Fixed grate incinerator

A fixed grate and incinerator technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of incineration manufacturers' production interests, excessive thermal expansion of blades, and "stuck" problems, so as to avoid overheating and expansion of the shaft and Stuck, reliable and stable work, good work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

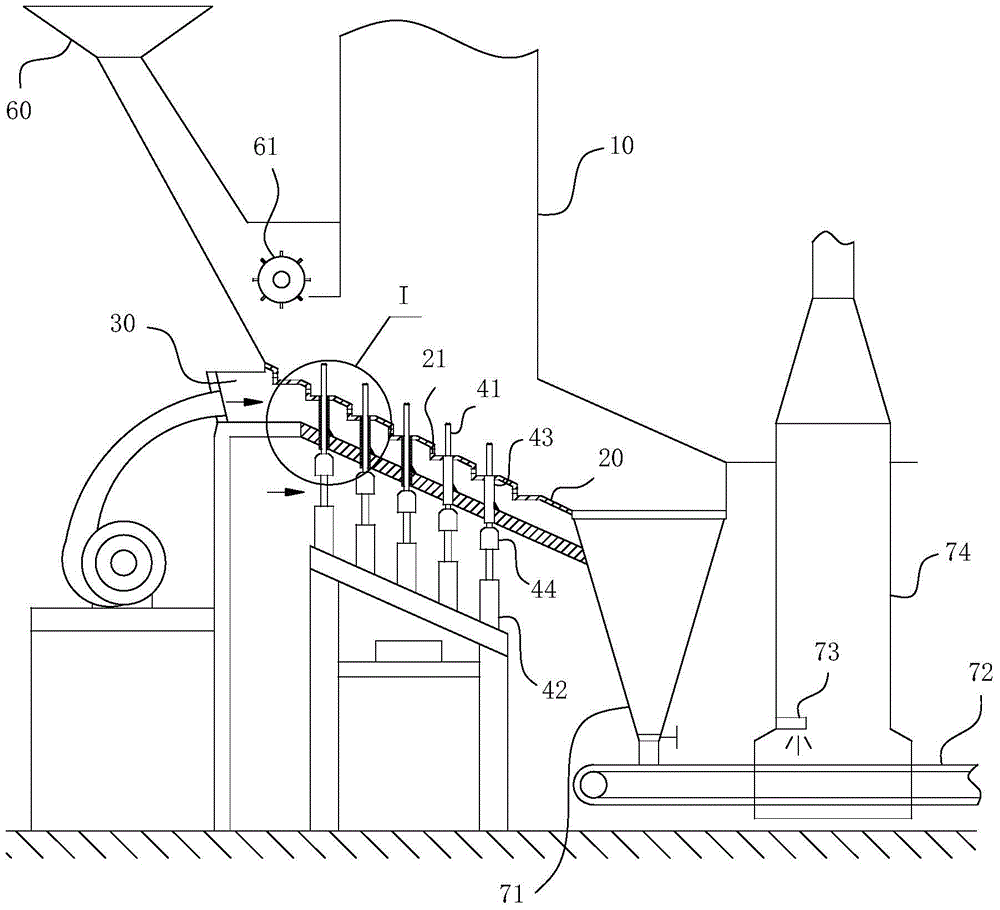

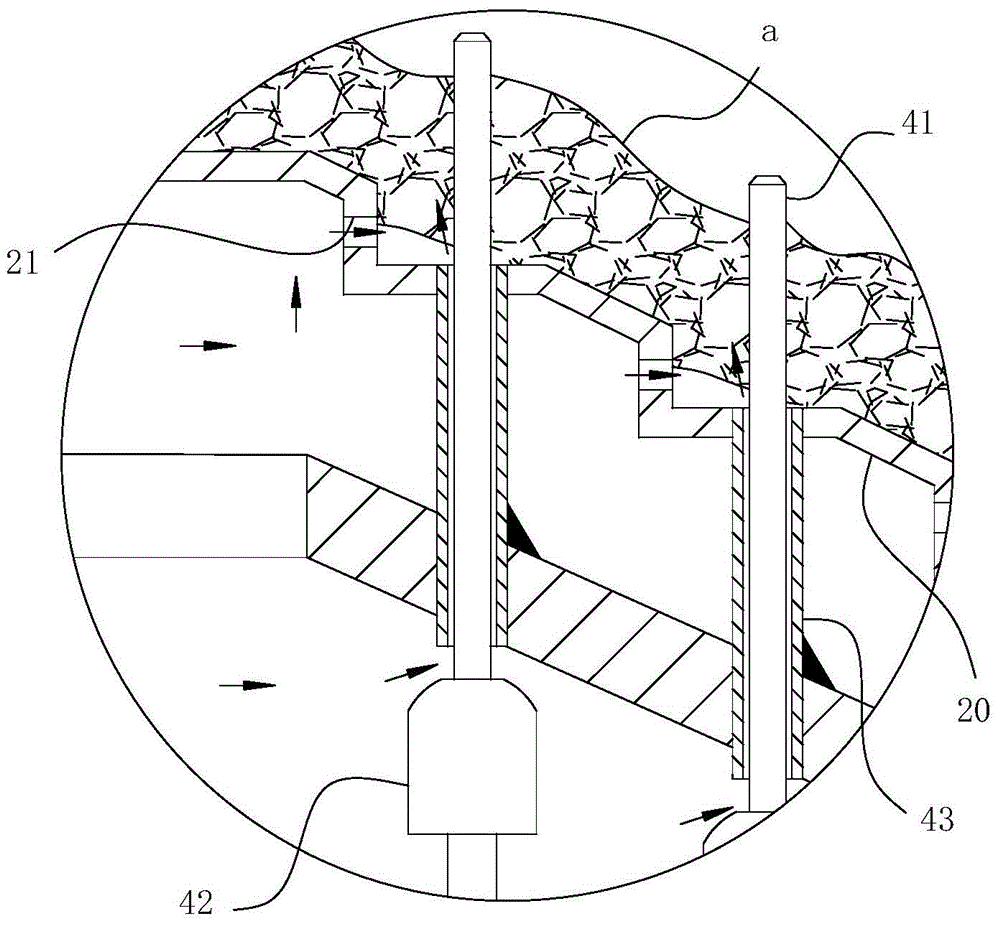

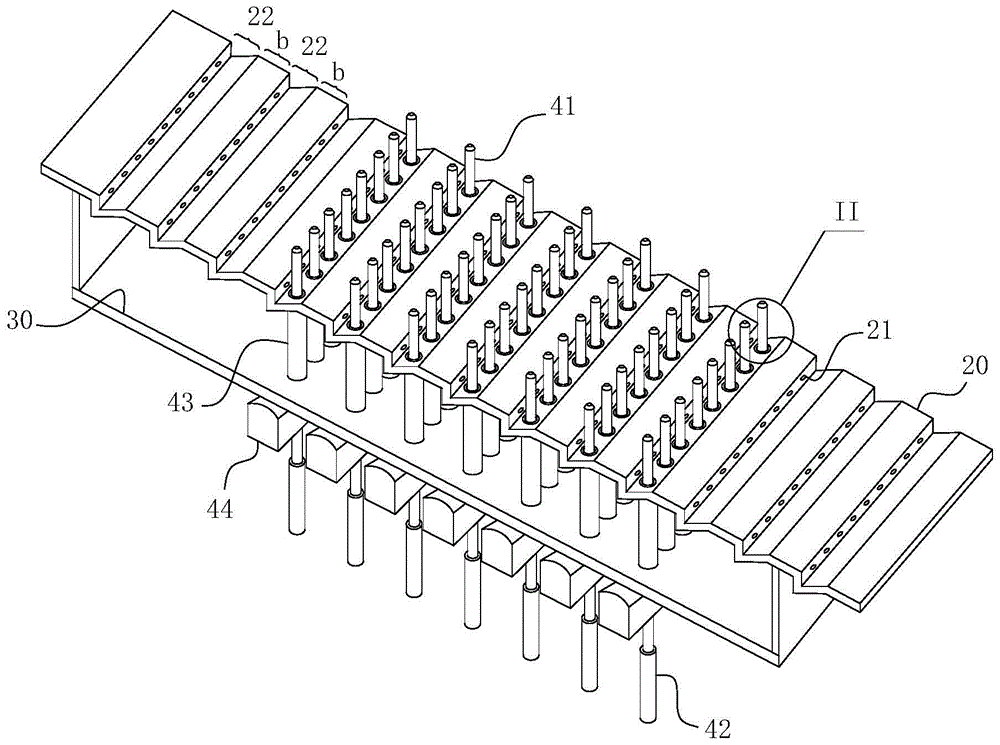

[0036] For ease of understanding, combined here Figure 1-4 Specifically set forth the component structure of the present invention and its specific work flow:

[0037] Concrete structure of the present invention, refer to figure 1 As shown, it includes a main combustion chamber 10 and a fixed fire grate 10 located in the main combustion chamber 10 , and a hot air chamber 30 communicating with an external air supply assembly is arranged below the main combustion chamber 10 . The row surface of the fixed furnace 20 is inclined up and down from the feed end to the slag discharge end to form a slope, and horizontal stage stages 22 are arranged in sections on the slope surface of the row body. A plurality of horizontal ventilation holes 21 communicating with the hot air chamber 30 and the main combustion chamber 10 are added at the straight plate of the horizontal platform stage 22, and all hot air in the hot air chamber 30 enters the main combustion chamber 10 from the ventilati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com