Membrane lining container type fermentation device and compost and deodorization method using same

A container-type, fermentation device technology, applied in fertilization devices, preparation and application of organic fertilizers, etc., can solve the problems of long construction period, inconvenient movement of biological filters, and high operating costs, and achieves short construction period and shortened compost heating cycle. , the effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

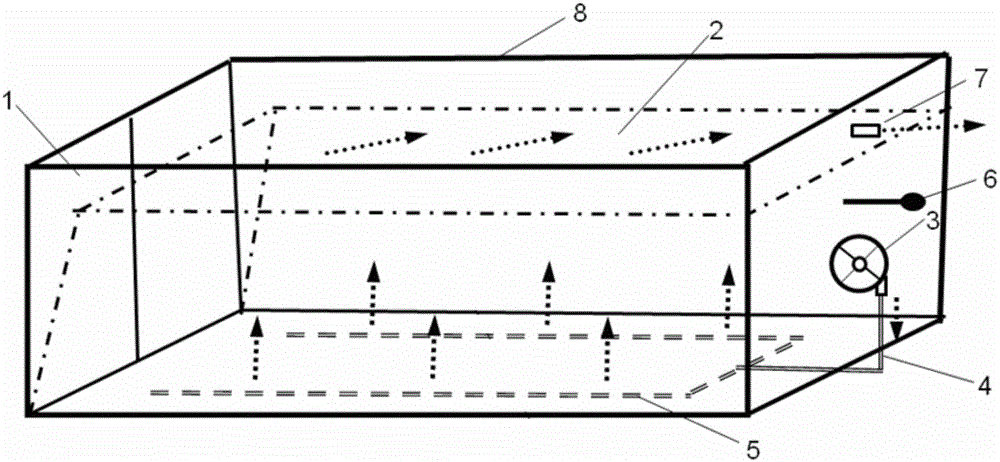

[0025] Specific implementation mode one: combine figure 1 As shown, the film-lined container type fermentation device of the present embodiment includes a container door 1, a waterproof breathable membrane 2, a blower 3, an air inlet pipe 4, a perforated air pipe 5, a temperature detector 6, an air outlet pipe 7, and a container 8; 8 is provided with a perforated air pipe 5 at the bottom, a waterproof breathable membrane 2 is arranged on the upper part of the container 8 and extends to the bottom of the container door 1, an air outlet pipe 7 is arranged on the upper part of the waterproof breathable membrane 2, and a blower 3 and a temperature detection device are arranged on the lower part of the waterproof breathable membrane 2 Device 6.

[0026] In the waterproof and breathable membrane 2 in this embodiment, since small water droplets cannot pass through the waterproof and breathable membrane, the lower surface of the waterproof and breathable membrane contains a large numb...

specific Embodiment approach 2

[0029] Specific embodiment two: the present embodiment utilizes the method for composting by the above-mentioned film-lined container-type fermentation device, and proceeds according to the following steps:

[0030] Utilize the method for composting in the above-mentioned membrane-lined container type fermentation device, carry out according to the following steps:

[0031] 1. Stack the organic solid waste at the bottom of the membrane-lined container-type fermentation device at a height of 120-250 cm, and close the container door;

[0032] 2. When the temperature in the container 8 is lower than 65°C, turn on the blower 3 for intermittent ventilation, and stop for 15-45 minutes after every 15-45 minutes of ventilation. When the temperature in the container 8 is higher than 65°C, continue to ventilate until the temperature is lower than 50~55℃, the fermentation tail gas is discharged;

[0033] 3. After 10 to 15 days of fermentation, the fermented organic solid waste is taken ...

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the film-lined container-type fermentation device described in step one can also be a plurality of film-lined container-type fermentation devices placed side by side, connected in series through the outlet pipe 7 together. Other steps and parameters are the same as those in Embodiment 1.

[0035] Although the floor space of this embodiment is slightly larger, it is especially suitable for use under the condition of lack of container handling equipment, saving manpower and material resources, and reducing energy consumption.

[0036] In this embodiment, the air outlet pipe 7 introduces the fermentation tail gas in the first film-lined container-type fermentation device into the second film-lined container-type fermentation device, and preheats the low-temperature material by blasting, thereby reducing the heating time of the material and shortening the temperature. Comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com