Coal seam convection heating system and method for in-situ pyrolysis of oil-rich coal

An in-situ pyrolysis and convection heating technology, which is applied in the fields of mining fluids, earth-moving drilling, surface mining, etc., can solve the problems of poor coal seam temperature uniformity, long coal seam heating cycle, and low overall energy efficiency, and achieves shortened heating cycle and high efficiency. Heating efficiency and energy utilization, the effect of high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

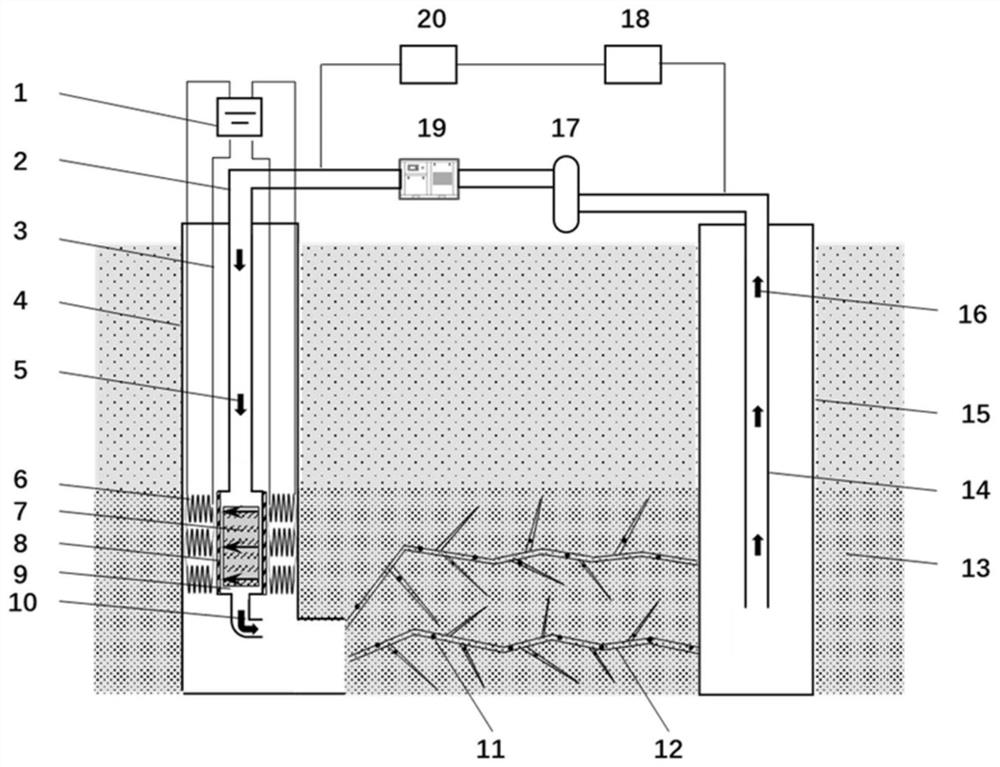

[0033] see figure 1 , an in-situ convective high-efficiency energy-saving heating system for coal seams in the process of in-situ pyrolysis (or dry distillation) of oil-rich coal, including a fluid electromagnetic heating device arranged at the bottom of the heat injection well 4 or the production well 15, the heat injection well 4 and the production well The wells 15 are connected through fracturing gaps 12 .

[0034] A power supply box 1 is arranged outside the heat injection well 4 or outside the production well 15. When the fluid electromagnetic heating device is arranged in the heat injection well 4, a power supply box 1 is arranged outside the heat injection well 4. When the fluid electromagnetic heating device is arranged in the production well In the middle of 15, a power supply box 1 is arranged outside the production well 15.

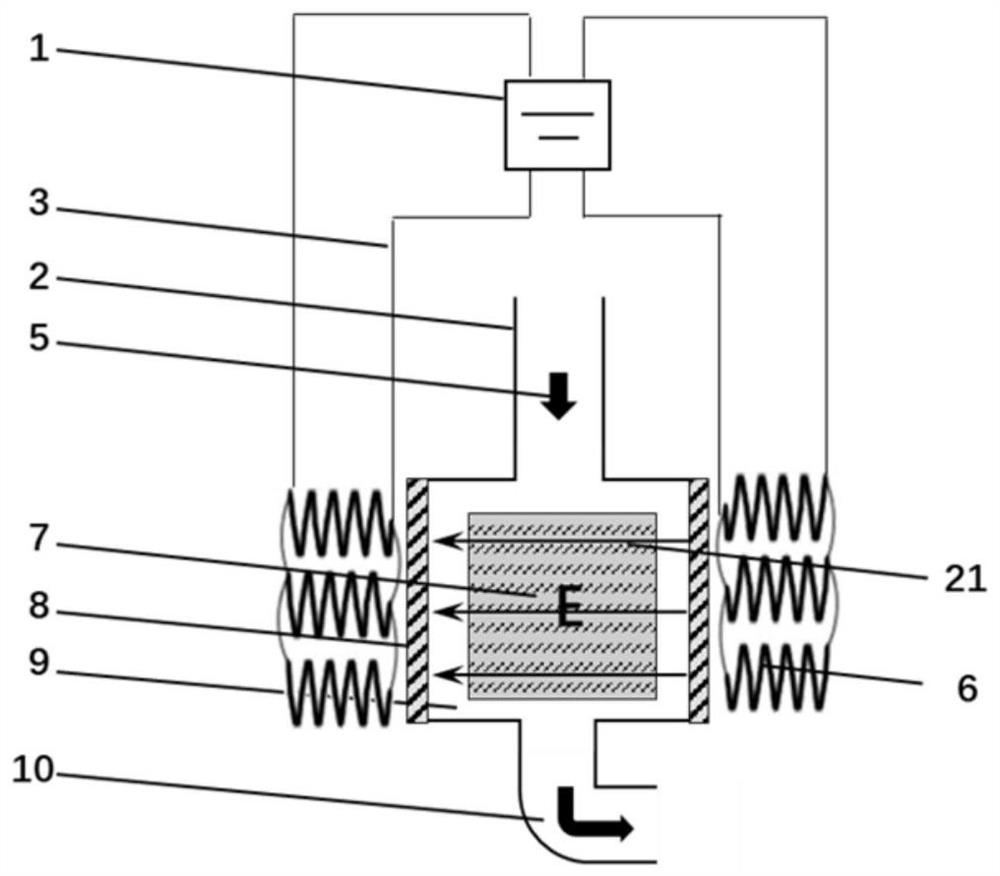

[0035] see figure 2 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com