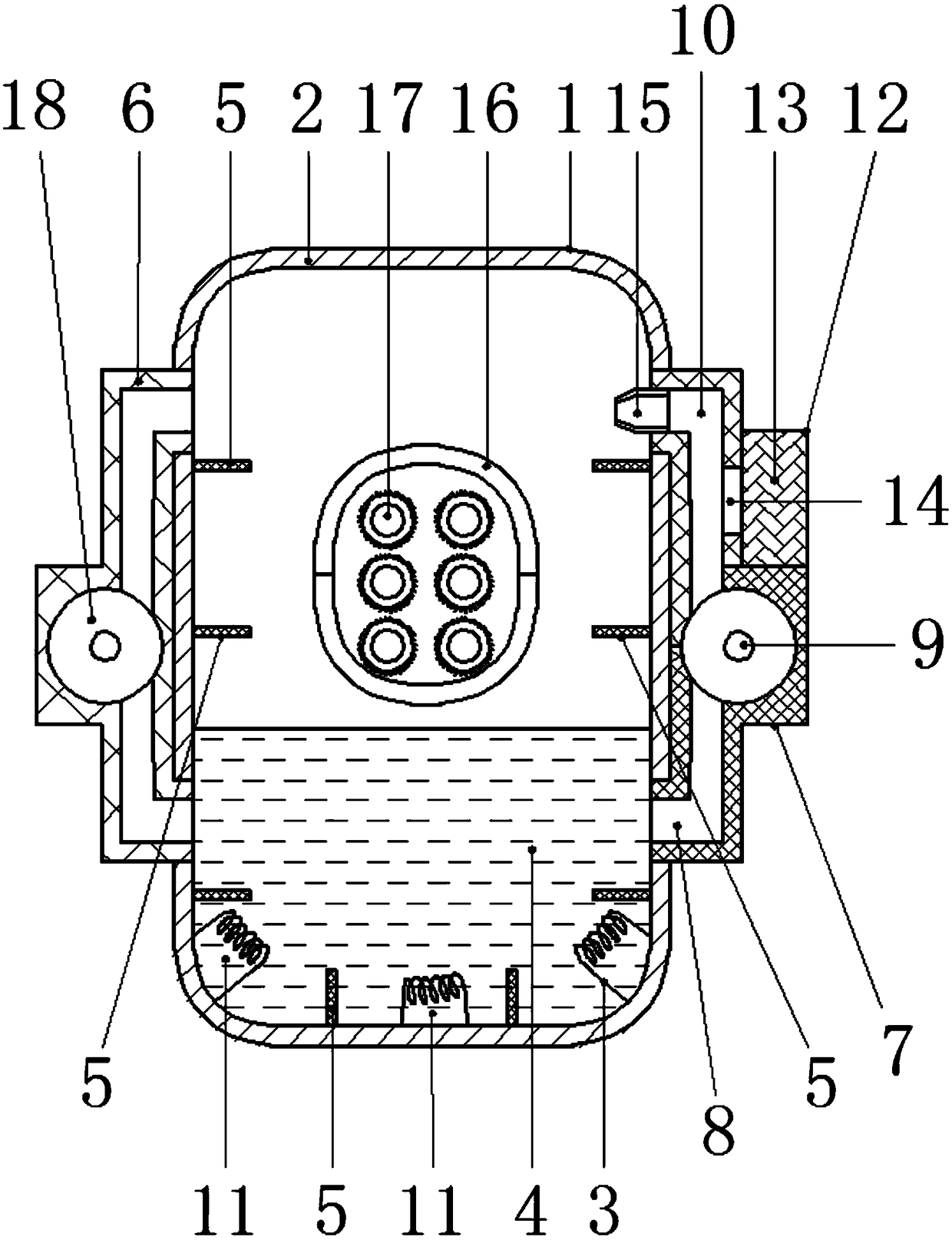

Heat dissipating device of an electromotor

ActiveUS8466588B2Effective rotationShorten the heating cycleMechanical energy handlingCooling/ventillation arrangementEngineeringWind force

