Pressure quenching process and equipment for diaphragm spring

A diaphragm spring and equipment technology, applied in the field of diaphragm spring press quenching process and equipment, can solve the problems of limited fatigue life of diaphragm spring, limited hardness of diaphragm spring, long heating cycle, etc., achieving obvious energy saving effect and reducing brittleness , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

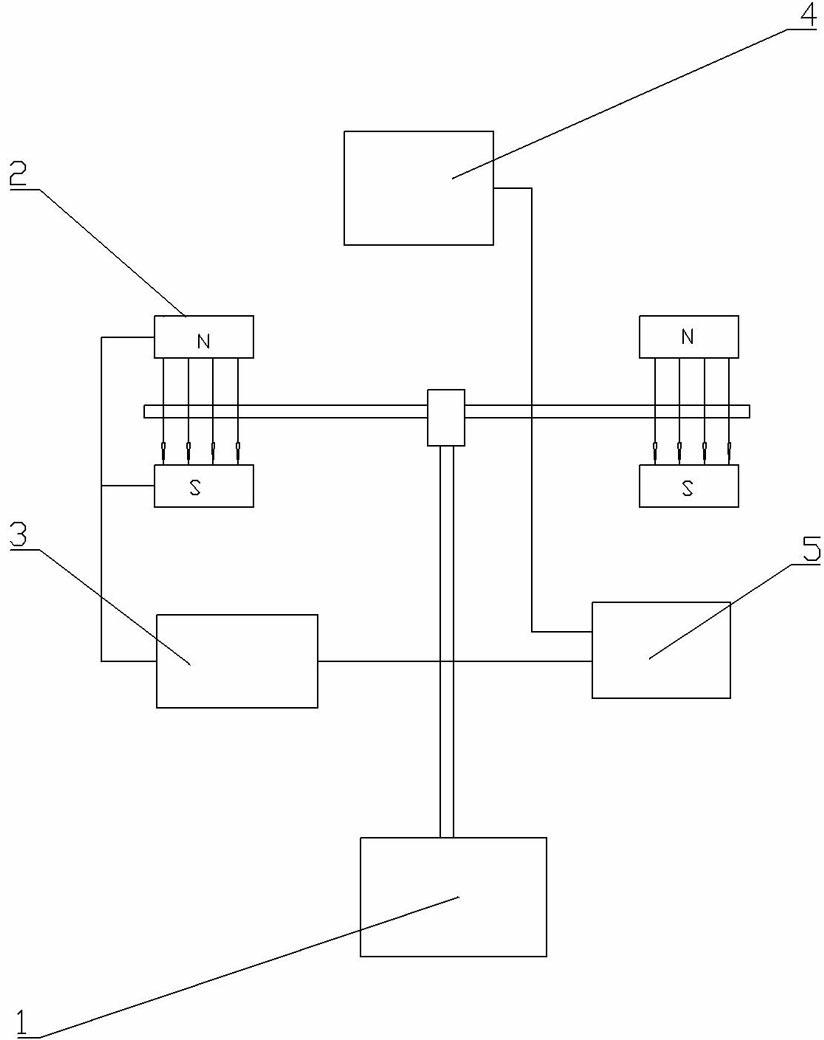

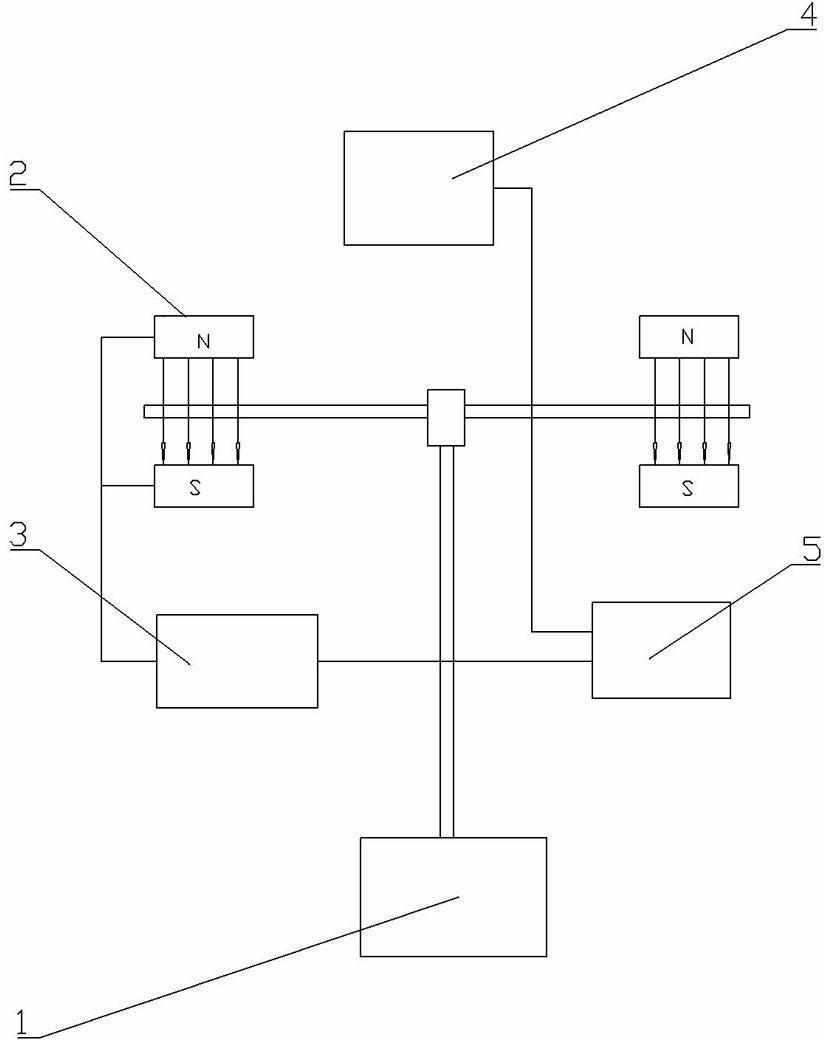

[0012] like figure 1 As shown, the key to realizing the press quenching method of the present invention lies in the press quenching equipment, which includes a rotating device 1, an induction coil 2, a high frequency power generating device 3, a temperature sensor 4, and an intelligent control device 5. In order to carry out intelligent control and comprehensive management, the rotating device 1, the high-frequency power generating device 3, and the temperature sensor 4 are all electrically connected to the intelligent control device 5, and the rotating device 1 includes a motor and is arranged on a motor rotating Clamping device on the shaft for clamping the diaphragm spring.

[0013] The working principle of the present invention is: after fixing the diaphragm spring on the rotating device 1, the intelligent control device 5 controls the rotation of the rotating device 1, and at the same time, controls the high-frequency power generating device 3 to provide 200 -250KH Z Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com