Furnace for testing limit of fire resistance of tunnel fire-proof protective material

A technology for protecting materials and refractory limit, applied in the direction of analysis of materials, material thermal analysis, furnaces, etc., can solve the problems of increased risk of collapse of steel structure buildings, non-refractory and other problems, achieve reasonable furnace structure, excellent thermal insulation performance, and reduce spiral flow zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

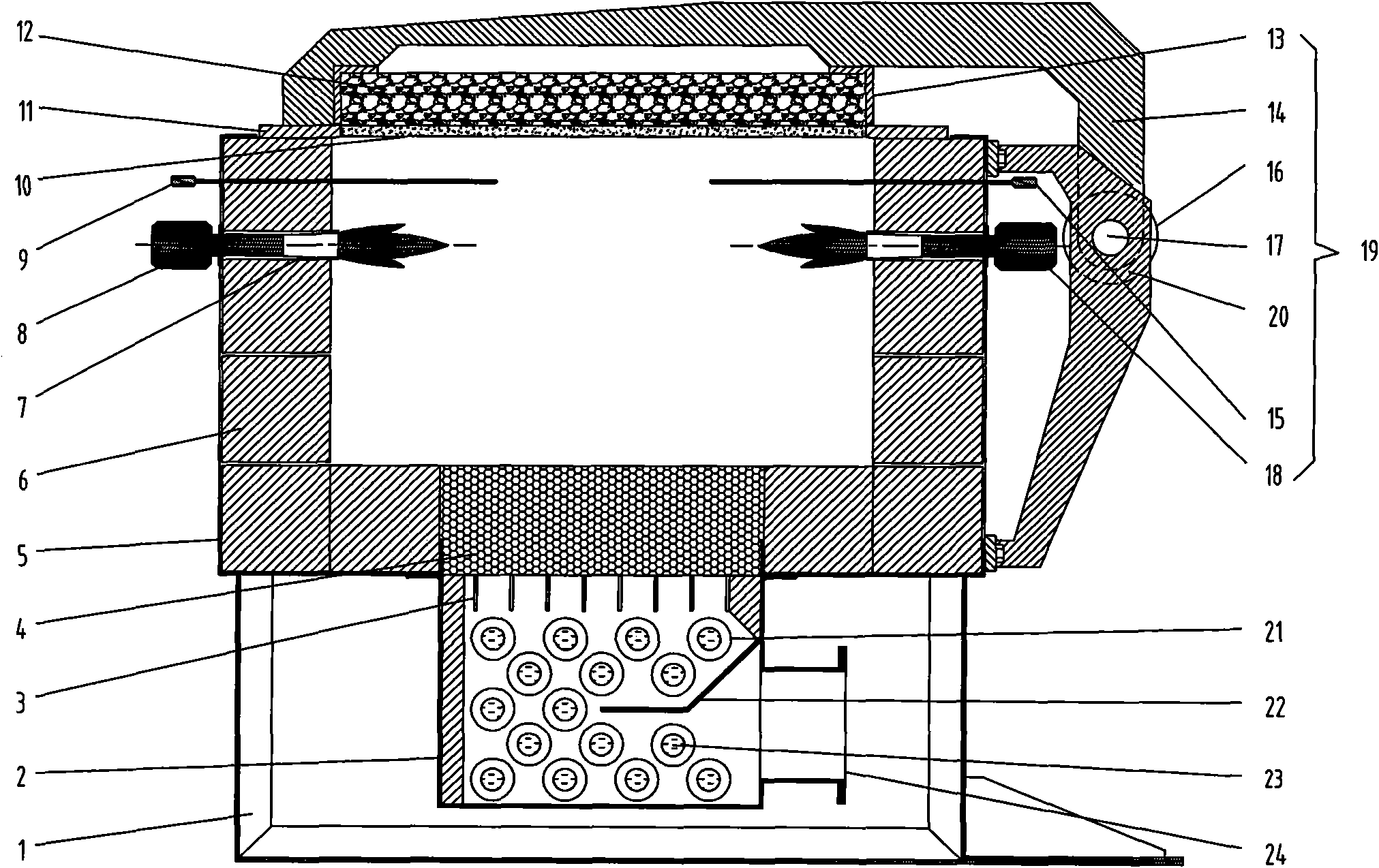

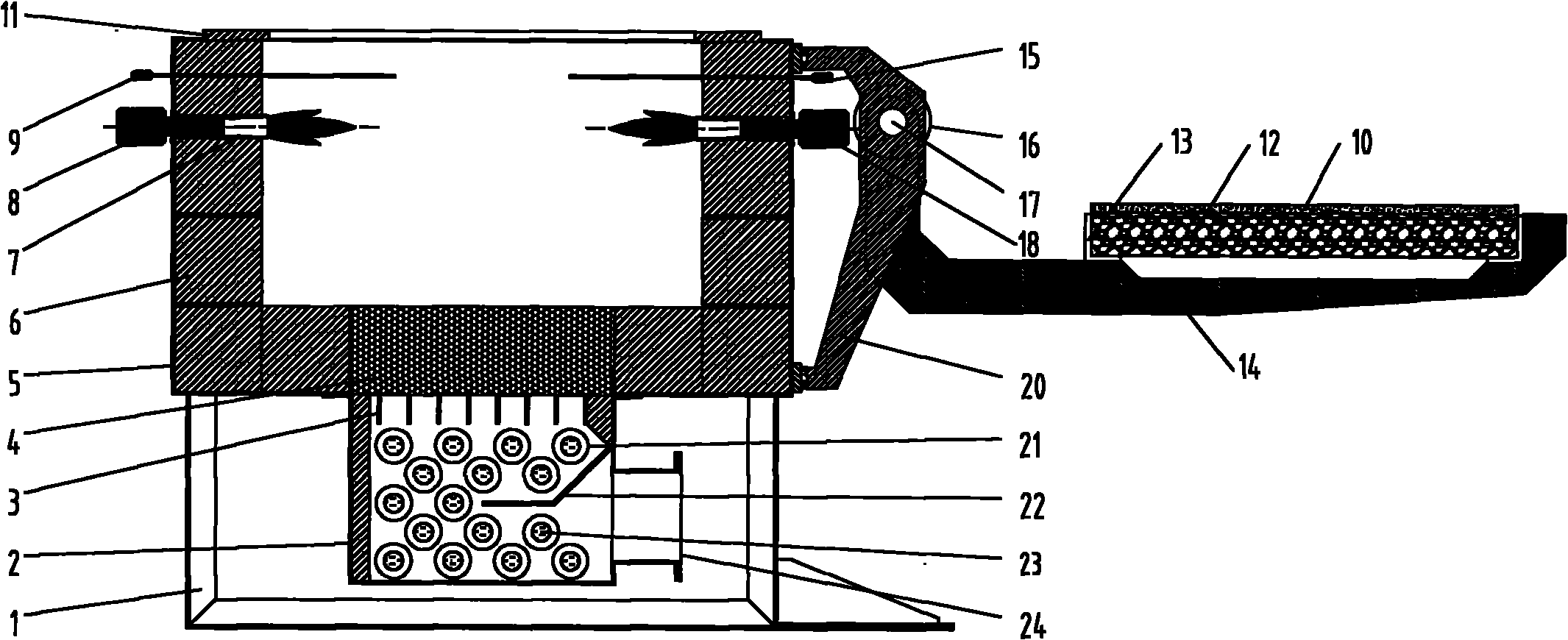

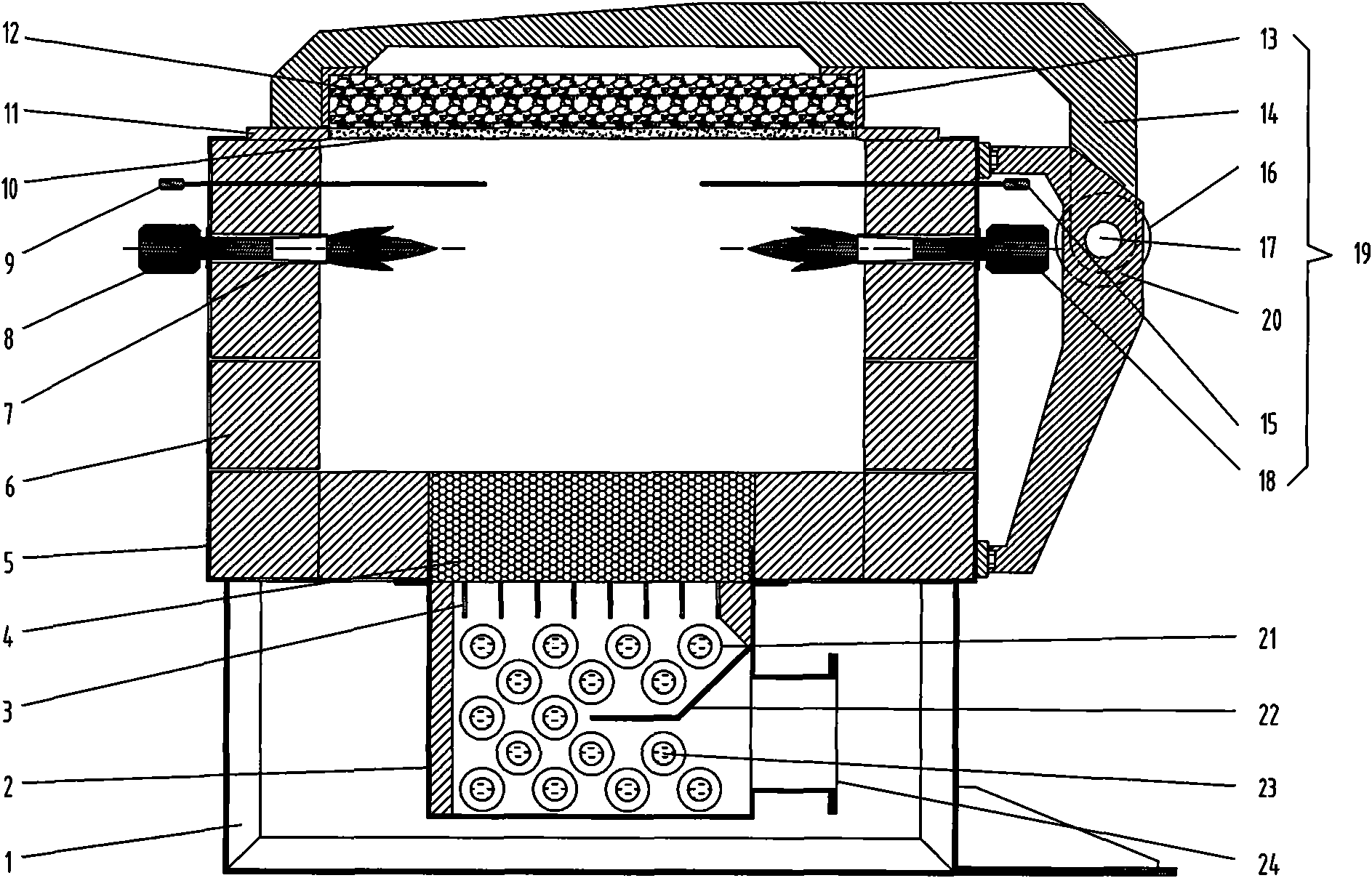

[0025] See figure 1 , the tunnel fire protection material fire resistance limit test furnace of the present invention is a special-purpose detection furnace body designed for tunnel fire protection materials. The furnace body is arranged on the furnace body support 1. The furnace body structure design has the following characteristics: The cover is on the top of the furnace body, and the short-flame burner is heated at the bottom of the sample 12. The furnace body includes the furnace shell 5, the furnace lining 6, the short-flame burner 8, the short-flame burner 18, the temperature measuring thermocouple 9, and the temperature measuring thermocouple 15. Sample clamping and turning device 19. Honeycomb heat absorbing plate 4. Water-cooled multi-tube cooler 2. The furnace shell 5 is provided with a modular structure furnace lining 6. The bottom ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com