Owner:METAL INDS RES & DEV CENT

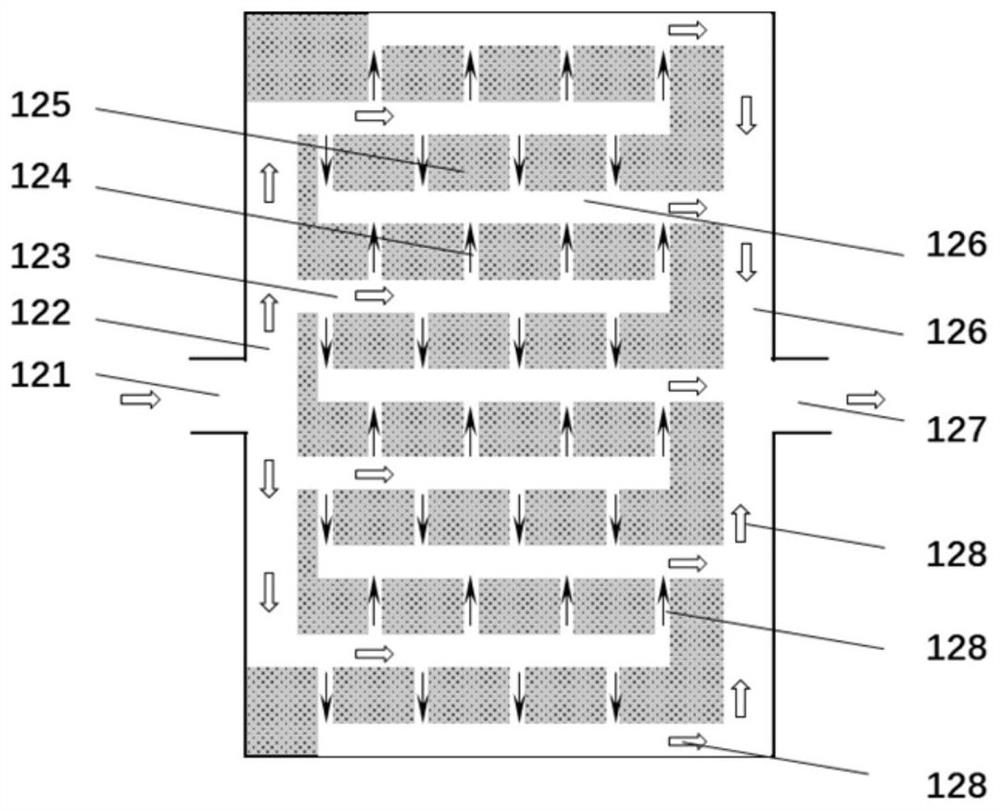

Modified heat chamber and method to improve heat cycle efficiency using airflow control

The present invention relates to improvements in the art of operating large heat chambers so as to reduce both the time and the cost required for heating materials. More specifically, the modified heat chamber of the present invention provides a programmable control mechanism capable of significantly reducing areas with temperature variations or hot and cold spots. A programmable heat chamber leads to significant reductions in the required processing time and in the cost of the required energy.

Owner:LAFFLER DONALD L +1

Furnace for testing limit of fire resistance of tunnel fire-proof protective material

InactiveCN101846453BReasonable structureUniform and stable lateral temperatureFurnace typesMaterial thermal analysisCombustorFlue gas

Owner:辽宁同辉科技发展有限公司

A heat treatment device for an automobile transmission gear

ActiveCN105861805BPerfect control of process detailsAdjust the difference in real timeFurnace typesHeat treatment process controlTemperature controlAdditive ingredient

Owner:FUJIAN SHANGKUN GEARBOX MFG

Energy-saving boiler

InactiveCN1702373AReduce condensationIncrease the heating areaBoiler drums/headersWater heatersCombustorSteam condensation

This invention relates to a boiler, which comprises housing, fire box, flame tube, burner and ignition device, wherein the flame tube is filled with water, and the fire tube is arranged in the water layer; one side of the flame tube facing fire box is extended and has a reservior hole, which is connected with the flame tube. The top of the flame tube is steam, and the fire tube is located in the corresponding steam layer, and the fire tube inside the steam layer is the extended section of water layer. Inside the housing has a heatproof ring, and between the ring and housing forms insulation cavity with water, and the water is connected with the water layer in the flame tube. Such structure increases heated area and decrease heating cycle; the discharged heat can be absorbed by the steam, which can decrease steam condensation and increase heat efficiency.

Owner:应连根

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com