Heat treatment technology for automobile transmission gears

A technology of automobile gearbox and heat treatment container, which is applied in heat treatment furnace, heat treatment equipment, heat treatment process control and other directions, can solve the problems of inability to meet the performance requirements of key parts, long production cycle, coarse grains, etc., and achieves easy control of internal organization, The effect of less pollutants and improved deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

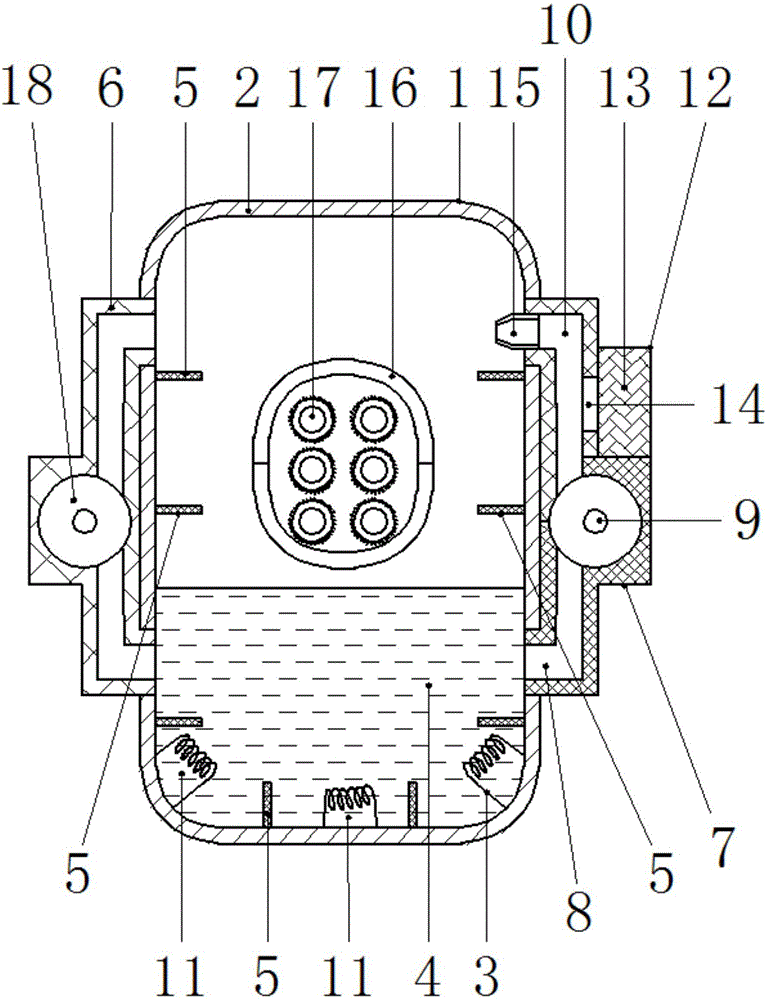

[0039] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0040] refer to figure 1 As shown, a heat treatment process for automotive gearbox gears, including heat treatment dependent heat treatment container, heat treatment liquid and heat treatment process steps, the heat treatment container includes a heat treatment tank, heat treatment tank temperature control device, heat treatment liquid, feeding device, Tank liquid observation sensor, soot treatment device and heat treatment liquid circulation device, the heat treatment liquid circulation device includes a liquid inlet pipeline, a motor pump, and a liquid outlet pipeline connected in sequence, and the liquid outlet pipeline is provided with a nozzle for spraying heat treatment liquid , the heat treatment tank tank temperature control device is provided with an electric heater immersed in the heat treatment liquid, the heat treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com